6000, 8000, & 15000

|

|

|

- Benjamin Lamb

- 6 years ago

- Views:

Transcription

1 aquaforce , 8000, & Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) ?

2 1 A A. Wildlife Protection System E C B F B. Pump C. Outlet adaptor D D. Ball Joint E. Hosetail & Nut F. Strainer Cage G G. End Cap H. Flow Control H E The pump is electrically operated and is designed to pump solid particles up to 10mm in diameter with minimal prestrainer maintenance. These types of pumps are particularly suitable for pumping water to external filters or for use in high flow waterfalls or watercourse applications where low maintenance is important. The pump does not use oil or grease for lubrication and can be used safely in ponds containing fish or plants. The motor consists of a sealed stator and water-cooled rotor. All electrical components are isolated from the water. ATTENTION Introduction AUTOMATIC CUT-OUT To help ensure your pump s long life and to prevent damage, it is fitted with automatic thermal overload protection. This switches off the pump if it overheats. If this occurs, switch off the power at the mains supply to the pump. Check for the cause. Usually it will be debris blocking the inlets of the pump or obstructing the impeller. Remove the obstruction and wait for the pump to cool down. Then switch on the pump again. General Safety Guidelines Failure to observe the following notices may result in injury, product damage or loss of fish. 1. This pump has been designed for the use with ponds only. Only use this pump for the operation of pond filter systems, water displays, waterfalls etc. Do not use this pump for any other use (i.e. do not use this pump in swimming pools, bathrooms, central heating systems etc). Using the product for any other application may result in injury or product damage. 2. This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety. Children should be supervised to ensure that they do not play with the appliance. (Australia & NZ only) This appliance is not intended for use by young children or infirm persons unless they have been adequately supervised by a responsible person to ensure that they can use the appliance safely. Young children should be supervised to ensure that they do not play with the appliance. 3. WARNING: Always unplug or disconnect all appliances in the pond from the electricity supply before putting your hands in the water whilst equipment is being installed, repaired, maintained or handled. 4. Never use the mains supply cable to lift the pump, as this may cause damage. We recommend fitting a lifting cord to the handle on the strainer cage when the pump is installed in deep water. 5. Do not operate or leave the pump in freezing conditions. 6. Protect the pump from direct sunlight. Direct sunlight may overheat the motor. 7. Never allow the pump to run dry. 8. Do not operate this pump without the strainer cage properly attached. Using the pump without the strainer cage may invalidate your guarantee. 9. ATTENTION: This product is not suitable for water temperatures above 35ºC. 10. ATTENTION: Do not operate this product if the mains supply cable or the motor has become damaged in any way. The supply cable cannot be replaced as it is permanently encased in the motor housing and should therefore be disposed of according to local regulations. 11. If you live in a hard water area (water with high calcium or limescale content), the pump, rotor assembly and inside of motor should be cleaned at regular intervals (See MAINTENANCE). 12. Only use accessories which have been designed for use with this product. The use of any other accessories may invalidate your guarantee. Installing this product in the garden is classed as 'notifiable' in the revised Building Regulations for England and Wales. The Regulations require you to tell your local authority building control department that you intend to install this product before installation. Your local authority will let you know how you can get your installation approved.

3 Electrical Connections 1. WARNING: Always unplug or disconnect all appliances in the pond from the electricity supply before putting your hands in the water whilst equipment is being installed, repaired, maintained or handled. 2. Check that the voltage marked on the unit corresponds to the mains supply. 3. The pump is supplied with 10m of 3 core electric cable which is permanently connected and sealed to the motor. The supply cable cannot be replaced. If the cable is damaged, the pump should be discarded. This product is designed to be permanently wired to the mains supply in a dry weatherproof enclosure through a Double-Pole Switched Fused Spur - (Disconnector) to BS 3676 with a minimum contact gap of 3mm in each pole. Fitted with a 3 or 5 Amp fuse. The installation must conform to the National and Local wiring regulations which could include the use of plastic or metal conduit to protect the cable. 4. A 10mA or 30mA Residual Current Device (RCD) Must be fitted to the mains supply. 5. WARNING: This appliance must be earthed and it is essential that the connections are made using the following code; Brown Live Blue Neutral Green/Yellow Earth The BROWN lead should be connected to the LIVE terminal which may be marked with an L or coloured brown or red. The BLUE lead should be connected to the NEUTRAL terminal which may be marked with an N or coloured blue or black. The GREEN/YELLOW lead should be connected to the EARTH terminal which may be marked with an E ( ) or coloured green or green/yellow. 6. If an extension cable is required, this should be connected to the end of the pump cable using a weatherproof cable connector. The joint must be positioned in a suitable dry housing. The extension cable should be of 3 core 0.75mm2 Polychloroprene rubber insulated cable (ref: HO5 RN-F) and permanently wired to the mains supply with a 3 or 5 Amp fuse. 7. The pump cable (and extension cable) should be positioned and adequately protected against damage especially where contact with gardening equipment, (lawn mowers, forks etc..) children and domestic animals may occur. 8. Consult a qualified electrician or local authority if in any doubt about wiring to the mains supply. Typical Installation 2 Most common Aquaforce set up NOTE: When running amphibiously, the dry sited pump MUST be positioned horizontally, as shown Amphibious operation

4 - Submerged Operation ASSEMBLY 1. Open the clips at either end of the strainer cage (Fig 1 f) and open the cage. 2. Remove the Wildlife Protection system (Fig 1 a). 3. Remove & unpack the ball joint, hosetails & Flow control (Fig 1 d, e & h). 4.Remove the mains supply cable and Pump Assembly & Installation unwind. 5. Ensure that the outlet of the pump is secured to the outlet adaptor (Fig 1 c). Locate the pump onto its mounting area ensuring that the adaptor piece slots into the location ribs in the front of the lower cage (Fig 4). 4 Note: For the 6000 & 8000 pump the adaptor should be orientated with the outlet at the bottom of the cage (fig 5). For the & pumps, the adaptor should be orientated with the outlet towards the top of the cage (Fig 5) / / Locate the mains supply cable into the recess on the side of the cage. Ensure it is seated in the correct position so that the cable does not get trapped when the cage is closed. (Fig 6) Close the cage lid ensuring that the end cap (Fig 1 g) is in its correct position and secure by pressing in the centre of the clips (Fig 7) Checking that the ball joint s inlet and outlet bosses are in line, firmly screw the nut on to the screw thread on the outlet adaptor (Fig 8). 8

5 9. Using small bore hoses leads to excessive restriction of the water flow. The larger the diameter of hose that you use the better the performance of the pump will be, especially over long hose runs. The hosetail supplied with this unit will accommodate 25mm (1"), 32mm (1.25") and 40mm (1.6") hose as well a ¾ BSP screw thread for attaching fountain accessories. We would always recommend that on pumps of this size, that the 40mm diameter hose should be used when using the pump as a waterfall pump or in combination with a filter (Fig 2 & 3). Once you have selected the hose diameter you wish to use, cut the steps off the hosetail which are smaller than the hose diameter to eliminate restriction (Fig 9). Attach a suitable length hose to the hosetail and secure with a suitable hose clip and position the outlet end of the hose in the desired position Screw the hosetail directly onto the outlet boss of the ball joint (Fig 10). The ball joint can be rotated to allow the hose to be directed away from the pump. 10 Position 11. For the best results, the pump should be positioned in the deepest part of the pond at least 200mm under the surface. This will ensure the best circulation of water in the pond and when being used as a filtration pump, its solids handling capability will be maximised. For best results, the pump should not be placed directly on the bottom of the pond. We recommend that the pump be installed on a flat level Wildlife Protection System (WPS) 12. If you have fish or other wildlife in your pond, there are periods in the year during which they may breed. At this time the fish fry are small and can be sucked into the pump. To minimise this possibility, the Aquaforce range of pumps has a unique Wildlife Protection System (WPS), which reduces the inlet strainer hole size down to 2mm at this critical time in fishes life cycle. To use this feature, locate the WPS s 4 legs into the corresponding area in the lower cage as shown in Fig 12 ensuring that the WPS is the correct way round. Close platform which is raised approximately 300mm from bottom of pond. This will prevent the pump sucking dirt directly from the bottom of the pond and will also ensure that sufficient water remains in the pond in the event of accidental leakage of pond water (See fig 11). the top of the cage and secure the clips. Whilst the WPS is in use, you may need to unblock the Strainer Cage more frequently. Once the fish or other wildlife have grown to a sufficient size you can then remove the WPS from your pump s cage and return the strainer size to its maximum 10mm size mm

6 Using The Flow Control The flow Control (Fig 1 - h) can vary the amount of water entering the pump. Alternatively, it can be used to connect a second inlet to the pump such as a satellite filter or a skimmer. Do not use the flow control when the pump is being used amphibiously. 1. Open the cage and remove the end cap (Fig 1 - g). 2. Close the flow control by rotating the outer part until the arrows are aligned. 3. Firmly screw the flow control to the inlet of the pump aligning the arrows on the flow control with the arrow in the centre of the top of the pump chamber (Fig 13). 4. Locate the pump into the cage. Ensure that the slots in the outlet adaptor align with the ribs in the lower cage and that the grip of the flow control is on the outside of the cage (Fig 4) To use as a flow control, screw the end cap to the free end of the flow control. 6. Rotate the grip to the desired position. This varies the opening size on the flow control. The arrow on the grip aligns with the pointer on the outside of the top cage. When the pointed end of the arrow is aligned with the pointer on the outside of the filter cage, this indicates minimum flow. When the wide end of the arrow is aligned with the pointer, this indicates maximum flow (See fig 14). 7. Locate the cable into its recess (See point 6 under Submerged Operation), close the cage lid and secure the clips. 8. This allows you to reduce the flow of water to your filter and control the waterfall size To use a second inlet connect a suitable length of hose to a hosetail which has been cut to a suitable diameter and screw to the free end of the flow control in place of the end cap (Fig 15) The other end of the hose can be connected to a satellite filter (Fig 16) (available as a spare from Hozelock) or to a skimmer (Fig 17). 11. By rotating the grip of the flow control, the amount of water coming through the satellite filter or skimmer can be varied

7 - AMPHIBIOUS This pump can be used amphibiously (i.e. it can be used whilst not submerged). WARNING! Ensure that the unit does not take in air or run dry otherwise your pump will be damaged! NOTE: This pump does not self prime. Pump Installation The suction hose and pump must be filled with water before switching on. 1. Open the clips at either end of the strainer cage, open the cage, and remove all the contents. 2. Unscrew the outlet adaptor from the pump outlet and locate it into the ribs in the lower cage (Fig 18) Place the pump under the surface of the water near the side of the pond to allow water to flow into the pumping chamber (Fig 19) Cut 2 hosetails to the required size (See point 9 under Submerged Operation). Attach a suitable length hose to each hosetail and secure with suitable hose clips. 5. Submerge the inlet hose under the surface of the water ensuring that the complete hose fills. Screw the hosetail to the inlet of the pump ensuring a watertight seal using the washer provided (Fig 20) Fix the outlet hose to the pump outlet by screwing on the hosetail. Ensure a watertight seal using the washer provided (Fig 21). 7. Check that the pump chamber and hose are full of water and switch on the pump. The pump can now be removed from the water to it s amphibious operating location ensuring that the inlet end of the hose remains submerged. 8. To prevent the pump becoming clogged, connect the cage to the inlet end of the inlet hose using another hosetail. 9. When using the pump amphibiously, protect the pump from direct sunlight. Direct sunlight may overheat the motor. 10. The ball joint is not designed to be used out of water. 21

8 The Hozelock Cyprio range of Aquaforce pumps have been designed to allow fast and easy maintenance. To prolong the life of your pump and keep your pump in peak condition, you should follow these maintenance guidelines. Caution: Always unplug or disconnect ALL appliances in the pond from the electricity supply before putting your hands in the water or starting maintenance. 1. When the pump is newly installed, you should check your pump daily that it is performing correctly. 2. If you notice a drop in performance (low flow) you should clean the strainer cage. Cleaning intervals will vary depending on the condition of your pond s water. This could be as often as weekly in the summer months. To clean the strainer cage, open the clips and remove the pump. The cage can then be wiped clean of debris blocking the strainer holes and washed in clean water. You should also check that the pump chamber & rotor are not blocked with debris. 3. At least once a year you should completely disassemble the pump including the rotor assembly as described below and wash all components in clean, fresh water. Replace worn or broken parts. Pump Dismantling & Assembly (6000 & 8000) - Fig Switch off the pump and remove the strainer cage as described above and remove the pump. 2. Ensure the pump is cool before dismantling it. 3. Unscrew the 3 posidrive screws in the chamber. 4. Gently pull the pump chamber (d) squarely away from the motor body (a). 5. Pull the rotor assembly (c) out of the motor body. Important! Take extra care so as to not drop the rotor assembly. 6. Wash out all of the components in clean water. Do not use detergents or other chemical cleaners. 7. Ensure the o-ring (b) is on it s seat (fig 29). Replace the rotor assembly into the motor body, ensuring that the holes in the plate behind the impeller locate onto the pins on the motor body. Refit the pump chamber and screws and return the pump to the strainer cage. Pump Dismantling & Assembly (12000 & 15000) - Fig Switch off the pump and remove the strainer cage as described above and remove the pump. 2. Ensure the pump is cool before / /15000 Maintenance a b dismantling it. 3. Unscrew the 4 posidrive screws in the chamber. 4. Rotate the pump chamber (d) as far as it will go and gently pull the chamber squarely away from the motor body (a). 5. Pull the rotor assembly (c) out of the motor body. Important! Take extra care so as to not drop the rotor assembly. 6. Wash out all of the components in clean water. Do not use detergents or other chemical cleaners. 7. Ensure the o-ring (b) is on it s seat (fig 24). Replace the rotor assembly into the motor body, ensuring that the holes in the plate behind the impeller locate onto the pins on the motor body. Refit the pump 24 a b c c d d chamber and screws and return the pump to the strainer cage. 4. If you live in a hard water area (water with high levels of calcium or limescale content), the pump, rotor assembly and steel can should be cleaned at regular intervals. The cleaning interval required will vary depending on the hardness of your water, so you should inspect for signs of calcium build up regularly. To clean off calcium or limescale deposits a small nylon bristled brush (such as a toothbrush) may be used. Dismantle the pump as described above and remove the rotor. Clean the limescale deposits from the rotor using fresh clean water If excessive calcium deposits build up, the thermal overload protection may be activated (See INTRODUCTION).

9 Winter Care 1. Your pump should be removed from your pond during the autumn. 2. Clean the pump as described above. 3. During winter, we recommend storing the pump in a bucket of water. This is to prevent the bearings from drying out and potentially seizing. This is especially important if you have been using your pump in a hard water area. The bucket of water containing the pump should be stored in a frost protected area. Troubleshooting/Fault Finding Important - Please keep this section for reference. LOW FLOW FROM PUMP 1. Ensure that the strainer cage is clean. 2. A small diameter outlet pipe will restrict outlet flow. 3. Ensure that there is no blockage within the pump chamber. 4. If using the pump amphibiously, ensure that the ball joint is not being used and check that the washers provided are used when fixing the hosetail to the pumps. NO FLOW FROM PUMP 1. Check the power supply is on. 2. Check the fuse, RCD and wiring. 3. Check that the rotor assembly is not jammed, blocked, damaged or showing signs of excessive wear. 4. Ensure that the strainer cage is clean. 5. The thermal overload protection has tripped. (see INTRODUCTION). Hozelock Cyprio 3 Year Guarantee To activate your warranty please go to If this pump, excluding the rotor assembly, becomes unserviceable within 3 years of the date of purchase it will be repaired or replaced at our option free of charge, unless in our opinion it has been damaged or misused. Liability is not accepted for damage due to accident, improper installation or use. Liability is limited to replacement of a faulty pump. This guarantee is not transferable. It does not affect your statutory rights. To obtain the benefits of the guarantee, firstly contact Hozelock Cyprio Consumer Services who may request that the pump is sent along with proof of purchase directly to the address below. Hozelock Cyprio Ltd. Midpoint Park, Birmingham B76 1AB. England Telephone: SPARE PARTS Contact the Consumer Services Helpline on All spare parts can be purchased at Part No Model no Spares 1. Pump Chamber Assembly and Seal. Z10008 Z10009 Z10010 Z Rotor Assembly. Z10001 Z10002 Z10003 Z Outlet Adaptor Z10011 Z10011 Z10011 Z Strainer Cage Assembly/Satellite Filter Ball Joint Z10013 Z10013 Z10013 Z Stepped Hosetail, Washer & Nut Z10012 Z10012 Z10012 Z Flow Control Valve & End Cap Z Z Z Z Performance* Aquaforce Saleable Part number Volts (V) 230V 50Hz 230V 50Hz 230V 50Hz 230V 50Hz 230V 50Hz 230V 50Hz 230V 50Hz Power (w) Max Flow, QMax, (l/hr) Max Head, HMax, (m) IP Rating IPX8 IPX8 IPX8 IPX8 IPX8 IPX8 IPX8 Max submersion depth, (m) Max Water Temperature TMax, ( C) 35 C 35 C 35 C 35 C 35 C 35 C 35 C Amphibious use *Measured under controlled conditions

10

11

12 Hozelock Cyprio Midpoint Park, Birmingham B76 1AB. England. Tel: +44 (0) The Aquatics Division of Hozelock Group Do not dispose of electrical appliances as unsorted municipal waste, use separate collection facilities. Contact your local government for information regarding the collection systems available. If electrical appliances are disposed of in landfills or dumps, hazardous substances can leak into the groundwater and get into the food chain, damaging your health and well-being. In the EU, when replacing old appliances with new ones, the retailer is legally obligated to take back your old appliance for disposal at least free of charge.

air pump 2700/4500 ? 2YEAR GUARANTEE UK AIRPUMP _33435 CASC /10/ :16 Page 1

33719-000 UK AIRPUMP 2700-4500_33435 CASC.450 13/10/2011 09:16 Page 1 2823 1820 1380 air pump 2700/4500 Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com

33719-000 UK AIRPUMP 2700-4500_33435 CASC.450 13/10/2011 09:16 Page 1 2823 1820 1380 air pump 2700/4500 Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com

EASYCLEAR 3000 YEAR GUARANTEE

2823 3003 EASYCLEAR 3000? Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 33854-005 3 YEAR GUARANTEE 1 G D B C F A E I 2 J 3 K H 4A

2823 3003 EASYCLEAR 3000? Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 33854-005 3 YEAR GUARANTEE 1 G D B C F A E I 2 J 3 K H 4A

Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0)

7825 flood PUMP Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 33713-001? 1 AUTO ON AUTO OFF 400mm 190mm 2 3 25mm 32mm 4 5 50cm 50cm

7825 flood PUMP Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 33713-001? 1 AUTO ON AUTO OFF 400mm 190mm 2 3 25mm 32mm 4 5 50cm 50cm

Vorton 11/18/36/55 2YEAR. GUARANTEE. Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: +44 (0)

1554 1557 1558 1559 Vorton 11/18/36/55? Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: +44 (0) 121 313 1122 www.hozelock.com 33029-000 www.hozelock.com 2YEAR GUARANTEE 1 2 3 4 5 6 7 8 9

1554 1557 1558 1559 Vorton 11/18/36/55? Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: +44 (0) 121 313 1122 www.hozelock.com 33029-000 www.hozelock.com 2YEAR GUARANTEE 1 2 3 4 5 6 7 8 9

EasyClear 3000/ YEAR GUARANTEE. Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: +44 (0)

1760 1762 EasyClear 3000/4500 Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: +44 (0) 121 313 1122 www.hozelock.com 33902-000 www.hozelock.com? 3 YEAR GUARANTEE 1 G D B C F A E I 2 J 3 K

1760 1762 EasyClear 3000/4500 Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: +44 (0) 121 313 1122 www.hozelock.com 33902-000 www.hozelock.com? 3 YEAR GUARANTEE 1 G D B C F A E I 2 J 3 K

6000/7500/ YEAR GUARANTEE. Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: +44 (0)

EasyClear 6000/7500/9000 1764 1766 1768 Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: +44 (0) 121 313 1122 www.hozelock.com 33904-000 www.hozelock.com? 3 YEAR GUARANTEE 1 C B D J K E H

EasyClear 6000/7500/9000 1764 1766 1768 Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: +44 (0) 121 313 1122 www.hozelock.com 33904-000 www.hozelock.com? 3 YEAR GUARANTEE 1 C B D J K E H

Saturn Booster PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE USE AND KEEP THEM FOR FUTURE REFERENCE

1560 Saturn Booster PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE USE AND KEEP THEM FOR FUTURE REFERENCE The Hozelock Cyprio Saturn Booster is an innovative selfcleaning mechanical prefilter. GB Designed

1560 Saturn Booster PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE USE AND KEEP THEM FOR FUTURE REFERENCE The Hozelock Cyprio Saturn Booster is an innovative selfcleaning mechanical prefilter. GB Designed

SUBMERSIBLE DIRTY WATER PUMP

SUBMERSIBLE DIRTY WATER PUMP MODEL NO: DWP100A, DWP150A, DWP200A PART NO: 7230098, 7230099, 7230100 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS LS1117 - ISS 2 INTRODUCTION Thank you for

SUBMERSIBLE DIRTY WATER PUMP MODEL NO: DWP100A, DWP150A, DWP200A PART NO: 7230098, 7230099, 7230100 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS LS1117 - ISS 2 INTRODUCTION Thank you for

Nuts (x2) Vacuum Unit Tubes (x4) Support Handle Main Handle Hose Adaptor & Waste Hose Cable Clips (x4) Wide Nozzle Narrow Nozzle Open Nozzle

2823 1752 PondVac aution! Please keep these operating instructions in a safe place. Ensure that all operation and maintenance is carried out in line with these instructions. D B E G H B D E F G H I J Nuts

2823 1752 PondVac aution! Please keep these operating instructions in a safe place. Ensure that all operation and maintenance is carried out in line with these instructions. D B E G H B D E F G H I J Nuts

SUBMERSIBLE WATER PUMPS

OPERATING & MAINTENANCE INSTRUCTIONS SUBMERSIBLE WATER PUMPS Model Nos. HIPPO-3 and 3A 6/97 Thank you for purchasing this CLARKE, HIPPO Submersible Pump. These highly efficient pumps are designed for pumping

OPERATING & MAINTENANCE INSTRUCTIONS SUBMERSIBLE WATER PUMPS Model Nos. HIPPO-3 and 3A 6/97 Thank you for purchasing this CLARKE, HIPPO Submersible Pump. These highly efficient pumps are designed for pumping

submersible water pumps

instructions for submersible water pumps model no s: WPC100.V2 WPC100A.V2 WPC150.V2 WPC150A.V2 WPC235.V2 WPC235A.V2 WPC250 WPC250A Thank you for purchasing a Sealey product. Manufactured to a high standard,

instructions for submersible water pumps model no s: WPC100.V2 WPC100A.V2 WPC150.V2 WPC150A.V2 WPC235.V2 WPC235A.V2 WPC250 WPC250A Thank you for purchasing a Sealey product. Manufactured to a high standard,

OPERATION & MAINTENANCE INSTRUCTIONS

SUBMERSIBLE PUMPS MODEL NO: PSV3A, PSV4A, PSSV2A & PVP11A PART NO: 7236042, 7236044, 7236050 & 7236060 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS GC07/17 iss 4 INTRODUCTION Thank you for

SUBMERSIBLE PUMPS MODEL NO: PSV3A, PSV4A, PSSV2A & PVP11A PART NO: 7236042, 7236044, 7236050 & 7236060 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS GC07/17 iss 4 INTRODUCTION Thank you for

Pico Power Pressure Washer

7920 Pico Power Pressure Washer www.hozelock.com? Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: 01702 482 760 www.hozelock.com 33608-000 2 Year guarantee Contents A B D C E F G H I J K

7920 Pico Power Pressure Washer www.hozelock.com? Hozelock Ltd. Midpoint Park, Birmingham, B76 1AB. England Tel: 01702 482 760 www.hozelock.com 33608-000 2 Year guarantee Contents A B D C E F G H I J K

High Pressure Washer 130

High Pressure Washer 130 7901 WARNING: Do not use the appliance without reading this instruction sheet ORIGINAL INSTRUCTIONS Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121 313

High Pressure Washer 130 7901 WARNING: Do not use the appliance without reading this instruction sheet ORIGINAL INSTRUCTIONS Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121 313

Heavy Duty Pressure Washer 150

Heavy Duty Pressure Washer 150 7902 WARNING: Do not use the appliance without reading this instruction sheet Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com

Heavy Duty Pressure Washer 150 7902 WARNING: Do not use the appliance without reading this instruction sheet Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com

Compact Pressure Washer 100

Compact Pressure Washer 100 7900 WARNING: Do not use the appliance without reading this instruction sheet ORIGINAL INSTRUCTIONS Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121

Compact Pressure Washer 100 7900 WARNING: Do not use the appliance without reading this instruction sheet ORIGINAL INSTRUCTIONS Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121

UV Biological Pond Filter. Inlet /Outlet Size

EasyFilter PXPF04500 PXPF12000 UV Biological Pond Filter PXPF20000, PXPF30000 Model Power Rating Dimensions Diamtr x hght Inlet /Outlet Size Max Pond Vol. (Ltrs) Rec. Pump PXEF04500 7W 270 x 370 12/20/25mm

EasyFilter PXPF04500 PXPF12000 UV Biological Pond Filter PXPF20000, PXPF30000 Model Power Rating Dimensions Diamtr x hght Inlet /Outlet Size Max Pond Vol. (Ltrs) Rec. Pump PXEF04500 7W 270 x 370 12/20/25mm

CLEAN WATER PUMP. MODEL No: Hippo4A OPERATION & MAINTENANCE INSTRUCTIONS. Part No:

CLEAN WATER PUMP MODEL No: Hippo4A Part No: 7230535 OPERATION & MAINTENANCE INSTRUCTIONS 0807 INTRODUCTION Thank you for purchasing this CLARKE clean water pump. This highly efficient pump is designed

CLEAN WATER PUMP MODEL No: Hippo4A Part No: 7230535 OPERATION & MAINTENANCE INSTRUCTIONS 0807 INTRODUCTION Thank you for purchasing this CLARKE clean water pump. This highly efficient pump is designed

SUBMERSIBLE WATER PUMP. Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS

1117 SUBMERSIBLE WATER PUMP Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS GUARANTEE This product is guaranteed against faults in

1117 SUBMERSIBLE WATER PUMP Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS GUARANTEE This product is guaranteed against faults in

INFRARED IP55 HEATER INSTRUCTIONS FOR: MODEL:- QZWP45N 1. SAFETY INSTRUCTIONS

INSTRUCTIONS FOR: INFRARED IP55 HEATER MODEL:- QZWP45N Thank you for purchasing a Consort Claudgen product. Manufactured to a high standard this product will, if used according to these instructions and

INSTRUCTIONS FOR: INFRARED IP55 HEATER MODEL:- QZWP45N Thank you for purchasing a Consort Claudgen product. Manufactured to a high standard this product will, if used according to these instructions and

ALL IN ONE SERIES HOTLINE 1300 AQUATEC INSTRUCTION MANUAL MODEL 03AS310 03AS311. DATE JULY 2017 v2.0. AQP All in One 1000 Instructions.

INSTRUCTION MANUAL DATE JULY 2017 v2.0 HOTLINE 1300 AQUATEC MODEL 03AS310 03AS311 AQP All in One 1000 Instructions.indd 1 CONGRATULATIONS ON YOUR PURCHASE OF THIS PRODUCT BY AQUAPRO, THE ANSWERS FOR YOUR

INSTRUCTION MANUAL DATE JULY 2017 v2.0 HOTLINE 1300 AQUATEC MODEL 03AS310 03AS311 AQP All in One 1000 Instructions.indd 1 CONGRATULATIONS ON YOUR PURCHASE OF THIS PRODUCT BY AQUAPRO, THE ANSWERS FOR YOUR

1300W Pressure Washer RACHP133A

1300W Pressure Washer RACHP133A Waste electrical products should not be disposed of with household waste. Please recycle where facilities exist. Check with your local authority or retailer for recycling

1300W Pressure Washer RACHP133A Waste electrical products should not be disposed of with household waste. Please recycle where facilities exist. Check with your local authority or retailer for recycling

PJ130S High Pressure Cleaner

PJ130S High Pressure Cleaner Operator Manual Original instructions WARNING: Do not use the machine without reading the instruction sheet. Item Description OVERVIEW 1. High pressure washer 2. On/off switch

PJ130S High Pressure Cleaner Operator Manual Original instructions WARNING: Do not use the machine without reading the instruction sheet. Item Description OVERVIEW 1. High pressure washer 2. On/off switch

User Instructions for Remote Controlled 2kW Rotisserie Effect Fan Heater Model 1276

200662_2 Page 1 User Instructions for Remote Controlled 2kW Rotisserie Effect Fan Heater Model 1276 These instructions should be read carefully and retained for future reference. Important Notes These

200662_2 Page 1 User Instructions for Remote Controlled 2kW Rotisserie Effect Fan Heater Model 1276 These instructions should be read carefully and retained for future reference. Important Notes These

APW-VAP-150P High Pressure Cleaner Operator Manual

APW-VAP-150P High Pressure Cleaner Operator Manual BEFORE OPERATING THIS APPLIANCE PLEASE READ THESE INSTRUCTIONS CAREFULLY Item Description OVERVIEW 1. High pressure washer 2. On/off switch 3. Water outlet

APW-VAP-150P High Pressure Cleaner Operator Manual BEFORE OPERATING THIS APPLIANCE PLEASE READ THESE INSTRUCTIONS CAREFULLY Item Description OVERVIEW 1. High pressure washer 2. On/off switch 3. Water outlet

EFX 600. aquamanta. Instruction Manual. 4year guarantee. the experts in aquatic technology. >600 Litres

EFX 600 aquamanta TM the experts in aquatic technology >600 Litres Coldwater Tropical Marine 4year guarantee Instruction Manual Important Safeguards This appliance is not intended for use by persons (including

EFX 600 aquamanta TM the experts in aquatic technology >600 Litres Coldwater Tropical Marine 4year guarantee Instruction Manual Important Safeguards This appliance is not intended for use by persons (including

PUDDLE PUMP PUDDLE PUMP. MODEL No: PSP125 OPERATION & MAINTENANCE INSTRUCTIONS. Part No:

PUDDLE PUMP PUDDLE PUMP MODEL No: PSP125 Part No: 7230692 OPERATION & MAINTENANCE INSTRUCTIONS 1007 SPECIFICATIONS Model number... PSP125 Rated voltage... 230VAC 50Hz Input power... 293 Watts Maximum delivery

PUDDLE PUMP PUDDLE PUMP MODEL No: PSP125 Part No: 7230692 OPERATION & MAINTENANCE INSTRUCTIONS 1007 SPECIFICATIONS Model number... PSP125 Rated voltage... 230VAC 50Hz Input power... 293 Watts Maximum delivery

Pond Oxygenator. Single / Twin / Four.

Pond Oxygenator Single / Twin / Four www.blagdonwatergardening.co.uk www.interpetcentral.com Congratulations on buying a Blagdon Pond Oxygenator air pump. These air pumps have been specifically designed

Pond Oxygenator Single / Twin / Four www.blagdonwatergardening.co.uk www.interpetcentral.com Congratulations on buying a Blagdon Pond Oxygenator air pump. These air pumps have been specifically designed

WC2 & WC3 Installation & Maintenance Instructions

WC2 & WC3 Installation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information WC3 shown WC2 WC3 IMPORTANT

WC2 & WC3 Installation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information WC3 shown WC2 WC3 IMPORTANT

PERFORMANCE SHOWER PRODUCTS

INSTALLER PLEASE LEAVE INSTRUCTIONS WITH CUSTOMER PERFORMANCE SHOWER PRODUCTS INSTALLATION INSTRUCTIONS FOR REGENERATIVE MAINS SHOWER PUMP Model: PR35D Medium pressure twin PR50D Medium pressure twin PR50S

INSTALLER PLEASE LEAVE INSTRUCTIONS WITH CUSTOMER PERFORMANCE SHOWER PRODUCTS INSTALLATION INSTRUCTIONS FOR REGENERATIVE MAINS SHOWER PUMP Model: PR35D Medium pressure twin PR50D Medium pressure twin PR50S

PHOTECH AMPHIBIOUS PA35/PA320/PA520 THE POND MASTERS GUIDE TO. Blagdon - The Pond Masters The name you can rely on

Established over 40 years ago, Blagdon are committed to producing a comprehensive range of high quality, easy to use, pond equipment. An ongoing programme of research and development ensures excellent

Established over 40 years ago, Blagdon are committed to producing a comprehensive range of high quality, easy to use, pond equipment. An ongoing programme of research and development ensures excellent

HEAVY DUTY BRASS SHOWER PUMPS

HEAVY DUTY BRASS SHOWER PUMPS YOUR GUARANTEE IS AT RISK IF PUMP NOT INSTALLED CORRECTLY. SEE SECTION 2 IMPORTANT INSTRUCTIONS Performance Shower Products SERVICE HELPLINE TEL: 01883 730339 1. GENERAL Your

HEAVY DUTY BRASS SHOWER PUMPS YOUR GUARANTEE IS AT RISK IF PUMP NOT INSTALLED CORRECTLY. SEE SECTION 2 IMPORTANT INSTRUCTIONS Performance Shower Products SERVICE HELPLINE TEL: 01883 730339 1. GENERAL Your

BLOW DRY & GO HAIR KIT

BLOW DRY & GO HAIR KIT LSGS11P Instruction Manual My BLow DRy and go HAiR KiT is perfect with everything you need to style your hair the way you want - wherever you are. This kit includes accessories for

BLOW DRY & GO HAIR KIT LSGS11P Instruction Manual My BLow DRy and go HAiR KiT is perfect with everything you need to style your hair the way you want - wherever you are. This kit includes accessories for

Operating Instructions UniTech Perfect

Operating Instructions UniTech Perfect Technische Daten Rated Voltage Power Consumption Max. flow rate Max. head height Cable Protection Dimensions Weight Perfect 5000 49W 5100 l/h 1,85m Perfect 7000 78W

Operating Instructions UniTech Perfect Technische Daten Rated Voltage Power Consumption Max. flow rate Max. head height Cable Protection Dimensions Weight Perfect 5000 49W 5100 l/h 1,85m Perfect 7000 78W

T-SERIES. Wall & Panel Models. Installation, Set-up and Operating Instructions. 230V/1/50Hz

T-SERIES Wall & Panel Models Installation, Set-up and Operating Instructions Stock Ref. Nos. WIRED 456166A (9" WL) 456167A (9" PL) 456174A (12" WL) 456175A (12" PL) WIRELESS 456170A (9" WL) 456171A (9"

T-SERIES Wall & Panel Models Installation, Set-up and Operating Instructions Stock Ref. Nos. WIRED 456166A (9" WL) 456167A (9" PL) 456174A (12" WL) 456175A (12" PL) WIRELESS 456170A (9" WL) 456171A (9"

Tempest TP420/180 Electric Pressure Washer

Please dispose of packaging for the product in a responsible manner. It is suitable for recycling. Help to protect the environment, take the packaging to the local amenity tip and place into the appropriate

Please dispose of packaging for the product in a responsible manner. It is suitable for recycling. Help to protect the environment, take the packaging to the local amenity tip and place into the appropriate

Compact Cyclonic Bagless Upright Vacuum Cleaner

Compact Cyclonic Bagless Upright Vacuum Cleaner Model Number: RHUV20MR05 For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm & Saturday 9am 1pm Or visit

Compact Cyclonic Bagless Upright Vacuum Cleaner Model Number: RHUV20MR05 For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm & Saturday 9am 1pm Or visit

NON-SUBMERSIBLE WATER PUMP

NON-SUBMERSIBLE WATER PUMP MODEL NO: CEB103 PART NO: 7230327 OPERATION & MAINTENANCE INSTRUCTIONS LS0114 INTRODUCTION Thank you for purchasing this CLARKE Water Pump, which is a general purpose pump, suitable

NON-SUBMERSIBLE WATER PUMP MODEL NO: CEB103 PART NO: 7230327 OPERATION & MAINTENANCE INSTRUCTIONS LS0114 INTRODUCTION Thank you for purchasing this CLARKE Water Pump, which is a general purpose pump, suitable

User Guide. Please read carefully before use. Your Hoover Guarantee. Your Hoover Guarantee. Contents. IMPORTANT Safety Reminders

Your Hoover Guarantee Contents Your Hoover Guarantee During year 1 HOOVER engineers will replace or repair all defective parts free of charge, except for parts subject to fair wear and tear such as belts,

Your Hoover Guarantee Contents Your Hoover Guarantee During year 1 HOOVER engineers will replace or repair all defective parts free of charge, except for parts subject to fair wear and tear such as belts,

WARNING: Ensure that the UV is switched off at the mains before you attempt to conduct any type of maintenance on the EazyPod Complete.

EPC11904121MAN UK English INSTALLATION AND OPERATING MANUAL WARNING: Ensure that the UV is switched off at the mains before you attempt to conduct any type of maintenance on the EazyPod Complete. Evolution

EPC11904121MAN UK English INSTALLATION AND OPERATING MANUAL WARNING: Ensure that the UV is switched off at the mains before you attempt to conduct any type of maintenance on the EazyPod Complete. Evolution

1752 Pond Vac D A B A E G C H I J F

1752 Pond Vac B aution! Please keep these B operating in a safe place. nsure that all operation and maintenance is carried out in line with these. B Nuts (x2) Vacuum Unit Tubes (x4) Support andle Main

1752 Pond Vac B aution! Please keep these B operating in a safe place. nsure that all operation and maintenance is carried out in line with these. B Nuts (x2) Vacuum Unit Tubes (x4) Support andle Main

Specifications. Vacuum motor power consumption(w/hp) 1200 / 1.6. Exhaust water pump power consumption(w/hp 800 / 1.1

Specifications Rated voltage (V) AC 110-120V or 220-240V / 50-60Hz Vacuum motor power consumption(w/hp) 1200 / 1.6 Exhaust water pump power consumption(w/hp 800 / 1.1 Exhaust water pump flow (GPH/LPH)

Specifications Rated voltage (V) AC 110-120V or 220-240V / 50-60Hz Vacuum motor power consumption(w/hp) 1200 / 1.6 Exhaust water pump power consumption(w/hp 800 / 1.1 Exhaust water pump flow (GPH/LPH)

CPE RANGE PUMPS CPE RANGE PUMPS. MODEL Nos: CPE15A1 15A3 20A1 20A3 30A1 30A3 PART Nos:

CPE RANGE PUMPS CPE RANGE PUMPS MODEL Nos: CPE15A1 15A3 20A1 20A3 30A1 30A3 PART Nos: 7120305 7120310 7120315 7120320 7120325 7120330 OPERATION & MAINTENANCE INSTRUCTIONS GC0514 Contents Specifications...

CPE RANGE PUMPS CPE RANGE PUMPS MODEL Nos: CPE15A1 15A3 20A1 20A3 30A1 30A3 PART Nos: 7120305 7120310 7120315 7120320 7120325 7120330 OPERATION & MAINTENANCE INSTRUCTIONS GC0514 Contents Specifications...

INSTALLATION AND INSTRUCTION MANUAL IMPORTANT PLEASE READ:

EAZYPODAUTO1140318MAN UK English INSTALLATION AND INSTRUCTION MANUAL IMPORTANT PLEASE READ: When you first start up the EazyPod Automatic, the cleaning cycle will start first. You will need to wait up

EAZYPODAUTO1140318MAN UK English INSTALLATION AND INSTRUCTION MANUAL IMPORTANT PLEASE READ: When you first start up the EazyPod Automatic, the cleaning cycle will start first. You will need to wait up

INDUSTRIAL VACUUM CLEANER WITH AUTO START/STOP

INSTRUCTIONS FOR INDUSTRIAL VACUUM CLEANER WITH AUTO START/STOP MODEL NO: PC200SDAUTO.V3 Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according

INSTRUCTIONS FOR INDUSTRIAL VACUUM CLEANER WITH AUTO START/STOP MODEL NO: PC200SDAUTO.V3 Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according

2400W Pressure Washer RAC-HP125

2400W Pressure Washer RAC-HP125 Waste electrical products should not be disposed of with household waste. Please recycle where facilities exist. Check with your local authority or retailer for recycling

2400W Pressure Washer RAC-HP125 Waste electrical products should not be disposed of with household waste. Please recycle where facilities exist. Check with your local authority or retailer for recycling

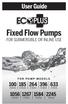

User Guide. Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE FOR PUMP MODELS # # # # # # # # #728333

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

Mobile Air Conditioner Instruction Manual Model TC-N9KM

Mobile Air Conditioner Instruction Manual Model TC-N9KM Please read and retain these instructions for future reference SPECIFICATION Model no. Cooling capacity Power/Ampere consumption for cooling* Air

Mobile Air Conditioner Instruction Manual Model TC-N9KM Please read and retain these instructions for future reference SPECIFICATION Model no. Cooling capacity Power/Ampere consumption for cooling* Air

WARNING: Warns of health hazards and identifies possible risks of injury. CAUTION: Indicates possible dangers to the machine or other objects.

VBT3ASV USER GUIDE SAFETY INFORMATION About this user guide Read this user guide completely before using the machine. Keep this user guide for reference. If you pass your machine on to third parties, it

VBT3ASV USER GUIDE SAFETY INFORMATION About this user guide Read this user guide completely before using the machine. Keep this user guide for reference. If you pass your machine on to third parties, it

A4 Laminator. Installation & User Instructions Please keep for future reference 908/6197

A4 Laminator Installation & User Instructions Please keep for future reference 908/6197 Important Please read these instructions fully before installing or using These instructions contain important information

A4 Laminator Installation & User Instructions Please keep for future reference 908/6197 Important Please read these instructions fully before installing or using These instructions contain important information

ELECTRIC ASHCAN MODEL NO: ASHVAC1200 OPERATING & MAINTENANCE INSTRUCTIONS PART NO: ORIGINAL INSTRUCTIONS

ELECTRIC ASHCAN MODEL NO: ASHVAC1200 PART NO: 6471133 OPERATING & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS GC1216 INTRODUCTION Thank you for purchasing this CLARKE product which is designed for fast,

ELECTRIC ASHCAN MODEL NO: ASHVAC1200 PART NO: 6471133 OPERATING & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS GC1216 INTRODUCTION Thank you for purchasing this CLARKE product which is designed for fast,

Contents. Warning: Installation... 2 Warning: Operation...2 Warning: Disposal...3

SV14.3000 OPERATING MANUAL Model SV14.3000 SAVE THESE INSTRUCTIONS Section 1 Warning: Installation... 2 Warning: Operation...2 Warning: Disposal...3 Section 2 Instructions for use...4 Changing the bag

SV14.3000 OPERATING MANUAL Model SV14.3000 SAVE THESE INSTRUCTIONS Section 1 Warning: Installation... 2 Warning: Operation...2 Warning: Disposal...3 Section 2 Instructions for use...4 Changing the bag

T-SERIES. Window & Roof Models. Installation, Set-up and Operating Instructions. 230V/1/50Hz

T-SERIES Window & Roof Models Installation, Set-up and Operating Instructions Stock Ref. Nos. WIRED 456165A (9" WW) 456168A (9" RF) 456173A (12" WW) 456176A (12" RF) WIRELESS 456169A (9" WW) 456172A (9"

T-SERIES Window & Roof Models Installation, Set-up and Operating Instructions Stock Ref. Nos. WIRED 456165A (9" WW) 456168A (9" RF) 456173A (12" WW) 456176A (12" RF) WIRELESS 456169A (9" WW) 456172A (9"

Compact Cyclonic Bagless Cylinder Vacuum Cleaner

Compact Cyclonic Bagless Cylinder Vacuum Cleaner Model Number: RHCV35BM01 220-240V AC 50/60Hz 700W For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm &

Compact Cyclonic Bagless Cylinder Vacuum Cleaner Model Number: RHCV35BM01 220-240V AC 50/60Hz 700W For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm &

LUCCI AIRFUSION BREEZE PEDESTAL FAN

LUCCI AIRFUSION BREEZE PEDESTAL FAN INSTALLATION OPERATION MAINTENANCE WARRANTY INFORMATION CAUTION READ INSTRUCTIONS CAREFULLY FOR SAFE INSTALLATION AND FAN OPERATION. V1.0- E N ( 0 8 / 2 0 1 8 ) THANK

LUCCI AIRFUSION BREEZE PEDESTAL FAN INSTALLATION OPERATION MAINTENANCE WARRANTY INFORMATION CAUTION READ INSTRUCTIONS CAREFULLY FOR SAFE INSTALLATION AND FAN OPERATION. V1.0- E N ( 0 8 / 2 0 1 8 ) THANK

Pond Pump 280 / 420 / 575. Operating instructions Notice d emploi Instrucciones de uso

Pond Pump 280 / 420 / 575 Operating instructions Notice d emploi Instrucciones de uso REMINDER CALL 1-866-627-3435 BEFORE RETURNING TO STORE. Part Description QTY A Pump 1 B 3/4 in. ID tubing adapter with

Pond Pump 280 / 420 / 575 Operating instructions Notice d emploi Instrucciones de uso REMINDER CALL 1-866-627-3435 BEFORE RETURNING TO STORE. Part Description QTY A Pump 1 B 3/4 in. ID tubing adapter with

INSTRUCTION MANUAL Model: SU3022

INSTRUCTION MANUAL Model: SU3022 GUARANTEE This product is guaranteed for 2 years from the date of original purchase. If any defect arises due to faulty materials or workmanship, the unit will, either

INSTRUCTION MANUAL Model: SU3022 GUARANTEE This product is guaranteed for 2 years from the date of original purchase. If any defect arises due to faulty materials or workmanship, the unit will, either

Compact Cyclonic Pro Bagless Cylinder Vacuum Cleaner

Compact Cyclonic Pro Bagless Cylinder Vacuum Cleaner Model Number: RHCV15SB05 220-240V AC 50/60Hz 1000W For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am

Compact Cyclonic Pro Bagless Cylinder Vacuum Cleaner Model Number: RHCV15SB05 220-240V AC 50/60Hz 1000W For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am

of the openings blocked with any object that may restrict the airflow.

Operating manual Please read carefully before assembling or using your DCO vacuum cleaner. Important safety instructions please read before use WHEN USING THE DYSON DCO VACUUM CLEANER PLEASE ADHERE TO

Operating manual Please read carefully before assembling or using your DCO vacuum cleaner. Important safety instructions please read before use WHEN USING THE DYSON DCO VACUUM CLEANER PLEASE ADHERE TO

CoCo LoCo BLOW & GO NUTS DRYER. LSHD24 Instruction Manual

CoCo LoCo BLOW & GO NUTS DRYER LSHD24 Instruction Manual This GORGeous PiNK and rose gold dryer is infused with coconut oil to give your hair a boost when it s driving you nuts. With a powerful 2400W motor

CoCo LoCo BLOW & GO NUTS DRYER LSHD24 Instruction Manual This GORGeous PiNK and rose gold dryer is infused with coconut oil to give your hair a boost when it s driving you nuts. With a powerful 2400W motor

Easy Guide Luna 1300 Luna 1400 PARTS CHECKLIST - LUNA 1300 AND LUNA ONLY. Telescopic extension tube. Carpet washer. Hose and hand grip

R Easy Guide Luna 1300 Luna 1400 PARTS CHECKLIST - LUNA 1300 AND LUNA 1400 1400 ONLY Telescopic extension tube Hose and hand grip Carpet washer Quick Clip tube (for washing) Hard floor washer Luna Washing

R Easy Guide Luna 1300 Luna 1400 PARTS CHECKLIST - LUNA 1300 AND LUNA 1400 1400 ONLY Telescopic extension tube Hose and hand grip Carpet washer Quick Clip tube (for washing) Hard floor washer Luna Washing

pond and garden LED feature light

Established over 50 years ago, Blagdon are committed to producing a comprehensive range of high quality, easy to use, pond equipment. An ongoing programme of research and development ensures excellent

Established over 50 years ago, Blagdon are committed to producing a comprehensive range of high quality, easy to use, pond equipment. An ongoing programme of research and development ensures excellent

Single Cyclonic Cylinder Vacuum Cleaner

Single Cyclonic Cylinder Vacuum Cleaner Model Number: RHCV3001 220-240V~, 50/60Hz, 800W For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm & Saturday 9am

Single Cyclonic Cylinder Vacuum Cleaner Model Number: RHCV3001 220-240V~, 50/60Hz, 800W For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm & Saturday 9am

Turbo Cyclonic Pro Bagless Cylinder Vacuum Cleaner

Turbo Cyclonic Pro Bagless Cylinder Vacuum Cleaner Model Number: RHCV20MR04 220-240V~, 50/60Hz, 900W For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm

Turbo Cyclonic Pro Bagless Cylinder Vacuum Cleaner Model Number: RHCV20MR04 220-240V~, 50/60Hz, 900W For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm

Installation, Operating and Servicing Instructions

Installation, Operating and Servicing Instructions Wall Mounted Water Boiler WMB3F/B,WMB3F/W Please make a note of your product details for future use: Date Purchased: Model Number: Serial Number: Dealer:

Installation, Operating and Servicing Instructions Wall Mounted Water Boiler WMB3F/B,WMB3F/W Please make a note of your product details for future use: Date Purchased: Model Number: Serial Number: Dealer:

User Instruction Manual

User Instruction Manual 4 & 6 Slot Toasters This covers the Burco 4 & 6 slot toasters TSSL14 & TSSL16 444440355 & 444440356 Red End Cap 4 slot 444440606 Red End Cap 6 slot 444440608 Cream End Cap 4 slot

User Instruction Manual 4 & 6 Slot Toasters This covers the Burco 4 & 6 slot toasters TSSL14 & TSSL16 444440355 & 444440356 Red End Cap 4 slot 444440606 Red End Cap 6 slot 444440608 Cream End Cap 4 slot

Installation Instructions & Operating Manual IMPORTANT

Installation Instructions & Operating Manual IMPORTANT These instructions should be read carefully and retained for future reference TABLE OF CONTENTS SECTION 1: WARNINGS & ELECTRIC SPECIFICATIONS 1.1

Installation Instructions & Operating Manual IMPORTANT These instructions should be read carefully and retained for future reference TABLE OF CONTENTS SECTION 1: WARNINGS & ELECTRIC SPECIFICATIONS 1.1

22.2V Turbo Lite Ultra Cordless Handheld Vacuum

22.2V Turbo Lite Ultra Cordless Handheld Vacuum Model Number: RHHS2202 For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm & Saturday 9am 1pm Or visit us

22.2V Turbo Lite Ultra Cordless Handheld Vacuum Model Number: RHHS2202 For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm & Saturday 9am 1pm Or visit us

Autofill wall mounted water. boiler. Getting the best from your water. boiler. Please read and keep these instructions

Autofill wall mounted water boiler Please read and keep these instructions For Burco wall mounted boilers 76700 (SKU 444448534), 76702 (SKU 444448546), & 76704 (SKU444448548) Getting the best from your

Autofill wall mounted water boiler Please read and keep these instructions For Burco wall mounted boilers 76700 (SKU 444448534), 76702 (SKU 444448546), & 76704 (SKU444448548) Getting the best from your

Flo~mate Mains Boost Pump Installation & Maintenance Instructions

~ Flo~mate Mains Boost Pump Installation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information FOR POSITIVE

~ Flo~mate Mains Boost Pump Installation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information FOR POSITIVE

EH W Pressure Washer

EH1684 1600W Pressure Washer 1 IMPORTANT Installer and Users please note: These instructions should be read carefully and left with the user of the product for future reference. BEFORE USE You must inspect

EH1684 1600W Pressure Washer 1 IMPORTANT Installer and Users please note: These instructions should be read carefully and left with the user of the product for future reference. BEFORE USE You must inspect

Get Cleaning... What s your Vax s model number? User Guide. Carpet Washer Vax Careline: AU: NZ:

User Guide Vax Careline: AU: 1300 361 505 NZ: 0800 800 900 Carpet Washer Get Cleaning... What s your Vax s model number? W8 W8 W0 W0 W0 W W W W W What s your serial number? (Located on the base of the

User Guide Vax Careline: AU: 1300 361 505 NZ: 0800 800 900 Carpet Washer Get Cleaning... What s your Vax s model number? W8 W8 W0 W0 W0 W W W W W What s your serial number? (Located on the base of the

Paper Shredder. Installation & User Instructions Please keep for future reference 913/0153

Paper Shredder Installation & User Instructions Please keep for future reference 913/0153 Important Please read these instructions fully before installing or using These instructions contain important

Paper Shredder Installation & User Instructions Please keep for future reference 913/0153 Important Please read these instructions fully before installing or using These instructions contain important

POWER WASHER MODEL NO: JET 9000 OPERATION & MAINTENANCE INSTRUCTIONS. WARNING: Do not use the machine without reading this manual PART NO:

WARNING: Do not use the machine without reading this manual POWER WASHER MODEL NO: JET 9000 PART NO: 7333502 OPERATION & MAINTENANCE INSTRUCTIONS GC0913 INTRODUCTION Thank you for purchasing this CLARKE

WARNING: Do not use the machine without reading this manual POWER WASHER MODEL NO: JET 9000 PART NO: 7333502 OPERATION & MAINTENANCE INSTRUCTIONS GC0913 INTRODUCTION Thank you for purchasing this CLARKE

AQUARIUM HEATER RANGE AH-25 / AH-50 AH-100 / AH-200 AH-300

AQUARIUM HEATER RANGE AH-25 / AH-50 AH-100 / AH-200 AH-300 To ensure your new aquarium heater is set up and running correctly, and to prevent any accidental damage or injury, please read and follow the

AQUARIUM HEATER RANGE AH-25 / AH-50 AH-100 / AH-200 AH-300 To ensure your new aquarium heater is set up and running correctly, and to prevent any accidental damage or injury, please read and follow the

Safety and Instruction Manual

T14002 Safety and Instruction Manual PLEASE READ CAREFULLY 30cm Ceramic Coated Electric Sauté Pan T14002 30cm Ceramic Coated Electric Sauté Pan TECHNICAL DATA Description: Model: Rated Voltage: Input power:

T14002 Safety and Instruction Manual PLEASE READ CAREFULLY 30cm Ceramic Coated Electric Sauté Pan T14002 30cm Ceramic Coated Electric Sauté Pan TECHNICAL DATA Description: Model: Rated Voltage: Input power:

Power Wash 2000W Car. User Guide. HPW2C-ZA hoover.za.com. Version 1.0

Power Wash 2000W Car User Guide HPW2C-ZA hoover.za.com Version 1.0 2 CONTENTS MACHINE OVERVIEW 3 Contents Machine Overview General Safety Information Operation Maintenance FAQs Warranty Other Information

Power Wash 2000W Car User Guide HPW2C-ZA hoover.za.com Version 1.0 2 CONTENTS MACHINE OVERVIEW 3 Contents Machine Overview General Safety Information Operation Maintenance FAQs Warranty Other Information

Refresh & Clean Carpet Washer

Refresh & Clean Carpet Washer Model Number: RHCC5001 220-240 V~, 50/60Hz, 500-600W For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm & Saturday 9am 1pm

Refresh & Clean Carpet Washer Model Number: RHCC5001 220-240 V~, 50/60Hz, 500-600W For Customer Services & Spare Parts please call 0345 209 7461 Opening times: Monday - Friday 8am 8pm & Saturday 9am 1pm

Installation & Operating Instructions

Installation & Operating Instructions Note: to prevent damage, do not attempt to operate this unit before reading the manual thoroughly THE ANSWER 410, 325 INT (UK) Manufactured by Evolution Aqua Ltd.

Installation & Operating Instructions Note: to prevent damage, do not attempt to operate this unit before reading the manual thoroughly THE ANSWER 410, 325 INT (UK) Manufactured by Evolution Aqua Ltd.

INSTALLATION & USER INSTRUCTIONS

INSTALLATION & USER INSTRUCTIONS LED ELECTRIC STOVE Christchurch, Dorset BH23 2BT Tel: 01202 588 638 Fax: 01202 499 639 www.ekofires.co.uk e-mail: sales@ekofires.co.uk MODELS COVERED BY THESE INSTRUCTIONS

INSTALLATION & USER INSTRUCTIONS LED ELECTRIC STOVE Christchurch, Dorset BH23 2BT Tel: 01202 588 638 Fax: 01202 499 639 www.ekofires.co.uk e-mail: sales@ekofires.co.uk MODELS COVERED BY THESE INSTRUCTIONS

air conditioner/dehumidifier 9000btu/hr

instructions for air conditioner/dehumidifier 9000btu/hr model no: SAC9001 Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

instructions for air conditioner/dehumidifier 9000btu/hr model no: SAC9001 Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

Lo-Carbon T-series Window & Roof Models

Lo-Carbon T-series Window & Roof Models Installation & User Instructions WIRED 456165A (9 WW) 456168A (9 RF) 456173A (12 WW) 456176A (12 RF) WIRELESS 456169A (9 WW) 456172A (9 RF) 456177A (12 WW) 456180A

Lo-Carbon T-series Window & Roof Models Installation & User Instructions WIRED 456165A (9 WW) 456168A (9 RF) 456173A (12 WW) 456176A (12 RF) WIRELESS 456169A (9 WW) 456172A (9 RF) 456177A (12 WW) 456180A

Australia. New Zealand

.... Australia New Zealand 2 5 3 4 JA JB JC JD JE JF JG JH JI JJ JK JL JM JN JO 5 Intended use Your Black & Decker vacuum cleaner has been designed to vacuum dry substances. This product is intended for

.... Australia New Zealand 2 5 3 4 JA JB JC JD JE JF JG JH JI JJ JK JL JM JN JO 5 Intended use Your Black & Decker vacuum cleaner has been designed to vacuum dry substances. This product is intended for

INSTRUCTIONS FOR SAFE USE INSTRUCTIONS FOR SAFE USE

USER MANUAL INSTRUCTIONS FOR SAFE USE This appliance should only be used for domestic cleaning, as described in this user guide. Please ensure that this guide is fully understood before operating the appliance.

USER MANUAL INSTRUCTIONS FOR SAFE USE This appliance should only be used for domestic cleaning, as described in this user guide. Please ensure that this guide is fully understood before operating the appliance.

Built-in Gas Hob CZ55554 CZ55571

Built-in Gas Hob CZ55554 CZ55571 INSTALLATION AND OPERATING INSTRUCTIONS The product may differ from the one illustrated but the installation and operation procedure remains the same The product may differ

Built-in Gas Hob CZ55554 CZ55571 INSTALLATION AND OPERATING INSTRUCTIONS The product may differ from the one illustrated but the installation and operation procedure remains the same The product may differ

Conception Wall Fire. Instruction Manual THE SCIENCE BEHIND CLEAN.

Conception Wall Fire Instruction Manual BEHIND CLEAN www.beldray.com Please read all of the instructions carefully and retain for future reference. Safety Instructions When using electrical appliances,

Conception Wall Fire Instruction Manual BEHIND CLEAN www.beldray.com Please read all of the instructions carefully and retain for future reference. Safety Instructions When using electrical appliances,

Model 1174 Electric Heater User instructions for LED effect 2kw Inset Heater

200688_6 Page 1 Model 1174 Electric Heater User instructions for LED effect 2kw Inset Heater These instructions should be read carefully and retained for future reference Important Notes This heater must

200688_6 Page 1 Model 1174 Electric Heater User instructions for LED effect 2kw Inset Heater These instructions should be read carefully and retained for future reference Important Notes This heater must

ELECTRIC ASH CAN Model: CVACASH500 Part No:

ELECTRIC ASH CAN Model: CVACASH500 Part No: 6471132 OPERATING & MAINTENANCE INSTRUCTIONS GC0614 INTRODUCTION Thank you for purchasing this electrically powered Ash Can which is designed for fast, easy

ELECTRIC ASH CAN Model: CVACASH500 Part No: 6471132 OPERATING & MAINTENANCE INSTRUCTIONS GC0614 INTRODUCTION Thank you for purchasing this electrically powered Ash Can which is designed for fast, easy

TTB582PMP Barcode: Ref. No.: 55753

Original Instructions_DFT_TTB582PMP(XKS-751PW)_V1_131114 TTB582PMP Barcode: 01045598 Ref. No.: 55753 Submersible Pump TTB582PMP This product can be used by children aged from 8 years and above and persons

Original Instructions_DFT_TTB582PMP(XKS-751PW)_V1_131114 TTB582PMP Barcode: 01045598 Ref. No.: 55753 Submersible Pump TTB582PMP This product can be used by children aged from 8 years and above and persons

2kW Wall Mounted Electric Fire Complete with flat glass front panel. Installation Instructions & Operating Manual

2kW Wall Mounted Electric Fire Complete with flat glass front panel Installation Instructions & Operating Manual GEORGIA Please read the instructions carefully before the installation or use of this electric

2kW Wall Mounted Electric Fire Complete with flat glass front panel Installation Instructions & Operating Manual GEORGIA Please read the instructions carefully before the installation or use of this electric

3000W Pressure Washer RAC - HP006

3000W Pressure Washer RAC - HP006 Pressure Washer - Assemble and peration Assembly WANING: Before assembly ensure the on/off switch is off and the unit is not connected to the electric supply. Connect

3000W Pressure Washer RAC - HP006 Pressure Washer - Assemble and peration Assembly WANING: Before assembly ensure the on/off switch is off and the unit is not connected to the electric supply. Connect

User instructions. VA20HD, VA55HD, VA55IND and VA75IND. Commercial wet/dry vacuum cleaners CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE

User instructions VA20HD, VA55HD, VA55IND and VA75IND Commercial wet/dry vacuum cleaners CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE 03-8112-0000 Iss.3 07/08 http://www.truvox.com/products/vacuums/valet_aqua

User instructions VA20HD, VA55HD, VA55IND and VA75IND Commercial wet/dry vacuum cleaners CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE 03-8112-0000 Iss.3 07/08 http://www.truvox.com/products/vacuums/valet_aqua

HOT WASHER MODEL NO: KING150

WARNING: Do not use the hot washer without reading this manual HOT WASHER MODEL NO: KING150 PART NO: 7320175 OPERATION & MAINTENANCE INSTRUCTIONS LS1215 INTRODUCTION Thank you for purchasing this CLARKE

WARNING: Do not use the hot washer without reading this manual HOT WASHER MODEL NO: KING150 PART NO: 7320175 OPERATION & MAINTENANCE INSTRUCTIONS LS1215 INTRODUCTION Thank you for purchasing this CLARKE

50L/D DEHUMIDIFIER. Model Number: IG9805 INSTRUCTIONS FOR USE

50L/D DEHUMIDIFIER Model Number: IG9805 INSTRUCTIONS FOR USE Thank you for purchasing this product. Please read these instructions carefully before use. SAFETY INSTRUCTIONS IMPORTANT: This appliance is

50L/D DEHUMIDIFIER Model Number: IG9805 INSTRUCTIONS FOR USE Thank you for purchasing this product. Please read these instructions carefully before use. SAFETY INSTRUCTIONS IMPORTANT: This appliance is

professional pressure washer

instructions for professional pressure washer model no: PW3500 Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions, and

instructions for professional pressure washer model no: PW3500 Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions, and

CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE

User instructions Model X46 Escalator and Travelator cleaner CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE 03-7845-0000 Iss.1 07/04 Fig 1 Fig 2 2 Contents Page 1 Product information... 4 1.1

User instructions Model X46 Escalator and Travelator cleaner CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE 03-7845-0000 Iss.1 07/04 Fig 1 Fig 2 2 Contents Page 1 Product information... 4 1.1

HIGH PERFORMANCE POOL & SPA PUMPS

HIGH PERFORMANCE POOL & SPA PUMPS INSTALLATION AND OPERATION MANUAL PREMIUM PR SERIES PR50F, PR75F, PR100F, PR125F, PR150F, PR200F Reltech Australia Pty Ltd 43-45 Kylta Rd West Heidelberg Vic 3081 Ph:

HIGH PERFORMANCE POOL & SPA PUMPS INSTALLATION AND OPERATION MANUAL PREMIUM PR SERIES PR50F, PR75F, PR100F, PR125F, PR150F, PR200F Reltech Australia Pty Ltd 43-45 Kylta Rd West Heidelberg Vic 3081 Ph:

WELCOME BLUE - NEUTRAL BROWN LIVE GREEN AND YELLOW - EARTH

Zephyr 16 DC FAN WELCOME Thank you and congratulation for choosing an EcoAir DC Fan to help you improve the air quality within your home. Inside you will find many helpful tips on how to use and maintain

Zephyr 16 DC FAN WELCOME Thank you and congratulation for choosing an EcoAir DC Fan to help you improve the air quality within your home. Inside you will find many helpful tips on how to use and maintain

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS Please leave this instruction booklet with the pump as it contains maintenance and safety information (Original Instructions) MODELS This operating manual covers

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS Please leave this instruction booklet with the pump as it contains maintenance and safety information (Original Instructions) MODELS This operating manual covers

FHA 1100 A1 Domestic Water Pump

FHA 1100 A1 Domestic Water Pump Translation of original operation manual 6 Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the device. / Translation

FHA 1100 A1 Domestic Water Pump Translation of original operation manual 6 Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the device. / Translation