CWS Series. Operating Instructions and Parts Manual PERFORMANCE SPECIFICATIONS CONSTRUCTION. * Refer to Page 13 for Jet Assembly Part Numbers

|

|

|

- Sheryl Thompson

- 5 years ago

- Views:

Transcription

1 Convertible Well Jet Pump Water Systems Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference. CWS Series POWER SUPPLY REQUIREMENTS MOTOR HORSEPOWER LIQUID TEMPERATURE RANGE SPECIFICATIONS 120 or 230 V, 60 Hz Split Phase 1 HP... (CWS100) 3/4 HP... (CWS75) 1/2 HP...(CWS50) 40 F- 120 F MOTOR HOUSE SEAL PLATE DIFFUSER IMPELLER SHAFT PUMP SUCTION CONSTRUCTION Cast Iron Cast Iron Thermoplastic Thermoplastic Carbon Steel 1-1/4 in. NPT CUT IN PRESSURE 30 PSI PUMP DISCHARGE 3/4 in. NPT CUT OUT PRESSURE 50 PSI PERFORMANCE Model HP PSI 0 ft 10 ft 20 ft 30 ft 40 ft 50 ft 60 ft 70 ft 80ft 90 ft CWS100 1 CWS75 3/ CWS50 1/ * Refer to Page 13 for Jet Assembly Part Numbers Intended for Indoor Use Only 2018, WAYNE/Scott Fetzer Company B 08/18

2 DESCRIPTION Jet pumps are single stage domestic water pumps designed for pumping potable water in applications where the water is up to 90 feet below pump center line. A pressure switch is a standard feature. A built-in control valve is available on deep well pumps. Deep well pumps must be mounted to either a pre-charged, conventional type, or free standing pressure tank. A Wayne jet assembly is required (not included) for operation of this pump. UNPACKING Inspect this unit before it is used. Occasionally, products are damaged during shipment. If the pump or components are damaged, return the unit to the place of purchase for replacement, or call Customer Support ( ). SAFETY SIGNAL WORDS To help recognize this information, observe the following signal words/ hazard classifications. GENERAL SAFETY INFORMATION CALIFORNIA PROPOSITION 65 This product can expose you to chemicals, including DEHP, which is known to the State of California to cause cancer, birth defects and reproductive harm. For more information, go to Ce produit peutvous exposer à des produits chimiques, notamment du DOP, reconnus par l État de Californie comme étant cancérigènes et à l origine d anomalies congénitales et de problèmes de l appareil reproductif. Pour plus de renseignements, visiter le site Danger indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury. La mention Danger indique une situation dangereuse imminente qui, si elle n est pas évitée, ENTRAÎNE la mort ou des blessures graves. Warning indicates a potentially hazardous situation which, if NOT avoided, COULD result in death or serious injury. La mention avertissement indique une situation potentiellement dangereuse qui, si elle n est pas évitée, risque d entraîner des lésions corporelles graves ou même la mort. Caution indicates a potentially hazardous situation which, if NOT avoided, MAY result in minor or moderate injury. MISE EN GARDE La mention mise en garde indique une situation potentiellement dangereuse qui, si elle n est pas évitée, pourrait entraîner des blessures mineures ou modérées. Notice indicates important information, that if not followed, may cause damage to equipment. This is the safety alert symbol. It is used to alert you to potential bodily injury hazards. Obey all safety messages that follow this symbol to avoid possible harm. NOTE: Information that requires special attention. GENERAL SAFETY 1. Read all manuals included with this product carefully. Be thoroughly familiar with the controls and the proper use of the equipment. 2. Know the pump application, limitations and potential hazards. Always install a pressure relief valve to match the system pressure rating and the maximum flow rate. TOUJOURS installer une soupape de surpression correspondant à la pression nominale et au débit maximal du système. Do not use to pump flammable or explosive fluids such as gasoline, fuel oil, kerosene, etc. Do not use in explosive atmospheres. Pump should be used to pump ONLY clear water. Failure to follow this warning will result in death or serious injury, and void warranty. Ne pas utiliser pour pomper des fluides inflammables ou explosifs tels que l essence, le mazout, le kérosène, etc. Ne pas utiliser dans des environnements explosifs. Pomper UNIQUEMENT de l eau claire. Le non-respect de cet avertissement entraînera la mort ou des blessures graves, annuler la garantie.. REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping. 2

3 CWS Series Disconnect power and release all pressure from the system before attempting to install, service, relocate or perform any maintenance. Lock the power disconnect in the open (off) position. Tag out the power disconnect to prevent unexpected application of power. Débrancher de la source d alimentation puis dissiper toute la pression du système avant d essayer d installer, de réparer, de déplacer ou de procéder à l entretien. Verrouiller le sectionneur de courant en position ouverte (OFF). Étiqueter le sectionneur de courant pour éviter toute mise sous tension imprévue. 3. Drain all water from the system before servicing. 4. Periodically inspect pump and system components. Perform routine maintenance as required (See Maintenance, page 8). Personal Safety: a. Wear safety glasses at all times when working with pumps. b. Keep work area clean, uncluttered and properly lighted replace all unused tools and equipment. c. Keep visitors at a safe distance from work area. 5. Do not pump chemicals or corrosive liquids. Pumping these liquids shortens the life of the pumps seals and moving parts and will void the warranty. Pump ONLY clear water. 6. When installing pump, cover the well to prevent foreign matter from falling into well and contaminating the water and/or damaging internal mechanical pumping components. 7. Always test the water from the well for purity before use. Check with local health department for test procedure. 8. Complete pump and piping system MUST be protected against below freezing temperatures. Freezing temperatures could cause severe damage and void the warranty. 9. Do not run the pump dry or damage will occur and will void warranty. This pump is designed for indoor installation only unless housed and protected from the elements. Failure to install indoors will significantly increase the risk of injury or death from electrical shock and void warranty. Cette pompe est conçue pour être installée à l intérieur sauf si elle est abritée et protégée contre les intempéries. Ne pas l installer à l abri dans un local augmente considérablement le risque de blessure ou de mort par électrocution, annuler la garantie. certified electrician. agréé ou certifié. All wiring should be performed by a licensed or Tout câblage doit être réalisé par un électricien 10. Make sure the line voltage and frequency of electrical current supply agrees with the motor wiring. 11. Do not attempt repairs to the electric motor. All repairs to the motor must be completed at a licensed or certified electrical motor repair shop. Do not touch an operating motor. Modern motors are designed to operate at high temperatures. NE PAS toucher un moteur en marche. Les moteurs modernes sont conçus pour fonctionner à des températures élevées. 12 Avoid kinking electrical cord and protect electrical cord from sharp objects, hot surfaces, oil and chemicals. 13. Keep fingers and foreign objects away from ventilation and other openings. Do not insert any objects into the motor. Risk of electric shock! Never connect the green (or green/yellow) wire to a live terminal! Risque de choc électrique! Ne JAMAIS brancher le fil vert (ou vert et jaune) à une borne sous tension! 14. Use wire of adequate size to minimize voltage drop at the motor. Do not handle pump or pump motor with wet hands, when standing on a wet or damp surface or when standing in water. Fatal electrical shock will occur. NE PAS manipuler de pompe ou de moteur de pompe avec les mains humides ou debout sur une surface mouillée ou humide, ou dans l eau. Ceci peut occasionner un choc électrique mortel. Pump motor is equipped with an automatic resetting thermal protector and may restart unexpectedly. Protector tripping is an indication of motor overheating because of operating pump at low heads (low discharge restriction), excessively high or low voltage, inadequate wiring, incorrect motor connections, excessive surrounding air temperature, inadequate ventilation, and/or defective motor or pump. Le moteur de la pompe est doté d un protecteur thermique à réinitialisation automatique et pourrait redémarrer de manière imprévue. Le déclenchement du protecteur est une indication de surchauffe du moteur à cause d une utilisation de la pompe à faible hauteur de chute (restriction de faible décharge), d une tension excessivement haute ou basse, d un câblage inadéquat, d un branchement incorrect du moteur, d une température ambiante excessive, d une ventilation inadéquate ou d une pompe ou d un moteur défectueux. 3

4 PRE-INSTALLATION WATER SUPPLIES The water supplies illustrated in Figure 16 (on page 13) are possible sources for water. These water supplies can be divided into two categories: SURFACE WATER Water from a lake, storage tank, stream, pond and cistern. This water is usually not fit for human consumption, but may be suitable for washing, irrigation or other household uses. GROUND WATER Water found in the water bearing stratum at various levels beneath the earth. Of all the fresh water found on earth only 3 percent is found on the surface and 97 percent is underground. WATER STORAGE Tanks are required for these pumps to operate as designed. TANKS - CONVENTIONAL STORAGE The function of the tank is to store a quantity of water under pressure. When full, the tank contains approximately 2/3 water and 1/3 compressed air. The compressed air forces the water out of the tank when a faucet is opened. An air volume control automatically replaces air lost or absorbed into the water. The usable water, or draw-down capacity, of the tank is approximately 1/6 of the tanks total volume when operated on a 30/50 pressure setting (Figure 1). TANKS - PRE-CHARGED STORAGE A pre-charged storage tank has a flexible bladder or diaphragm that acts as a barrier between the compressed air and water. This barrier prevents the air from being absorbed into the water and allows the water to be acted on by compressed air at initially higher than atmospheric pressures (pre-charged). More usable water is provided than with a conventional type tank. Pre-charged tanks are specified in terms of a conventional tank. For example, a 20 gallon pre-charged tank will have the same usable water or draw-down capacity as a 40 gallon conventional tank, but the tank is smaller in size (Figure 1). Pre-charged to be set at 28 PSI with the tank empty of water. CONVENTIONAL TANK AIR VOLUME CONTROL BLADDER PRE-CHARGED TANK INSTALLATION LOCATION Select a location as close to the water supply as possible. Be sure to comply with any state or local codes regarding the placement of the pump. The equipment must be protected from the elements or voids warranty. A basement or heated pump house is a good location. Make sure the pump has proper ventilation. The temperature surrounding the pump is not to exceed 100 F (38 C) or nuisance tripping of the motor overload may occur. This pump is designed for indoor installation only, unless housed and protected from the elements. Failure to install indoors will significantly increase the risk of injury or death from electrical shock. Cette pompe est conçue pour être installée à l intérieur sauf si elle est abritée et protégée contre les intempéries. Ne pas l installer à l abri dans un local augmente considérablement le risque de blessure ou de mort par électrocution. WELLS A new well should be pumped clear of sand before installing the pump. Sand will damage the pumping parts and seal. The drawdown level of the well should not exceed the maximum rated depth for the pump. The capacity of the pump will be reduced and a loss of prime may occur. PIPING Inlet piping may be copper, steel, or rigid PVC plastic. pipe). Flexible pipe is prohibited on suction pipe (inlet MISE EN GARDE Un tuyau flexible est interdit sur le tuyau d aspiration (tuyau d entrée). The pipe must be clean and free of rust or scale. Use a pipe joint compound on the male threads of the metal pipe. Plumber s seal tape should be used with plastic threads. All connections must be air tight to insure normal operation. Slope all inlet piping upwards towards the pump to prevent trapping air. Unions or hose couplings can be installed near pump to facilitate removal for servicing or storage. A rubber hose installed between the water system and the house piping will reduce the noise transmitted to the house. Plastic pipe can be used on all installations except 2 in. deep well jet. The 2 in. deep well jet requires 1-1/4 in. galvanized steel pipe and special machined couplings (1-13/16 in. O. D.). The galvanized steel pipe and the couplings restrict the flow of return water back to the jet unless the couplings are machined. Figure 1 - Conventional and Pre-charged Storage Tanks 4

5 CWS Series INSTALLATION (CONTINUED) PRESSURE SWITCH The pressure switch provides for automatic operation. The pump starts when pressure drops to a cut-in setting. The pump stops when pressure reaches a cut-out setting. The pressure switch preset and is NOT adjustable. PIPE SIZES Long horizontal pipe runs and an abundance of fittings and couplers decrease water pressure due to friction loss. See Chart 1, on page 5, to determine the proper pipe size. SHALLOW WELL INSTALLATION A shallow well jet assembly can be used with the deep well pump when the pump is located a maximum of 25 ft vertically above the water level (see converting to shallow well pump on page 7). Shallow well installations have only one pipe between the pump and water supply (Figure 2). DRILLED WELL (FIGURE 16, PAGE 13) 1. Install a foot valve on the first section of pipe (Figure 2, Illustration A). 2. Lower the pipe into the well. 3. Add pipe until the foot valve is 5 feet below the lowest anticipated water level. The foot valve must be at least 18 in. from the bottom of the well or sand or sediment could be drawn into the system. MISE EN GARDE Le clapet de pied doit au moins être à 45,7 cm (18 po) du fond du puits, sinon du sable ou des sédiments pourraient être aspirés dans le système. 4. After proper depth is reached, install a well seal or pitless adapter to support pipe and prevent surface. water and other contaminants from entering well. 5. Slope the horizontal pipe upward toward the pump to eliminate trapping air. Sloping the pipe will also aid in priming the pump. DRIVEN WELL (FIGURE 16, PAGE 13) Drive the point several feet below the water table. NOTE: A packer type foot valve can be installed in the well (Figure 2, Illustration B). This type of foot valve allows the piping to be filled with water when priming and makes the inlet pipe much easier to test for leaks. Follow the manufacturer s instructions when installing the packer type foot valve. As an alternative, an in-line check valve can be used with a driven well (Figure 2, Illustration C). The pipe between the check valve and the water level will always be under a vacuum. Leaking joints or couplings will allow air to leak into the pipe and cause abnormal pump operation. Make sure to use pipe joint compound on all male pipe threads. DUG WELL, CISTERN, LAKE AND SPRING INSTALLATION (FIGURE 16, PAGE 13) Install a foot valve on inlet pipe and lower into water. The foot valve must be at least 18 in. from the bottom of the well or sand or sediment could be drawn into the system. MISE EN GARDE Le clapet de pied doit au moins être à 45,7 cm (18 po) du fond du puits, sinon du sable ou des sédiments pourraient être aspirés dans le système. NOTE: When a lake is used as a water supply, make sure the inlet pipe is deep enough to be submerged at all times. Slope the horizontal piping upward toward the pump to prevent trapping air. The pipe must be removed during winter months or protected against freezing. Protect the pipe from damage from swimmers and boats. Install a screen around the inlet pipe to prevent the entrapment of swimmers, wildlife and debris. Installer un écran autour du tuyau d entrée pour éviter de piéger des nageurs, des animaux et des débris. 5

6 INSTALLATION (CONTINUED) Figure 2 WELL SEAL WELL CASING TO PUMP PACKER TYPE FOOT VALVE ILLUSTRATION A TO PUMP FOOT VALVE DRIVE POINT DEEP WELL INSTALLATION DRILLED WELL (4 IN. OR LARGER) WITH TWO PIPE JET (FIGURE 16, ON PAGE 13 AND FIGURE 3, BELOW) 1. Assemble a 1-1/4 in. foot valve (not included) to the jet body. A 1-1/4 in. coupling is required to connect the larger pipe to the jet assembly. 2. Connect the 1 in. pipe threads into the smaller opening in the jet body. 3. Lower the jet into the well. Add pipe as needed. Be sure to use pipe joint compound, or plumber s seal tape on all male threads. 4. Position the jet feet below the lowest anticipated water level, but never closer than 5 feet from the bottom of the well, if possible. 5. Install a well seal to support the pipe and prevent surface water and other contaminants from entering the well. 6. Install the horizontal pipe from the well to the pump. Piping from the vertical well pipe to the pump should never be smaller than the well pipes. 7. Slope both pipes upward toward the pump to prevent trapping air. If the horizontal distance exceeds 25 feet, see Chart 1, on page 7 for the recommended pipe sizes. DUG WELL, CISTERN, LAKE AND SPRING WITH TWO PIPE JET (FIGURE 16, PAGE 13) 1. Install a 1-1/4 in. foot valve (not included) to the jet body. A 1-1/4 in. coupling is required to connect the larger pipe to the jet assembly. 2. Connect the 1 in. pipe threads into the smaller opening in the jet body. 3. Lower the jet into the water below the lowest anticipated water level, but never closer than 18 in. from the bottom. Sand or debris may be drawn into the system if the jet is too close to the bottom. 4. Provide protection for the jet and pipes against damage from boats or swimmers if a lake is used for the water supply. Figure 2 ILLUSTRATION B Install a screen around the inlet pipe to prevent the entrapment of swimmers, wildlife and debris. TO PUMP Installer un écran autour du tuyau d entrée pour éviter de piéger des nageurs, des animaux et des débris. IN-LINE CHECK VALVE 1-1/4 IN. PIPE JET BODY DRIVE POINT 1 IN. PIPE FOOT VALVE Figure 2 ILLUSTRATION C Figure 3 - Two Pipe Jet (4 Casing or Greater) 6

7 CWS Series INSTALLATION (CONTINUED) 5. Slope the horizontal pipes upward toward the pump to prevent trapping air. If horizontal distance exceeds 25 feet, see Chart 1 for recommended pipe sizes. DRILLED WELL (2 IN.) WITH SINGLE PIPE PACKER (FIGURES 16 AND 4) NOTE: Single pipe packer jets rely on the space between single pipe and inside of well casing for return water to operate jet. Two inch installations must use 1-1/4 in. galvanized steel pipe with special turned couplings (1-13/16 in. O.D.) to avoid restricting flow of return water back to jet. 1. Assemble the foot valve and packer to the jet body. 2. Lubricate the rubber cups with petroleum jelly. 3. Attach the first section of pipe and lower jet into well. 4. Add pipe until the jet is positioned 5-15 feet below the lowest anticipated water level. The jet should never be closer than 5 feet from the bottom of the well or sand and sediment may be drawn into the system. 5. With the jet in position, fill the pipes with water to make sure the rubber cups are sealed against inside of the well casing. It may be necessary to move the jet up and down to seat the cups. 6. Install the casing adapter and the horizontal pipes. 7. Slope both pipes upward toward the pump to eliminate trapping air. If the horizontal distance exceeds 25 feet, see Chart 1 below, for the recommended pipe sizes. CHART 1 - PIPE SIZING DEEP WELL PUMP WITH HORIZONTAL AND VERTICAL STORAGE TANK (FIGURES 5 AND 6) 1. Install the air volume control on the tank as shown. 1-1/4 IN. PIPE PACKER Figure 4 - Single Pipe Jet (2 Casing) CUPS FOOT VALVE 2. Connect the copper tube from the air volume control to the 1/8 in. NPT opening directly above the 1-1/4 in. opening on the front of the pump. 3. Install a valve and isolating hose between the system and the house plumbing to aid in pump removal for servicing and for reducing noise transmitted through the house piping. 4. Provide a faucet at the lowest point in the system to drain for service or storage. Pump Model Pump Opening Horizontal Distance (Feet) Deep Well Inlet: Suction 1-1/4 in. 1-1/2 in. Inlet: Drive 1 in. 1-1/4 in. Outlet 3/4 in. 1 in. PUMP PRIME PLUG PRESSURE SWITCH OUTLET TO JET ASSEMBLY AIR VOLUME CONTROL TUBING CONVENTIONAL TANK AIR VOLUME CONTROL Figure 5 - Horizontal Tank 7

8 INSTALLATION (CONTINUED) AIR VOLUME CONTROL AIR VOLUME CONTROL TUBING SUCTION CONVERTING THE DEEP WELL PUMP TO SHALLOW WELL OPERATION (FIGURE 8) For shallow wells (25 feet or less), a bolt-on shallow well jet is available as an accessory for deep well pumps. The jet attaches to the front of the pump with the two bolts provided and converts the deep well pump into a shallow well pump. The shallow well jet has a 1 in. NPT inlet and a 1/8 in. NPT opening for an air volume control. For optimum performance, an inline check valve on the inlet side of the shallow well jet is recommended. PRESSURE SWITCH OUTLET PRIME PLUG TO JET ASSEMBLY OUTLET PRIMING PLUG DRIVE Figure 6 - Vertical Tank DEEP WELL PUMP WITH PRE-CHARGED STORAGE TANK (FIGURE 7) 1. Check tank pre-charge using a tire pressure gauge. Set air pressure in tank to 28 psi which is 2 psi below pressure switch cut-in level. An air valve is located on the side and will accept a standard fitting from a bicycle pump or air line. 2. Check the pressure with the power off, faucets open and no water flowing (zero water pressure). 3. Install a valve and isolator hose between the system and the house plumbing to aid in pump removal for servicing and for reducing noise transmitted to the house through the piping. 4. Provide a faucet at the lowest point in the system to drain for service or storage. Figure 7 - Pre-charged Storage Tank 8

9 CWS Series ELECTRICAL Risk of electrical shock. This pump is designed for indoor installation only, unless housed and protected from the elements. Installer un écran autour du tuyau d entrée pour éviter de piéger des nageurs, des animaux et des débris. Select the proper size wire and fuse. Time delay fuses are recommended over standard fuses for motor circuit protection. All pump motors have built-in automatic overload protection that will prevent damage to the motor due to overheating. If wire run is a short distance, a cord/plug assembly may be used as long as it meets the minimum wire gage size called out in Chart 2. TO AIR VOLUME CONTROL Disconnect power and release all pressure from the system before attempting to install, service, relocate or perform any maintenance. Débrancher de la source d alimentation puis dissiper toute la pression du système avant d essayer d installer, de réparer, de déplacer ou de procéder à l entretien. OPERATION PRIMING THE SHALLOW WELL PUMP To prevent damage to the pump, do not start motor until pump has been filled with water. Pour éviter d endommager la pompe, ne pas démarrer le moteur tant que la pompe n a pas été remplie d eau. When the deep well pump is used with the bolton shallow well jet, be sure the control valve slot (Figure 11) is in the vertical (open) position at all times. 1. Remove prime plug. JET ASSEMBLY Figure 8 - Shallow Well Jet Do not connect to electric power supply until unit is permanently grounded. Connect ground wire to approved ground then connect terminal provided. Ne pas connecter à l alimentation électrique tant que l unité n est pas mise à la terre en permanence. Brancher le fil de mise à la terre à la masse approuvée puis raccorder la borne fournie. A metal underground water pipe or well casing at least 10 feet long makes the best ground electrode. If plastic pipe or insulated fittings are used, run a wire directly to the metal well casing or use a ground electrode furnished by the power company. There is only one proper ground terminal on the unit. The terminal is located under the pressure switch cover, is painted green and is identified as GRD. The ground connection must be made at this terminal (Figure 9). The ground conductor must not be smaller than the circuit conductors supplying the motor. The voltage of power supply must match the voltage of the pump. The unit has dual voltage motors preset at the factory to 115 volts. The motors can be converted to 230 volts by changing the voltage selector to the desired voltage (Figure 10). Disconnect power, use needle nose pliers to pull the selector out approximately 1/4 in., point too, and then reinsert in correct position. 2. Fill pump and piping completely full of water. 3. Replace the prime plug. HP 1/2 3/4 1 CHART 2 - RECOMMENDED FUSE AND WIRING DATA - 60 HZ MOTORS Volt Dual Element Fuse 250V Distance in Feet From Meter to Motor to to to Wire Size * above is the suggested size only. Check with local or state code for proper sizing. 9

10 OPERATION (CONTINUED) GROUND SCREW LINE PRIMING THE DEEP WELL PUMP To prevent damage to the pump, do not start motor until pump has been filled with water. Pour éviter d endommager la pompe, ne pas démarrer le moteur tant que la pompe n a pas été remplie d eau. MOTOR Figure 9 - Electrical Connections 1 L1 3 L2 1. Remove prime plug. 2. Fill pump and piping completely full of water. 3. Replace the prime plug. 4. Close the control valve (Figure 11) and open a nearby faucet. 5. Start the motor. The pressure inside the pump body will build almost immediately as the pump, jet and piping become completely filled with water. 6. Slowly open the control valve. Water will begin to flow. Continue to open the control valve until maximum flow is achieved. Opening the valve too far will cause the water to stop flowing. OPEN 1/4 IN. TURN CLOSED 230 V 115 V Figure 11 - Control Valve Figure 10 - Voltage Selector 4. Open a faucet to vent the system. 5. Start the motor. Water will pump in a few minutes. If pump fails to prime in 5 minutes, stop motor and refill pump with water. Priming time is proportional to the amount of air in inlet pipe. Do not allow pump to get hot. 6. Let the system operate for several minutes to flush all pipes. 7. Close faucet and allow pump to build pressure in tank. When the pressure reaches the cut-out setting, the motor will stop. The system is now in operation and will automatically cycle on demand. 7. Adjust the valve until there is a steady flow of water. The valve should be opened as much as possible without losing pressure. 8. Let the system operate for several minutes to flush all piping. 9. Close the faucets and allow the pump to build pressure in the tank. When the pressure reaches the cut-out setting, the motor will stop. The system is now in operation and will automatically cycle upon demand. 10

11 CWS Series MAINTENANCE Disconnect power and release all pressure from the system before attempting to install, service, relocate or perform any maintenance. Lock the power disconnect in the open (off) position. Tag out the power disconnect to prevent unexpected application of power. Débrancher de la source d alimentation puis dissiper toute la pression du système avant d essayer d installer, de réparer, de déplacer ou de procéder à l entretien. Verrouiller le sectionneur de courant en position ouverte (OFF). Étiqueter le sectionneur de courant pour éviter toute mise sous tension imprévue. MISE EN GARDE DRAINING THE PUMP Protect the pump from freezing during winter conditions. Protéger la pompe du gel pendant l hiver. Drain openings are provided on all models. To drain the pump: 1. Remove drain plug and prime plug to vent the system. 2. Drain all piping to a point below the freeze line. DRAINING THE TANK Conventional tanks can be drained by opening an outlet at the lowest point in the system. Remove plug or the air volume control to vent the tank. Pre-charged tanks force virtually all the water from the tank when system pressure is released. No draining is necessary. RESTARTING PUMP If the pump has been serviced, drained or has not been used for some time, be sure there is water in the pump housing (volute) and the piping to the well. There must be water in the pump housing (volute) at all times when the pump is running to avoid internal damage of seal members (See Priming the Shallow Well or Priming the Deep Well Sections). WATERLOGGED TANKS: CONVENTIONAL When a tank system has an inadequate ratio of air and water, the pump will start and stop often and erratically. 1. Disconnect the power to the pump. 2. Open the lowest faucet in the system to release all pressurized water in the system. 3. Prime the pump (See Priming the Shallow Well or Priming the Deep Well Sections). 4. Reconnect the power to the pump. NOTE: As the pump refills the tank with water, the air volume control supplies the tank with the correct air to water ratio for the system to operate. If the air volume control is good, the pump will shut off at the desired cut-off and will be adjusted correctly. WATERLOGGED TANKS: PRE-CHARGED If a pre-charged tank becomes waterlogged, the bladder is normally leaking or broken. 1. Test the tank by depressing the air valve. The air valve will expel water if the bladder is broken. 2. Replace the tank. NOTE: Once an internal bladder is leaking or broken, the bladder cannot be repaired. The tank must be replaced. PRE-CHARGED TANK Some air is lost through the internal bladder in any tank. To prevent tank failure, check the tank pre-charge on a yearly basis. 1. Disconnect power to the pump 2. Open a faucet nearest the tank and allow all water to drain from the tank. 3. Measure the tank pre-charge at the valve stem using a tire gauge. 4. If necessary, adjust the pre-charge with an air pump psi on 1/2, 3/4 and 1 HP pumps. LUBRICATION The bearing used in the pumps are lifetime lubricated at the factory and require no additional lubrication. CWS REPAIR KIT 1. Disconnect power from the pump. 2. Open faucet nearest the tank and allow all of the water to drain from the tank and pump. 3. Remove 4 cap screws holding pump housing, do not disconnect pressure switch (Figure 12). 4. Remove pump housing from pump assembly, move it out of the way. 5. Using a 5/16 socket or flat blade screw drive remove the 2 screws from the diffuser on the pump assembly. 6. Remove the diffuser. 7. Remove the black plastic cap from the back of the motor, exposing the motor shaft end. 8. Using a large flat bladed screw driver hold the motor shaft while unscrewing the impeller. 9. Remove the seal plate. Pay attention to how the original shaft seal is installed before disassembly. 11

12 10. Remove the shaft seal from the impeller, make sure the stainless steel sleeve comes off the impeller, all you should see on the back of the impeller is the brass colored threaded insert (Figure 13). 11. Remove the ceramic seat and rubber boot part of the seal from the cast iron seal plate (Figure 13). 12. Remove the square cut gasket from the seal plate. 13. Reassemble the pump with new parts in reverse order. 14. Wipe down the seal plate to remove any debris or loose rust. 15. Push the ceramic seat of the shaft seal into the seal plate using the cardboard ring provided to keep the ceramic face clean. You can use a little water or dish soap to lubricate the seal pocket to make assembly easier. 16. Slide the square cut gasket over the flange on the seal plate, make sure not to let the gasket twist. 17. Carefully slip the seal plate over the shaft so as not to disturb seal position in the seal plate. The seal plate must be orientated during assembly so the two holes are on a horizontal line across the motor shaft (Figure 14). 18. Push the bellows side of the shaft seal over the impeller hub, you can use a little water or dish soap to lubricate the impeller hub to make assembly easier (Figure 15). Make sure after assembly the back carbon and white ceramic surfaces are in contact. 19. Holding the motor shaft with a flat blade screw driver thread the impeller onto the motor shaft, hand tighten. Lubricate the nose of the impeller with potable water safe lubricant. 20. Replace the plastic cap over the motor shaft end. 21. Reassemble the diffuser, make sure the arrow indicating the top is pointed toward the top of the pump, torque the two screws to 30 ±10 inch pounds. NOTES SEAL PLATE MOTOR IMPELLER SEAL PLATE SEAL SEAT SEAL FACING MUST BE CLEAN FOR PROPER SEAL Figure 15 - Motor Shaft 22. Using the (4) cap screws reattach the pump housing and base to the pump body. Torque the screws to 140 ±40 inch pounds. 23. Reattach the plumbing connections, reconnect the power and prime the pump (See section on priming the pump). After reassembling the pump check for leaks. If a leak is detected, repair before using the pump. 12

13 CWS Series (A) SPRING (B) LAKE, STREAM, POND SHALE (A) SPRING: A spring that emerges from the ground. Occurs when water in permeable materials is trapped between impermeable material as rock or clay. (B) LAKE, STREAM or POND: Surface water, unless treated, is usually not safe for human consumption. It may be used for purposes such as washing or irrigation. Figure 16 - Water Supplies WATER SUPPLIES (C) DUG WELL (D) DRIVEN WELL TOP SOIL CLAY PERMEABLE MATERIAL WATER BEARING SAND (C) DUG WELL: A hole is excavated several feet in diameter to a fairly shallow depth. It is then lined with brick, stone or concrete to prevent cave-in. (D) DRIVEN WELL: Pipe with a pointed screen is driven into the ground below the water table. The depth is usually less than 50 feet. Available diameters are 1" through 2". (E) DRILLED WELL (F) CISTERN WATER TABLE (E) DRILLED WELL: A hole bored into the earth with machinery and lined with pipe. Depths range from a few feet to over 1000 feet. Common well diameters are 2", 3", 4" and 6" for domestic water wells. (F) CISTERN: An underground tank built to collect rain water from rooftops. The water is not fit for human consumption. 13

14 TROUBLE SHOOTING CHART Symptom Possible Cause(s) Corrective Action Pump will not run 1. Power off 1. Turn power on or call power com pa ny 2. Blown fuse or tripped breaker 2. Replace fuse or reset circuit break er 3. Faulty pressure switch 3. Replace 30/50 pressure switch 4. Motor overload tripped 4. Let cool. Overload will automatically reset 5. Low supply voltage 5. Contact an electrician Motor hums but will not run 1. Line voltage does not match selector switch 1. Check voltage 2. Wiring too small 2. Rewire 3. Damage or misalignment causing rotating 3. Replace or take to service shop for re pair parts to bind 4. Low supply voltage 4. Contact an electrician Overload trips 1. Low supply voltage 1. Contact an electrician 2. Damage or misalignment causing rotating parts to bind 2. Take to motor repair shop or locate and repair mechanical binding 3. High surrounding temperature 3. Provide a shaded, well-ventilated area for pump 4. Rapid cycling 4. See Pump starts and stops too often sec tion 5. Inadequate wiring 5. Rewire Pump runs but delivers little or no water 1. Water level below pump intake 1. Lower suction pipe further into well Note: Check to make sure pump is properly 2. Control valve open too far (deep well) 2. Adjust control valve or repeat priming procedure. primed before looking for other causes. 3. Discharge not vented while priming 3. Open faucet, repeat priming pro ce dure Unscrew priming plug and see if water is in 4. Leaking in piping on well side of pump 4. Repair piping as needed priming hole. 5. Well screen or inlet strainer clogged 5. Clean or replace as necessary 6. Clogged nozzle (deep well) 6. Pull jet and clear obstruction 7. Air volume control diaphragm ruptured 7. Replace air volume control (See Page 7) 8. Foot valve may be clogged or stuck closed 8. Clean or replace as needed 9. Pump not fully primed 9. Continue priming, paus ing ev ery 5 min utes to cool pump body. Refill pump as need ed 10. Control valve completely closed (deep well) 10. Adjust control valve per deep well prim ing procedure (see page 8) 11. Water level below maximum lift spec i fi cation 11. Select applicable pump and/or jet as sem bly 12. Undersized piping 12. Replace as needed 13. Gaseous well 13. Install baffle on pump intake to pre vent gas from entering system 14. Distorted venturi 14. Inspect and replace 15. Incorrect jet assembly for application 15. Purchase a jet assembly matched to your sys tem when replacing another brand pump 16. Undersized pump 16. Increase horsepower of pump 17. Pump cavitates, (sounds like pumping gravel) 17. Increase suction plumbing diameter or decrease pipe friction 18. Low supply voltage 18. Contact an electrician Pump starts and stops too of ten 1. Water logged tank (conventional tank) 1. See waterlogged conventional tank on page Air volume control tubing kinked or clogged 2. Clean or replace as needed 3. Air volume control tubing connected to 3. Move to correct pump opening wrong opening on pump 4. Incorrect tank pre-charge (pre-charged tank) 4. Add or release air as needed 5. Ruptured diaphragm/bladder (pre-charged tank) 5. Replace tank 6. Leak in house piping 6. Locate and repair leak 7. Foot valve or check valve stuck open 7. Remove and replace 8. Motor overload tripping 8. See overload trips section 9. Faulty pressure switch 9. Replace 30/50 pressure switch 14

15 CWS Series For Replacement Parts or Customer Support, Call Please provide following information: - Model number - Serial number (if any) - Part description and number as shown in parts list Address parts correspondence to: Wayne Water Systems 101 Production Drive Harrison, OH U.S.A. 1 REPLACEMENT PARTS Ref. No. Description Models Qty. 1 (2) Square-Ring Gaskets, Impeller, Jet Pump Dissfuser, and Shaft Seal Assembly CWS50, CWS75, CWS WYN1 (CWS50) WYN1 (CWS75) WYN1 (CWS100) 2 30/50 Pressure Swtich Kit WYN1 (ALL MODELS) 1 1 JET ASSEMBLIES Description Vertical Distance (ft.) Part No. Qty. Jet Assemblies N/A WYN1 (CWS50, Shallow) WYN1 (CWS75, CWS100, Shallow) 2 Inch Casing Jet Assemblies WYN1 (ALL MODELS) Inch Casing Jet Assemblies WYN1 (ALL MODELS) 1 15

16 LIMITED WARRANTY For three years for CWS Series models from the date of purchase, from an authorized dealer, Wayne Water Systems will repair or replace, at its option for the original purchaser, any part or parts of its Well Pumps or Water Pumps ( Product ) found upon examination by Wayne Water Systems to be defective in materials or workmanship. Please call Wayne Water Systems ( ) for warranty instructions. Be prepared to provide the model number and the serial number when exercising this warranty. All transportation charges on Products or parts submitted for repair or replacement must be paid by purchaser. This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect, improper installation, improper maintenance, or failure to operate in accordance with Wayne Water Systems written instructions. THIS WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES, OBLIGATIONS OR AGREEMENTS, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, AND ANY RIGHTS OR REMEDIES AGAINST ANY PERSON OR ENTITY UNDER THE UNIFORM COMMERCIAL CODE OR OTHERWISE WITH RESPECT TO THE SALE OF THE PRODUCT. THE REMEDIES AND OBLIGATIONS STATED IN THIS WARRANTY ARE THE SOLE AND EXCLUSIVE REMEDIES OF AND OBLIGATIONS TO THE OWNER FOR ANY AND ALL MATTERS ARISING WITH RESPECT TO OR IN ANY WAY CONNECTED WITH THE PRODUCT, REGARDLESS OF THE SOURCE OR PROVIDER OF SUCH GOODS. IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT, WARRANTY TORT (INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL WAYNE WATER SYSTEMS OR ANY AFFILIATE BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES. You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST send a copy of the purchase receipt along with the material or correspondence. Please call Wayne Water Systems ( ) for return authorization and instructions. DO NOT MAIL THIS FORM TO Wayne Water Systems. Use this form only to maintain your records. MODEL NO. SERIAL NO. INSTALLATION DATE ATTACH YOUR RECEIPT HERE 16

Shallow Well Jet Pump Water Systems

Shallow Well Jet Pump Water Systems Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others

Shallow Well Jet Pump Water Systems Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others

Self-Priming* Portable Multi-Use Pump

Self-Priming* Portable Multi-Use Pump Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others

Self-Priming* Portable Multi-Use Pump Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others

SPA BLOWER OWNER'S MANUAL XXXX, XXXX, XXXX, XXXX, XXXX, XXXX fax

SPA BLOWER OWNER'S MANUAL 80015-XXXX, 80016-XXXX, 80017-XXXX, 80018-XXXX, 80019-XXXX, 80020-XXXX fax 888.610.3839 2015 323300-015 6/15 THIS PAGE INTENTIONALLY LEFT BLANK. 2 Operating Instructions and Parts

SPA BLOWER OWNER'S MANUAL 80015-XXXX, 80016-XXXX, 80017-XXXX, 80018-XXXX, 80019-XXXX, 80020-XXXX fax 888.610.3839 2015 323300-015 6/15 THIS PAGE INTENTIONALLY LEFT BLANK. 2 Operating Instructions and Parts

STOP. SAFETY INFORMATION Please read and understand this entire manual before attempting to assemble, operate or install the product.

STOP Power supply required Questions, problems, missing parts? Before returning to your retailer, call our customer service department at 1-800-742-5044, 7:30 a.m. - 5 p.m., EST, Monday - Friday. 115 volts

STOP Power supply required Questions, problems, missing parts? Before returning to your retailer, call our customer service department at 1-800-742-5044, 7:30 a.m. - 5 p.m., EST, Monday - Friday. 115 volts

HALLMARK INDUSTRIES INC. HALLMARK INDUSTRIES INC. Safety WARNING WARNING. Must reset the voltage! Shallow Well Jet Pumps

Safety Important Safety Instructions SAVE THESE INSTRUCTIONS - This manual contains important instructions that should be followed during installation, operation, and maintenance of the product. Save this

Safety Important Safety Instructions SAVE THESE INSTRUCTIONS - This manual contains important instructions that should be followed during installation, operation, and maintenance of the product. Save this

LC Series - Light Commercial Pump Station Installation and Operation Manual

LC Series - Light Commercial Pump Station Installation and Operation Manual Please keep this manual with the pump station Content Rain Bird LC Series Overview... Safety Instruction... Operation... 3 Pump

LC Series - Light Commercial Pump Station Installation and Operation Manual Please keep this manual with the pump station Content Rain Bird LC Series Overview... Safety Instruction... Operation... 3 Pump

Operating Instructions and Parts Manual MOTOR HOUSING MOTOR SHAFT IMPELLER VOLUTE PUMP DISCHARGE PERFORMANCE. Model Discharge Head Max Flow

Condensate Pump Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety

Condensate Pump Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety

OWNERS GUIDE TO INSTALLATION AND OPERATION

OWNERS GUIDE TO INSTALLATION AND OPERATION SPM SERIES HIGH POWER CENTRIFUGALS READ THESE INSTRUCTIONS CAREFULLY Read these installation instructions in detail before installing your pump. Be sure to check

OWNERS GUIDE TO INSTALLATION AND OPERATION SPM SERIES HIGH POWER CENTRIFUGALS READ THESE INSTRUCTIONS CAREFULLY Read these installation instructions in detail before installing your pump. Be sure to check

QUICK PRIME INSTALLATION AND SERVICE MANUAL

QUICK PRIME INSTALLATION AND SERVICE MANUAL NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part #

QUICK PRIME INSTALLATION AND SERVICE MANUAL NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part #

QUICK PRIME INSTALLATION AND SERVICE MANUAL

QUICK PRIME INSTALLATION AND SERVICE MANUAL NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part #

QUICK PRIME INSTALLATION AND SERVICE MANUAL NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part #

SELF-PRIMING CENTRIFUGAL PUMPS BMLS-M & BMLS-H

SELF-PRIMING CENTRIFUGAL PUMPS BMLS-M & BMLS-H INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS HP Phase Medium Head High Head 3 1 BMLS 300 M BMLS 300 H 3 3 BMLS 300 M3 BMLS 300 H3 5 1 BMLS 500 M BMLS

SELF-PRIMING CENTRIFUGAL PUMPS BMLS-M & BMLS-H INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS HP Phase Medium Head High Head 3 1 BMLS 300 M BMLS 300 H 3 3 BMLS 300 M3 BMLS 300 H3 5 1 BMLS 500 M BMLS

INSTALLATION & OPERATING INSTRUCTIONS

INSTALLATION & OPERATING INSTRUCTIONS WARNING RISK OF ELECTRIC SHOCK. CONNECT ONLY TO A CIRCUIT PROTECTED BY A GROUND-FAULT CIRCUIT-INTERRUPTER. THE UNIT SHOULD BE INSTALLED BY A QUALIFIED SERVICE REPRESENTATIVE.

INSTALLATION & OPERATING INSTRUCTIONS WARNING RISK OF ELECTRIC SHOCK. CONNECT ONLY TO A CIRCUIT PROTECTED BY A GROUND-FAULT CIRCUIT-INTERRUPTER. THE UNIT SHOULD BE INSTALLED BY A QUALIFIED SERVICE REPRESENTATIVE.

OWNER S MANUAL INSTALLATION AND OPERATING INSTRUCTIONS REPAIR PARTS LIST

OWNER S MANUAL INSTALLATION AND OPERATING INSTRUCTIONS REPAIR PARTS LIST SCX1740 SERIES CENTRIFUGAL PUMP High Head - Noryl Impellers MODELS Model ODP MOTORS TEFC MOTORS HP Number 115/230/60/1 20-230/460/60/3

OWNER S MANUAL INSTALLATION AND OPERATING INSTRUCTIONS REPAIR PARTS LIST SCX1740 SERIES CENTRIFUGAL PUMP High Head - Noryl Impellers MODELS Model ODP MOTORS TEFC MOTORS HP Number 115/230/60/1 20-230/460/60/3

LS Condensate Removal Pump Installation, Operation and Service Instructions

Bell & Gossett Instruction Manual 6-71-075-115 LS Condensate Removal Pump Installation, Operation and Service Instructions INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER S USE. WARNING: This safety

Bell & Gossett Instruction Manual 6-71-075-115 LS Condensate Removal Pump Installation, Operation and Service Instructions INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER S USE. WARNING: This safety

Installation Instructions

Installation Instructions 42" Island Vent Hood ZV1050 monogram.com 1 Safety Information BEFORE YOU BEGIN Read these instructions completely and carefully. Save these instructions for local inspector s

Installation Instructions 42" Island Vent Hood ZV1050 monogram.com 1 Safety Information BEFORE YOU BEGIN Read these instructions completely and carefully. Save these instructions for local inspector s

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS FOR THERMADOR BUILT-IN DISHWASHERS Models: DW244UB / DW244UW DW245UB / DW245UW DW246UB / DW246UW / DW246US DWI246UB / DWI246UW Please read this entire instruction manual before

INSTALLATION INSTRUCTIONS FOR THERMADOR BUILT-IN DISHWASHERS Models: DW244UB / DW244UW DW245UB / DW245UW DW246UB / DW246UW / DW246US DWI246UB / DWI246UW Please read this entire instruction manual before

IMpORTANT SAFETy INSTRUcTIONS

Table of contents SAFETy SETUp OpERATION MAINTENANcE Safety... 2 Specifications... 4 Setup... 4 Operation... 6 WARNING SyMBOLS AND DEFINITIONS Maintenance... 9 Parts List and Diagram... 10 Warranty...

Table of contents SAFETy SETUp OpERATION MAINTENANcE Safety... 2 Specifications... 4 Setup... 4 Operation... 6 WARNING SyMBOLS AND DEFINITIONS Maintenance... 9 Parts List and Diagram... 10 Warranty...

568X, 587X, 588X Series

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

SMF PUMP OWNER S MANUAL

SMF PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

SMF PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

Installation Instructions

Installation Instructions If you have questions, call 800.626.2000 or visit our website at: www.monogram.com Automatic Icemaker ZDI15 ZDIS15 Design Guide with BEFORE YOU BEGIN Read these instructions completely

Installation Instructions If you have questions, call 800.626.2000 or visit our website at: www.monogram.com Automatic Icemaker ZDI15 ZDIS15 Design Guide with BEFORE YOU BEGIN Read these instructions completely

Elite Primer Baldor Series External Pond Pump

Elite Primer Baldor Series External Pond Pump ( 5250PPB21, 6440PPB23, 7550PPB26, 9600PPB28) Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS, READ AND FOLLOW ALL INSTRUCTIONS. SAVE THESE INSTRUCTIONS

Elite Primer Baldor Series External Pond Pump ( 5250PPB21, 6440PPB23, 7550PPB26, 9600PPB28) Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS, READ AND FOLLOW ALL INSTRUCTIONS. SAVE THESE INSTRUCTIONS

Installation Instructions

Installation Instructions If you have questions, call 800.626.2000 or visit our website at: www.monogram.com Automatic Icemaker ZDI15 ZDIS15 Design Guide with Installation Instructions Installation Instructions

Installation Instructions If you have questions, call 800.626.2000 or visit our website at: www.monogram.com Automatic Icemaker ZDI15 ZDIS15 Design Guide with Installation Instructions Installation Instructions

INSTRUCTION BOOK FOR. Professional Electrol

INSTRUCTION BOOK FOR Professional Electrol Important Safety Instructions When using your video equipment, basic safety precautions should always be followed, including the following: 1. Read and understand

INSTRUCTION BOOK FOR Professional Electrol Important Safety Instructions When using your video equipment, basic safety precautions should always be followed, including the following: 1. Read and understand

WARNING. Pro Pack Portable Spray Pack 3A1292C. Operation. Model 24F893 Maximum Working Pressure 12 psi (0.83 bar, MPa)

Operation Pro Pack Portable Spray Pack - For use with Graco hand-held sprayers (except Fine-Finish sprayers) - - For portable spray applications of water-based and oil-based (mineral spirit-type) architectural

Operation Pro Pack Portable Spray Pack - For use with Graco hand-held sprayers (except Fine-Finish sprayers) - - For portable spray applications of water-based and oil-based (mineral spirit-type) architectural

Installation and Operating Instructions

Installation and Operating Instructions WaterQuick Pro II Advanced - Hot Water Circulation Pump WaterQuick Pro II Advanced Step 1. Choose the appropriate place to install the pump and Flow Monitor: WaterQuick

Installation and Operating Instructions WaterQuick Pro II Advanced - Hot Water Circulation Pump WaterQuick Pro II Advanced Step 1. Choose the appropriate place to install the pump and Flow Monitor: WaterQuick

"S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S12 S16

Webster Pumps "S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S12 S16 PLEASE READ THE FOLLOWING INFORMATION PRIOR TO INSTALLING AND USING Webster PUMPS or HAYWARD VALVES,

Webster Pumps "S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S12 S16 PLEASE READ THE FOLLOWING INFORMATION PRIOR TO INSTALLING AND USING Webster PUMPS or HAYWARD VALVES,

CHAMPION PUMP OWNER S MANUAL

CHAMPION PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

CHAMPION PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

WATLOW IND. WATROD Circulation Heater Installation & Maintenance Manual I&M NUMBER: Page: 1 Date: 6/11/2008 Rev: 2.00

I&M NUMBER: 316-42-5-1 Page: 1 Pre Installation Check to make sure that heater received is the same as that ordered. Watlow heaters are built to comply with UL and CSA dielectric requirements, it may be

I&M NUMBER: 316-42-5-1 Page: 1 Pre Installation Check to make sure that heater received is the same as that ordered. Watlow heaters are built to comply with UL and CSA dielectric requirements, it may be

55-Gallon Dispenser Package

INSTRUCTIONS-PARTS LIST INSTRUCTIONS This manual contains important warnings and information. READ AND KEEP FOR REFERENCE. 308 666 Rev. A Husky 715 55-Gallon Dispenser Package 100 psi (6.9 bar) Maximum

INSTRUCTIONS-PARTS LIST INSTRUCTIONS This manual contains important warnings and information. READ AND KEEP FOR REFERENCE. 308 666 Rev. A Husky 715 55-Gallon Dispenser Package 100 psi (6.9 bar) Maximum

K Series (Model A) Fan Forced Wall Heaters

(400mm) 15-3/4" (35mm) 1-3/8" (95mm) 3-3/4" K Series (Model A) Fan Forced Wall Heaters (485mm) 19-1/8" (463mm) 18-1/4" FILE #E21609 Installation & Maintenance Instructions Dear Owner, Congratulations Thank

(400mm) 15-3/4" (35mm) 1-3/8" (95mm) 3-3/4" K Series (Model A) Fan Forced Wall Heaters (485mm) 19-1/8" (463mm) 18-1/4" FILE #E21609 Installation & Maintenance Instructions Dear Owner, Congratulations Thank

CHUGGER PUMP Chugger Max Models

CHUGGER PUMP Chugger Max Models CHUGGER PUMP is a home brew beer pump designed to transfer hot and cold liquids between brewing vessels. FDA Compliant Materials. Components are UL Recognized. Note: NOT

CHUGGER PUMP Chugger Max Models CHUGGER PUMP is a home brew beer pump designed to transfer hot and cold liquids between brewing vessels. FDA Compliant Materials. Components are UL Recognized. Note: NOT

Use & Care Manual. Electric Tankless Water Heaters. With Installation Instructions for the Installer AP15447 (10/10)

Use & Care Manual With Installation Instructions for the Installer Electric Tankless Water Heaters The purpose of this manual is twofold: one, to provide the installer with the basic directions and recommendations

Use & Care Manual With Installation Instructions for the Installer Electric Tankless Water Heaters The purpose of this manual is twofold: one, to provide the installer with the basic directions and recommendations

Installation & Operating Guide

5-036 HOT WATER TANK Installation & Operating Guide Read all instructions thoroughly. Keep this guide for future reference. Proof of purchase is required for Warranty. Staple receipt or proof of purchase

5-036 HOT WATER TANK Installation & Operating Guide Read all instructions thoroughly. Keep this guide for future reference. Proof of purchase is required for Warranty. Staple receipt or proof of purchase

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning

SM-909/SM /2" Sweat 3/4" Sweat 3 3/8" F.L. Max. Max. Line Weight Model No. HP Inlet/Outlet Volts Amps Fluid Temp. Pressure (Lbs.

Installation & Operating Manual Please read this manual carefully before attempting to install, operate or maintain the product described. Failure to comply with the information provided in this manual

Installation & Operating Manual Please read this manual carefully before attempting to install, operate or maintain the product described. Failure to comply with the information provided in this manual

K Specifications. Max. Water Volume

K 2.35 High Pressure Washer Operator Manual Overview... 2 Precautions... 2-4 Assembly Instructions... 4 Operating Instructions... 5 Using the Accessories... 6 Working with Detergents... 7 Shut Down and

K 2.35 High Pressure Washer Operator Manual Overview... 2 Precautions... 2-4 Assembly Instructions... 4 Operating Instructions... 5 Using the Accessories... 6 Working with Detergents... 7 Shut Down and

K Specifications. Max. Water Volume

K 2.75 High Pressure Washer Operator Manual Overview... 2 Precautions... 2-4 Assembly Instructions... 4 Operating Instructions... 5 Using the Accessories... 6 Working with Detergents... 7 Shut Down and

K 2.75 High Pressure Washer Operator Manual Overview... 2 Precautions... 2-4 Assembly Instructions... 4 Operating Instructions... 5 Using the Accessories... 6 Working with Detergents... 7 Shut Down and

569, 570, 571, 572 Series

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

OWNER S MANUAL INSTALLATION, OPERATION, & PARTS SAVE THIS INSTRUCTION MANUAL

OWNER S MANUAL INSTALLATION, OPERATION, & PARTS 72729 To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. SAVE THIS INSTRUCTION MANUAL Use of

OWNER S MANUAL INSTALLATION, OPERATION, & PARTS 72729 To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completely. SAVE THIS INSTRUCTION MANUAL Use of

INSTALLATION INSTRUCTION In-Ground

SAFETY INSTRUCTION IMPORTANT: NEVER attempt any work without shutting off the electricity. Read all instructions before installing. System is intended for installation by a qualified electrician in accordance

SAFETY INSTRUCTION IMPORTANT: NEVER attempt any work without shutting off the electricity. Read all instructions before installing. System is intended for installation by a qualified electrician in accordance

2 INLET / HIGH HEAD DRAIN PUMP SYSTEMS MODELS , INSTALLATION INSTRUCTIONS PREINSTALLATION CHECKLIST

Your Peace of Mind is Our Top Priority Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies. MAIL TO: P.O. BOX 637 Louisville,

Your Peace of Mind is Our Top Priority Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies. MAIL TO: P.O. BOX 637 Louisville,

INSTALLATION INSTRUCTION In-Ground Color Changing

SAFETY INSTRUCTION IMPORTANT: NEVER attempt any work without shutting off the electricity. Read all instructions before installing. System is intended for installation by a qualified electrician in accordance

SAFETY INSTRUCTION IMPORTANT: NEVER attempt any work without shutting off the electricity. Read all instructions before installing. System is intended for installation by a qualified electrician in accordance

IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS. Table of Contents WARNING.

Eagle Pump Owners Manual IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Table of Contents SECTION I. INSTALLATION... 2 SECTION II. OPERATION & MAINTENANCE... 2 SECTION

Eagle Pump Owners Manual IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Table of Contents SECTION I. INSTALLATION... 2 SECTION II. OPERATION & MAINTENANCE... 2 SECTION

INSTRUCTION BOOK FOR. Senior Electrol

INSTRUCTION BOOK FOR Senior Electrol Important Safety Instructions When using your video equipment, basic safety precautions should always be followed, including the following: 1. Read and understand all

INSTRUCTION BOOK FOR Senior Electrol Important Safety Instructions When using your video equipment, basic safety precautions should always be followed, including the following: 1. Read and understand all

OPERATION MANUAL Dated: 04/09/2018 Document Name: SHV _OM Page 1 of 8. Ion Technologies SHV40, 75 & 100 Sewage Ejector Pump SAFETY WARNINGS

Ion Technologies SHV40, 75 & 100 Sewage Ejector Pump Page 1 of 8 biohazard risk exists. Installer(s) and/or service personnel must use proper Personal Protective Equipment and follow handling procedures

Ion Technologies SHV40, 75 & 100 Sewage Ejector Pump Page 1 of 8 biohazard risk exists. Installer(s) and/or service personnel must use proper Personal Protective Equipment and follow handling procedures

569, 570, 571, 572 Series

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Installation Instructions If you have questions, call 800-GE-CARES or visit our website at:

Installation Instructions If you have questions, call 800-GE-CARES or visit our website at: www.monogram.com 30" Convection Built-In Ovens Models: ZET1038 ZET1058 Monogram. We bring good things to life.

Installation Instructions If you have questions, call 800-GE-CARES or visit our website at: www.monogram.com 30" Convection Built-In Ovens Models: ZET1038 ZET1058 Monogram. We bring good things to life.

7 1/4" 3 3/8" Pump Max. Max. Line Weight Model No. HP Housing Inlet/Outlet Fluid Temp. Pressure (Lbs.)

Installation & Operating Manual Please read this manual carefully before attempting to install, operate or maintain the product described. Failure to comply with the information provided in this manual

Installation & Operating Manual Please read this manual carefully before attempting to install, operate or maintain the product described. Failure to comply with the information provided in this manual

ChemScan mini Analyzer for Low Ammonia Monitoring Installation, Operation and Maintenance Manual

ChemScan mini Analyzer for Low Ammonia Monitoring Installation, Operation and Maintenance Manual asaanalytics.com ChemScan mini Low Ammonia Analyzer O&M Manual - Rev 223K TABLE OF CONTENTS ANALYZER DESCRIPTION

ChemScan mini Analyzer for Low Ammonia Monitoring Installation, Operation and Maintenance Manual asaanalytics.com ChemScan mini Low Ammonia Analyzer O&M Manual - Rev 223K TABLE OF CONTENTS ANALYZER DESCRIPTION

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR PUMP 88 PUMP PARTS BREAKDOWN REF # Order # Mfr # Description 1 NEP4 AC 348 Lid Knobs NEP AC 380 Strainer Lid 3 NEP6

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR PUMP 88 PUMP PARTS BREAKDOWN REF # Order # Mfr # Description 1 NEP4 AC 348 Lid Knobs NEP AC 380 Strainer Lid 3 NEP6

"S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S2 S4 S5 SS6 SS7 S8

Webster Pumps "S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S2 S4 S5 SS6 SS7 S8 PLEASE READ THE FOLLOWING INFORMATION PRIOR TO INSTALLING AND USING Webster PUMPS or HAYWARD

Webster Pumps "S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S2 S4 S5 SS6 SS7 S8 PLEASE READ THE FOLLOWING INFORMATION PRIOR TO INSTALLING AND USING Webster PUMPS or HAYWARD

IMpORTANT SAFETy INSTRUcTIONS

Table of contents SAFETy SETUp OpERATION MAINTENANcE Safety... 2 Specifications... 4 Setup... 4 Operating Instructions... 6 WARNING SyMBOLS AND DEFINITIONS Maintenance... 9 Parts List and Diagram... 11

Table of contents SAFETy SETUp OpERATION MAINTENANcE Safety... 2 Specifications... 4 Setup... 4 Operating Instructions... 6 WARNING SyMBOLS AND DEFINITIONS Maintenance... 9 Parts List and Diagram... 11

INSTANT HOT WATER DISPENSER

INSTANT HOT WATER DISPENSER Tank Installation Materials required (not provided) 2 mounting bracket screws (and 2 plastic anchors if attaching to drywall) Shut-Off valve and T fitting Components When you

INSTANT HOT WATER DISPENSER Tank Installation Materials required (not provided) 2 mounting bracket screws (and 2 plastic anchors if attaching to drywall) Shut-Off valve and T fitting Components When you

! The Caution Symbol (exclamation point) alerts you to a "CAUTION", a safety or

I&M NUMBER: 316-42-10-1 Page: 1 Pre Installation Check to make sure that heater received is the same as that ordered. Elements may come in contact with each other during shipment. Minor adjustments to

I&M NUMBER: 316-42-10-1 Page: 1 Pre Installation Check to make sure that heater received is the same as that ordered. Elements may come in contact with each other during shipment. Minor adjustments to

OWNER S MANUAL FOR AIR ADMIRAL VACUUM/PRESSURE STATION MODELS:

OWNER S MANUAL FOR AIR ADMIRAL VACUUM/PRESSURE STATION MODELS: 79202-00 79202-05 79202-30 79202-35 Approval Agency s Model 79202-00 & 79202-05 Model 79202-30 & 79202-35 Not recommended for pumping acid,

OWNER S MANUAL FOR AIR ADMIRAL VACUUM/PRESSURE STATION MODELS: 79202-00 79202-05 79202-30 79202-35 Approval Agency s Model 79202-00 & 79202-05 Model 79202-30 & 79202-35 Not recommended for pumping acid,

Patterson/AMT Inline Circulator Pump Refer to pump manual for General Operating and Safety Instructions.

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

AGA TOTAL CONTROL. Model No. - TC3

AGA TOTAL CONTROL Model No. - TC3 Installation Guide REMEMBER: when replacing a part on this appliance, use only replacement parts that you can be assured conform to the safety and performance specification

AGA TOTAL CONTROL Model No. - TC3 Installation Guide REMEMBER: when replacing a part on this appliance, use only replacement parts that you can be assured conform to the safety and performance specification

200i User s information manual

M2i-UM-1 WARNING: If the information in this manual is not followed exactly, a fire or explosion may result, causing property damage, personal injury or loss of life. Cast iron condensing boiler 200i User

M2i-UM-1 WARNING: If the information in this manual is not followed exactly, a fire or explosion may result, causing property damage, personal injury or loss of life. Cast iron condensing boiler 200i User

Installation Manual CARBONATOR With Plain-Water Booster

CORNELIUS INC One Cornelius Place Anoka, MN 55303-6234 Telephone (800) 238-3600 Facsimile (763) 422-3246 Installation Manual CARBONATOR With Plain-Water Booster IMPORTANT: It is the responsibility of the

CORNELIUS INC One Cornelius Place Anoka, MN 55303-6234 Telephone (800) 238-3600 Facsimile (763) 422-3246 Installation Manual CARBONATOR With Plain-Water Booster IMPORTANT: It is the responsibility of the

Instant Hot Water Dispenser Owner s Manual

Model Hot1 Instant Hot Water Dispenser Owner s Manual Installation, Care & Use Instalacion, cuidado & uso Installation, soin et utilisation WHAT YOU SHOULD KNOW BEFORE YOU BEGIN For your satisfaction and

Model Hot1 Instant Hot Water Dispenser Owner s Manual Installation, Care & Use Instalacion, cuidado & uso Installation, soin et utilisation WHAT YOU SHOULD KNOW BEFORE YOU BEGIN For your satisfaction and

Installation & Operating Guide

HOT WATER DISPENSER Installation & Operating Guide Read all instructions thoroughly. Keep this guide for future reference. Proof of purchase is required for Warranty. Staple receipt or proof of purchase

HOT WATER DISPENSER Installation & Operating Guide Read all instructions thoroughly. Keep this guide for future reference. Proof of purchase is required for Warranty. Staple receipt or proof of purchase

O w n e r s M a n u a l

Owner s Manual 2 CONTENTS Getting Started Important Safety Instructions... 2 Polarization Instructions... 3 Description of the Vacuum... 4 Operation Turning the Vacuum On... 5 Hose Cleaning... 5 Cleaning

Owner s Manual 2 CONTENTS Getting Started Important Safety Instructions... 2 Polarization Instructions... 3 Description of the Vacuum... 4 Operation Turning the Vacuum On... 5 Hose Cleaning... 5 Cleaning

GE Monogram. Automatic. Icemaker. Installation Instructions. Models ZDI15 ZDIS15. monogram.com

GE Monogram Automatic Icemaker Installation Instructions Models ZDI15 ZDIS15 monogram.com Before you begin Read these instructions completely and carefully. IMPORTANT - Save these instructions for local

GE Monogram Automatic Icemaker Installation Instructions Models ZDI15 ZDIS15 monogram.com Before you begin Read these instructions completely and carefully. IMPORTANT - Save these instructions for local

ECONO FLO VSA 165 VARIABLE SPEED PUMP OWNER S MANUAL

ECONO FLO VSA 165 VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all

ECONO FLO VSA 165 VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all

K 3.97 M. Specifications or visit our website: In USA call: Part No

K 3.97 M High Pressure Washer Operator Manual Overview... 2 Precautions... 2-4 Assembly Instructions... 4-5 Operating Instructions... 5-6 GFCI Instructions... 6 Using the Accessories... 6 Working with

K 3.97 M High Pressure Washer Operator Manual Overview... 2 Precautions... 2-4 Assembly Instructions... 4-5 Operating Instructions... 5-6 GFCI Instructions... 6 Using the Accessories... 6 Working with

MODEL: LSS-280

5300467 MODEL: LSS-280 200 Gallon Skid Sprayer Assembly / Operation Instructions / Parts Your authorized dealer is the best source of replacement parts and service. To obtain prompt, efficient service,

5300467 MODEL: LSS-280 200 Gallon Skid Sprayer Assembly / Operation Instructions / Parts Your authorized dealer is the best source of replacement parts and service. To obtain prompt, efficient service,

Specifications Information and Repair Parts Manual 316A-95, 316B-95, 393A-95, 393B A-95 thru 394D-95, 399A-95

Specifications Information and Repair Parts Manual 316A-95, 316B-95, 393A-95, 393B-95 394A-95 thru 394D-95, 399A-95 Please read and save this Repair Parts Manual. Read this manual and the General Operating

Specifications Information and Repair Parts Manual 316A-95, 316B-95, 393A-95, 393B-95 394A-95 thru 394D-95, 399A-95 Please read and save this Repair Parts Manual. Read this manual and the General Operating

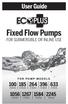

User Guide. Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE FOR PUMP MODELS # # # # # # # # #728333

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

WET/DRY VACUUM. QUEST for Continuous Improvement Windsor s Quality Management System is Certified ISO MODEL: T1. Operating Instructions (ENG)

WET/DRY VACUUM Operating Instructions (ENG) MODEL: T1 y QUEST for Continuous Improvement Windsor s Quality Management System is Certified ISO 9001. Read these instructions before operating the machine.

WET/DRY VACUUM Operating Instructions (ENG) MODEL: T1 y QUEST for Continuous Improvement Windsor s Quality Management System is Certified ISO 9001. Read these instructions before operating the machine.

Register at

Power Shovel Model No. 38361 Serial No. 313000001 and Up Register at www.toro.com. If, after carefully reading this manual, you still have questions or problems, call toll free 1-800-808-2963 (US) or 1-800-808-3072

Power Shovel Model No. 38361 Serial No. 313000001 and Up Register at www.toro.com. If, after carefully reading this manual, you still have questions or problems, call toll free 1-800-808-2963 (US) or 1-800-808-3072

Installation & Operation Manual. AromaFlo. mr.steam. Feel Good Inc.

Installation & Operation Manual AromaFlo Feel Good Inc. WARNING Risk of electric shock - This pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electric

Installation & Operation Manual AromaFlo Feel Good Inc. WARNING Risk of electric shock - This pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electric

Turbo Stick Vac. OWNER S MANUAL Model EP V., 60Hz., 7.5 Amps.

OWNER S MANUAL Model EP600 120V., 60Hz., 7.5 Amps. Turbo Stick Vac For information or assistance: EURO-PRO Operating LLC 94 Main Mill Street, Door 16 Plattsburgh, NY 12901 Tel.: 1 866 98SHARK (74275) www.sharkvac.com

OWNER S MANUAL Model EP600 120V., 60Hz., 7.5 Amps. Turbo Stick Vac For information or assistance: EURO-PRO Operating LLC 94 Main Mill Street, Door 16 Plattsburgh, NY 12901 Tel.: 1 866 98SHARK (74275) www.sharkvac.com

Plastic Housing Plastic Housing Stainless Housing SM /8" 3 3/8"

Installation & Operating Manual Please read this manual carefully before attempting to install, operate or maintain the product described. Failure to comply with the information provided in this manual

Installation & Operating Manual Please read this manual carefully before attempting to install, operate or maintain the product described. Failure to comply with the information provided in this manual

Technical Data TYPE T14 & T14D TEMPERATURE PILOT SPENCE ENGINEERING COMPANY, INC. 150 COLDENHAM ROAD, WALDEN, NY SD 4511A T14 PILOT

Technical Data SD 4511A SPENCE ENGINEERING COMPANY, INC. 150 COLDENHAM ROAD, WALDEN, NY 12586-2035 TYPE T14 & T14D TEMPERATURE PILOT PRINTED IN U.S.A. SD 4511A/9811 5 13 /16 D 4 7 /8 1 13 /16 T14 PILOT

Technical Data SD 4511A SPENCE ENGINEERING COMPANY, INC. 150 COLDENHAM ROAD, WALDEN, NY 12586-2035 TYPE T14 & T14D TEMPERATURE PILOT PRINTED IN U.S.A. SD 4511A/9811 5 13 /16 D 4 7 /8 1 13 /16 T14 PILOT

Patterson/AMT Inline Circulator Pump Refer to pump manual for General Operating and Safety Instructions.

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

K 2.90 M. Specifications Operating pressure, max PSI Water volume GPM Voltage V Amp draw AMPS

K 2.90 M High Pressure Washer Operator Manual Overview... 2 Important Precautions... 3-4 Assembly Instructions... 4 Operating Instructions... 5 GFCI Instructions... 6 Using the Accessories... 6 Working

K 2.90 M High Pressure Washer Operator Manual Overview... 2 Important Precautions... 3-4 Assembly Instructions... 4 Operating Instructions... 5 GFCI Instructions... 6 Using the Accessories... 6 Working

2 SPEED PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR 2 SPEED PUMP

2 SPEED PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR 2 SPEED PUMP 8308 PUMP PARTS BREAKDOWN Ref # Part # Manf. # Descrip on 1 NEP2134 AC 81361 PUMP LID 2 NEP2135 AC 81396 PUMP LID

2 SPEED PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR 2 SPEED PUMP 8308 PUMP PARTS BREAKDOWN Ref # Part # Manf. # Descrip on 1 NEP2134 AC 81361 PUMP LID 2 NEP2135 AC 81396 PUMP LID

Models Series Series

Models 3180-Series 3181-Series INDUSTRIAL DIAPHRAGM PUMPS Commercial Duty, 3 GPM/1 LPM FEATURES Sealless Easy Installation Run Dry Ability Flow to 3 GPM/1 LPM Self-Priming Low Amp Draw Thermal Overload

Models 3180-Series 3181-Series INDUSTRIAL DIAPHRAGM PUMPS Commercial Duty, 3 GPM/1 LPM FEATURES Sealless Easy Installation Run Dry Ability Flow to 3 GPM/1 LPM Self-Priming Low Amp Draw Thermal Overload

BG6UL. 6 Inch Bench Grinder Assembly & Operating Instructions

BG6UL 6 Inch Bench Grinder Assembly & Operating Instructions READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. This manual provides important information

BG6UL 6 Inch Bench Grinder Assembly & Operating Instructions READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. This manual provides important information

READ MANUAL BEFORE OPERATING SYSTEM Read the owner s manual thoroughly before operating to ensure the most efficient use of the system.