HAYWARD POOL PRODUCTS

|

|

|

- Vernon Adams

- 6 years ago

- Views:

Transcription

1 P/N: IS3220VSC Rev: B OWNER S MANUAL INSTALLATION, OPERATION, & PARTS TriStar Energy Solution TM Variable Speed Pump Control The Hayward TriStar Pump is specifically engineered for the demanding requirements of today s in ground swimming pool/spa that is equipped with large capacity filters, heaters, and pool cleaning equipment. The TriStar is a self priming pump that includes an improved seal and impeller design that will provide many years of efficient, dependable, corrosion free service. The advanced design provides superior performance while reducing maintenance requirements. NOTE To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. WARNING The TriStar ES (Energy Solution) variable speed pump control is designed for use only with Hayward SP322063EEV 2.7 THP 3 phase pump. Do not use with any other pump models. Use of this control with any other pump model will void warranty. Refer to TriStar Owner s Guide (IS3200) for all applicable pump installation, operation, and troubleshooting information. SAVE THIS INSTRUCTION MANUAL HAYWARD POOL PRODUCTS 620 DIVISION STREET ELIZABETH, NJ (908)

2 TriStar Variable Speed Pump Control Page 2 of 16 IMPORTANT SAFETY INSTRUCTIONS Before installing or servicing this electrical equipment, turn power supply OFF. Basic safety precautions should always be followed, including the following: Failure to follow instructions may result in injury. This is the safety alert symbol. When you see this symbol on your pump or in this manual, look for one of the following signal words and be alert to the potential for personal injury. WARNING warns about hazards that could cause serious personal injury, death or major property damage and if ignored presents a potential hazard. CAUTION warns about hazards that will or can cause minor or moderate personal injury and/or property damage and if ignored presents a potential hazard. It can also make consumers aware of actions that are unpredictable and unsafe. The NOTICE label indicates special instructions that are important but not related to hazards. WARNING Read and follow all instructions in this owner s manual and on the equipment. Failure to follow instructions can cause severe injury and/or death. WARNING This product should be installed and serviced only by a qualified professional. CAUTION All electrical wiring MUST be in conformance with all applicable local codes, regulations, and the National Electric Code (NEC). Use of non Hayward replacement parts voids warranty. ATTENTION INSTALLER THIS MANUAL CONTAINS IMPORTANT INFORMATION ABOUT THE INSTALLATION, OPERATION, AND SAFE USE OF THIS PUMP THAT MUST BE FURNISHED TO THE END USER OF THIS PRODUCT. FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS COULD RESULT IN SERIOUS INJURY. WARNING To reduce risk of injury, do not permit children to use or climb on this product. Closely supervise children at all times. Components such as the filtration system, pumps, and heaters must be positioned to prevent children from using them as a means of access to the pool. CAUTION This pump is intended for use on permanently installed swimming pools and may also be used with hot tubs and spas if so marked. Do NOT use with storable pools. A permanently installed pool is constructed in or on the ground or in a building such that it cannot be readily disassembled for storage. A storable pool is constructed so that it is capable of being readily disassembled for storage and reassembled to its original integrity. Though this product is designed for outdoor use, it is strongly advised to protect the electrical components from the weather. Select a well drained area, one that will not flood when it rains. It requires free circulation of air for cooling. Do not install in a damp or non ventilated location. If installed within an outer enclosure or beneath the skirt of a hot tub or spa, adequate ventilation and free circulation of air must be provided to prevent overheating of the motor. WARNING Pool and spa components have a finite life. All components should be inspected frequently and replaced at least every ten years, or if found to be damaged, broken, cracked, missing, or not securely attached.

3 TriStar Variable Speed Pump Control Page 3 of 16 WARNING Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable local codes, regulations, and the National Electric Code (NEC). Hazardous voltage can shock, burn, and cause death or serious property damage. To reduce the risk of electric shock, do NOT use an extension cord to connect unit to electric supply. Provide a properly located electrical receptacle. Before working on pump or motor, turn off power supply to the pump. WARNING To reduce the risk of electric shock replace damaged wiring immediately. Locate conduit to prevent abuse from lawn mowers, hedge trimmers and other equipment. WARNING Failure to bond pump to pool structure will increase risk for electrocution and could result in injury or death. To reduce the risk of electric shock, see installation instructions and consult a professional electrician on how to bond pump. Also, contact a licensed electrician for information on local electrical codes for bonding requirements. Notes to the electrician: Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding lug to reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm 2 ) solid copper bonding wire to the pressure wire connector provided on the motor housing and to all metal parts of swimming pool, spa, or hot tub, and to all electrical equipment, metal piping (except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or hot tub. IMPORTANT Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and other general wiring procedures. CAUTION: The equipment and controls shall be located not less than 1 M horizontally from the spa or hot tub. ATTENTION: Maintenir une distance minimale, mesuree dans un plan horizontal, de 1 M entre la cuve de relaxation et les appareils et commandes. CAUTION: When required by the Canadian electrical code, part I, section 68, connect only to a circuit protected by a class A ground fault circuit interrupter. ATTENTION: Si l'installation est visee par la section 68 du code Canadien de l ielectricite, premiere partie, brancher uniquement a une derivation protegee par un disjoncteur differentiel de classe A. WARNING Suction Entrapment Hazard. Suction in suction outlets and/or suction outlet covers which are damaged, broken, cracked, missing, or unsecured cause severe injury and/or death due to the following entrapment hazards: Hair Entrapment Hair can become entangled in suction outlet cover. Limb Entrapment A limb inserted into an opening of a suction outlet sump or suction outlet cover that is damaged, broken, cracked, missing, or not securely attached can result in a mechanical bind or swelling of the limb. Body Suction Entrapment A differential pressure applied to a large portion of the body or limbs can result in an entrapment. Evisceration/ Disembowelment A negative pressure applied directly to the intestines through an unprotected suction outlet sump or suction outlet cover which is damaged, broken, cracked, missing, or unsecured can result in evisceration/disembowelment. Mechanical Entrapment There is potential for jewelry, swimsuits, hair decorations, fingers, toes, or knuckles to be caught in an opening of a suction outlet cover resulting in mechanical entrapment. WARNING To Reduce the risk of Entrapment Hazards: When outlets are small enough to be blocked by a person, a minimum of two functioning suction outlets per pump must be installed. Suction outlets in the same plane (i.e. floor or wall), must be installed a minimum of three feet (3 ) [0.91 meter] apart, as measured from near point to near point. Dual suction fittings shall be placed in such locations and distances to avoid dual blockage by a user. Dual suction fittings shall not be located on seating areas or on the backrest for such seating areas. The maximum system flow rate shall not exceed the values shown in the Pipe Sizing Chart found at the bottom of page 5 of the TriStar Owner s Guide (IS3200). Never use pool or spa if any suction outlet component is damaged, broken, cracked, missing, or not securely attached. Replace damaged, broken, cracked, missing, or not securely attached suction outlet components immediately. In addition to two or more suction outlets per pump installed in accordance with latest IAF (formerly NSPI) standards and CPSC guidelines, follow all national, state, and local codes applicable. Installation of a vacuum release or vent system, which relieves entrapping suction, is recommended.

4 TriStar Variable Speed Pump Control Page 4 of 16 WARNING Hazardous Pressure. Pool and spa water circulation systems operate under hazardous pressure during start up, normal operation, and after pump shut off. Stand clear of circulation system equipment during pump start up. Failure to follow safety and operation instructions could result in violent separation of the pump housing and cover due to pressure in the system, which could cause property damage, severe personal injury, or death. Before servicing pool and spa water circulation system, all system and pump controls must be in off position and filter manual air relief valve must be in open position. Before starting system pump, all system valves must be set in a position to allow system water to return back to the pool. Do not change filter control valve position while system pump is running. Before starting system pump, fully open filter manual air relief valve. Do not close filter manual air relief valve until a steady stream of water (not air or air and water mix) is discharged from the valve. All suction and discharge valves MUST be OPEN when starting the circulation system. Failure to do so could result in severe personal injury and/or property damage. WARNING Separation Hazard. Failure to follow safety and operation instructions could result in violent separation of pump components. Strainer cover must be properly secured to pump housing with strainer cover lock ring. Before servicing pool and spa circulation system, all system and pump controls must be in off position and filter manual air relief valve must be in open position. Do not operate pool and spa circulation system if a system component is not assembled properly, damaged, or missing. Do not operate pool and spa circulation system unless filter manual air relief valve body is in locked position in filter upper body. All suction and discharge valves MUST be OPEN when starting the circulation system. Failure to do so could result in severe personal injury and/or property damage. WARNING Never operate or test the circulation system at more than 50 PSI maximum. WARNING Fire and burn hazard. Motors operate at high temperatures and if they are not properly isolated from any flammable structures or foreign debris they can cause fires, which may cause severe personal injury or death. It is also necessary to allow the motor to cool for at least 20 minutes prior to maintenance to minimize the risk for burns. WARNING Failure to install according to defined instructions may result in severe personal injury or death. General Information Introduction This manual contains information for the proper installation and operation of the Hayward TriStar Energy Solution Variable Speed Pump Control. The instructions in this manual MUST be followed precisely. Failure to install according to defined instructions will void warranty. Control Features & Benefits 6 programmable speeds allow you to size the pump to your pool, maximize energy efficiency so you use just enough electricity for each specific task, provide greater flexibility for spa and water features, and improve water circulation quality. Extremely quiet operation, providing flexibility of placement for your equipment pad. 24 hour programmable clock to customize each speed s length of operation. Wall mounted enclosure provides easy access. 6 speed interface is easy to program and use, providing superior energy management by defaulting to a Low Filter speed to filter your pools water. Easy to use membrane touch pad. Illuminated digital display is easy to use at night. Adapts to Goldline controls for remote operation. Integrated memory recalls settings. Comes complete with 9 1/2 ft. of cable and 8 ft. of conduit to connect to the pump. Temperature and electrical loading protection.

5 TriStar Variable Speed Pump Control Page 5 of 16 Installation & Wiring ATTENTION Refer to TriStar Owner s Guide (IS3200) for all applicable pump installation, operation, and troubleshooting information. Electrical WARNING All electrical wiring MUST conform to local codes, regulations, and the National Electric Code (NEC). WARNING Ground and bond control and motor before connecting to electrical power supply. Failure to ground and bond control and motor can cause serious or fatal electrical shock hazard. Do NOT ground to a gas supply line. To avoid dangerous or fatal electrical shock, turn OFF power to control and motor before working on electrical connections. Fire Hazard match supply voltage to control and motor nameplate voltage. Insure that the electrical supply available agrees with the control and motor s voltage, phase, and cycle, and that the wire size is adequate for the HP (kw) rating and distance from the power source. Use copper conductors only. Line Power Supply Specs Voltage: 230VAC, 60 Hz, Single Phase Breaker: 20 amps Wire Size: 12 AWG Use copper conductors only. For indoor/outdoor use. A disconnecting means located within sight of this control, and at least 5 ft. from the inside wall of the pool, spa, or hot tub, must be provided. Voltage Voltage at control and motor MUST NOT be more than 10% above or below motor name plate rated voltage, or components may overheat, causing overload tripping and reduced component life. If voltage is less than 90% or more than 110% of rated voltage when motor is running at full load, consult power company. Grounding And Bonding Install, ground, bond, and wire control and motor in accordance with local or national electrical code requirements. Permanently ground control and motor. Use green ground terminal provided under motor canopy or access place; use size and type wire required by code. Connect control and motor ground terminals to control enclosure ground. Bond control and motor to pool structure. Bonding will connect all metal parts within and around the pool with a continuous wire. Bonding reduces the risk of a current passing between bonded metal objects, which could potentially cause electrical shock if grounded or shorted. Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and general wiring procedures. Use a solid copper conductor, size 8 or larger. Run wire from external bonding lug to reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm 2 ) solid copper bonding wire to the pressure wire connector provided on the control and motor housings and to all metal parts of swimming pool, spa, or hot tub, and to all electrical equipment, metal piping (except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or hot tub. Wiring WARNING All electrical wiring MUST conform to local codes, regulations, and the National Electric Code (NEC). Control and pump MUST be permanently connected to circuit. If other lights or appliances are also on the same circuit, be sure to add their amp loads before calculating wire and circuit breaker sizes. Use the load circuit breaker as the Master On Off switch. If the variable speed pump and control are being used to replace an existing pump that was controlled by a separate mechanical time clock, the control should be connected directly to the line power supply, bypassing the time clock. The time clock can then be used to power other equipment (such as a heater, heat pump, or booster pump) that requires the filter pump to be operating when used. If the time clock is used in this manner, it should be set to power the equipment during a time cycle when the variable speed pump is operating at an appropriate flow rate, as defined by the steps set in the sequencer menu.

6 TriStar Variable Speed Pump Control Page 6 of 16 Installation Notes 1. TURN OFF THE ELECTRICAL POWER AT THE CIRCUIT BREAKER. 2. Find a location for the SP3220VSC on a vertical flat surface, out of the direct sunlight, which will not be flooded, and above the pump. This location must be within 8 feet of the pump. Mount the control enclosure to this location using the provided attachment points. The control must be mounted such that the enclosure vents are free from obstructions and the door may be opened without issue. Do not mount the control enclosure inside a panel or tightly enclosed area, or directly to the side of a house. 3. Open door and remove panel containing control interface by removing two screws. Disconnect interface cable from Emerson SK drive, and place interface panel in a safe location away from water such that the interface does not make contact with anything. 4. Connect 230VAC line power supply wiring to terminal block and ground strip as shown. Spade terminals with up turned lugs must be used to connect wiring to terminal block. 5. Connect included phase wiring from control to pump wiring marked #1 3 as shown in wiring diagram below. Connect green ground wire to motor ground screw. 6. Connect the control to the pool bonding system using 8AWG (6AWG for Canada) wire. A lug for bonding is provided on the outside/bottom of the enclosure. 7. After all electrical connections have been made, reconnect interface cable plug to Emerson SK drive, and replace interface panel using two screws. 8. Apply power to the system, and proceed to Installer Initial Setup on page 7. Wiring Diagram

7 TriStar Variable Speed Pump Control Page 7 of 16 Operation & Setup VARIABLE SPEED INTERFACE INSTALLER INITIAL SETUP 1 : Event Performed function Keypad active functions Display message Initial Power On. Or System checks to determine if initial setup parameters were previously set. If not, Press Time Up/Dn button to select desired language. Press 6 (OK) to store current settings. SELECT LANGUAGE *ENGLISH *ESPANOL Initial Setup Override system enters Select *FRANCAIS (pressing 4 during Power On). Language step of initial setup procedure. Language selection is complete. Clock setup. Press 5 (Next) or 2 (Previous) buttons to select day of week, hours, and minutes settings. Press Time Up/Dn buttons to change the selected value (selected value will be displayed with underlining cursor). Press 6 (OK) to store current settings. CHECK THE CLOCK *SET Mon 12:50pm Clock setting is complete. Prime Mode setup. Press Time Up/Dn buttons to select desired prime mode 2 (prime mode should be selected based on height of pump inlet above water level in pool). Press 6 (OK) to store current settings. PICK PRIME MODE *MORE THAN 5 FT *5 FEET OR LESS Prime mode selection is complete. Timer disabled: pump runs according to prime mode selected, and defaults to P2. Timer enabled: pump remains stopped until system time reaches Timer On setting. Use 1 6 buttons to switch pump to a preset mode. Use Time Up/Dn buttons to cause remaining time for current mode to increase/decrease by 5 minutes. Use % Flow Up/Dn buttons to change pump speed within predefined range. *PRIME MODE* (when timer is disabled) *PUMP STOPPED* (when timer is enabled, until system time reaches Timer On setting)

8 TriStar Variable Speed Pump Control Page 8 of 16 VARIABLE SPEED INTERFACE INITIAL SETUP NOTES: 1 ) When power is applied to the system for the first time, or if initial setup override is engaged, the user will have to set the system language, clock, and prime mode before the pump will operate. During the initial system setup, the 1 (Exit) button is not active. The user must make these selections before the system will allow the pump to operate. If a mistake is made during the initial setup, the user may override the incorrect setup by disconnecting power to the system, and re applying power while pressing the 4 button. The language and clock settings may be changed after initial system setup as shown in the Installer Setup chart if needed. 2 ) The user must select the prime mode based on the layout of their pump installation. Choose MORE THAN 5 FT if the inlet of the pump is more than 5 feet above the water level in the pool, or choose 5 FEET OR LESS if the inlet of the pump is 5 feet or less above the water level in the pool.

9 TriStar Variable Speed Pump Control Page 9 of 16 VARIABLE SPEED INTERFACE INSTALLER SETUP CHART Event Performed function Keypad active functions Display message Normal operation any mode except prime Operate according to active mode with % flow set for this mode and for preset time. Press 3 and 4 simultaneously for more than 5 seconds to enter setup mode. The current active mode is continued without any change or interruption. *SETUP MAIN MENU SETUP mode User keypad and display are in setup mode. The current active pump mode is continued without any change or interruption. Press 1 (Exit) to exit setup. System will return to current active mode and current preset is displayed, for example P2.LOW FILTER. P2. LOW FILTER (for example) SETUP mode (continued) (as above) Press 5 (Next) or 2 (Prev) to scroll through all available main menu options. See display for current menu option. *LANGUAGE SETUP *CLOCK/TIMER *PRIME HEIGHT *PRESET SETUP *SEQUENCER *RANGE SETUP *HARDWARE SETUP *CONTROL SETUP SETUP mode (continued) (as above) Press 6 (OK) to enter selected menu option, for example LANGUAGE SETUP. *LANGUAGE SETUP *ENGLISH Press 1 (Exit) to exit the menu. SETUP mode: LANGUAGE SETUP function This feature allows setting desired language of displayed messages. Press Time Up/Dn buttons to select desired language. Press 6 (OK) to store current settings. *ENGLISH *ESPANIOL *FRENCH *ENGLISH SET! SETUP mode: CLOCK/TIMER function This menu allows the user to set the current day of week and time of day, as well as enable or disable the timer function, and define the timer on and off time. To change day of week or time of day, confirm by pressing 6 (OK) button. An underlining cursor will appear below day of week value. Press 5 (Next) or 2 (Prev) to select either day of week, hours, or minutes with underlining cursor. Press Time Up/Dn buttons to change selected value. *SET Sun 7:36pm (for example) *SET Sun 7:36pm *SET Sun 7:36pm *SET Sun 7:36pm Pressing 6 (OK) causes system to store preset current time. *CLOCK SAVED! Pressing 5 (Next) allows the user to enable or disable the Timer. Use Time Up/Dn buttons to select between Timer Enable or Timer Disable. Pressing 6 (OK) causes system to store this option. *TIMER ENABLED *TIMER DISABLED *TIMER SAVED!

10 TriStar Variable Speed Pump Control Page 10 of 16 Press 5 (Next) to define the Timer On time. To change these settings, confirm by pressing 6 (OK). An underlining cursor will appear below hours value. Press 5 (Next) or 2 (Prev) to select hours or minutes to be set, and use Time Up/Dn buttons to select desired value. Press 6 (OK) to store this option. *TMR.ON *TMR.ON *TMR.ON 8:00am 8:00am 8:00am *TIMER SAVED! Press 5 (Next) to define the Timer Off time. This setting is changed the same as above. *TMR.OFF 5:00pm SETUP mode: PRIME HEIGHT function This menu allows the user to view the prime mode that was selected during initial setup. Press 6 (OK) to display the prime mode that was selected during initial setup. After initial setup, this becomes a read only display. *MORE THAN 5 FT (for example) SETUP mode: PRESET SETUP function This menu allows the user to define the pump speed and duration for each preset, which should be customized for each installation. Use 5 (Next) or 2 (Prev) to select preset to be setup. For example, user stops on mode 4 (Medium High). Using % Flow Up/Dn buttons for currently displayed mode number causes desired pump speed to be set within predefined range. Using Time Up/Dn buttons for currently displayed mode number causes desired time to be set within predefined range. *SELECT PRESET: 4 *P4.SPEED= 20% *P4.TIME= 1h 30m Press 6 (OK) to store preset time and % flow settings. Each preset is set the same as above. *P4.STORED! SETUP mode: SEQUENCER function This menu allows the user to define the active preset and duration for each sequence step, which should be customized for each installation. Use 5 (Next) or 2 (Prev) to select sequence step to be setup. Empty may be selected if the user does not need all of the sequence steps. Stop may be selected if the user wishes to stop the pump during peak energy periods or another time of day. For example, user stops on sequence step 1 (S1). Use % Flow Up/Dn to select desired active preset for displayed sequence step, or to select Stop Mode or Empty. If Empty is selected, the sequence step will be skipped, and the next step will be active. When presets or Stop are selected for the sequence step, the step time defaults to the time set for the displayed preset. This step time may be changed using the Time Up/Dn buttons. Press 6 (OK) to store sequence step settings. Each sequence step is set the same as above. *S1:P1 *S1:P3 *S1:STOP *S1:EMPTY *S1.STORED! 0h30min 1h45min 3h30min

11 TriStar Variable Speed Pump Control Page 11 of 16 SETUP mode: RANGE SETUP function This menu allows the user to define the range of pump speed that the % Flow Up/Dn buttons may temporarily change for each preset. Use 5 (Next) or 2 (Prev) to select preset range to be setup. For example, user stops on preset 6 (Maximum Flow). Press % Flow Up/Dn buttons to display lowest possible flow for this preset. Press Time Up/Dn buttons to display highest possible flow for this preset. Press 6 (OK) to store this setting. Each preset range is set the same as above. *SELECT PRESET: 6 *P6.L SPEED= 15% *P6.H SPEED= 100% *P6.STORED!

12 TriStar Variable Speed Pump Control Page 12 of 16 POOL & SPA CONTROLLER BASIC OPERATION 3 : Event Performed function Keypad active functions Display message Power Off RTC 4 operation only. All inactive >OFF< Power On Configuration OK Check configuration and proceed to Stop Mode. System enters Stop Mode until RTC 4 reaches Timer On time, or the user selects a preset on the keypad. All other functions are disabled. HAYWARD POOL&SPA *VERSION 1.27* *PUMP STOPPED* Stop Mode Pump is stopped until RTC 4 reaches Timer On time, or the user selects a preset on the keypad. Buttons 1 6 are active. When the user selects a preset on the keypad, the system enters Prime Mode. After priming, the system operates according to the preset that was selected. *PRIME > *P3 *PRIME > *P1 Prime Mode Pump will prime first when a preset is selected during Stop Mode. Pressing Time Up/Dn causes remaining time for Prime Mode to be displayed. Pressing 1 6 changes the preset which will be activated upon completion of Prime Mode. 8 min REMAINS *PRIME > *P4 Pressing Flow Up/Dn displays pump speed. Pump speed cannot be changed during Prime Mode. PUMP SPEED 85% End of prime Operate according to active mode with flow set for this mode and for preset time. After Prime Mode is completed, the pump will operate according to the preset that was selected, and will re enter Stop Mode when the preset expires. P4. MEDIUM HIGH (P4 indicates preset #4) Timer activates the system. The system enters On Period System enters Prime Mode if the pump was stopped prior to On Period, or system enters first sequence step if pump was running prior to On Period. *TIMER IS=ON* *PRIME MODE* S1 8:40am *P3 (S1 indicates sequence step #1; 8:40am is current time; *P3 is currently running preset defined in sequence step S1) System operates during On Period System advances through sequence steps unil RTC 4 reaches Timer Off time. If sequence steps end before Timer Off time is reached, system will default to P2 Low Filter speed. % Flow and Time buttons as well as 1 6 buttons are active. The % Flow and Time buttons may be used to temporarily change the flow and time of the current sequence step. The 1 6 buttons may be used to temporarily override the current sequence step. The system will operate according to the selected preset and will advance to the next sequence step when the preset expires. S1 8:40am *P4 (where *P4 is manually selected preset which overrides the current sequence step)

13 TriStar Variable Speed Pump Control Page 13 of 16 Timer deactivates the system. The system enters Off Period Pump is stopped and system enters Stop Mode. System enters Stop Mode as before. *TIMER IS=OFF* *PUMP STOPPED* VARIABLE SPEED INTERFACE BASIC OPERATION NOTES: 3 ) Timer Enabled (recommended): When the timer is enabled, the pump will be stopped when the control first receives power, until the Timer ON time is reached, at which time it will prime and proceed through the steps defined in the Sequencer menu. The pump will stop when the system reaches the Timer OFF time. The pump may be manually stopped by pressing the 5 and 6 buttons simultaneously for more than 5 seconds. Pressing any preset button after manually stopping the pump will cause the pump to prime and operate according to the preset chosen. Timer Disabled: When the timer is disabled, the pump will prime when the control first receives power, and will then default to P2 (Low Filter). It will continue to run according to P2 until power is disconnected from the control. After the pump has primed, the % Flow and Time Up/Dn buttons, as well as the 1 6 buttons, are active. Pressing any of the 1 6 buttons will cause the pump to run temporarily according to the set flow and time for the chosen preset. The % Flow and Time Up/Dn buttons may be used to temporarily modify the set flow and time for the chosen preset. After the chosen preset expires, the pump will default back to P2. The pump may be manually stopped by pressing the 5 and 6 buttons simultaneously for more than 5 seconds. After the pump is stopped, it may be restarted by pressing the 5 and 6 buttons simultaneously again for more than 5 seconds, at which point the pump will prime and then default to P2 (Low Filter). 4 ) RTC Real Time Clock 5 ) Factory defaults are as follows. User/installer may note custom presets in the spaces provided. Mode Name Factory Presets Custom Presets % Flow Time % Flow Time PRIME 5 FEET OR LESS 65 6 min MORE THAN 5 FEET 85 8 min P1 Low min P2 Low Filter min P3 Medium Low min P4 Medium High min P5 High Filter Cleaner min P6 Maximum Flow min 6 ) If the sequencer is used, user/installer may note custom sequencer settings in the spaces provided. Sequence Preset Step Used Duration Timer On N/A N/A S1 S2 S3 S4 S5 S6 S7 S8 Timer Off N/A N/A Time Start

14 TriStar Variable Speed Pump Control Page 14 of 16 Troubleshooting ATTENTION Refer to TriStar Owner s Guide (IS3200) for all applicable pump installation, operation, and troubleshooting information. Error Codes DEFAULTS LOADED! indicates that system has been reset to factory defaults due to a bad configuration file stored in nonvolatile memory. User settings will need to be reset. SEQUENCER INIT indicates that sequencer settings have been cleared due to bad sequencer data file stored in non volatile memory. Sequencer settings will need to be reset. E1:REF.SPEED df indicates that control is not able to read maximum frequency value from the motor drive input power, which is used to calculate the actual % Flow. In such case, standard US value is used (60 Hz). E2:VFD Stopped indicates that motor drive is stopped, and should be running according to selected user mode. When *MANUAL STOP* is selected, this message is not displayed. E3:VFD Fault! indicates that motor drive is in fault (in trip). Fault conditions can be caused by motor overload (over temperature, over voltage, over current), or any other condition that causes motor drive to be inoperative such as motor stall or pump jam. In such case, the cause of motor fault should be corrected first, and then manual stop procedure should be performed to reset the drive and restore proper operation. E4:VFD Timeout! indicates that communication between motor drive and the system is corrupted or there is no connection. In such case, power should be disconnected from controller, and RS485 connection cable should be observed and replaced if necessary. E5:UART CRC Err indicates checksum errors during communication with motor drive. In such case, disconnect power from control, and ensure that all electrical wiring, connections, and terminals are properly attached and connected. E6:VFD EEPROM ER indicates that internal Emerson EEPROM memory is corrupted. In such case, the Emerson drive will not hold its predefined configuration upon power failure. The control sets this configuration every time it is powered up, so normal operation is possible, but it is recommended to replace the Emerson drive. CLOCK IS NOT SET indicates that the Real Time Clock in the control is not set or is invalid. In such case, the unit will not perform Timer or Sequencer functions until the RTC is set again by the user. This is an E7 error, however the E7 part of the message is not shown due to its length. E8:Check SETUP! indicates that default values for % Flow and Time for all modes were loaded as well as other parameters upon configuration/setup error. Such an error may occur when the system is powered up for the first time. In such case, operator should enter Setup menu (pressing and holding 3 and 4 buttons for more than 5 sec.) and check or modify all parameters. Exiting setup clears this error. If this error occurs every time the system is turned on (upon power on ), it means that non volatile memory (EEPROM) is corrupted and the interface should be replaced. E11:VFD OVERLOAD indicates that Emerson drive is overloaded. This message is reported directly from the Emerson drive. Usually in such condition the drive either reduces the output current which results in the pump operating at a slower speed or trips and restarts. E12:MAINS LOSS! indicates that Emerson drive has detected power loss on its internal power BUS. This message may also appear when mains power is lost and the unit is about to shut down automatically. E13:LOAD LIMIT! indicates that Emerson drive has reached its load limit defined in LOAD MENU. This is an indication that the motor drive and the pump current configuration are working at its load limits. E14:EXT.CTRL ERR Logic). indicates that the control has lost communication connection with external control unit (Goldline Aqua Hayward Pool Products, 2007 All rights reserved.

15 TriStar Variable Speed Pump Control Page 15 of 16 PRODUCT REGISTRATION (Retain For Your Records) DATE OF INSTALLATION INITIAL PRESSURE GAUGE READING (CLEAN FILTER) PUMP MODEL SP322063EEV HORSEPOWER 2.0 FRHP (2.7 THP) FILTER MODEL SERIAL NUMBER

16 TriStar Variable Speed Pump Control Page 16 of 16 HAYWARD LIMITED WARRANTY This control was inspected before shipment from our plant. To original purchasers of this control, Hayward Pool Products, 620 Division Street, Elizabeth, New Jersey, warrants its products to be free from defects in materials and workmanship for a period of ONE (1) year from the date of purchase. Parts which fail or become defective during the warranty period, except as a result of freezing, negligence, improper installation, use, or care, shall be repaired or replaced, at our option, without charge, within 90 days of the receipt of defective product, barring unforeseen delays. To obtain warranty replacements or repair, defective components or parts should be returned, transportation paid, to the place of purchase, or to the nearest authorized Hayward service center. For further Hayward dealer or service center information, contact Hayward customer service department. No returns may be made directly to the factory without the express written authorization of Hayward Pool Products, Inc. All other conditions and terms of the standard warranty apply. Hayward shall not be responsible for cartage, removal and/or reinstallation labor or any other such costs incurred in obtaining warranty replacements. The Hayward Pool Products warranty does not apply to components manufactured by others. For such products, the warranty established by the respective manufacturer will apply. Some states do not allow a limitation on how long an implied warranty lasts, or the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This product is intended for use only with SP322063EEV pump. Use with any other pump will void warranty. Hayward Pool Products 620 Division Street *Supersedes all previous publications. Elizabeth, NJ Retain this Warranty Certificate (upper portion) in a safe and convenient location for your records. DETACH HERE: Fill out bottom portion completely and mail within 10 days of purchase/installation, or register online.

17 P/N: IS3220VSCAQL Rev: A Variable Speed Control Operation (using Aqua Logic Control) ATTENTION Refer to TriStar Pump Owner s Guide (IS3200) for all applicable pump warning, installation, operation, and troubleshooting information. Refer to TriStar Energy Solution Owner s Guide (IS3220VSC) for all applicable control warning, installation, operation, and troubleshooting information. Owner s guides may also be obtained online at Wiring Input Power Wiring Turn off electrical power at the circuit breaker before making any power or communications wiring connections. The Hayward TriStar Energy Solution Variable Speed Control (VSC) requires 230VAC input power. The Aqua Logic filter relay should be used to provide the line power supply to the VSC. Refer to the Aqua Logic and VSC installation manuals for applicable wiring connections. Communications Wiring Use four conductor cable (typically phone cable) for communications connection between the VSC and the Aqua Logic control center as shown below. The maximum wiring distance is 500 feet (160 meters). Note that the terminals on both the VSC interface board and the Aqua Logic main board are numbered. The terminal connections should be matched between both terminal blocks (connect 1 to 1, 2 to 2, etc.). The communications cable should be routed through the knockout hole on the left side of the VSC enclosure, and a watertight fitting should be used to keep water and debris out of the opening. The communications cable should also be routed away from the Aqua Logic and VSC power connections if possible. Menu Settings Variable Speed Settings (for Aqua Logic control) Once the power and communications connections have been made between the Aqua Logic and the VSC and power is applied to the system, the Aqua Logic pump configuration, timers, and settings must be changed to allow variable speed operation. Refer to the Aqua Logic installation manual for applicable configuration and settings information.

IMPORTANT SAFETY INSTRUCTIONS

ISSQUAREHF Rev: D OWNER S MANUAL INSTALLATION, OPERATION, & PARTS High Flow DUAL SUBMERGED SUCTION OUTLET FRAMES & COVERS [Commonly called main drains] Basic safety precautions should always be followed,

ISSQUAREHF Rev: D OWNER S MANUAL INSTALLATION, OPERATION, & PARTS High Flow DUAL SUBMERGED SUCTION OUTLET FRAMES & COVERS [Commonly called main drains] Basic safety precautions should always be followed,

HAYWARD POOL PRODUCTS, INC. 620 Division Street Elizabeth, NJ Tel:

IS270T-05 Rev. B OWNER S MANUAL INSTALLATION, OPERATION & PARTS MODEL S270T PRO SERIES HIGH-RATE SAND FILTER Basic safety precautions should always be followed, including the following: Failure to follow

IS270T-05 Rev. B OWNER S MANUAL INSTALLATION, OPERATION & PARTS MODEL S270T PRO SERIES HIGH-RATE SAND FILTER Basic safety precautions should always be followed, including the following: Failure to follow

OWNER S MANUAL INSTALLATION, OPERATION, & PARTS. Super Pump Series

P/N: ISSPSERIES REV. A OWNER S MANUAL INSTALLATION, OPERATION, & PARTS *50HZ Models are not UL or CSA Listed. Super Pump Series The Hayward Super Pump TM is specifically engineered for the demanding requirements

P/N: ISSPSERIES REV. A OWNER S MANUAL INSTALLATION, OPERATION, & PARTS *50HZ Models are not UL or CSA Listed. Super Pump Series The Hayward Super Pump TM is specifically engineered for the demanding requirements

DUAL SUBMERGED SUCTION OUTLET SET. [Commonly called main drains] Owner s Manual

![DUAL SUBMERGED SUCTION OUTLET SET. [Commonly called main drains] Owner s Manual DUAL SUBMERGED SUCTION OUTLET SET. [Commonly called main drains] Owner s Manual](/thumbs/87/97370711.jpg) ISDUALSWG Rev G DUAL SUBMERGED SUCTION OUTLET SET [Commonly called main drains] Owner s Manual Contents Product Warnings. Introduction..... 3 Installation... 4 Replacement Parts.. 5 General Warnings. 6

ISDUALSWG Rev G DUAL SUBMERGED SUCTION OUTLET SET [Commonly called main drains] Owner s Manual Contents Product Warnings. Introduction..... 3 Installation... 4 Replacement Parts.. 5 General Warnings. 6

Pump - Owner s Manual

Pump - Owner s Manual INSTALLATION, OPERATION, & PARTS To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. SAVE THIS INSTRUCTION MANUAL Use only

Pump - Owner s Manual INSTALLATION, OPERATION, & PARTS To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. SAVE THIS INSTRUCTION MANUAL Use only

Owner s Manual ROBOTIC POOL CLEANER. Models: TigerShark, TigerShark QC, TigerShark Plus, TigerShark2, TigerShark2 Plus IMPORTANT SAFETY INSTRUCTIONS

ISRC10202 Rev: C TigerShark by SERIES Owner s Manual ROBOTIC POOL CLEANER Models: TigerShark, TigerShark QC, TigerShark Plus, TigerShark2, TigerShark2 Plus IMPORTANT SAFETY INSTRUCTIONS Basic safety precautions

ISRC10202 Rev: C TigerShark by SERIES Owner s Manual ROBOTIC POOL CLEANER Models: TigerShark, TigerShark QC, TigerShark Plus, TigerShark2, TigerShark2 Plus IMPORTANT SAFETY INSTRUCTIONS Basic safety precautions

HAYWARD POOL PRODUCTS, INC. 620 Division Street Elizabeth, NJ Tel:

IS310S Rev B OWNER S MANUAL INSTALLATION, OPERATION & PARTS MODELS S310S PRO SERIES HIGH RATE SAND FILTERS Basic safety precautions should always be followed, including the following: Failure to follow

IS310S Rev B OWNER S MANUAL INSTALLATION, OPERATION & PARTS MODELS S310S PRO SERIES HIGH RATE SAND FILTERS Basic safety precautions should always be followed, including the following: Failure to follow

Maxflo VS. Owner s Manual. MaxFlo VS Variable Speed Pump

IS2303VSP2 Rev-B Maxflo VS Owner s Manual Model SP2303VSP MaxFlo VS Variable Speed Pump Hayward s MaxFlo VS variable speed pump delivers incredible energy savings via its advanced hydraulic design combined

IS2303VSP2 Rev-B Maxflo VS Owner s Manual Model SP2303VSP MaxFlo VS Variable Speed Pump Hayward s MaxFlo VS variable speed pump delivers incredible energy savings via its advanced hydraulic design combined

70w and 140w Junction Box Transformer Kit For ColorLogic and CrystaLogic Pool, Spa and Accent Lights Spa Lights

ISLRBUY11H Rev B 70w and 140w Junction Box Transformer Kit For ColorLogic and CrystaLogic Pool, Spa and Accent Lights Spa Lights Owner s Manual LRBUY11H70 LRBUY11H14 MODELS: Contents Warnings. 2 Introduction.....

ISLRBUY11H Rev B 70w and 140w Junction Box Transformer Kit For ColorLogic and CrystaLogic Pool, Spa and Accent Lights Spa Lights Owner s Manual LRBUY11H70 LRBUY11H14 MODELS: Contents Warnings. 2 Introduction.....

MODEL VR1000 SERVICE MANUAL INSTALLATION & PARTS

PN: ISVR1000TECH Rev: J MODEL VR1000 SERVICE MANUAL INSTALLATION & PARTS WARNING Improper installation, use, or maintenance of this Vacuum Release System or associated equipment could cause serious or

PN: ISVR1000TECH Rev: J MODEL VR1000 SERVICE MANUAL INSTALLATION & PARTS WARNING Improper installation, use, or maintenance of this Vacuum Release System or associated equipment could cause serious or

OWNER S MANUAL INSTALLATION, OPERATION, & PARTS SAVE THIS INSTRUCTION MANUAL

OWNER S MANUAL INSTALLATION, OPERATION, & PARTS 72729 To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. SAVE THIS INSTRUCTION MANUAL Use of

OWNER S MANUAL INSTALLATION, OPERATION, & PARTS 72729 To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. SAVE THIS INSTRUCTION MANUAL Use of

Owner s Manual. Models SP32950VSP Variable Speed Pump SAVE THIS INSTRUCTION MANUAL

IS32950VSP Rev B TriStar VS 950 Owner s Manual Models SP32950VSP Variable Speed Pump Hayward TriStar VS 950 is the industry s most energy efficient variable speed pump. The totally enclosed, permanent

IS32950VSP Rev B TriStar VS 950 Owner s Manual Models SP32950VSP Variable Speed Pump Hayward TriStar VS 950 is the industry s most energy efficient variable speed pump. The totally enclosed, permanent

VL Series Pump. Owner s Manual. NOTE - To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely.

ISVL1285 Rev B VL Series Pump Owner s Manual NOTE - To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. READ AND FOLLOW ALL INSTRUCTIONS SAVE

ISVL1285 Rev B VL Series Pump Owner s Manual NOTE - To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. READ AND FOLLOW ALL INSTRUCTIONS SAVE

SwimPro by HAYWARD 620 Division Street Elizabeth, NJ Tel:

OWNER S MANUAL INSTALLATION, OPERATION & PARTS ISSW256T Rev. B SW96T75XS SERIES SW236TX5S SERIES SW256TX5DS SERIES SW256TX5S SERIS HIGH-RATE SAND FILTER SYSTEMS SW96T SW236T SW256T HIGH RATE SAND FILTERS

OWNER S MANUAL INSTALLATION, OPERATION & PARTS ISSW256T Rev. B SW96T75XS SERIES SW236TX5S SERIES SW256TX5DS SERIES SW256TX5S SERIS HIGH-RATE SAND FILTER SYSTEMS SW96T SW236T SW256T HIGH RATE SAND FILTERS

HAYWARD POOL PRODUCTS POMONA, CA CLEMMONS, NC NASHVILLE, TN

IS210T90 Rev. D OWNER S MANUAL INSTALLATION, OPERATION & PARTS MODEL S210T, S210T93 PRO SERIES HIGH-RATE SAND FILTRATION SYSTEM Basic safety precautions should always be followed, including the following:

IS210T90 Rev. D OWNER S MANUAL INSTALLATION, OPERATION & PARTS MODEL S210T, S210T93 PRO SERIES HIGH-RATE SAND FILTRATION SYSTEM Basic safety precautions should always be followed, including the following:

2 SPEED PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR 2 SPEED PUMP

2 SPEED PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR 2 SPEED PUMP 8308 PUMP PARTS BREAKDOWN Ref # Part # Manf. # Descrip on 1 NEP2134 AC 81361 PUMP LID 2 NEP2135 AC 81396 PUMP LID

2 SPEED PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR 2 SPEED PUMP 8308 PUMP PARTS BREAKDOWN Ref # Part # Manf. # Descrip on 1 NEP2134 AC 81361 PUMP LID 2 NEP2135 AC 81396 PUMP LID

ULTRA STRIP DRAIN OWNER S MANUAL VGB 2008 IMPORTANT SAFETY INSTRUCTIONS WARNING TO REDUCE THE RISK OF ENTRAPMENT HAZARDS:

VGB 2008 ULTRA STRIP DRAIN OWNER S MANUAL WARNING IMPORTANT SAFETY INSTRUCTIONS Read and keep these instructions for future reference. Follow all instructions in this owner s manual and on the equipment.

VGB 2008 ULTRA STRIP DRAIN OWNER S MANUAL WARNING IMPORTANT SAFETY INSTRUCTIONS Read and keep these instructions for future reference. Follow all instructions in this owner s manual and on the equipment.

DIAMOND STRIP DRAIN OWNER S MANUAL VGB 2008 IMPORTANT SAFETY INSTRUCTIONS WARNING TO REDUCE THE RISK OF ENTRAPMENT HAZARDS:

VGB 008 DIAMOND STRIP DRAIN OWNER S MANUAL WARNING IMPORTANT SAFETY INSTRUCTIONS Read and keep these instructions for future reference. Follow all instructions in this owner s manual and on the equipment.

VGB 008 DIAMOND STRIP DRAIN OWNER S MANUAL WARNING IMPORTANT SAFETY INSTRUCTIONS Read and keep these instructions for future reference. Follow all instructions in this owner s manual and on the equipment.

QUIETFLO OWNER S MANUAL

QUIETFLO OWNER S MANUAL INSTALLATION, OPERATION & PARTS To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completley. CAUTION - We highly recommend a qualified

QUIETFLO OWNER S MANUAL INSTALLATION, OPERATION & PARTS To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completley. CAUTION - We highly recommend a qualified

OWNER S MANUAL INSTALLATION, OPERATION, & PARTS

P/N: IS2700 REV. A OWNER S MANUAL INSTALLATION, OPERATION, & PARTS Max-Flo II Pump Series *50HZ Models are not UL Listed. The Hayward Max-Flo II is a series of high technology self-priming pumps that combines

P/N: IS2700 REV. A OWNER S MANUAL INSTALLATION, OPERATION, & PARTS Max-Flo II Pump Series *50HZ Models are not UL Listed. The Hayward Max-Flo II is a series of high technology self-priming pumps that combines

CHAMPION PUMP OWNER S MANUAL

CHAMPION PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

CHAMPION PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

OWNER S MANUAL INSTALLATION, OPERATION, & PARTS

P/N: IS2800X5 Rev. C OWNER S MANUAL INSTALLATION, OPERATION, & PARTS The Hayward Max-Flo is specifically engineered for the demanding requirements of today s in-ground swimming pool/spa that is equipped

P/N: IS2800X5 Rev. C OWNER S MANUAL INSTALLATION, OPERATION, & PARTS The Hayward Max-Flo is specifically engineered for the demanding requirements of today s in-ground swimming pool/spa that is equipped

HAYWARD POOL PRODUCTS, INC. 620 DIVISION STREET ELIZABETH, NJ (908) OWNER S MANUAL INSTALLATION, OPERATION, & PARTS

P/N: IS3200 Rev. D OWNER S MANUAL INSTALLATION, OPERATION, & PARTS TriStar Pump Series *50HZ Models are not UL Listed. The Hayward TriStar Pump is specifically engineered for the demanding requirements

P/N: IS3200 Rev. D OWNER S MANUAL INSTALLATION, OPERATION, & PARTS TriStar Pump Series *50HZ Models are not UL Listed. The Hayward TriStar Pump is specifically engineered for the demanding requirements

OWNER S MANUAL INSTALLATION, OPERATION, & PARTS

ISC2026 Rev A OWNER S MANUAL INSTALLATION, OPERATION, & PARTS Models C2000 C3000 C4000 C5000 SUPER STAR-CLEAR CARTRIDGE FILTERS MODEL EFFECTIVE FILTRATION RATE DESIGN FLOW RATE FT 2 M 2 GPM LPM C2000 225

ISC2026 Rev A OWNER S MANUAL INSTALLATION, OPERATION, & PARTS Models C2000 C3000 C4000 C5000 SUPER STAR-CLEAR CARTRIDGE FILTERS MODEL EFFECTIVE FILTRATION RATE DESIGN FLOW RATE FT 2 M 2 GPM LPM C2000 225

ECONO FLO VSA 165 VARIABLE SPEED PUMP OWNER S MANUAL

ECONO FLO VSA 165 VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all

ECONO FLO VSA 165 VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all

Variable Speed. IntelliFlo. Installation and User s Guide. Programmable Pump

IntelliFlo Variable Speed Programmable Pump (Compatible with IntelliComm communication center and EasyTouch, IntelliTouch and SunTouch control systems) Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS

IntelliFlo Variable Speed Programmable Pump (Compatible with IntelliComm communication center and EasyTouch, IntelliTouch and SunTouch control systems) Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS

SMF PUMP OWNER S MANUAL

SMF PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

SMF PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

MAXI PUMP INSTRUCTION MANUAL NE6151B /NE6171B READ THIS MANUAL CAREFULLY BEFORE USING YOUR MAXI PUMP

MAXI PUMP INSTRUCTION MANUAL NE6151B /NE6171B READ THIS MANUAL CAREFULLY BEFORE USING YOUR MAXI PUMP 8104 MAXI-PUMP PARTS BREAKDOWN Re f # 1 2 3 4 5 6 7a 7b 8 9 10 11 12 13 14 15 16 2 Part # NEP2134 NEP2135

MAXI PUMP INSTRUCTION MANUAL NE6151B /NE6171B READ THIS MANUAL CAREFULLY BEFORE USING YOUR MAXI PUMP 8104 MAXI-PUMP PARTS BREAKDOWN Re f # 1 2 3 4 5 6 7a 7b 8 9 10 11 12 13 14 15 16 2 Part # NEP2134 NEP2135

Installation, Operating, and Service Manual. Badu. EcoM3. Swimming Pool Pump

Installation, Operating, and Service Manual Badu EcoM3 Swimming Pool Pump Technical Support Address: Speck Pumps 8125 Bayberry Road Jacksonville, FL. 32256 USA Hours: 8:00 am to 5:00 pm EST Toll Free:

Installation, Operating, and Service Manual Badu EcoM3 Swimming Pool Pump Technical Support Address: Speck Pumps 8125 Bayberry Road Jacksonville, FL. 32256 USA Hours: 8:00 am to 5:00 pm EST Toll Free:

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning

HAYWARD POOL AND SPA/HOT TUB HEATERS H150FD, H200FD, H250FD, H300FD, H350FD & H400FD MODELS OWNER S MANUAL

HAYWARD POOL AND SPA/HOT TUB HEATERS H150FD, H200FD, H250FD, H300FD, H350FD & H400FD MODELS OWNER S MANUAL FOR YOUR SAFETY WARNING: If the information in these instructions is not followed exactly, a fire

HAYWARD POOL AND SPA/HOT TUB HEATERS H150FD, H200FD, H250FD, H300FD, H350FD & H400FD MODELS OWNER S MANUAL FOR YOUR SAFETY WARNING: If the information in these instructions is not followed exactly, a fire

IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS. Table of Contents WARNING.

Eagle Pump Owners Manual IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Table of Contents SECTION I. INSTALLATION... 2 SECTION II. OPERATION & MAINTENANCE... 2 SECTION

Eagle Pump Owners Manual IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Table of Contents SECTION I. INSTALLATION... 2 SECTION II. OPERATION & MAINTENANCE... 2 SECTION

Models: HP20654T, HP20654BT, HP20854T, HP20854BT and HP21104T INSTALLATION GUIDE SAVE THIS INSTALLATION GUIDE

HP13023770 Rev: E Models: HP20654T, HP20654BT, HP20854T, HP20854BT and HP21104T INSTALLATION GUIDE Important Information to keep for Service Model # Serial # Install Date SAVE THIS INSTALLATION GUIDE The

HP13023770 Rev: E Models: HP20654T, HP20654BT, HP20854T, HP20854BT and HP21104T INSTALLATION GUIDE Important Information to keep for Service Model # Serial # Install Date SAVE THIS INSTALLATION GUIDE The

LifeStar VS. Owner s Manual

LifeStar VS Owner s Manual Hayward LifeStar VS is the Aquatic Industry s most energy efficient variable speed pump. The totally enclosed, permanent magnet motor combined with its advanced hydraulic design

LifeStar VS Owner s Manual Hayward LifeStar VS is the Aquatic Industry s most energy efficient variable speed pump. The totally enclosed, permanent magnet motor combined with its advanced hydraulic design

POOL AND SPA/HOT TUB HEATERS H150FD, H200FD, H250FD, H300FD, H350FD & H400FD MODELS OWNER S MANUAL PRINTED 10/24/2011 AT 1:13 PM

PRINTED 10/24/2011 AT 1:13 PM POOL AND SPA/HOT TUB HEATERS H150FD, H200FD, H250FD, H300FD, H350FD & H400FD MODELS OWNER S MANUAL FOR YOUR SAFETY WARNING: If the information in these instructions is not

PRINTED 10/24/2011 AT 1:13 PM POOL AND SPA/HOT TUB HEATERS H150FD, H200FD, H250FD, H300FD, H350FD & H400FD MODELS OWNER S MANUAL FOR YOUR SAFETY WARNING: If the information in these instructions is not

IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS

Operating Manual MODEL RC554X AND 554230 ORP Digital Controller FEED ALERT ORP FLOW AUTO MODE SET LEVEL FEED TIME FLOW SWITCH ORP ORP OUTPUT POWER IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS

Operating Manual MODEL RC554X AND 554230 ORP Digital Controller FEED ALERT ORP FLOW AUTO MODE SET LEVEL FEED TIME FLOW SWITCH ORP ORP OUTPUT POWER IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS

Variable Speed. Installation and User s Guide. Programmable Pump IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS

Variable Speed Programmable Pump SAVE THESE INSTRUCTIONS Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS F IMPORTANT PUMP WARNING AND

Variable Speed Programmable Pump SAVE THESE INSTRUCTIONS Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS F IMPORTANT PUMP WARNING AND

AQUA-FLO A SERIES. The Bronze Pump designed exclusively for any swimming pool or spa application.

The Bronze Pump designed exclusively for any swimming pool or spa application. The A Series pump, including motor bracket, impeller, volute and trap, are unit cast from corrosion-resistant fine old world

The Bronze Pump designed exclusively for any swimming pool or spa application. The A Series pump, including motor bracket, impeller, volute and trap, are unit cast from corrosion-resistant fine old world

IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS

Operating Manual MODEL RC554P AND 554200 ph Digital Controller FEED ph FLOW ALERT AUTO MODE SET LEVEL FEED TIME ph CALIB FLOW SWITCH ph ph OUTPUT POWER IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL

Operating Manual MODEL RC554P AND 554200 ph Digital Controller FEED ph FLOW ALERT AUTO MODE SET LEVEL FEED TIME ph CALIB FLOW SWITCH ph ph OUTPUT POWER IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL

INTELLIFLO VF VARIABLE FLOW PUMP

INTELLIFLO VF VARIABLE FLOW PUMP INSTALLATION AND USER'S GUIDE IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS i CUSTOMER SERVICE / TECHNICAL SUPPORT If you have

INTELLIFLO VF VARIABLE FLOW PUMP INSTALLATION AND USER'S GUIDE IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS i CUSTOMER SERVICE / TECHNICAL SUPPORT If you have

Installation, Operation & Service Manual

Installation, Operation & Service Manual WARNING Improper installation, adjustment, alteration, service or maintenance can result in death, injury or property damage. Read the Installation, Operation and

Installation, Operation & Service Manual WARNING Improper installation, adjustment, alteration, service or maintenance can result in death, injury or property damage. Read the Installation, Operation and

CHALLENGER CENTRIFUGAL PUMP

CHALLENGER CENTRIFUGAL PUMP INSTALLATION AND USER S GUIDE IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS i CUSTOMER SERVICE / TECHNICAL SUPPORT If you have questions

CHALLENGER CENTRIFUGAL PUMP INSTALLATION AND USER S GUIDE IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS i CUSTOMER SERVICE / TECHNICAL SUPPORT If you have questions

Models: HP20654T, HP20654BT, HP20854T, HP20854BT and HP21104T OWNERS OPERATION & PARTS MANUAL SAVE THIS OWNERS MANUAL

HP13023772 Rev: E Models: HP20654T, HP20654BT, HP20854T, HP20854BT and HP21104T OWNERS OPERATION & PARTS MANUAL Attention Installer: Give this manual to the homeowner. Important Information to keep for

HP13023772 Rev: E Models: HP20654T, HP20654BT, HP20854T, HP20854BT and HP21104T OWNERS OPERATION & PARTS MANUAL Attention Installer: Give this manual to the homeowner. Important Information to keep for

SPA BLOWER OWNER'S MANUAL XXXX, XXXX, XXXX, XXXX, XXXX, XXXX fax

SPA BLOWER OWNER'S MANUAL 80015-XXXX, 80016-XXXX, 80017-XXXX, 80018-XXXX, 80019-XXXX, 80020-XXXX fax 888.610.3839 2015 323300-015 6/15 THIS PAGE INTENTIONALLY LEFT BLANK. 2 Operating Instructions and Parts

SPA BLOWER OWNER'S MANUAL 80015-XXXX, 80016-XXXX, 80017-XXXX, 80018-XXXX, 80019-XXXX, 80020-XXXX fax 888.610.3839 2015 323300-015 6/15 THIS PAGE INTENTIONALLY LEFT BLANK. 2 Operating Instructions and Parts

Owner s Manual PRINTED IN CANADA 05/2009

Owner s Manual PRINTED IN CANADA 05/2009 Table of contents Introduction 2 General Safety Instructions 4 Installation Instructions Location 6 Water piping 7 Electrical 7 Bonding 8 Bonding and plumbing

Owner s Manual PRINTED IN CANADA 05/2009 Table of contents Introduction 2 General Safety Instructions 4 Installation Instructions Location 6 Water piping 7 Electrical 7 Bonding 8 Bonding and plumbing

QUIETFLO PLUS OWNER S MANUAL INSTALLATION, OPERATION & PARTS SAVE THIS INSTRUCTION MANUAL

ADVANTAGE POOL PUMPS QUIETFLO PLUS OWNER S MANUAL INSTALLATION, OPERATION & PARTS To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. CAUTION

ADVANTAGE POOL PUMPS QUIETFLO PLUS OWNER S MANUAL INSTALLATION, OPERATION & PARTS To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. CAUTION

Spa Touch Control Panel with BP2100, BP6013 spa controllers. (Spa Owner s Manual insert)

Spa Touch Control Panel with BP2100, BP6013 spa controllers. (Spa Owner s Manual insert) P.N. 7876C (export) February 12, 2015 For Spas equipped with BP2100, BP6013 controllers and Spa Touch panel. Spa

Spa Touch Control Panel with BP2100, BP6013 spa controllers. (Spa Owner s Manual insert) P.N. 7876C (export) February 12, 2015 For Spas equipped with BP2100, BP6013 controllers and Spa Touch panel. Spa

OWNER S MANUAL. Vintage Classic HEAT COOL models. Proudly Made in the USA

OWNER S MANUAL Vintage Classic HEAT COOL models Proudly Made in the USA support@aquacomfort.com www.aquacomfort.com/service-and-support 888-475-7443 Manufacturing High Quality, High Efficiency Heat Pump

OWNER S MANUAL Vintage Classic HEAT COOL models Proudly Made in the USA support@aquacomfort.com www.aquacomfort.com/service-and-support 888-475-7443 Manufacturing High Quality, High Efficiency Heat Pump

SAVE THIS INSTRUCTION MANUAL

ISPF SERIES Rev. C OWNER S MANUAL INSTALLATION, OPERATION, & PARTS Power-Flo LX / Power-Flo II Pump Series The Hayward Power-Flo LX and Power-Flo II Pump Series are specifically engineered for the demanding

ISPF SERIES Rev. C OWNER S MANUAL INSTALLATION, OPERATION, & PARTS Power-Flo LX / Power-Flo II Pump Series The Hayward Power-Flo LX and Power-Flo II Pump Series are specifically engineered for the demanding

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR PUMP 88 PUMP PARTS BREAKDOWN REF # Order # Mfr # Description 1 NEP4 AC 348 Lid Knobs NEP AC 380 Strainer Lid 3 NEP6

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR PUMP 88 PUMP PARTS BREAKDOWN REF # Order # Mfr # Description 1 NEP4 AC 348 Lid Knobs NEP AC 380 Strainer Lid 3 NEP6

SPA HEATER INSTALLATION, OPERATION AND MAINTENANCE

SPA INSTALLATION, OPERATION AND MAINTENANCE MODELS: ST SERIES 5.5 & 11kW 240V SINGLE PHASE BEFORE YOU BEGIN CHECK ALL ELECTRICAL CONNECTIONS TO ALL COMPONENTS WITHIN THE FOR TIGHTNESS. CONNECTIONS CAN

SPA INSTALLATION, OPERATION AND MAINTENANCE MODELS: ST SERIES 5.5 & 11kW 240V SINGLE PHASE BEFORE YOU BEGIN CHECK ALL ELECTRICAL CONNECTIONS TO ALL COMPONENTS WITHIN THE FOR TIGHTNESS. CONNECTIONS CAN

Spa Control System OWNER S MANUAL

LIMITED WARRANTY ONE YEAR LIMITED WARRANTY: UNITED SPAS, INC. warrants, to the original purchaser, the Spa Equipment against defects in materials or workmanship for a period of one year from date of purchase.

LIMITED WARRANTY ONE YEAR LIMITED WARRANTY: UNITED SPAS, INC. warrants, to the original purchaser, the Spa Equipment against defects in materials or workmanship for a period of one year from date of purchase.

VARIABLE SPEED PUMP INSTALLATION AND USER S GUIDE IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS

VARIABLE SPEED PUMP INSTALLATION AND USER S GUIDE IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS i TABLE OF CONTENTS Important Pump Warning and Safety Instructions...

VARIABLE SPEED PUMP INSTALLATION AND USER S GUIDE IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS i TABLE OF CONTENTS Important Pump Warning and Safety Instructions...

XStream. Owner s Manual. Contents. MODELS: CC1000, CC1500, and Systems IMPORTANT SAFETY INSTRUCTIONS

ISCC100 Rev G XStream Owner s Manual Contents Product Warnings. 2 Introduction..... 3 Installation......3 Replacement Parts... 7 Warranty & Registration 8 MODELS: CC1000, CC1500, and Systems IMPORTANT

ISCC100 Rev G XStream Owner s Manual Contents Product Warnings. 2 Introduction..... 3 Installation......3 Replacement Parts... 7 Warranty & Registration 8 MODELS: CC1000, CC1500, and Systems IMPORTANT

Spa Touch Control Panel with 2000, 2100 controllers. (Spa Owner s Manual insert)

Spa Touch Control Panel with 2000, 2100 controllers (Spa Owner s Manual insert) P.N. 7876B February 11, 2015 For Spas equipped with BP2000, BP2100 controllers and Spa Touch panel. Spa Touch Control Panel

Spa Touch Control Panel with 2000, 2100 controllers (Spa Owner s Manual insert) P.N. 7876B February 11, 2015 For Spas equipped with BP2000, BP2100 controllers and Spa Touch panel. Spa Touch Control Panel

Gunite & Fiberglass Pools

Electrical Wiring The Pro Logic Control Center and PS-16 Expansion Unit require both high and low voltage connections. Low voltage connections will be made to actuators, sensors, remote keypad, etc. High

Electrical Wiring The Pro Logic Control Center and PS-16 Expansion Unit require both high and low voltage connections. Low voltage connections will be made to actuators, sensors, remote keypad, etc. High

Elite Primer Baldor Series External Pond Pump

Elite Primer Baldor Series External Pond Pump ( 5250PPB21, 6440PPB23, 7550PPB26, 9600PPB28) Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS, READ AND FOLLOW ALL INSTRUCTIONS. SAVE THESE INSTRUCTIONS

Elite Primer Baldor Series External Pond Pump ( 5250PPB21, 6440PPB23, 7550PPB26, 9600PPB28) Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS, READ AND FOLLOW ALL INSTRUCTIONS. SAVE THESE INSTRUCTIONS

OnCommand. Automation. Operation Manual ONCOM ONCOM-ACT ONCOM-RC ONCOM-ACT-RC ONCOM-POD2 ONCOM-ACT-POD2

092442A RevC OnCommand Automation \ Operation Manual Contents Introduction...2 Operation...3 Troubleshooting...29 Warranty...34 ONCOM ONCOM-ACT ONCOM-RC ONCOM-ACT-RC ONCOM-POD2 ONCOM-ACT-POD2 Hayward Pool

092442A RevC OnCommand Automation \ Operation Manual Contents Introduction...2 Operation...3 Troubleshooting...29 Warranty...34 ONCOM ONCOM-ACT ONCOM-RC ONCOM-ACT-RC ONCOM-POD2 ONCOM-ACT-POD2 Hayward Pool

INSTALLATION, OPERATION AND MAINTENANCE

INLINE HEATER INSTALLATION, OPERATION AND MAINTENANCE MODELS: ILS SERIES 1.5kW 120V SINGLE PHASE BEFORE YOU BEGIN CHECK ALL ELECTRICAL CONNECTIONS TO ALL COMPONENTS WITHIN THE HEATER FOR TIGHTNESS. CONNECTIONS

INLINE HEATER INSTALLATION, OPERATION AND MAINTENANCE MODELS: ILS SERIES 1.5kW 120V SINGLE PHASE BEFORE YOU BEGIN CHECK ALL ELECTRICAL CONNECTIONS TO ALL COMPONENTS WITHIN THE HEATER FOR TIGHTNESS. CONNECTIONS

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS VARIABLE SPEED BOOSTER PUMP IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS IMPORTANT SAFETY INFORMATION WARNING: RISK OF ELECTRICAL SHOCK

INSTALLATION INSTRUCTIONS VARIABLE SPEED BOOSTER PUMP IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS IMPORTANT SAFETY INFORMATION WARNING: RISK OF ELECTRICAL SHOCK

Booster Pump. Owner s Manual Model HSP Contents

IS30060 Rev A Booster Pump Owner s Manual Model HSP30060 Contents Product Warnings. 2 Introduction..... 4 Installation.... 4 Replacement Parts.. 10 Trouble Shooting... 11 Registration. 12 IMPORTANT SAFETY

IS30060 Rev A Booster Pump Owner s Manual Model HSP30060 Contents Product Warnings. 2 Introduction..... 4 Installation.... 4 Replacement Parts.. 10 Trouble Shooting... 11 Registration. 12 IMPORTANT SAFETY

OPERATORS MANUAL FOR Mi-T-M CORONA DISCHARGE OZONE GENERATORS

OPERATORS MANUAL FOR Mi-T-M CORONA DISCHARGE OZONE GENERATORS CAUTION RISK OF INJURY! READ MANUAL BEFORE OPERATING! This manual is an important part of the Corona Discharge Ozone Generator and must remain

OPERATORS MANUAL FOR Mi-T-M CORONA DISCHARGE OZONE GENERATORS CAUTION RISK OF INJURY! READ MANUAL BEFORE OPERATING! This manual is an important part of the Corona Discharge Ozone Generator and must remain

CONTENTS CONSIDERATIONS. General Plumbing Component Connection ILLUSTRATION. Control System CONFIGURATION. Voltage Verification CONNECTION

AIR SERIES SYSTEM INSTALLATION MANUAL CONTENTS CONSIDERATIONS General Plumbing Component Connection 2 2 2 ILLUSTRATION Control System 3 CONFIGURATION Voltage Verification 4 CONNECTION Component Connection

AIR SERIES SYSTEM INSTALLATION MANUAL CONTENTS CONSIDERATIONS General Plumbing Component Connection 2 2 2 ILLUSTRATION Control System 3 CONFIGURATION Voltage Verification 4 CONNECTION Component Connection

ProSeries HIGH RATE SAND FILTER. Owner s Manual. Contents. Models S144T S166T S210T S220T S244T S270T S310T2 S180T S210T2 S220T2 S244T2 S270T2 S360T2

IS20T Rev J ProSeries HIGH RATE SAND FILTER Owner s Manual Contents Warnings. 2 Introduction..... 4 Installation. 4 Replacement Parts... 6 Warrantee & Registration 8 Models S44T S66T S20T S220T S244T S270T

IS20T Rev J ProSeries HIGH RATE SAND FILTER Owner s Manual Contents Warnings. 2 Introduction..... 4 Installation. 4 Replacement Parts... 6 Warrantee & Registration 8 Models S44T S66T S20T S220T S244T S270T

IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS

Operating Manual MODELS RC554XP AND 554000 ORP/pH Digital Controller FEED ph ALERT FEED ORP ALERT F LOW ph MODE AUTO FEED ONCE SET LEVEL FEED TIME HI LOW ph CALIB ORP ph ORP IMPORTANT SAFETY INSTRUCTIONS

Operating Manual MODELS RC554XP AND 554000 ORP/pH Digital Controller FEED ph ALERT FEED ORP ALERT F LOW ph MODE AUTO FEED ONCE SET LEVEL FEED TIME HI LOW ph CALIB ORP ph ORP IMPORTANT SAFETY INSTRUCTIONS

Ion Genesis II Pump Controller Digital Level Control with Pump Alternation and High Water Alarm

Page 1 of 8 General Overview Thank you for purchasing an Ion Genesis controller. Take the time to read the instructions carefully before using this appliance. We strongly recommend that you keep this instruction

Page 1 of 8 General Overview Thank you for purchasing an Ion Genesis controller. Take the time to read the instructions carefully before using this appliance. We strongly recommend that you keep this instruction

M770 ph Controller Owner s Manual

M770 ph Controller Owner s Manual Table of Contents I. Introduction page 2 A. Water Chemistry page 2 B. Safety page 3 C. System Components page 4 D. Specifications page 7 E. Controller Panel Descriptions

M770 ph Controller Owner s Manual Table of Contents I. Introduction page 2 A. Water Chemistry page 2 B. Safety page 3 C. System Components page 4 D. Specifications page 7 E. Controller Panel Descriptions

INSTALLATION GUIDE AND OWNER S MANUAL. AccuMix II ELECTRIC INSTANTANEOUS WATER HEATER WITH ASSE 1070 APPROVED MIXING VALVE

INSTALLATION GUIDE AND OWNER S MANUAL AccuMix II ELECTRIC INSTANTANEOUS WATER HEATER WITH ASSE 1070 APPROVED MIXING VALVE 2 BEFORE ATTEMPTING ANY INSTALLATION, MODIFICATION OR SERVICE OF THIS HEATER, MAKE

INSTALLATION GUIDE AND OWNER S MANUAL AccuMix II ELECTRIC INSTANTANEOUS WATER HEATER WITH ASSE 1070 APPROVED MIXING VALVE 2 BEFORE ATTEMPTING ANY INSTALLATION, MODIFICATION OR SERVICE OF THIS HEATER, MAKE

AquaSaver DISPOSER CONTROL CENTER Installation Manual. Model AS-101K

AquaSaver DISPOSER CONTROL CENTER Installation Manual Model AS-1K The Danger signal indicates an immediately hazardous situation which, if not avoided, will result in death or serious injury. The Warning

AquaSaver DISPOSER CONTROL CENTER Installation Manual Model AS-1K The Danger signal indicates an immediately hazardous situation which, if not avoided, will result in death or serious injury. The Warning

IntelliFlo Variable Speed Pump (Compatible with IntelliTouch and IntelliComm)

Variable Speed Pump (Compatible with IntelliTouch and IntelliComm) Listed Installation and User's Guide IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Customer Support

Variable Speed Pump (Compatible with IntelliTouch and IntelliComm) Listed Installation and User's Guide IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Customer Support

IntelliFlo VS+ SVRS Variable Speed Programmable Pump with Safety Vacuum Release System (SVRS) Protection

IntelliFlo VS+ SVRS Variable Speed Programmable Pump with Safety Vacuum Release System (SVRS) Protection (Compatible with IntelliComm communication center, EasyTouch, IntelliTouch and SunTouch control

IntelliFlo VS+ SVRS Variable Speed Programmable Pump with Safety Vacuum Release System (SVRS) Protection (Compatible with IntelliComm communication center, EasyTouch, IntelliTouch and SunTouch control

TP600 and TP400 Control Panels

TP600 and TP400 Control Panels Balboa Water Group Revolution Series User Interface and Programming Reference Simplified Menus System Model: BP1500 / BP1600 - Other BP-Series Systems as required. Software

TP600 and TP400 Control Panels Balboa Water Group Revolution Series User Interface and Programming Reference Simplified Menus System Model: BP1500 / BP1600 - Other BP-Series Systems as required. Software

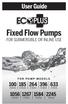

User Guide. Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE FOR PUMP MODELS # # # # # # # # #728333

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

Instructions for installation and use English. More documents on: H B /09

TM Instructions for installation and use English EN More documents on: www.zodiac-poolcare.com H0538700.B - 2015/09 Read this manual carefully before installing, maintaining or repairing this appliance!

TM Instructions for installation and use English EN More documents on: www.zodiac-poolcare.com H0538700.B - 2015/09 Read this manual carefully before installing, maintaining or repairing this appliance!

Use and Care Manual. Flammable Material Storage Refrigerator LRBFS06W1HC

Use and Care Manual Flammable Material Storage Refrigerator LRBFS06W1HC 7085 471-00 Table of Contents Table of Contents Page Please Read and Follow these Instructions... 2 California Proposition 65...

Use and Care Manual Flammable Material Storage Refrigerator LRBFS06W1HC 7085 471-00 Table of Contents Table of Contents Page Please Read and Follow these Instructions... 2 California Proposition 65...

OWNER S MANUAL. Vintage Signature Series models: AC750, AC1050, AC1100, AC1250, AC1500, AC1750. Proudly Made in the USA.

OWNER S MANUAL Vintage Signature Series models: AC750, AC1050, AC1100, AC1250, AC1500, AC1750 Proudly Made in the USA support@aquacomfort.com 888-475-7443 Manufacturing High Quality, High Efficiency Heat

OWNER S MANUAL Vintage Signature Series models: AC750, AC1050, AC1100, AC1250, AC1500, AC1750 Proudly Made in the USA support@aquacomfort.com 888-475-7443 Manufacturing High Quality, High Efficiency Heat

OWNER S MANUAL. Models: AC110, AC125, AC150 made from 2003 through Proudly Made in the USA

OWNER S MANUAL Models: AC110, AC125, AC150 made from 2003 through 2010 Proudly Made in the USA support@aquacomfort.com www.aquacomfort.com/service-and-support/ (888) 475-7443 Manufacturing High Quality,

OWNER S MANUAL Models: AC110, AC125, AC150 made from 2003 through 2010 Proudly Made in the USA support@aquacomfort.com www.aquacomfort.com/service-and-support/ (888) 475-7443 Manufacturing High Quality,

Pool Power Pak. III with On/Off Switch UL Models (1 HP), (1-1/2 HP) NEC Models (1 HP), (1-1/2 HP)

the original portable pool Pool Power Pak III with On/Off Switch UL Models 0-1076-000 (1 HP), 0-1077-000 (1-1/2 HP) NEC Models 0-1076-006 (1 HP), 0-1077-006 (1-1/2 HP) Owner's Guide 365-1783 PREPARATION

the original portable pool Pool Power Pak III with On/Off Switch UL Models 0-1076-000 (1 HP), 0-1077-000 (1-1/2 HP) NEC Models 0-1076-006 (1 HP), 0-1077-006 (1-1/2 HP) Owner's Guide 365-1783 PREPARATION

OWNER S Manual PRINTED IN CANADA 10/2009

OWNER S Manual PRINTED IN CANADA 10/2009 Table of contents Introduction 2 General Safety Instructions 4 Installation Instructions Location 6 Water piping 7 Electrical 7 Bonding 8 Bonding and plumbing

OWNER S Manual PRINTED IN CANADA 10/2009 Table of contents Introduction 2 General Safety Instructions 4 Installation Instructions Location 6 Water piping 7 Electrical 7 Bonding 8 Bonding and plumbing

Description of the vacuum

Description of the vacuum by RSBH-O, RSBH-C, RSBH-SB RSBHP-O & RSBHP-C Owner s Manual Contents IMPORTANT SAFETY INSTRUCTIONS... 3 Safety Features... 4 Polarization Instructions... 4 Benefits... 5 Description

Description of the vacuum by RSBH-O, RSBH-C, RSBH-SB RSBHP-O & RSBHP-C Owner s Manual Contents IMPORTANT SAFETY INSTRUCTIONS... 3 Safety Features... 4 Polarization Instructions... 4 Benefits... 5 Description

Use & Care Manual. Electric Tankless Water Heaters. With Installation Instructions for the Installer AP15447 (10/10)