Sump Pumps Instruction Manual & Safety Warnings

|

|

|

- Kristian Maxwell

- 5 years ago

- Views:

Transcription

1 Important Safety Instructions SAVE THESE INSTRUCTIONS. This manual contains important SAFETY WARNINGS and OPERATING INSTRUCTIONS. You will need to refer to it before attempting any installation or maintenance. ALWAYS keep these instructions with the unit so that they will be easily accessible. Failure to read and follow these warnings and instructions could result in property damage, serious injury, or death. Sump Pumps Instruction Manual & Safety Warnings Models S3033, S3050, S3100! WARNING Risk of electric shock. To reduce this risk, observe the following precautions. ALWAYS disconnect the pump and float switch controller from the power source before servicing or making adjustments. NEVER handle the pump or motor with wet hands or when standing on a wet or damp surface while the pump is plugged into the power source. MAKE SURE THERE IS A PROPERLY GROUNDED RECEPTACLE AVAILABLE. This pump is wired with a 3-prong grounded plug. To reduce the risk of electric shock, be certain that it is only connected to a properly grounded, 3-prong receptacle. If you have a 2-prong receptacle, have a licensed electrician replace it with a 3-prong receptacle according to local codes and ordinances. NEVER bypass grounding wires or remove the ground prong from the plug. DO NOT use an extension cord. The electrical outlet should be within the length of the pump s power cord, and at least 4 feet above the floor level to minimize potential hazards from flood conditions. DO protect the electrical cord from sharp objects, hot surfaces, oil, and chemicals. Avoid kinking the cord. MAKE SURE the supply circuit has a dedicated fuse or circuit breaker rated to handle the power requirements noted on the nameplate of the pump.! CAUTION To reduce the risk of hazards that can cause injury or property damage, observe the following precautions. DO NOT use the power cord or strain relief to carry the pump. Use the pump handle. DO NOT pull on the float switch cord. DO NOT expose the control unit to any type of moisture, water, rain or snow. DO NOT place the controller on the floor. The electrical outlet should be within the length of the pump s power cord and at least 4 ft above the floor. DO NOT operate this product if it has been damaged in any way. DO NOT use sump pumps in pits handling raw sewage, salt water, or hazardous liquids. This pump is for ground water only. DO NOT disassemble this product. When service is required, contact Glentronics technical support at Return the product to the manufacturer for any repairs at the following address: Glentronics, Inc., 645 Heathrow Drive, Lincolnshire, IL When installing or replacing a primary sump pump you should also install a battery backup sump pump system. Specifications 1/3 HP Model S3033 1/2 HP Model S HP Model S Pump diameter Volts 115V, 60Hz 115V, 60Hz 115V, 60Hz Amps Items Included: Pump Choice of controller, float Stainless steel hose clamp 2" x 1-1/2" reducer adapter (on 1/2 HP and 1 HP pumps only) You may also need: 1-1/2 rigid PVC pipe to connect to the existing plumbing A check valve or union PVC pipe cleaner and cement Note: The 1/2 HP and 1 HP pumps will accommodate a 2" discharge pipe. However, most homes have 1-1/2" pipes. Therefore we have included a 2" x 1-1/2" reducer adapter with this pump. You may replace your 1-1/2" discharge pipe with a 2" discharge pipe, and a 2" adapter to obtain the optimum gallons per hour. Dual Float Enhanced Deluxe Dual Float Switch Vertical Float Switch Tether Float Switch

2 NOTICES When a check valve is used, a 1/8 (3.2mm) air bleed hole must be drilled in the PVC pipe above the pump. Drill the hole at a 45º angle toward the bottom of the sump to avoid splashing water outside the sump pit. Make sure the hole is above the water line, and below the check valve. If a hole is not drilled above the pump, an air lock may prevent the pump from operating. The control unit must receive 115V AC +/- 5% and 60 Hz from the AC outlet. Primary pumps will not provide protection during a power outage. With the risk of property damage from high water levels, the addition of a Pro Series battery backup sump pump system is highly recommended. After the initial installation, be sure to check the operation by filling the sump with water and observing the pump operation through several full cycles. For continuous duty operation, the pump must be submerged at least 3/4 of the depth of the pump at all times. Do Not use the float switch and controller within this application. In instances where the discharge line is exposed to freezing temperatures, the pipe must be sloped downward so any remaining water will drain out. Failure to do so will prevent water from exiting the sump and damage the pump if the line freezes. Installation Instructions Prior to Installation 1. Visually inspect your pump. Products may be damaged during shipping. If the product has been damaged, contact your place of purchase or Glentronics, Inc. before installation. 2. Thoroughly read the instructions provided to learn specific details regarding installation and use. This manual should be retained for future reference.! WARNING This installation must be in accordance with the National Electric Code and all applicable local codes and ordinances. Installing the Pump 1. Use a pit that conforms to all local codes and is large enough to accommodate the pump and float switch. Larger sump pits are preferred, since they will extend the discharge cycle and reduce the number of times the pump turns on. 2. Clean the pit of all debris. The pump s strainer must be kept clear. 3. The pump should not be set directly onto a clay, earthen, or sand base. You should install bricks or blocks under the pump to provide a solid base. 4. The pump should be level. 5. Install discharge plumbing according to local, regional and state codes. Rigid PVC pipe is recommended. 6. An in-line check valve is recommended to prevent back-flow. This check valve is mandatory when sharing a discharge line with another pump (i.e. a back-up pump or a second primary pump). (a) When a check valve is used, a 1/8 (3.2mm) air bleed hole must be drilled in the PVC pipe above the pump. Drill the hole at a 45º angle toward the bottom of the sump to avoid splashing water outside the sump pit. Make sure the hole is above the water line, and below the check valve. If a hole is not drilled above the pump, an air lock may prevent the pump from operating. 7. Install a gate valve or ball valve if required by any codes. 8. The horizontal discharge pipe must be positioned in a downward slope so any remaining water will drain away. 9B Failure to do this will prevent water from exiting the pit and damage the pump if the line freezes. 9. If you are replacing an old sump pump: (a) Unplug the pump from the outlet. (b) Loosen the check valve or rubber union by unscrewing the bottom hose clamp. (If the existing system is installed without a check valve or rubber union, saw the pipe apart above the sump pit.) (c) Remove the old pump and unscrew the pipe and adapter. (d) If the adapter fits into the new pump, screw the pipe into the pump. If not, cut a piece of rigid PVC pipe and connect it to the 9C 9D new adapter by cleaning and cementing the two pieces together. (Follow the instructions on the PVC cleaner and cement.) (e) Lower the pump into the sump by the handle. (f) Connect the pipe on the pump to the existing discharge pipe with a rubber union or check valve and tighten the hose clamps securely. 10. A pit cover is recommended for all installations as a safety measure and to help prevent debris from falling into the pit. Be sure protect the cords from damage when installing a pit cover. Installing the Dual Float Switch The Pro Series Dual Float Switch is easy to install by using the enclosed metal hose clamp. 1. Hold the float switch to the discharge pipe so the cage is below the bracket. 2. Secure the float to the pipe with the enclosed hose clamp, but do not completely tighten the clamp at this time. 3. Position the float switch to a level where the bottom of the float cage is no lower than 5 above the bottom of the pump. To avoid debris pouring into the float, it should be positioned on the side of the discharge pipe opposite the drain tile. Note: It is important to mount the float below the drain tile that empties into the pit. Mounting it above the drain tile would allow water to fill the drain tile before the pump is activated to pump out the water. 4. Once the float switch is in the desired position, tighten the clamp. Installing the Vertical Float Switch The vertical float switch contains a single large float. Water will lift the float to the top of the lift rod which will raise the lift rod and activate the pump. As the pump evacuates the water from the pit the float will drop, lowering the lift rod and turning off the pump. Note: The vertical float switch must be moving freely at all times. Make sure the float switch does not come into contact with other pumps, wires, pipe or any other object that may be in the sump pit. The float switch must not come into contact with the sump pit floor or wall. If the float switch does not move freely the pump will not activate. 1. Fully open the metal hose clamp and insert it through the slots in the mounting bracket of the float switch. 2. Place the hose clamp over the discharge pipe so that the gripping tabs are against the pipe and select the desired activation level of the pump. 3. (a) When using the vertical float switch with either the Enhanced or Deluxe (Models VSC1.5 or VSC2), there are two rubber stoppers on the float switch rod. Do not remove or alter their position as it will disrupt the timing of the controller and how long the pump runs. (b) When using the vertical float switch without a controller (Model VS), the pumping range can be adjusted by moving the float stop up or down the lift rod. Note: It is important to mount the float so that the activation level is below the drain tile that empties into the pit. Mounting it above the drain tile would allow water to fill the drain tile before the pump is activated to pump out the water. 4. To avoid debris from pouring onto the float, it should be positioned on the side of the discharge pipe opposite the drain tile. 5. Once the float switch is in the desired position, securely tighten the hose clamp. Note: The cable from the switch must remain outside the hose clamp. Installing the Tether Float Switch The tether float contains a single float connected to a flexible tether. Water will raise the float to activate the pump. As the pump evacuates the water from the pit the float will fall and turn off the pump. Note: The tether float switch must be moving freely at all times. Make sure the float switch does not come into contact with other pumps, wires, pipe or any other object that may be in the sump pit. The float switch must not come into contact with the sump pit floor or wall. If the float switch does not move freely the pump will not activate. 1. Locate the desired activation point. Note: It is important to mount the float so that the activation level is below the drain tile that empties into the pit. Mounting it above the drain tile would allow water to fill the drain tile before the pump is activated to pump out the water. 2. Secure the float to the pipe with the enclosed hose clamp and bracket. Be sure the bracket is positioned as shown. Do not overtighten the hose clamp. Overtightening may cause damage to the mounting bracket. 3. To avoid debris from pouring onto the float, it should be positioned on the side of the discharge pipe opposite the drain tile. Note: DO NOT adjust the tether length to less than 4 as this can cause excessive stress on the cable or prevent the switch from operating. 2

3 Connecting the Pump and! WARNING Dual Float Plug the control box into a properly grounded, 3-prong receptacle, then insert the pump plug into the receptacle on the control box. For a neater installation, secure the power cord and the float switch cord to the discharge pipe with wire ties or hose clamps. Keep the cords separated from each other on opposite sides of the pipe. Make sure the outlet is single phase, 115V and 60HZ for all the pump installations. Enhanced 1. Mount the controller to the wall through the 2 holes on the cabinet using proper mounting hardware for the application. The controller should be mounted at least 4 from the floor and 1 from the outlet. 2. Check to ensure the float switch is connected to the controller. The float switch wire of the Enhanced includes a connector that can be separated from the controller when the wire needs to be threaded through small openings. When used with the Enhanced, the dual float switch has a safety locking pin. This pin will prevent the float switch from accidently being disconnected from the controller. Check to ensure the safety locking pin is inserted through the connector. 3. Plug the control box into a properly grounded, 3-prong receptacle. Then, plug the pump into the receptacle on the control box. Do not use an extension cord. 4. Using a flathead screwdriver, adjust the dial on the front of the controller to select the number of seconds that the pump will run after the float drops. The dial can be adjusted from 5-45 seconds. The manufacturer default is about 10 seconds. Deluxe 1. Mount the controller to the wall through the 2 holes on the cabinet using the proper mounting hardware for the application. The controller should be mounted at least 4 from the floor and within 2 of the outlet. 2. Check to ensure the float switch is connected to the controller. The float switch wire of the Deluxe includes a connector that can be separated from the controller when the wire needs to be threaded through small openings. When used with the Deluxe, the dual float switch has a safety locking pin. This pin will prevent the float switch from accidently being disconnected from the controller. Check to ensure the safety locking pin is inserted through the connector. 3. Open the plastic door on the top of the Deluxe and using a flat head screwdriver adjust the dial to select the number of seconds that the pump will run after the float drops. The timer can be adjusted from 5-45 seconds. The manufacturer default is about 10 seconds. Install a 9V alkaline battery and replace the plastic door. 4. Plug the control box into a properly grounded, 3-prong receptacle. Then, plug the pump into the receptacle on the control box. Do not use an extension cord. 5. Make sure the Power Failure Alarm slide switch is in the ON position. Connecting to a Security System (Deluxe Only) The Deluxe includes a terminal on the right side of the control box to connect to a security system or other alarm devices. There are (3) three positions for wire connections on this terminal: N.O. normally open, N.C. normally closed, and Common. 1. Check your security system to determine whether an open (no contact) or closed (making contact) connection is needed to activate the alarm. 2. The security system will provide (2) two connection terminals to extend wires to the control terminal. Strip two wires 1/4 each. Connect either wire to the common terminal. To secure the wire into the terminal, insert the exposed wire into the hole on the side of the terminal next to the screw marked common. Turn the screw a few turns to lock-in the wire. 3. If the security system requires a closing of a contact to activate the alarm, secure the other wire into the terminal hole labeled N.O. (normally open). If the security system requires an opening of a contact, secure the wire into the terminal hole labeled N.C. (normally closed). Connecting the Pump and Float Switch (Models VS and TS No ) 1. Plug the float switch cord into a properly grounded 3-prong receptacle. Then, plug the pump into the receptacle on the float switch cord. Do not use an extension cord. Completing the Installation (all models) 1. After the initial installation, be sure to check the pump operation by filling the sump with water and observing the pump through several full cycles. When using the Enhanced or Deluxe s, the pump should run for 10 seconds after the lower float drops. Note: When the pump activates, it should have a normal pumping sound. Any abnormal sound, vibration, or lack of output is the signal of a problem. Stop the pump and refer to the troubleshooting guide. The vertical and tether float switch must be moving freely at all times. Make sure the float switch does not come into contact with other pumps, wires, pipe or any other object that may be in the sump pit. The float switch must not come into contact with the sump pit floor or wall. If the float switch does not move freely the pump will not activate. 2. Replace the pit cover making sure not to pinch or crimp the pump wire with the cover. The pit cover either has a hole punch that will allow the cord to be passed through or one can be drilled in the cover. Product Operation Dual Float Switch The dual float switch contains two large floating rings enclosed within a protective cage. Water will lift the bottom float by a 1 4, which will activate the pump. If for any reason the lower float does not activate the pump, the water will rise and activate the second switch. As the pump evacuates the water from the pit the floats will drop. The pump will run for an additional 10 seconds to extend the cycle after the lower float drops. When using the Dual Float Switch with the Enhanced or Deluxe controller, the float switch wire will include a connector that can be separated from the controller when the wire needs to be threaded through small openings. The float switch connector has a safety locking pin. This pin will prevent the float switch from accidentally being disconnected from the controller. To remove the pin, push the pointed end of the pin into the float connector and pull it out from the other end. The float switch wire can now be disconnected. Make sure to reinstall the pin after the float switch is reconnected. Note: When mounting the float switch, position the bottom of the cage at the height you want the pump to activate. Vertical Float Switch with Enhanced or Deluxe s The vertical float switch contains a single large float. Water will lift the float by a 1 2, which will activate the pump. As the pump evacuates the water from the pit, the float will drop. The pump will run for an additional 10 seconds to evacuate the pit completely after the float drops. Note: There are two rubber stoppers on the float switch rod. Do not remove or alter their position as it will disrupt the timing of the controller and how long the pump runs. Note: When mounting the float switch, position the bottom of the float at the height you want the pump to activate. Tether Float Switch with Enhanced or Deluxe s The tether float contains a single float connected to a flexible tether. Water will raise the float to activate the pump. As the pump evacuates the water from the pit the float will fall and the pump will run for an additional ten seconds to empty the pit. Note: The tether float switch must be moving freely at all times. If the float switch does not move freely the pump will not activate. Dual Float The Dual Float will activate the pump when either float is lifted, and then shuts off automatically 10 seconds after the float drops. Plug the pump cord into the piggyback switch on the control unit. Enhanced The Enhanced features a dial to adjust the number of seconds that the pump will run after the float drops. The dial can be adjusted from 5-45 seconds. The manufacturer default is about 10 seconds. The LED on the front of controller will signal the unit is receiving power. The controller will also run the pump once a week for approximately four (4) seconds. This test will exercise the pump and help ensure the pump is working properly. Deluxe The Deluxe features a series of warnings (audible and visual) that pinpoint potential problems with the pump, switch and power conditions. The controller will sound an alarm when power has been interrupted, when the pump has run for more than 10 minutes continuously, or when the 9V battery is low. The 9V battery (sold separately) runs the controller during a power outage, allowing it to sound an alarm if the circuit breaker trips, the controller is not plugged in securely, or the home s power is interrupted. Note: The 9V battery will only power the controller, not the pump. The Deluxe On Light should be flashing Off is equipped with a USB data port. The purpose of this port is to allow Power Failure Alarm Slide switch to OFF during power failures to conserve battery energy and silence alarm AC power is out Make sure this controller is plugged into the wall outlet Check the circuit breaker The system is operating 9 volt battery low or slide switch is OFF Replace 9 volt alkaline battery or move switch to ON Pump or float problem The pump has run continuously for 10 minutes Refer to the instructions for possible causes High water alarm (optional feature) Water has reached the high water sensor Consider a communication with the Pro Series Connect Modules. The Pro Series 12 Amps maximum Connect Modules are Pro Series Model No. DFC2 separately sold accessories that will allow the user to stay connected Glentronics, Inc. and receive remote Sump Pump notifications of potential problems and needed maintenance while away from home. The System Deluxe has a dial (located in the battery compartment) to adjust the number of seconds that the pump will run after the float drops. The Deluxe will also run the pump once a week for approximately four (4) seconds. This test will exercise the pump and help ensure the pump is working properly. Operating the Pump in a Continuous Duty Application This pump is rated for continuous duty and may be used in applications requiring continuous pumping including fountains or ponds. For use in any continuous duty application the pump should be plugged directly into the wall outlet without the use of the controller. The outlet must be a single phase properly grounded 3-prong receptacle, 115V, 60HZ. For continuous duty operation, the pump must be submerged at least 3/4 of the depth of the pump at all times. Remote Connection N.C. N.O. Common Deluxe Float Battery Backup 3

4 Understanding the Warnings & Alarms - Deluxe s AC power is out There are several causes for power failure. The most common causes are a power outage by the electric company or a tripped circuit breaker. Although the deluxe controller can not run the pump, it will sound an alarm indicating the loss of power. This will allow the homeowner to address the problem. If this warning light and alarm are on, the control box is not receiving AC power for one of many reasons: 1. The control box is not plugged in 2. The power to the house is out 3. The circuit breaker to that outlet has been tripped 4. The ground fault interrupter on that outlet has been tripped 5. A power brownout is taking place Power Failure Alarm slide switch When the controller is not receiving AC power, the monitoring features and the audible alarms are powered by the 9-volt battery. This type of battery will power the controller for many hours, but not indefinitely. Once the source of the AC power alarm is determined, it is suggested that the Power Failure Alarm slide switch be turned to the OFF position until the power is restored. This will preserve the battery and silence the alarm. When AC power is restored, slide this switch back to the ON position. Note: If the AC power is restored and the slide switch is in the OFF position, the alarm and light for the 9-volt battery warning will activate, even if the battery is good. This is a reminder to reset the alarm. Slide the switch to the ON position. If the battery is good, the light will go out. If the alarm continues to sound, replace the battery. The system is operating This light should be ON and flashing at all times. It is included to indicate that the system is monitoring the sump conditions. This light will not illuminate when: 1. The power is out and the Power Failure Alarm slide switch is in the OFF position 2. The power is out and the 9V battery is discharged 3. The controller is not functioning. Contact the Glentronics service department The 9-volt battery low or slide switch is OFF 1. The 9-volt battery located in the top of the control box is coming to the end of its useful life. Replace it with a new 9-volt alkaline battery. 2. The Power Failure Alarm switch is in the OFF position. It must be in the ON position at all times, except when silencing an actual power failure condition. Pump or float problem This key feature monitors the time that the float switch is up continuously or in the activated position. It is unusual for a pump run for 10 or more minutes continuously. This can occur for many different reasons. Either the float is stuck in the up position, there is a mechanical problem with the pump, or there is a problem with the plumbing connections. Please refer to the Troubleshooting Guide on page 5. High water alarm (optional feature*) When water reaches the optional water sensor, it will activate the warning light, audible alarm, and remote terminal. The activation of the water sensor could indicate that there is a failure of the main pump or plumbing problem. Please refer to the Troubleshooting Guide on page 5. *This feature requires the additional purchase of the water sensor (Model PS-WS). Accessories for the Deluxe Connect Modules and High Water Alarm Connect Modules - WiFi Module Home Automation Module (Requires purchase of PS-WiFi or PS-HZM) The Deluxe is equipped with a USB data port. The purpose of this port is to allow communication with the Pro Series Connect Modules. The Pro Series Connect Modules are separately sold accessories that will allow the user to stay connected and receive remote notifications of potential problems and needed maintenance while away from home. High Water Alarm - Accessory for the Deluxe (Requires the additional purchase of Model PS-WS) Water Sensor The water sensor is designed to warn you of a potential flood. If you are installing it in the sump pit, it must to be installed between the basement floor and the primary float switch. If there is a failure with either the main pump or the plumbing system, the water level will rise past the primary float switch and activate the water sensor. When the water sensor is activated, it will trigger a warning light, an audible alarm, and the remote terminal on the controller. This water sensor is only designed to give you a warning of a potential problem; it will not activate the primary pump. Maintenance Check List Maintenance should be performed 1-2 times per year. 1. Remove all debris from the bottom of the pit and make sure the pump s strainer is clear of debris. 2. Remove all debris floating in the water. 3. Remove all debris from the float switch cage. 4. Fill the pit with water. Make sure pump turns on at the intended level. 5. While the pump is running, make sure pump is evacuating water at a good pace. 6. While the pump is running, make sure a stream of water is escaping from the air bleed hole. If not, clear the hole of any deposits or debris. Backup Installation When the power goes out, the Pro Series AC sump pump will not operate. For protection during a power outage, a Pro Series battery backup system should be installed. There are three systems with matching batteries that will provide protection. The illustration at right is an example of a typical battery backup installation. Visit our website for more information about the Pro Series AC sump pumps and battery backup sump pump products. 4

5 Troubleshooting (Always unplug the pump from the controller before performing any maintenance) The pump will not start or run Thermal protector tripping or not functioning Pump starts and stops too frequently Pump will not shut off Insufficient or no water volume Abnormal sound or vibration Pump is not plugged in Water is not high enough to activate the pump Open circuit Poor power source Low voltage Bad power cable Locked impeller Defective float switch Defective pump Locked impeller Incorrect power supply Overburdened due to heavy sand content in the water Pump running continuously with no water present Float switch or sensor is mounted too low Water flowing back from pipe Malfunctioning float switch Clogged or frozen discharge Blocked intake strainer One or both of the floats is obstructed and cannot drop down Defective float switch Check valve installed with no air bleed hole in pipe or pump Check valve is stuck or installed upside down Check valve on secondary pump will not close and water re-circulates within the system Worn impeller Partially blocked impeller Clogged or frozen discharge Broken or leaking pipe Low power voltage Check valve installed with no air bleed hole in pipe or pump Check valve is stuck or installed upside down Pump is air locked Check valve on secondary pump will not close and water re-circulates within the system Blocked intake screen Broken impeller *Consult a licensed electrician. If the above solutions do not solve the problem, contact Glentronics customer service Plug pump in properly (see instructions) Make sure float switch is positioned properly Check circuit breaker or fuse Check circuit line wires and cable* Check line wires and source voltage* Replace with new cable* Remove strainer and clear obstruction Replace float switch with new float switch Replace pump with new pump Remove strainer and clear obstruction Check power supply source and voltage Use water filter or replace with a higher wattage pump Check float switch Raise float switch or adjust timer (Enhanced or Deluxe ) Install or replace check valve Replace float switch with new float switch Clear blockage or thaw frozen line Clear debris from intake strainer Clear debris from inside the float cage (Loosen nut on top of float, then remove c-clip on bottom of float. Remove debris. Tighten nut on top of float, then replace c-clip on bottom of float.) When reassembling the float, the magnetic strip on the inside of the float should be facing down. Replace float switch with new float switch Drill a bleed hole in the discharge pipe, or clean debris from the existing hole in the pipe or pump Reverse or replace check valve. Make sure the check valve is installed with the flow arrow pointing up and out of the pit. Replace the check valve on the secondary pump Replace impeller & adjust spacing between impeller and cover Remove strainer and clear obstruction Clear blockage or thaw frozen line Repair piping Check power voltage, wires and cable condition Drill a bleed hole in the discharge pipe, or clean debris from the existing hole in the pipe or pump Reverse or replace the check valve. Be sure check valve is installed with flow arrow pointing up and out of the pit. Remove debris from the air bleed hole Replace the check valve on the secondary pump Clear debris from intake screen Replace impeller with new one 5

6 Limited Warranty By opening this package and using this GLENTRONICS, INC. product, you are agreeing to be bound by the terms of the GLENTRONICS, INC. limited warranty ( warranty ) as set out below. Do not use your product until you have read the terms of the warranty. If you do not agree to the terms of the warranty, do not use the product and return it within the return period stated on your purchase receipt from the retail store or authorized distributor where you purchased it for a refund. To the extent permitted by law, this warranty and the remedies set forth are exclusive and in lieu of all other warranties, remedies and conditions, whether oral, written, statutory, express or implied. GLENTRONICS, INC. disclaims all statutory and implied warranties, including without limitation, warranties of merchantability and fitness for a particular purpose and warranties against hidden or latent defects, to the extent permitted by law. GLENTRONICS, INC. will not be liable for any incidental, special or consequential damages for breach of any express or implied warranties on this product. In so far as such warranties cannot be disclaimed, GLENTRONICS, INC. limits the duration and remedies of such warranties to the duration of this express warranty and, AT GLENTRONICS, INC.'s option, the repair or replacement services described below. Some states (countries and provinces) do not allow limitations on how long an implied warranty (or condition) may last, so the limitation described above may not apply to you. Any and all causes of action arising from, filed as a result of or in reference to, this warranty or the products described under this warranty shall be governed by and construed under the laws of the State of Illinois. Any cause of action arising from, filed as a result of or in reference to, this warranty or the products described under this warranty shall be filed only in the Circuit Court of the 18th Judicial District, Lake County, Waukegan, Illinois, or in the Northern District of Illinois if filed in Federal Court. The maximum liability for any product described in this warranty shall be the cost of product replacement only. If any term is held to be illegal or unenforceable, the legality or enforceability of the remaining terms shall not be affected or impaired. What is Covered by this Warranty? GLENTRONICS, INC. warrants to the end purchaser that its pumps, switch and control unit products are free from defective materials and workmanship for the periods indicated below: All parts and labor (excluding installation) for a period of: 5 years from the date of installation, when purchased and installed by a contractor and used intermittently as a sump pump (S3 Series), otherwise 3 years 1 year from the date of installation when used in continuous duty operations such as fountains or ponds The defective product must be returned directly to the factory, postage prepaid with the original bill of sale or receipt to the address listed below. GLENTRONICS, INC., at its option, will either repair or replace the product and return it postage prepaid. What is NOT Covered by this Warranty? This warranty does not cover the cost or value of damaged property, including expressly any property that has been affected by water overflow, seepage or flooding. If GLENTRONICS, INC. determines that a product is deemed defective under this warranty agreement, it will repair or replace the PRODUCT ONLY. GLENTRONICS, INC. will not cover the cost to reinstall the product, nor will GLENTRONICS, INC. pay the cost of having a plumber or contractor repair or replace the product. GLENTRONICS, INC. will not repair or replace a product that was installed incorrectly. A product shall be considered installed incorrectly when it deviates in any way from the instructions described in this manual. This warranty does not cover product problems resulting from handling liquids hotter than 104 degrees Fahrenheit, handling inflammable liquids, solvents, strong chemicals or severe abrasive solutions; user abuse; misuse, neglect, improper maintenance, commercial or industrial use; improper connection or installation, damages caused by lightning strikes; excessive surges in AC line voltage; water damage to the controller; other acts of nature, or failure to operate in accordance with the enclosed written instructions. How to Obtain Warranty Service Within thirty (30) days of the product s defective performance, the unit must be shipped, freight prepaid, or delivered to GLENTRONICS, INC. to provide the services described hereunder in either its original carton and inserts, or a similar package affording an equal degree of protection. Products not received by GLENTRONICS, INC. at the address indicated below within thirty (30) days of the product s defective performance will not be considered for warranty service. Products received after the above mentioned timeframe fall outside of the timeframe for warranty service and will not be eligible for warranty service. The product must be returned to GLENTRONICS, INC. for inspection in order to be considered for warranty service. If the product is not returned to GLENTRONICS, INC. or the product is inspected by any person, plumber, contractor or business other than GLENTRONICS, INC., this warranty shall no longer be valid. Prior to defective operation, the unit must not have been previously altered, repaired or serviced by anyone other than GLENTRONICS, INC., or its agent; the serial number on the unit must not have been altered or removed; the unit must not have been subject to accident, misuse, abuse or operated contrary to the instructions contained in the accompanying manual. The dealer's dated bill of sale, or installer s invoice must be retained as evidence of the date of purchase and to establish warranty eligibility. Where are Products Sent for Warranty Service? Glentronics, Inc., 645 Heathrow Drive, Lincolnshire, IL How Can I Obtain More Information? By calling /18 Glentronics, Inc

2 INLET / HIGH HEAD DRAIN PUMP SYSTEMS MODELS , INSTALLATION INSTRUCTIONS PREINSTALLATION CHECKLIST

Your Peace of Mind is Our Top Priority Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies. MAIL TO: P.O. BOX 637 Louisville,

Your Peace of Mind is Our Top Priority Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies. MAIL TO: P.O. BOX 637 Louisville,

STOP. SAFETY INFORMATION Please read and understand this entire manual before attempting to assemble, operate or install the product.

STOP Power supply required Questions, problems, missing parts? Before returning to your retailer, call our customer service department at 1-800-742-5044, 7:30 a.m. - 5 p.m., EST, Monday - Friday. 115 volts

STOP Power supply required Questions, problems, missing parts? Before returning to your retailer, call our customer service department at 1-800-742-5044, 7:30 a.m. - 5 p.m., EST, Monday - Friday. 115 volts

SolidFlo G2 Solid Handling Pumps Product Manual

SolidFlo G2 Solid Handling Pumps Product Manual For Models: SolidFlo G2 1250 (Item #130030) SolidFlo G2 2000 (Item #130031) SolidFlo G2 2650 (Item #130032) SolidFlo G2 3600 (Item #130033) Table of Contents:

SolidFlo G2 Solid Handling Pumps Product Manual For Models: SolidFlo G2 1250 (Item #130030) SolidFlo G2 2000 (Item #130031) SolidFlo G2 2650 (Item #130032) SolidFlo G2 3600 (Item #130033) Table of Contents:

OPERATION MANUAL Dated: 04/09/2018 Document Name: SHV _OM Page 1 of 8. Ion Technologies SHV40, 75 & 100 Sewage Ejector Pump SAFETY WARNINGS

Ion Technologies SHV40, 75 & 100 Sewage Ejector Pump Page 1 of 8 biohazard risk exists. Installer(s) and/or service personnel must use proper Personal Protective Equipment and follow handling procedures

Ion Technologies SHV40, 75 & 100 Sewage Ejector Pump Page 1 of 8 biohazard risk exists. Installer(s) and/or service personnel must use proper Personal Protective Equipment and follow handling procedures

Lubi Submersible Condensate Removal Pumps

Please read and retain these instructions for future reference. Kindly read this manual carefully before making any effort to assemble, install, operate or maintain our pumps. Please protect yourself and

Please read and retain these instructions for future reference. Kindly read this manual carefully before making any effort to assemble, install, operate or maintain our pumps. Please protect yourself and

PUREPOWER SERIES CENTRAL VACUUM POWER UNITS PP500, PP600 & PP650

USER GUIDE PUREPOWER SERIES CENTRAL VACUUM POWER UNITS PP500, PP600 & PP650 AB0039 FOR RESIDENTIAL USE ONLY!! BROAN-NUTONE LLC; HARTFORD, WISCONSIN WWW.NUTONE.COM 1-888-336-3948 REGISTER YOUR PRODUCT ONLINE

USER GUIDE PUREPOWER SERIES CENTRAL VACUUM POWER UNITS PP500, PP600 & PP650 AB0039 FOR RESIDENTIAL USE ONLY!! BROAN-NUTONE LLC; HARTFORD, WISCONSIN WWW.NUTONE.COM 1-888-336-3948 REGISTER YOUR PRODUCT ONLINE

20 High Velocity Fan with 135 Tilt Head

20 High Velocity Fan with 135 Tilt Head Model No.: FF-50-A Operating Instructions V.140311 4002234 Thank you for choosing a Soleus Air High Velocity Fan. This owner s manual will provide you with valuable

20 High Velocity Fan with 135 Tilt Head Model No.: FF-50-A Operating Instructions V.140311 4002234 Thank you for choosing a Soleus Air High Velocity Fan. This owner s manual will provide you with valuable

MIGHTY PRO 1/4 HP CHILLER

1 MIGHTY PRO 1/4 HP CHILLER FOR TANKS UP TO 170 GALLONS TOP QUALITY & HIGHLY EFFICIENT INTEGRATED DUAL STAGE THERMOSTAT 2 ASSEMBLY PARTS FRONT TOP VIEW BACK 3 SET UP INSTRUCTIONS 1. Remove chiller and

1 MIGHTY PRO 1/4 HP CHILLER FOR TANKS UP TO 170 GALLONS TOP QUALITY & HIGHLY EFFICIENT INTEGRATED DUAL STAGE THERMOSTAT 2 ASSEMBLY PARTS FRONT TOP VIEW BACK 3 SET UP INSTRUCTIONS 1. Remove chiller and

16 Stand Fan with Remote Control Model No: FS3-40R-30

16 Stand Fan with Remote Control Model No: FS3-40R-30 FEATURES Remote Control 3 Speed Settings 4 Hour Auto-off Timer Oscillation LED Display Panel Adjustable Height Adjustable Tilt Head Whisper Quiet Operation

16 Stand Fan with Remote Control Model No: FS3-40R-30 FEATURES Remote Control 3 Speed Settings 4 Hour Auto-off Timer Oscillation LED Display Panel Adjustable Height Adjustable Tilt Head Whisper Quiet Operation

Air Pump Up to 800 gallons

Air Pump Up to 800 gallons REMINDER CALL 1-888-755-6750 BEFORE RETURNING TO STORE. PACKAGE CONTENTS ITEM #PBPAPK40W Questions, problems, missing parts? Before returning to your retailer, call our customer

Air Pump Up to 800 gallons REMINDER CALL 1-888-755-6750 BEFORE RETURNING TO STORE. PACKAGE CONTENTS ITEM #PBPAPK40W Questions, problems, missing parts? Before returning to your retailer, call our customer

18 INCHES, OSCILLATING STAND FAN

To Buy: Contact Sylvane at 800-934-9194 or visit www.sylvane.com For Product Support: Contact Soleus Air at (888) 876-5387 18 INCHES, OSCILLATING STAND FAN OWNER S MANUAL Model # FSM-45 PLEASE READ AND

To Buy: Contact Sylvane at 800-934-9194 or visit www.sylvane.com For Product Support: Contact Soleus Air at (888) 876-5387 18 INCHES, OSCILLATING STAND FAN OWNER S MANUAL Model # FSM-45 PLEASE READ AND

Ion Genesis II Pump Controller Digital Level Control with Pump Alternation and High Water Alarm

Page 1 of 8 General Overview Thank you for purchasing an Ion Genesis controller. Take the time to read the instructions carefully before using this appliance. We strongly recommend that you keep this instruction

Page 1 of 8 General Overview Thank you for purchasing an Ion Genesis controller. Take the time to read the instructions carefully before using this appliance. We strongly recommend that you keep this instruction

ion Genesis Pump Controller

High Water Alarm Document No.: IONG_OM Page 1 of 7 Table of Contents Safety Precautions.......................... 1 General Overview.......................... 1 Installation.................................2

High Water Alarm Document No.: IONG_OM Page 1 of 7 Table of Contents Safety Precautions.......................... 1 General Overview.......................... 1 Installation.................................2

SPA BLOWER OWNER'S MANUAL XXXX, XXXX, XXXX, XXXX, XXXX, XXXX fax

SPA BLOWER OWNER'S MANUAL 80015-XXXX, 80016-XXXX, 80017-XXXX, 80018-XXXX, 80019-XXXX, 80020-XXXX fax 888.610.3839 2015 323300-015 6/15 THIS PAGE INTENTIONALLY LEFT BLANK. 2 Operating Instructions and Parts

SPA BLOWER OWNER'S MANUAL 80015-XXXX, 80016-XXXX, 80017-XXXX, 80018-XXXX, 80019-XXXX, 80020-XXXX fax 888.610.3839 2015 323300-015 6/15 THIS PAGE INTENTIONALLY LEFT BLANK. 2 Operating Instructions and Parts

WA A Aqua Sub Bottom-load Water Cooler

WA1-02-21A Aqua Sub Bottom-load Water Cooler 4002638 Thank you for choosing a Soleus Air Water Cooler. This owner s manual will provide you with valuable information necessary for the proper care and maintenance

WA1-02-21A Aqua Sub Bottom-load Water Cooler 4002638 Thank you for choosing a Soleus Air Water Cooler. This owner s manual will provide you with valuable information necessary for the proper care and maintenance

52 STRATHMERE CEILING FAN

52 STRATHMERE CEILING FAN Owner s Manual Models #20341 If a problem cannot be remedied or you are experiencing difficulty with installation, please contact the Service Department: 1-877-459-3267, 9 a.m.-

52 STRATHMERE CEILING FAN Owner s Manual Models #20341 If a problem cannot be remedied or you are experiencing difficulty with installation, please contact the Service Department: 1-877-459-3267, 9 a.m.-

Xaact Spot. Xaact Hot Spot

Xaact Spot & Xaact Hot Spot INFORMATION & OPERATING INSTRUCTIONS READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE OPERATING THE MACHINE 78-00012 Rev. 101211 1 CONTENTS: Machine Specifications............

Xaact Spot & Xaact Hot Spot INFORMATION & OPERATING INSTRUCTIONS READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE OPERATING THE MACHINE 78-00012 Rev. 101211 1 CONTENTS: Machine Specifications............

QUICK PRIME INSTALLATION AND SERVICE MANUAL

QUICK PRIME INSTALLATION AND SERVICE MANUAL NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part #

QUICK PRIME INSTALLATION AND SERVICE MANUAL NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part #

1 HP Air Mover. Owner s Manual

1 HP Air Mover Owner s Manual WARNING: Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety precautions may

1 HP Air Mover Owner s Manual WARNING: Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety precautions may

WHEATGRASS JUICER C O M M E R C I A L. INSTRUCTION MANUAL Model No

COMMERCIAL PRODUCTS ATTENTION If any components of this unit are broken, do not operate properly, or for product returns, please contact Pragotrade at 1-800-814-4895 Outside the U.S. call 440-638-3131.

COMMERCIAL PRODUCTS ATTENTION If any components of this unit are broken, do not operate properly, or for product returns, please contact Pragotrade at 1-800-814-4895 Outside the U.S. call 440-638-3131.

OWNER S MANUAL. Models SCU-H11, SCU-H9, SCU-H7, SCU-H5, SCU-H3

Warranty Information Maintenance Troubleshooting Operating Instructions Installation OWNER S MANUAL Models SCU-H11, SCU-H9, SCU-H7, SCU-H5, SCU-H3 DOMESTIC USE ONLY Please read this document carefully

Warranty Information Maintenance Troubleshooting Operating Instructions Installation OWNER S MANUAL Models SCU-H11, SCU-H9, SCU-H7, SCU-H5, SCU-H3 DOMESTIC USE ONLY Please read this document carefully

ELECTRIC FIREPLACE OWNER S MANUAL

ELECTRIC FIREPLACE OWNER S MANUAL MODELS EL1346C 4001358 WARNING: If the information in this manual is not followed exactly, a fire or electrical shock may result causing property damage, personal injury

ELECTRIC FIREPLACE OWNER S MANUAL MODELS EL1346C 4001358 WARNING: If the information in this manual is not followed exactly, a fire or electrical shock may result causing property damage, personal injury

Instruction Manual. Dogeroo, Super Dogeroo, and Mini Dogeroo

Instruction Manual Dogeroo, Super Dogeroo, and Mini Dogeroo Model No. 8102, 8103, 8108 10700 Medallion Drive, Cincinnati, Ohio 45241-4807 USA Part No. 87793 SAFETY PRECAUTIONS Page 2 INSTALLATION INSTRUCTIONS

Instruction Manual Dogeroo, Super Dogeroo, and Mini Dogeroo Model No. 8102, 8103, 8108 10700 Medallion Drive, Cincinnati, Ohio 45241-4807 USA Part No. 87793 SAFETY PRECAUTIONS Page 2 INSTALLATION INSTRUCTIONS

NOTICE TO INSTALLER: Instructions must remain with installation. FW Supersedes HomeGuard OPTIMA

NOTICE TO INSTALLER: Instructions must remain with installation. FW1379 1018 Supersedes 0615 Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies

NOTICE TO INSTALLER: Instructions must remain with installation. FW1379 1018 Supersedes 0615 Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies

IMPORTANT SAFEGUARDS

IMPORTANT SAFEGUARDS Definitions Whenever used, the following symbol and terms identify safety and property damage messages and designate a level of hazard seriousness. - This is the safety alert symbol.

IMPORTANT SAFEGUARDS Definitions Whenever used, the following symbol and terms identify safety and property damage messages and designate a level of hazard seriousness. - This is the safety alert symbol.

Condensate Pump. Installation and Safety Instructions CP-16 CP

Condensate Pump Installation and Safety Instructions CP-16 CP-16-230 CP-16 CP-16-230 Rated Voltage 120 Volts / 60 Hz 220 Volts / 60 Hz (208-230) Rated Current Draw 1.9 Amps 1.0 Amps Input Type USA 3-prong

Condensate Pump Installation and Safety Instructions CP-16 CP-16-230 CP-16 CP-16-230 Rated Voltage 120 Volts / 60 Hz 220 Volts / 60 Hz (208-230) Rated Current Draw 1.9 Amps 1.0 Amps Input Type USA 3-prong

48 TAYLOR CEILING FAN

48 TAYLOR CEILING FAN Owner s Manual Models #20554 If a problem cannot be remedied or you are experiencing difficulty in installation, please contact the Service Department: 1-877-459-3267, 9 a.m.- 5 p.m.

48 TAYLOR CEILING FAN Owner s Manual Models #20554 If a problem cannot be remedied or you are experiencing difficulty in installation, please contact the Service Department: 1-877-459-3267, 9 a.m.- 5 p.m.

10 Table/Wall Mount Fan Model No: FTY-25 Operating Instructions FTY Soleus Air International

10 Table/Wall Mount Fan Model No: FTY-25 Operating Instructions 3077997 FTY-25 2010 Soleus Air International Thank you for choosing a Soleus Air Table Fan. This owner s manual will provide you with valuable

10 Table/Wall Mount Fan Model No: FTY-25 Operating Instructions 3077997 FTY-25 2010 Soleus Air International Thank you for choosing a Soleus Air Table Fan. This owner s manual will provide you with valuable

STOP. For missing, damaged parts or technical help, Call before returning product

STAR SW0614 1213 Supersedes 0212 POWERFLUSH OPTIMA Quality Products Since 1866! MODEL #S1201/S1202/S1203 Product information presented here reflects conditions at time of publication. Consult factory regarding

STAR SW0614 1213 Supersedes 0212 POWERFLUSH OPTIMA Quality Products Since 1866! MODEL #S1201/S1202/S1203 Product information presented here reflects conditions at time of publication. Consult factory regarding

PORTABLE DEHUMIDIFIER

PORTABLE DEHUMIDIFIER User s Manual For information or assistance, please contact: Soleus International 9451 Telstar Ave. El Monte, CA 91731 Tel: 1-888-876-5387 www.soleusair.com POWERED BY: KEEP THESE

PORTABLE DEHUMIDIFIER User s Manual For information or assistance, please contact: Soleus International 9451 Telstar Ave. El Monte, CA 91731 Tel: 1-888-876-5387 www.soleusair.com POWERED BY: KEEP THESE

ELECTRIC FIREPLACE HEATER WITH SINGLE GLASS DOOR

ELECTRIC FIREPLACE HEATER WITH SINGLE GLASS DOOR Model 91797 ASSEMBLY and Operating Instructions Visit our website at: http://www.harborfreight.com Read this material before using this product. Failure

ELECTRIC FIREPLACE HEATER WITH SINGLE GLASS DOOR Model 91797 ASSEMBLY and Operating Instructions Visit our website at: http://www.harborfreight.com Read this material before using this product. Failure

AUTO SPEED BLENDER INSTRUCTION MANUAL MODEL: BLCLMB1

AUTO SPEED BLENDER INSTRUCTION MANUAL MODEL: BLCLMB1 1 TABLE OF CONTENTS IMPORTANT SAFEGUARDS 3 POLARIZED PLUG 4 PRODUCT DIAGRAM 5 USAGE INSTRUCTIONS PREPARING YOUR AUTO SPEED BLENDER FOR USE 6 HOW TO

AUTO SPEED BLENDER INSTRUCTION MANUAL MODEL: BLCLMB1 1 TABLE OF CONTENTS IMPORTANT SAFEGUARDS 3 POLARIZED PLUG 4 PRODUCT DIAGRAM 5 USAGE INSTRUCTIONS PREPARING YOUR AUTO SPEED BLENDER FOR USE 6 HOW TO

52 BARSTOW CEILING FAN

52 BARSTOW CEILING FAN Owner s Manual Models #20519 If a problem cannot be remedied or you are experiencing difficulty with installation, please contact the Service Department: 1-877-459-3267, 9 a.m.-

52 BARSTOW CEILING FAN Owner s Manual Models #20519 If a problem cannot be remedied or you are experiencing difficulty with installation, please contact the Service Department: 1-877-459-3267, 9 a.m.-

Use and Care Manual. Flammable Material Storage Refrigerator LRBFS06W1HC

Use and Care Manual Flammable Material Storage Refrigerator LRBFS06W1HC 7085 471-00 Table of Contents Table of Contents Page Please Read and Follow these Instructions... 2 California Proposition 65...

Use and Care Manual Flammable Material Storage Refrigerator LRBFS06W1HC 7085 471-00 Table of Contents Table of Contents Page Please Read and Follow these Instructions... 2 California Proposition 65...

52 BAYTOWNE CEILING FAN

52 BAYTOWNE CEILING FAN Owner s Manual Models #20501 If a problem cannot be remedied or you are experiencing difficulty in installation, please contact the Service Department: 1-877-459-3267, 9 a.m.- 5

52 BAYTOWNE CEILING FAN Owner s Manual Models #20501 If a problem cannot be remedied or you are experiencing difficulty in installation, please contact the Service Department: 1-877-459-3267, 9 a.m.- 5

Installation Instructions / Warranty. Starck 10111XX XX XX1

Installation Instructions / Warranty Starck 10111XX1 10120XX1 10211XX1 90502203 1/2005 Starck single control lavatory faucet 10111XX1 Starck tall single control lavatory faucet 10120XX1 Starck single control

Installation Instructions / Warranty Starck 10111XX1 10120XX1 10211XX1 90502203 1/2005 Starck single control lavatory faucet 10111XX1 Starck tall single control lavatory faucet 10120XX1 Starck single control

(The chances are you re never going to read me) Owner s Manual HEAVY DUTY SHD-1T.

(The chances are you re never going to read me) Owner s Manual HEAVY DUTY SHD-1T www.simplicityvac.com Index Important Safety Instructions............................................................ 2

(The chances are you re never going to read me) Owner s Manual HEAVY DUTY SHD-1T www.simplicityvac.com Index Important Safety Instructions............................................................ 2

Prime chiller. Inline Chiller. Instructions for Models #2645,2646

Prime chiller Inline Chiller Instructions for Models #2645,2646 Warning and Safety Instructions... Page 2 Chiller Installation... Page 3 Temperature Controller Programming... Page 5 Warranty... Page 7

Prime chiller Inline Chiller Instructions for Models #2645,2646 Warning and Safety Instructions... Page 2 Chiller Installation... Page 3 Temperature Controller Programming... Page 5 Warranty... Page 7

36 IN. ELECTIC FIREPLACE FMI MODEL # LEF36 Mounting Base Feet and Wall Mounting Bracket Included

F3610G FMI PRODUCTS, LLC 36 IN. ELECTIC FIREPLACE FMI MODEL # LEF36 Mounting Base Feet and Wall Mounting Bracket Included FMI Products, LLC TABLE OF CONTENTS Safety Information... 3 Operating Instructions...

F3610G FMI PRODUCTS, LLC 36 IN. ELECTIC FIREPLACE FMI MODEL # LEF36 Mounting Base Feet and Wall Mounting Bracket Included FMI Products, LLC TABLE OF CONTENTS Safety Information... 3 Operating Instructions...

IMpORTANT SAFETy INSTRUcTIONS

Table of contents SAFETy SETUp OpERATION MAINTENANcE Safety... 2 Specifications... 4 Setup... 4 Operation... 6 WARNING SyMBOLS AND DEFINITIONS Maintenance... 9 Parts List and Diagram... 10 Warranty...

Table of contents SAFETy SETUp OpERATION MAINTENANcE Safety... 2 Specifications... 4 Setup... 4 Operation... 6 WARNING SyMBOLS AND DEFINITIONS Maintenance... 9 Parts List and Diagram... 10 Warranty...

DISHWASHER. Models DW2432 and DW2432SS. Installation Manual. Write Serial Number (on inner door of unit) here:

DISHWASHER Models DW2432 and DW2432SS Installation Manual Write Serial Number (on inner door of unit) here: Felix Storch, Inc. Summit Appliance Division 770 Garrison Avenue Bronx, New York 10474 www.summitappliance.com

DISHWASHER Models DW2432 and DW2432SS Installation Manual Write Serial Number (on inner door of unit) here: Felix Storch, Inc. Summit Appliance Division 770 Garrison Avenue Bronx, New York 10474 www.summitappliance.com

Drink Mixer Operation Manual

Drink Mixer Operation Manual Page 3 READ BEFORE USE. 840177410 10/14 Mixer Safety IMPORTANT SAFETY INSTRUCTIONS Your safety and the safety of oth ers is very important. We have provided many important

Drink Mixer Operation Manual Page 3 READ BEFORE USE. 840177410 10/14 Mixer Safety IMPORTANT SAFETY INSTRUCTIONS Your safety and the safety of oth ers is very important. We have provided many important

nova extreme retrofit High Output T5 Lighting Kit

nova extreme retrofit High Output T5 Lighting Kit Instructions for Model Nova Extreme Retrofit Model#1130-1135 Important Safety Instructions... Page 2 Installation Instructions... Page 4 Warranty... Page

nova extreme retrofit High Output T5 Lighting Kit Instructions for Model Nova Extreme Retrofit Model#1130-1135 Important Safety Instructions... Page 2 Installation Instructions... Page 4 Warranty... Page

Three Phase Simplex. Installation (937) Installation Instructions and Operation/Troubleshooting Manual. Installation of Floats.

Three Phase Simplex Installation Instructions and Operation/Troubleshooting Manual This control panel must be installed and serviced by a licensed electrician in accordance with the National Electric Code

Three Phase Simplex Installation Instructions and Operation/Troubleshooting Manual This control panel must be installed and serviced by a licensed electrician in accordance with the National Electric Code

Installation Guide. For Models: E-PD52ABZ5C4 E-PD52BP5C4 E-PD52WW5C4 READ THESE INSTRUCTIONS AND SAVE THEM FOR FUTURE USE

READ THESE INSTRUCTIONS AND SAVE THEM FOR FUTURE USE Federal regulations require all ceiling fans with light kits manufactured or imported after January 1, 2009, to limit total wattage consumed by the

READ THESE INSTRUCTIONS AND SAVE THEM FOR FUTURE USE Federal regulations require all ceiling fans with light kits manufactured or imported after January 1, 2009, to limit total wattage consumed by the

ELSTON 52 CEILING FAN

ELSTON 52 CEILING FAN MODEL #10290 Español p. 21 Questions, problems, missing parts? Before returning to your retailer, call our customer service department at 1-877-361-3883, Monday - Thursday, 8 am -

ELSTON 52 CEILING FAN MODEL #10290 Español p. 21 Questions, problems, missing parts? Before returning to your retailer, call our customer service department at 1-877-361-3883, Monday - Thursday, 8 am -

Single Phase Simplex SXL21=3, SXL24=3, SXH21=3, and SXH24=3

Single Phase Simplex SXL21=3, SXL24=3, SXH21=3, and SXH24=3 Manufactured by SJE-Rhombus Installation Instructions and Operation/Troubleshooting Manual 7000 Apple Tree Avenue Bergen, New York 14416 Phone:

Single Phase Simplex SXL21=3, SXL24=3, SXH21=3, and SXH24=3 Manufactured by SJE-Rhombus Installation Instructions and Operation/Troubleshooting Manual 7000 Apple Tree Avenue Bergen, New York 14416 Phone:

FLCH4R Garage and Utility Electric Heater

FLCH4R Garage and Utility Electric Heater Installation, Operation & Maintenance Instructions Model No. Volts Amps Watts BTU/HR Phase High Low High Low High Low Min Fuse Size* FLCH4R 208 17.3 8.66 3600

FLCH4R Garage and Utility Electric Heater Installation, Operation & Maintenance Instructions Model No. Volts Amps Watts BTU/HR Phase High Low High Low High Low Min Fuse Size* FLCH4R 208 17.3 8.66 3600

Outdoor Refrigerator. Be sure unit is standing upright 24 hours prior to plug-in. Model: BLZ-SSRF-50DH

Outdoor Refrigerator Be sure unit is standing upright 24 hours prior to plug-in. Model: BLZ-SSRF-50DH IMPORTANT SAFEGUARDS Read all instructions before using this appliance. Use this appliance only for

Outdoor Refrigerator Be sure unit is standing upright 24 hours prior to plug-in. Model: BLZ-SSRF-50DH IMPORTANT SAFEGUARDS Read all instructions before using this appliance. Use this appliance only for

e Heater/Exhaust Fan/Light User s Guide

e Heater/Exhaust Fan/Light User s Guide abflh70l, BFLH85L Item Stock Number(s): BFLH70L, BFLH85L IMPORTANT INSTRUCTIONS - OPERATING MANUAL READ AND SAVE THESE INSTRUCTIONS READ CAREFULLY BEFORE ATTEMPTING

e Heater/Exhaust Fan/Light User s Guide abflh70l, BFLH85L Item Stock Number(s): BFLH70L, BFLH85L IMPORTANT INSTRUCTIONS - OPERATING MANUAL READ AND SAVE THESE INSTRUCTIONS READ CAREFULLY BEFORE ATTEMPTING

Steam Bug. World's smallest steam iron great for travel

Steam Bug World's smallest steam iron great for travel Table of contents Location of Parts and Accessories........................................... 2 Location of Controls........................................................

Steam Bug World's smallest steam iron great for travel Table of contents Location of Parts and Accessories........................................... 2 Location of Controls........................................................

42 Oscillating Tower Fan with Remote Control. OWNER S MANUAL Model # FC1-42R-03

42 Oscillating Tower Fan with Remote Control OWNER S MANUAL Model # FC1-42R-03 3149097 PLEASE READ AND SAVE THESE INSTRUCTIONS 42 IN. OSCILLATING TOWER FAN W/ REMOTE CONTROL Thank you for choosing a Soleus

42 Oscillating Tower Fan with Remote Control OWNER S MANUAL Model # FC1-42R-03 3149097 PLEASE READ AND SAVE THESE INSTRUCTIONS 42 IN. OSCILLATING TOWER FAN W/ REMOTE CONTROL Thank you for choosing a Soleus

Owner s Manual CPU-1QD CPU-1 CPU-1T CPU-2 CPU-2T HEAVY DUTY UPRIGHT VACUUMS. Save These Instructions

Owner s Manual HEAVY DUTY UPRIGHT VACUUMS CPU-1QD CPU-1 CPU-1T CPU-2 CPU-2T Save These Instructions Index Important Safety Instructions.... 2 Polarization Instructions....3 Grounding Instructions.....

Owner s Manual HEAVY DUTY UPRIGHT VACUUMS CPU-1QD CPU-1 CPU-1T CPU-2 CPU-2T Save These Instructions Index Important Safety Instructions.... 2 Polarization Instructions....3 Grounding Instructions.....

MariGlo LED. Inspiring Excellence in Fish Keeping! 45 / 60 / 90 / 120.

MariGlo LED 45 / 60 / 90 / 120 Inspiring Excellence in Fish Keeping! Instruction version: 01/10/2013 Important Safeguards To guard against injury, basic safety precautions should be observed, including

MariGlo LED 45 / 60 / 90 / 120 Inspiring Excellence in Fish Keeping! Instruction version: 01/10/2013 Important Safeguards To guard against injury, basic safety precautions should be observed, including

gamma pond Ultraviolet Sterilizers

gamma pond Ultraviolet Sterilizers Instructions for Models #1410 8w, 1411 15w, 1412 25w, 1403-40w Important Safety Instructions... Page 2 Installation... Page 3 Maintenance & Winterizing... Page 5 Warranty...

gamma pond Ultraviolet Sterilizers Instructions for Models #1410 8w, 1411 15w, 1412 25w, 1403-40w Important Safety Instructions... Page 2 Installation... Page 3 Maintenance & Winterizing... Page 5 Warranty...

e Bath Fan with Light User s Guide

e Bath Fan with Light User s Guide abfl100rnl, BFL125RNL Item Stock Number(s): BFL100RNL, BFL125RNL IMPORTANT INSTRUCTIONS - OPERATING MANUAL READ AND SAVE THESE INSTRUCTIONS READ CAREFULLY BEFORE ATTEMPTING

e Bath Fan with Light User s Guide abfl100rnl, BFL125RNL Item Stock Number(s): BFL100RNL, BFL125RNL IMPORTANT INSTRUCTIONS - OPERATING MANUAL READ AND SAVE THESE INSTRUCTIONS READ CAREFULLY BEFORE ATTEMPTING

QUICK PRIME INSTALLATION AND SERVICE MANUAL

QUICK PRIME INSTALLATION AND SERVICE MANUAL NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part #

QUICK PRIME INSTALLATION AND SERVICE MANUAL NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part #

IMpORTANT SAFETy INSTRUcTIONS

Table of contents SAFETy SETUp OpERATION MAINTENANcE Safety... 2 Specifications... 4 Setup... 4 Operating Instructions... 6 WARNING SyMBOLS AND DEFINITIONS Maintenance... 9 Parts List and Diagram... 11

Table of contents SAFETy SETUp OpERATION MAINTENANcE Safety... 2 Specifications... 4 Setup... 4 Operating Instructions... 6 WARNING SyMBOLS AND DEFINITIONS Maintenance... 9 Parts List and Diagram... 11

Instruction Leaflet. Read instructions before operating. Retain for future reference.

pure indoor living 2-In-1 Dual Desk/Stand FAN MODEL: BSF1211C-CN Instruction Leaflet Read instructions before operating. Retain for future reference. Questions? Comments? Call 1-800-253-2764 in North America

pure indoor living 2-In-1 Dual Desk/Stand FAN MODEL: BSF1211C-CN Instruction Leaflet Read instructions before operating. Retain for future reference. Questions? Comments? Call 1-800-253-2764 in North America

Installation Guide. For Models: E-DCF52BNK5C3 E-DCF52FBZ5C3 E-DCF52MWW5C3 READ THESE INSTRUCTIONS AND SAVE THEM FOR FUTURE USE

READ THESE INSTRUCTIONS AND SAVE THEM FOR FUTURE USE Federal regulations require ceiling fans with light kits manufactured or imported after January 1, 2009, to limit total wattage consumed by the light

READ THESE INSTRUCTIONS AND SAVE THEM FOR FUTURE USE Federal regulations require ceiling fans with light kits manufactured or imported after January 1, 2009, to limit total wattage consumed by the light

MightyMax Tower Fan MIGHTY POWERFUL. MIGHTY QUIET.

MightyMax Tower Fan MIGHTY POWERFUL. MIGHTY QUIET. TABLE OF CONTENTS Warnings and Cautions... Location of Parts and Controls... 4 Location of Controls and LCD Icons (Main Unit)... 5 Location of Controls

MightyMax Tower Fan MIGHTY POWERFUL. MIGHTY QUIET. TABLE OF CONTENTS Warnings and Cautions... Location of Parts and Controls... 4 Location of Controls and LCD Icons (Main Unit)... 5 Location of Controls

SSS BPV- 40 Backpack Vacuum

SSS BPV- 40 Backpack Vacuum Manual The contents of this manual are based on the latest product information available at the time of publication. Triple S reserves the right to make changes or improvements

SSS BPV- 40 Backpack Vacuum Manual The contents of this manual are based on the latest product information available at the time of publication. Triple S reserves the right to make changes or improvements

AquaStream. ½ HP Floating Fountain. Please Keep for Your Records. Model #AS05 6A, 120V/60Hz Owner s Manual UNIT IDENTIFICATION

TM Included Classic Pattern Dimensions: 6 h x 16 w Included Included Crown & Rocket Pattern Dimensions: Trumpet: 8 h Crown: 4 h x 32 w Geyser Pattern Dimensions: 14 h x 7 w AquaStream ½ HP Floating Fountain

TM Included Classic Pattern Dimensions: 6 h x 16 w Included Included Crown & Rocket Pattern Dimensions: Trumpet: 8 h Crown: 4 h x 32 w Geyser Pattern Dimensions: 14 h x 7 w AquaStream ½ HP Floating Fountain

SSS Intrepid 16 FMS. Manual

SSS Intrepid 16 FMS Manual The contents of this manual are based on the latest product information available at the time of publication. Triple S reserves the right to make changes or improvements to its

SSS Intrepid 16 FMS Manual The contents of this manual are based on the latest product information available at the time of publication. Triple S reserves the right to make changes or improvements to its

User Manual. Wine Cellar

User Manual Wine Cellar MODEL: WWT060MB WWT080MB WWT100MB WWT120MB 1. READ these instructions carefully before installing and operating the Wine Cellar. Keep them for further reference. 2. Record in the

User Manual Wine Cellar MODEL: WWT060MB WWT080MB WWT100MB WWT120MB 1. READ these instructions carefully before installing and operating the Wine Cellar. Keep them for further reference. 2. Record in the

GRUNDFOS INSTRUCTIONS. Sololift2 C-3. Installation and operating instructions

GRUNDFOS INSTRUCTIONS Sololift2 C-3 Installation and operating instructions English (US) English (US) Installation and operating instructions Original installation and operating instructions. CONTENTS

GRUNDFOS INSTRUCTIONS Sololift2 C-3 Installation and operating instructions English (US) English (US) Installation and operating instructions Original installation and operating instructions. CONTENTS

InstructIon Manual KrEs EQuIPMEnt stands

Instruction Manual Instruction Manual SELF-CONTAINED AND REMOTE Kairak KRES model refrigerated equipment stand units are available in many lengths from 36 to 120 inches long. These units are available

Instruction Manual Instruction Manual SELF-CONTAINED AND REMOTE Kairak KRES model refrigerated equipment stand units are available in many lengths from 36 to 120 inches long. These units are available

Installation Instructions / Warranty. Metris 31060XX XX XX1

Installation Instructions / Warranty Metris 31060XX1 31020XX1 31261XX1 Metris Single Control Lavatory Mixer 31060XX1 Tall Lavatory Mixer 31020XX1 Single Control Bidet Mixer 31261XX1 31060XX1 31020XX1 31261XX1

Installation Instructions / Warranty Metris 31060XX1 31020XX1 31261XX1 Metris Single Control Lavatory Mixer 31060XX1 Tall Lavatory Mixer 31020XX1 Single Control Bidet Mixer 31261XX1 31060XX1 31020XX1 31261XX1

52 SAN LUCAS CEILING FAN

52 SAN LUCAS CEILING FAN Owner s Manual Models #20551 If a problem cannot be remedied or you are experiencing difficulty in installation, please contact the Service Department: 1-877-459-3267, 9 a.m.-

52 SAN LUCAS CEILING FAN Owner s Manual Models #20551 If a problem cannot be remedied or you are experiencing difficulty in installation, please contact the Service Department: 1-877-459-3267, 9 a.m.-

Model: C C Ambassador 20. Automatic Carpet Scrubber OPERATION SERVICE PARTS CARE

Ambassador 20 Automatic Carpet Scrubber Model: C8420-115 C8420-240 OPERATION SERVICE PARTS CARE This manual is furnished with each new Minuteman Ambassador 20. This provides the necessary operating and

Ambassador 20 Automatic Carpet Scrubber Model: C8420-115 C8420-240 OPERATION SERVICE PARTS CARE This manual is furnished with each new Minuteman Ambassador 20. This provides the necessary operating and

WET/DRY VACUUM MODEL SV-12

WET/DRY VACUUM MODEL SV-12 INTRODUCTION OPERATING & MAINTENANCE INSTRUCTIONS READ THIS BOOK This operator s book has important information for the use and safe operation of this machine. Read this book

WET/DRY VACUUM MODEL SV-12 INTRODUCTION OPERATING & MAINTENANCE INSTRUCTIONS READ THIS BOOK This operator s book has important information for the use and safe operation of this machine. Read this book

FROZEN CONCOCTION MAKER

The Navigator Bahamas TM FROZEN CONCOCTION MAKER The Best Margaritas Come From Margaritaville Model DM0500 Series User Manual IMPORTANT SAFEGUARDS WHEN USING ELECTRICAL APPLIANCES, BASIC SAFETY PRECAUTIONS

The Navigator Bahamas TM FROZEN CONCOCTION MAKER The Best Margaritas Come From Margaritaville Model DM0500 Series User Manual IMPORTANT SAFEGUARDS WHEN USING ELECTRICAL APPLIANCES, BASIC SAFETY PRECAUTIONS

OPERATION, SERVICE & PARTS MANUAL

OPERATION, SERVICE & PARTS MANUAL BROASTER 620NXP & 621 EASY BREADER Be sure ALL installers read, understand, and have access to this manual at all times. MODEL 620NXP MODEL 621 Genuine Broaster Chicken,

OPERATION, SERVICE & PARTS MANUAL BROASTER 620NXP & 621 EASY BREADER Be sure ALL installers read, understand, and have access to this manual at all times. MODEL 620NXP MODEL 621 Genuine Broaster Chicken,

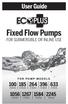

User Guide. Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE FOR PUMP MODELS # # # # # # # # #728333

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

52 BERKSHIRE CEILING FAN

52 BERKSHIRE CEILING FAN Owner s Manual Models #20223, 20224 If a problem cannot be remedied or you are experiencing difficulty in installation, please contact the Service Department: 1-877-459-3267, 9

52 BERKSHIRE CEILING FAN Owner s Manual Models #20223, 20224 If a problem cannot be remedied or you are experiencing difficulty in installation, please contact the Service Department: 1-877-459-3267, 9

Industrial Vacuums, Inc

Instructions/Spare Parts Manual Nilfisk Model GWD255 Drum Top Vacuum CAUTION: This Nilfisk vacuum cleaner is not to be used in explosion-hazardous areas, as serious injury could result. Under no circumstances

Instructions/Spare Parts Manual Nilfisk Model GWD255 Drum Top Vacuum CAUTION: This Nilfisk vacuum cleaner is not to be used in explosion-hazardous areas, as serious injury could result. Under no circumstances

e Bath Fan with Light User s Guide

e Bath Fan with Light User s Guide abfl125rok Item Stock Number(s): BFL125ROK IMPORTANT INSTRUCTIONS - OPERATING MANUAL READ AND SAVE THESE INSTRUCTIONS READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL,

e Bath Fan with Light User s Guide abfl125rok Item Stock Number(s): BFL125ROK IMPORTANT INSTRUCTIONS - OPERATING MANUAL READ AND SAVE THESE INSTRUCTIONS READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL,

DUVAL 52 CEILING FAN MODELS #50201, Español p. 19 LISTED FOR DAMP LOCATION

DUVAL 52 CEILING FAN MODELS #50201, 50206 Español p. 19 LISTED FOR DAMP LOCATION Questions, problems, missing parts? Before returning to your retailer, call our customer service department at 1-877-361-3883,

DUVAL 52 CEILING FAN MODELS #50201, 50206 Español p. 19 LISTED FOR DAMP LOCATION Questions, problems, missing parts? Before returning to your retailer, call our customer service department at 1-877-361-3883,

Installation Guide. For Models: E-MLV36BNK4LK1 E-MLV36ESP4LK1 E-MLV36WW4LK1 READ THESE INSTRUCTIONS AND AND SAVE THEM FOR FUTURE USE

READ THESE INSTRUCTIONS AND AND SAVE THEM FOR FUTURE USE Federal regulations require ceiling fans with light kits manufactured or imported after January 1, 2009, to limit total wattage consumed by the

READ THESE INSTRUCTIONS AND AND SAVE THEM FOR FUTURE USE Federal regulations require ceiling fans with light kits manufactured or imported after January 1, 2009, to limit total wattage consumed by the

Installation & Service Manual

Installation & Service Manual Table of Contents Unpacking & Inspection... 2 Basic Guidelines... 2 Specifications... 3 Before Starting Installation Where to install the filter... 4 Tools, pipe, fittings

Installation & Service Manual Table of Contents Unpacking & Inspection... 2 Basic Guidelines... 2 Specifications... 3 Before Starting Installation Where to install the filter... 4 Tools, pipe, fittings

PUREPOWER SERIES CENTRAL VACUUM POWER UNITS PP500, PP600 & PP650

USER GUIDE PUREPOWER SERIES CENTRAL VACUUM POWER UNITS PP500, PP600 & PP650 AB0039 FOR RESIDENTIAL USE ONLY!! MODELS SFDB-DQ, SFDB-DR AND SFDB-DS 30042509E IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS

USER GUIDE PUREPOWER SERIES CENTRAL VACUUM POWER UNITS PP500, PP600 & PP650 AB0039 FOR RESIDENTIAL USE ONLY!! MODELS SFDB-DQ, SFDB-DR AND SFDB-DS 30042509E IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS

Sanitaire. Owner s Guide. 10 GALLON Box Extractor SC6088 Series IMPORTANT

Sanitaire 10 GALLON Box Extractor SC6088 Series Part No. SC6088 Rev 2 (3/14) Owner s Guide IMPORTANT Do not return this product to the store. Call 1-800-800-8975* Monday - Friday 8:00 AM to 7:30 PM and

Sanitaire 10 GALLON Box Extractor SC6088 Series Part No. SC6088 Rev 2 (3/14) Owner s Guide IMPORTANT Do not return this product to the store. Call 1-800-800-8975* Monday - Friday 8:00 AM to 7:30 PM and

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR PUMP 88 PUMP PARTS BREAKDOWN REF # Order # Mfr # Description 1 NEP4 AC 348 Lid Knobs NEP AC 380 Strainer Lid 3 NEP6

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR PUMP 88 PUMP PARTS BREAKDOWN REF # Order # Mfr # Description 1 NEP4 AC 348 Lid Knobs NEP AC 380 Strainer Lid 3 NEP6

IMPORTANT SAFETY INSTRUCTIONS EC-AG1-25 EC-AG1, EC-AG2 SAVE THESE INSTRUCTIONS.

IMPORTANT SAFETY INSTRUCTIONS 2 1. Read and Follow All Instructions 2. Read this manual completely before attempting installation. 3. All permanent electrical connections should be made by a qualified

IMPORTANT SAFETY INSTRUCTIONS 2 1. Read and Follow All Instructions 2. Read this manual completely before attempting installation. 3. All permanent electrical connections should be made by a qualified

Because you re not like everyone else. EVAPORATIVE COOLER EC220W OWNER S MANUAL

Because you re not like everyone else. EVAPORATIVE COOLER EC220W OWNER S MANUAL 2 BECAUSE YOU RE NOT LIKE EVERYONE ELSE. And neither are we. Always at the forefront of our industry, our goal is to offer

Because you re not like everyone else. EVAPORATIVE COOLER EC220W OWNER S MANUAL 2 BECAUSE YOU RE NOT LIKE EVERYONE ELSE. And neither are we. Always at the forefront of our industry, our goal is to offer

Air Cleaning Equipment, Inc. 303 N. Main St. Broadway, NC iers.com

Read and Save These Instructions Horizon Galaxy - Installation and Operations Manual Air Cleaning Equipment, Inc. 303 N. Main St. Broadway, NC 27505 www.horizondehumidif iers.com 1 Safety Notes: The Horizon

Read and Save These Instructions Horizon Galaxy - Installation and Operations Manual Air Cleaning Equipment, Inc. 303 N. Main St. Broadway, NC 27505 www.horizondehumidif iers.com 1 Safety Notes: The Horizon

Prime Chiller Mini-Chillers

Prime Chiller Mini-Chillers Instructions for Model#2680, 2635 Warning and Safety Instructions... Page 2 Chiller Installation... Page 3 Programming Thermostat... Page 4 Warranty... Page 5 EMAIL:INFO@CURRENT-USA.COM

Prime Chiller Mini-Chillers Instructions for Model#2680, 2635 Warning and Safety Instructions... Page 2 Chiller Installation... Page 3 Programming Thermostat... Page 4 Warranty... Page 5 EMAIL:INFO@CURRENT-USA.COM

TILGHMAN CEILING FAN. LISTED For Damp Location E ITEM # MODEL #WCK52LMW5N WCK52NWZ5N. Español p. 20 ATTACH YOUR RECEIPT HERE

ITEM #0294980 0294981 TILGHMAN CEILING FAN Harbor Breeze is a registered trademark of LF, LLC. All Rights Reserved. MODEL #WCK52LMW5N WCK52NWZ5N Español p. 20 ATTACH YOUR RECEIPT HERE Serial Number Purchase