Instructions for installation and use English. More documents on: H B /09

|

|

|

- Hortense Small

- 6 years ago

- Views:

Transcription

1 TM Instructions for installation and use English EN More documents on: H B /09

2 Read this manual carefully before installing, maintaining or repairing this appliance! The symbol indicates important information that must be taken into consideration in order to avoid risk of harm to persons or damage to the appliance. The symbol indicates useful information. Warnings As part of a continuous improvement process our products may be modified without prior notice. For exclusive use as a circulation/filtration pump for swimming pools. Must not be used for any other purposes. The appliance must be installed by a qualified technician in compliance with the manufacturer s instructions and with applicable local standards. The installer is responsible for installation of the equipment and for compliance with national installation regulations. Under no circumstances shall the manufacturer be held liable in the event of failure to comply with applicable national installation regulations. The equipment must be connected to a circuit breaker. This circuit breaker must be connected fixed to the equipment and in accordance with current standards in the country where the equipment is installed. Wrong installation may cause serious damage to property or serious injuries (possibly causing death). It is important that this equipment is operated by competent and qualified (both physically and mentally) people who have previously received the instructions for use (by reading this manual). Any person not meeting these criteria should not go near the equipment, due to the risk of electric shock or other risk resulting in equipment damage or serious injury, possibly death. If the appliance suffers a malfunction: do not try to repair the appliance yourself, contact your installer. Before carrying out any operations on the equipment, disconnect the power supply and make sure that the equipment is powered down. Failure to respect these instructions may lead to a risk of electric shock and cause serious injury or even death. Before carrying out any operations, check that: The voltage indicated on the maker's plate of the appliance corresponds to the mains voltage, The power supply network is suitable for the use of the exchanger and that it is earthed. Removing or bypassing one of the safety devices automatically voids the guarantee, as does fitting replacement parts not sold by Zodiac. Keep the appliance out of the reach of children. This pump is compatible with all types of water treatment used in a swimming pool. Refer to the Zodiac warranty conditions for details of the permitted water balance values. Never run the pump dry or out of the water (this will invalidate the warranty) 1 H B - EN

3 Contents 1. Information before installing General delivery terms and conditions Contents Technical specifications Installation Selecting the location Positioning the equipment Hydraulic connections Electric connections Use User interface presentation Checks before starting up Start the appliance Use and configuration of the user interface Maintenance Maintenance instructions Wintering Recycling...7 EN 5. Troubleshooting Error codes Equipment malfunction Registering the product... 8 Available in the appendices at the end of this manual: Dimensions Description Performance curves CE declaration of conformity H B - EN

4 1. Information before installing 1.1 General delivery terms and conditions All equipment, even postage and packing paid, travels at the risks and perils of the recipient. Written reserves should be made on the transporter s delivery documents if damage during transport is discovered by the recipient (confirmed by registered letter to the transporter within 48 hours). 1.2 Contents FloPro e3 x1 1.3 Technical specifications Power supplied: 1.0 HP W Mains power supply: 230 Vac - 50 Hz Operation from 1000 to 2850 rpm (set in ranges of 50 rpm) Number of programmable speeds: 3 Maximum rate at 8 metres from a water column: 18 m³/h Operating temperatures: from 2 to 50 C air and 2 to 35 C water Protection index: IPX5 2. Installation Ø63/50 mm union couplings x2 2.1 Selecting the location The pump must be installed: before the filter, a heating and/or water treatment system, at a minimum distance of 3.5 metres from the edge of the pool, to avoid any water being sprayed onto the equipment. Some standards allow for other distances. Refer to the regulations in effect in the country of installation. ideally 30 cm below the water level, out of an area subject to flooding, or on a base with drainage, in a ventilated space to enable it to cool down. The pump must not be installed: in an area subject to splashing or rain. more than 1 m above the water level. near a heat source or flammable gas. Fit a non-return valve if the filter is installed above the water level. Fit suction and discharge isolation valves if the pump is installed below the water level. Easy access is required for maintenance work on the equipment. Use as few elbow joints as possible. 2.2 Positioning the equipment Place on a stable, solid (e.g. concrete floor) and level surface. If necessary, use the bases (2 types of base, not supplied, available as an option) to raise the pump to the level of the existing pipes. Screw the pump to the ground using the adapted foundation bolt. 3 H B - EN

5 2.3 Hydraulic connections 1: pump 2: filter 3: heating system 4: water treatment system Respect the hydraulic connection direction (see $ "Dimensions" in the appendix). Pipes Maximum suction rate at 1.8 metres/second Maximum discharge rate at 2.4 metres/second Ø50 mm 14 m³/h 19 m³/h Ø 63 mm 20 m³/h 27 m³/h Choose the dimension of the pipes according to the size of the pool and respecting the hydraulic rules which apply in the installation country. Performance curves are available in the appendix for the pipe dimensions. The use of suction and discharge union couplings is recommended to facilitate operations on the equipment (the pump intake and output are threaded by 2" on the interior). If there need to be more than 10 elbow joints on the hydraulic circuit, increase the pipe diameter. Avoid high points to simplify priming. Check that the hydraulic corrections are correctly tightened and that there are no leaks. The pipes must be supported to prevent any risk of breakage due to the weight of water. 2.4 Electric connections Risk of electric shock inside the equipment may cause serious injury or even death. Only a qualified and experienced technician is authorised to carry out cabling in the equipment. The equipment must be connected to an earth socket. Any unsuitable electrical connection will invalidate the warranty. Incorrectly tightened terminals may cause the terminal unit to heat up and invalidate the warranty. If the supply cable is damaged, it must be replaced by a qualified technician Voltage and protection Electrical protection: by circuit breaker (D curve), with a 30 ma dedicated differential circuit breaker (circuit breaker or switch) at the head of the line. The equipment and the swimming pool and any other electrical equipment must be connected to the Earth. Acceptable variation in voltage: +/-10% (during operation) Power supply and clock Connect the pump to the 230 Vac relay downstream of the swimming pool electrical cabinet's filtration clock. The filtration unit clock directly controls the pump's electricity supply, which then starts with the selected speed. EN H B - EN

6 2.4.3 Connecting the motor's power supply Open the electrical cabinet by unscrewing the 3 screws on the user interface and tilting it to the side (pay attention to the wires underneath). Run the supply cable through the gland and connect it to the (earth) and L-N terminals: Close the unit again, making sure that the seal is correctly in place. Power supply cable section: provided for information purposes for a maximum length of 45 metres (calculation base: NFC15-100), must be checked and adapted to the installation conditions and standards of the installation country. Electrical characteristics: Maximum absorbed intensity Cable cross-section Electrical protection Voltage A mm² Type A 230V-50Hz 4.8 3x1.5 3G Use 3.1 User interface presentation Symbol Key LED Key LED Key LED Designation "ECO" speed activation Speed reduction in setting mode Flashing: in priming mode (approx. 2 minutes on start-up) Fixed: speed in operation "CLEAN" speed activation Recording of the current setting (press for 10 seconds) Flashing: in priming mode (approx. 2 minutes on start-up) Fixed: speed in operation "BOOST" speed activation Speed increase in setting mode Flashing: in priming mode (approx. 2 minutes on start-up) Fixed: speed in operation Key Shutdown of the speed during operation LED Flashing: pump stopped, powered up Fixed: pump in operation LED The number of flashes indicates the error in progress 3.2 Checks before starting up Check that the hydraulic connections are correctly tightened. Check that the pump is stable, level and flush. The electricity supply cable must be insulated against any cutting or hot elements that may damage it. The hydraulic circuit must be bled and not contain any foreign bodies. The pump pre-filter strainer cover must be correctly closed (by hand) and its seal clean and in place. Check that the valves are open. To prevent against any risk of explosion that may cause material damage, serious injury or even death, make sure that the hydraulic circuit is free of any debris or blockage and is not subject to excessive pressure. Never run the pump "dry" as this may damage it. The pre-filter strainer cover must be closed by hand (do not use any tools). 3.3 Start the appliance Start a speed, the pump always starts in "priming" mode (2850 rpm for approx. 2 minutes). The pump is self-priming. However, you are strongly recommended to fill the pre-filter strainer with water before starting it up for the first time to facilitate the procedure. Bleed any air present in the filtration circuit using the bleed normally present on the filter (refer to the swimming pool filter's manual). Check that there are no leaks on the hydraulic circuit. The pump has a priming capacity up to 3 metres above the swimming pool water level (if the hydraulic circuit is perfectly sealed). 5 H B - EN

7 3.4 Use and configuration of the user interface Speed Keys to start the speed Default speed "ECO" speed 1400 rpm "CLEAN" speed 2150 rpm "BOOST" speed 2850 rpm When the pump is running, it displays the operating speed and an LED lights up above the key which corresponds to the speed. If the mains supply is disconnected (manually or via the filtration clock) the pump will restart at the last speed active. To modify the setting of one of the three speeds: the speed you want to modify must be operating, press the key that corresponds to this speed for 5 seconds (the corresponding green LED must flash). press or until you reach the speed you want (increments of 50 rpm). Press for 10 seconds to save. To stop the pump, press. You may reset the pump to return it to "factory" configuration: - make sure that the pump is powered up but stopped ("OFF" is displayed on the screen). EN - press + + for 5 seconds until the 3 corresponding green LEDs flash once. - release the keys: the pump is now reset. 4. Maintenance 4.1 Maintenance instructions General maintenance of the appliance is recommended when the pool is wintered and before restarting, to check that it operates correctly and maintains its performance, as well as to prevent certain types of failure. These operations are carried out at the user's expense, by a qualified technician. Make sure that the pump or electrical compartment contain no foreign bodies. Clean the outside of the appliance, do not use solvent-based products. Check that the user interface is correctly connected. Check the connection of the metal masses to the earth. Check that the electrical cables are correctly tightened and connected and that the electrical unit is clean. Clean the pre-filter strainer, the cover and the seal regularly. Check that the pre-filter strainer is correctly in place, or it may prevent the cover from closing fully. 4.2 Wintering The pump must be fully wintered in the event of frost or extended electrical disconnection. If the pump freezes it may cause severe damage and invalidate the warranty. To avoid damaging the equipment with condensation, do not fully cover it. If the pump is positioned below the water level, close the isolation valves at suction and discharge. Drain the pump (using the 2 bleed screws) and the hydraulic circuit, following the swimming pool manufacturer's instructions. Remove the 2 bleed screws and keep them to reinstall them when the pump is put back into operation. You are recommended to disconnect the electrical power cable then unscrew the hydraulic connectors to store the pump in a dry place away from frost. 4.3 Recycling This symbol means that your appliance must not be thrown into a normal bin. It will be selectively collected for the purpose of reuse, recycling or creating value. If it contains any substances that may be harmful to the environment, these will be eliminated or neutralised. Contact your dealer for recycling information. H B - EN

8 5. Troubleshooting 5.1 Error codes Number of flashes Malfunction Possible causes Solutions 1 User interface is The user interface resets itself Check the electrical connections inside defective constantly the user interface housing. Replace the motor - interface assembly if necessary. 2 Network subvoltage below 180VCA. voltage rises over 209VCA again for at The network voltage has fallen The interface will reset when the least 6 seconds 3 Temperature Motor temperature too high (+100 C) Motor temperature too low (-20 C) 4 Surge activation The surge protection has been activated 5 Network overvoltage The voltage exceeds 269VCA 6 Motor shaft jammed Motor start-up impossible The motor has stopped 7 Automatic verification At least one of the automatic tests failed on start-up or during operation 8 Motor fault At least one of the phases is disconnected 5.2 Equipment malfunction Malfunction Possible causes Solutions Pre-filter screen and/or filter blocked with dirt Valves incorrectly set The water does not circulate correctly Air bubbles are present in the pre-filter screen There are air intakes There is no air in the circuit but the pressure is low There is no debris in the pump but the pressure is low There is a water leak between the motor and the pump body The pump heats up and switches off sometimes The pump does not start There is no damage to the user interface Air blocked in the circuit Swimming pool water level too low Incorrect pre-filter cover seal Couplings incorrectly tightened Coupling seals incorrectly positioned or damaged Debris jammed in the pump The turbine and the pump diffuser are worn Electrical problem Seal worn Mechanical lining damaged or defective Poor air circulation around the motor Poor electrical connections Current variations too high No electrical supply to the pump The user interface cable is damaged The "error" light flashes Cables damaged or poorly connected in the user interface housing Wait until normal temperature conditions return and restart the pump. Check the electrical supply. Restart the pump. The interface will reset when the voltage returns to a normal value. Break the pump circuit and check that no debris is blocking the turbine (remove the pre-filter screen). Check that there is no debris blocking the rear fan. Break the pump circuit then reconnect it to reset it. Check the electrical connections inside the user interface housing. Clean the pre-filter screen and/or the filter Set the valves Bleed the circuit Check the water level and top up if necessary Check that the cover and its seal are water-tight Retighten the couplings Change the seals Remove the debris by hand by opening the cover and removing the pre-filter screen If debris remains, you must dismantle the pump to access the turbine Caution: these tasks must be carried out by a qualified technician Have the turbine and the diffuser replaced by a qualified technician Have the electrical installation checked by a qualified technician Replace the seal Replace the mechanical lining Caution: these tasks must be carried out by a qualified technician Check that the motor is ventilated enough to cool down Check the electrical connections Have the electrical network checked by a qualified technician Check the electrical connections Check the condition of the user interface cable See 5.1 Error codes Check the condition of the user interface cables 7 H B - EN

9 6. Registering the product Register your product on our website: you will be the first to be informed of new Zodiac products and special offers, You can help us to constantly improve our product quality. Europe & Rest of the World America Australia Pacific EN H B - EN

10 Dimensions Weight pump only : 10 kg Description A B C D E F Performance graphs Water admission Water discharge Pre-filter cover User interface Pump motor Drain Hydraulic head Flow H B - EN

11

12 Votre revendeur / your retailer Zodiac Pool Care Europe - BP St Barthélémy d Anjou cedex - S.A.S.U. au capital de / SIREN / RCS PARIS Pour plus de renseignements, merci de contacter votre revendeur. For further information, please contact your retailer. ZODIAC is a registered trademark of Zodiac International, S.A.S.U., used under license.

FloPro e3 H C /01. Instructions for installation and use - English. More documents on:

FloPro e3 Instructions for installation and use - English Filtration pump Translation of the original instructions in french EN More documents on: www.zodiac-poolcare.com H0538700.C - 2017/01 WARNINGS

FloPro e3 Instructions for installation and use - English Filtration pump Translation of the original instructions in french EN More documents on: www.zodiac-poolcare.com H0538700.C - 2017/01 WARNINGS

1. Information before installation General terms of delivery, storage and transport

EN Read this manual carefully before installing, maintaining or repairing this device! The symbol indicates important information that must be taken into account in order to avoid risk of personal injury

EN Read this manual carefully before installing, maintaining or repairing this device! The symbol indicates important information that must be taken into account in order to avoid risk of personal injury

1. Information before installation General terms of delivery, storage and transport

EN Read this manual carefully before installing, maintaining or repairing this device! The symbol indicates important information that must be taken into account in order to avoid risk of personal injury

EN Read this manual carefully before installing, maintaining or repairing this device! The symbol indicates important information that must be taken into account in order to avoid risk of personal injury

Instructions for installation and use English. More languages on: H A /11

Instructions for installation and use English EN More languages on: www.zodiac-poolcare.com H0435000.A - 2013/11 Read this notice carefully before installing, maintaining or repairing this appliance! The

Instructions for installation and use English EN More languages on: www.zodiac-poolcare.com H0435000.A - 2013/11 Read this notice carefully before installing, maintaining or repairing this appliance! The

Instructions for installation

Instructions for installation Read this notice carefully before installing, maintaining or repairing this appliance! The symbol indicates important information that you must take into account to avoid

Instructions for installation Read this notice carefully before installing, maintaining or repairing this appliance! The symbol indicates important information that you must take into account to avoid

Instructions for installation and use English

FR N Instructions for installation and use English EN H03839-00.A - W2365A - 2012/10 Read this manual carefully before installing, maintaining or repairing this appliance! The symbol indicates important

FR N Instructions for installation and use English EN H03839-00.A - W2365A - 2012/10 Read this manual carefully before installing, maintaining or repairing this appliance! The symbol indicates important

Instructions for installation and use RE/I. Industrial electric heater for swimming pool

Instructions for installation and use RE/I Industrial electric heater for swimming pool Réf. : N.D.010.A.EN Ver. 06-2010 1. Installation... 2 1.1 General... 2 1.1.1 Precautions... 2 1.1.2 General terms

Instructions for installation and use RE/I Industrial electric heater for swimming pool Réf. : N.D.010.A.EN Ver. 06-2010 1. Installation... 2 1.1 General... 2 1.1.1 Precautions... 2 1.1.2 General terms

Diag box. Notice d installation et d utilisation Français. Instructions for installation and use English. Montage- und Gebrauchsanleitung Deutsch

Diag box Notice d installation et d utilisation Français Instructions for installation and use English EN Montage- und Gebrauchsanleitung Deutsch Installatie en gebruikshandleiding Nederlands Manual de

Diag box Notice d installation et d utilisation Français Instructions for installation and use English EN Montage- und Gebrauchsanleitung Deutsch Installatie en gebruikshandleiding Nederlands Manual de

Hydroxynator H A /01. Instructions for installation and use English. More languages on:

Hydroxynator Instructions for installation and use English EN NL ES PT More languages on: www.zodiac-poolcare.com H0451600.A - 2014/01 Read this notice carefully before installing, maintaining or repairing

Hydroxynator Instructions for installation and use English EN NL ES PT More languages on: www.zodiac-poolcare.com H0451600.A - 2014/01 Read this notice carefully before installing, maintaining or repairing

Z300 PM30 EverFirst H B Instructions for installation and use English. More documents on:

Z300 PM30 EverFirst Instructions for installation and use English EN More documents on: www.zodiac-poolcare.com H0548600.B - 2016-05 WARNINGS Failure to respect the warnings may cause serious damage to

Z300 PM30 EverFirst Instructions for installation and use English EN More documents on: www.zodiac-poolcare.com H0548600.B - 2016-05 WARNINGS Failure to respect the warnings may cause serious damage to

Vortex. Instructions for installation and use English. More documents on: H D /12 - EC11--

Vortex Instructions for installation and use English EN More documents on: www.zodiac-poolcare.com H0491600.D - 2016/12 - EC11-- Notes WARNINGS GENERAL WARNINGS Failure to respect the warnings may cause

Vortex Instructions for installation and use English EN More documents on: www.zodiac-poolcare.com H0491600.D - 2016/12 - EC11-- Notes WARNINGS GENERAL WARNINGS Failure to respect the warnings may cause

Notice d installation et d utilisation Français. Instructions for installation and use English. Montage- und Gebrauchsanleitung Deutsch

OV 3300 - OV 3400 - OV 3410 OV 3450 - OV 3500 - OV 3510 RV 4200 - RV 4310 RV 4400 - RV 4430 - RV 4460 RV 4550 - RV 4560 RV 5400 - RV 5470 RV 5500 - RV 5600 Vortex TM 3 PLUS - Vortex TM 4 PLUS Notice d

OV 3300 - OV 3400 - OV 3410 OV 3450 - OV 3500 - OV 3510 RV 4200 - RV 4310 RV 4400 - RV 4430 - RV 4460 RV 4550 - RV 4560 RV 5400 - RV 5470 RV 5500 - RV 5600 Vortex TM 3 PLUS - Vortex TM 4 PLUS Notice d

V80-H Multistage Pump Instruction Manual

V80-H Multistage Pump Instruction Manual PRODUCT OVERVIEW The VADA horizontal multistage centrifugal pumps combine the functional benefits of centrifugal pumps and the practical benefits of self priming

V80-H Multistage Pump Instruction Manual PRODUCT OVERVIEW The VADA horizontal multistage centrifugal pumps combine the functional benefits of centrifugal pumps and the practical benefits of self priming

Section 1. Information before installation

2 3 Section 1. Information before installation 1.1 General delivery conditions All equipment, even carriage and packaging paid, is shipped at the recipient s risk. If damaged caused during transport is

2 3 Section 1. Information before installation 1.1 General delivery conditions All equipment, even carriage and packaging paid, is shipped at the recipient s risk. If damaged caused during transport is

SUBMERSIBLE WATER PUMPS

OPERATING & MAINTENANCE INSTRUCTIONS SUBMERSIBLE WATER PUMPS Model Nos. HIPPO-3 and 3A 6/97 Thank you for purchasing this CLARKE, HIPPO Submersible Pump. These highly efficient pumps are designed for pumping

OPERATING & MAINTENANCE INSTRUCTIONS SUBMERSIBLE WATER PUMPS Model Nos. HIPPO-3 and 3A 6/97 Thank you for purchasing this CLARKE, HIPPO Submersible Pump. These highly efficient pumps are designed for pumping

3 4WD 4. Instructions for installation and use English

3 4WD 4 Instructions for installation and use English EN H0360600.A2.EN Ver.05/2011 1 Summary PRECAUTIONSBEFOREUSE...2 1.1IMPORTANTSAFETYINSTRUCTIONS...2 1.2.CONTENTOFTHEPACKAGE...2 1.3.ASSEMBLINGTHECADDY...2

3 4WD 4 Instructions for installation and use English EN H0360600.A2.EN Ver.05/2011 1 Summary PRECAUTIONSBEFOREUSE...2 1.1IMPORTANTSAFETYINSTRUCTIONS...2 1.2.CONTENTOFTHEPACKAGE...2 1.3.ASSEMBLINGTHECADDY...2

VADA - V80-H PRODUCT OVERVIEW CONSTRUCTION USAGE LIMITATIONS MOTOR WARRANTY

PRODUCT OVERVIEW The VADA horizontal multistage centrifugal pumps combine the functional benefits of centrifugal pumps and the practical benefits of self priming pumps. They warrant high hydraulic and

PRODUCT OVERVIEW The VADA horizontal multistage centrifugal pumps combine the functional benefits of centrifugal pumps and the practical benefits of self priming pumps. They warrant high hydraulic and

Notice d installation et d utilisation Français. Instructions for installation and use English. Manual de instalación y de uso Español

Notice d installation et d utilisation Français Instructions for installation and use English Manual de instalación y de uso Español Montage- und Gebrauchsanleitung Deutsch FR EN ES DE Manuale di installazione

Notice d installation et d utilisation Français Instructions for installation and use English Manual de instalación y de uso Español Montage- und Gebrauchsanleitung Deutsch FR EN ES DE Manuale di installazione

CHAMPION PUMP OWNER S MANUAL

CHAMPION PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

CHAMPION PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

Product waste disposal - Protection of the environment:

Product waste disposal - Protection of the environment: In accordance with the provisions of the Waste Electrical and Electronic Equipment (WEEE - 2002/ 96/ EC) Directive, used electric and electronic

Product waste disposal - Protection of the environment: In accordance with the provisions of the Waste Electrical and Electronic Equipment (WEEE - 2002/ 96/ EC) Directive, used electric and electronic

VADA - Rain2Main Automatic Rainwater Controller

PRODUCT OVERVIEW / APPLICATION The Vada Rain2Main is designed to select between stored rainwater (when available) and mains supply water, and send this water to your toilet cistern, washing machine, garden

PRODUCT OVERVIEW / APPLICATION The Vada Rain2Main is designed to select between stored rainwater (when available) and mains supply water, and send this water to your toilet cistern, washing machine, garden

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR PUMP 88 PUMP PARTS BREAKDOWN REF # Order # Mfr # Description 1 NEP4 AC 348 Lid Knobs NEP AC 380 Strainer Lid 3 NEP6

TIDALWAVE I/G POOL PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR PUMP 88 PUMP PARTS BREAKDOWN REF # Order # Mfr # Description 1 NEP4 AC 348 Lid Knobs NEP AC 380 Strainer Lid 3 NEP6

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning

Elite Primer Baldor Series External Pond Pump

Elite Primer Baldor Series External Pond Pump ( 5250PPB21, 6440PPB23, 7550PPB26, 9600PPB28) Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS, READ AND FOLLOW ALL INSTRUCTIONS. SAVE THESE INSTRUCTIONS

Elite Primer Baldor Series External Pond Pump ( 5250PPB21, 6440PPB23, 7550PPB26, 9600PPB28) Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS, READ AND FOLLOW ALL INSTRUCTIONS. SAVE THESE INSTRUCTIONS

Instructions for installtion and use English

FR Instructions for installtion and use English EN More languages on: www.zodiac-poolcare.com H03746-00.A - WBU02005-2012/10 Read this manual carefully before installing, maintaining or repairing this

FR Instructions for installtion and use English EN More languages on: www.zodiac-poolcare.com H03746-00.A - WBU02005-2012/10 Read this manual carefully before installing, maintaining or repairing this

SMF PUMP OWNER S MANUAL

SMF PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

SMF PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

IMPORTANT- RETAIN FOR FUTURE REFERENCE CALL:

GENOA WALL FIREPLACE Assembly instructions Actual product size H56 x W96 x D4cm Need Help? With: Assembly instructions Missing or damaged parts IMPORTANT- RETAIN FOR FUTURE REFERENCE CALL: 0333 777 8999

GENOA WALL FIREPLACE Assembly instructions Actual product size H56 x W96 x D4cm Need Help? With: Assembly instructions Missing or damaged parts IMPORTANT- RETAIN FOR FUTURE REFERENCE CALL: 0333 777 8999

ECONO FLO VSA 165 VARIABLE SPEED PUMP OWNER S MANUAL

ECONO FLO VSA 165 VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all

ECONO FLO VSA 165 VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all

WET & DRY GARAGE VAC 20L CAPACITY WATT 1.5M MOTOR TANK STEEL HOSE KP702 ON BOARD ACCESSORY STORAGE SUCTION STAINLESS

WET & DRY GARAGE VAC 20L CAPACITY 1.5M SUCTION HOSE STAINLESS STEEL TANK ON BOARD ACCESSORY STORAGE 1250 WATT MOTOR KP702 Table of Contents 20L WET & DRY GARAGE VAC Know Your Product...1 Vacuum Safety

WET & DRY GARAGE VAC 20L CAPACITY 1.5M SUCTION HOSE STAINLESS STEEL TANK ON BOARD ACCESSORY STORAGE 1250 WATT MOTOR KP702 Table of Contents 20L WET & DRY GARAGE VAC Know Your Product...1 Vacuum Safety

PUDDLE PUMP PUDDLE PUMP. MODEL No: PSP125 OPERATION & MAINTENANCE INSTRUCTIONS. Part No:

PUDDLE PUMP PUDDLE PUMP MODEL No: PSP125 Part No: 7230692 OPERATION & MAINTENANCE INSTRUCTIONS 1007 SPECIFICATIONS Model number... PSP125 Rated voltage... 230VAC 50Hz Input power... 293 Watts Maximum delivery

PUDDLE PUMP PUDDLE PUMP MODEL No: PSP125 Part No: 7230692 OPERATION & MAINTENANCE INSTRUCTIONS 1007 SPECIFICATIONS Model number... PSP125 Rated voltage... 230VAC 50Hz Input power... 293 Watts Maximum delivery

PRO-230 PRO-350 PRO-400 PRO-500 PRO-500DS ECO-PRO

GERMAN ENGINEERED PUMPS SINCE 1909 PRO SERIES PUMPS INSTALLATION AND OPERATION MANUAL PRO-230 PRO-350 PRO-400 PRO-500 PRO-500DS ECO-PRO 1 PRO SERIES PUMPS INSTALLATION AND OPERATION MANUAL PRO-230 PRO-350

GERMAN ENGINEERED PUMPS SINCE 1909 PRO SERIES PUMPS INSTALLATION AND OPERATION MANUAL PRO-230 PRO-350 PRO-400 PRO-500 PRO-500DS ECO-PRO 1 PRO SERIES PUMPS INSTALLATION AND OPERATION MANUAL PRO-230 PRO-350

HOT WASHER MODEL NO: KING150

WARNING: Do not use the hot washer without reading this manual HOT WASHER MODEL NO: KING150 PART NO: 7320175 OPERATION & MAINTENANCE INSTRUCTIONS LS1215 INTRODUCTION Thank you for purchasing this CLARKE

WARNING: Do not use the hot washer without reading this manual HOT WASHER MODEL NO: KING150 PART NO: 7320175 OPERATION & MAINTENANCE INSTRUCTIONS LS1215 INTRODUCTION Thank you for purchasing this CLARKE

Warning: 230V / 1ph / 50Hz V / 3ph / 50Hz. Remarks: Make sure that you have enough power. (See page 15 Cable table)

1 2 Warning: - Do not place your hand or any other objects into the air outlet and fan. It could damage the heat pump and cause injuries; - In case of any abnormality with the heat pump, cut off the power

1 2 Warning: - Do not place your hand or any other objects into the air outlet and fan. It could damage the heat pump and cause injuries; - In case of any abnormality with the heat pump, cut off the power

Moisture inside the drum is due to final testing.

Safety instructions Scope of delivery depending on model Moisture inside the drum is due to final testing. Removing the transport braces Water connection depending on model The washing machine is heavy

Safety instructions Scope of delivery depending on model Moisture inside the drum is due to final testing. Removing the transport braces Water connection depending on model The washing machine is heavy

CLEAN WATER PUMP. MODEL No: Hippo4A OPERATION & MAINTENANCE INSTRUCTIONS. Part No:

CLEAN WATER PUMP MODEL No: Hippo4A Part No: 7230535 OPERATION & MAINTENANCE INSTRUCTIONS 0807 INTRODUCTION Thank you for purchasing this CLARKE clean water pump. This highly efficient pump is designed

CLEAN WATER PUMP MODEL No: Hippo4A Part No: 7230535 OPERATION & MAINTENANCE INSTRUCTIONS 0807 INTRODUCTION Thank you for purchasing this CLARKE clean water pump. This highly efficient pump is designed

Instruction manual Harmo PAC ZVWX1017/1022/1032/1041/1055/1056/1061

Instruction manual Harmo PAC ZVWX1017/1022/1032/1041/1055/1056/1061 Imported by: Zwembad BVBA Industrieweg 9 3190 Boortmeerbeek België www.harmopool.eu 0 Table of content Introduction... 2 Safety instructions...

Instruction manual Harmo PAC ZVWX1017/1022/1032/1041/1055/1056/1061 Imported by: Zwembad BVBA Industrieweg 9 3190 Boortmeerbeek België www.harmopool.eu 0 Table of content Introduction... 2 Safety instructions...

2 SPEED PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR 2 SPEED PUMP

2 SPEED PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR 2 SPEED PUMP 8308 PUMP PARTS BREAKDOWN Ref # Part # Manf. # Descrip on 1 NEP2134 AC 81361 PUMP LID 2 NEP2135 AC 81396 PUMP LID

2 SPEED PUMP INSTRUCTION MANUAL READ THIS MANUAL CAREFULLY BEFORE USING YOUR 2 SPEED PUMP 8308 PUMP PARTS BREAKDOWN Ref # Part # Manf. # Descrip on 1 NEP2134 AC 81361 PUMP LID 2 NEP2135 AC 81396 PUMP LID

Steam Trap BK 45 BK 45-U BK 45-LT BK 46

Steam Trap BK 45 BK 45-U BK 45-LT BK 46 Original Installation Instructions 810437-08 Contents Foreword... 3 Availability... 3 Formatting features in the document... 3 Safety... 3 Use for the intended purpose...

Steam Trap BK 45 BK 45-U BK 45-LT BK 46 Original Installation Instructions 810437-08 Contents Foreword... 3 Availability... 3 Formatting features in the document... 3 Safety... 3 Use for the intended purpose...

CONTENTS CONSIDERATIONS. General Plumbing Component Connection ILLUSTRATION. Control System CONFIGURATION. Voltage Verification CONNECTION

AIR SERIES SYSTEM INSTALLATION MANUAL CONTENTS CONSIDERATIONS General Plumbing Component Connection 2 2 2 ILLUSTRATION Control System 3 CONFIGURATION Voltage Verification 4 CONNECTION Component Connection

AIR SERIES SYSTEM INSTALLATION MANUAL CONTENTS CONSIDERATIONS General Plumbing Component Connection 2 2 2 ILLUSTRATION Control System 3 CONFIGURATION Voltage Verification 4 CONNECTION Component Connection

1. Take the hoses and elbow out of the holders, depending on model. max. 100 cm. min. * cm

Safety instructions The washing machine is heavy - take care when lifting. Caution: frozen hoses may rip/burst. Do not install the washing machine in areas exposed to frost or outdoors. The washing machine

Safety instructions The washing machine is heavy - take care when lifting. Caution: frozen hoses may rip/burst. Do not install the washing machine in areas exposed to frost or outdoors. The washing machine

OPERATION & MAINTENANCE INSTRUCTIONS

SUBMERSIBLE PUMPS MODEL NO: PSV3A, PSV4A, PSSV2A & PVP11A PART NO: 7236042, 7236044, 7236050 & 7236060 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS GC07/17 iss 4 INTRODUCTION Thank you for

SUBMERSIBLE PUMPS MODEL NO: PSV3A, PSV4A, PSSV2A & PVP11A PART NO: 7236042, 7236044, 7236050 & 7236060 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS GC07/17 iss 4 INTRODUCTION Thank you for

Installer manual AG-AA10. Air/air heat pump IHB GB AG-AA10-30 AG-AA10-40/50

-30 Installer manual Air/air heat pump -40/50 IHB GB 1516-1 331554 Table of Contents 1 Important information 2 5 Installation 7 Safety information 2 Model combinations 7 Read before starting the installation

-30 Installer manual Air/air heat pump -40/50 IHB GB 1516-1 331554 Table of Contents 1 Important information 2 5 Installation 7 Safety information 2 Model combinations 7 Read before starting the installation

TTV 1500 / TTV 3000 OPERATING MANUAL CONVEYING FAN TRT-BA-TTV TC EN

TTV 1500 / TTV 3000 EN OPERATING MANUAL CONVEYING FAN TRT-BA-TTV1500-3000-TC2016-26-004-EN Table of contents Notes regarding the operating manual... 2 You can download the current version of the operating

TTV 1500 / TTV 3000 EN OPERATING MANUAL CONVEYING FAN TRT-BA-TTV1500-3000-TC2016-26-004-EN Table of contents Notes regarding the operating manual... 2 You can download the current version of the operating

Notice d installation et d utilisation Français. Instructions for installation and use English. Montage- und Gebrauchsanleitung Deutsch

Notice d installation et d utilisation Français Instructions for installation and use English EN Montage- und Gebrauchsanleitung Deutsch Installatie en gebruikshandleiding Nederlands Manual de instalación

Notice d installation et d utilisation Français Instructions for installation and use English EN Montage- und Gebrauchsanleitung Deutsch Installatie en gebruikshandleiding Nederlands Manual de instalación

INSTALLATION GUIDE NZ AU C

DISHWASHER DW60 models INSTALLATION GUIDE NZ AU 591217C 12.17 1 SAFETY AND WARNINGS! WARNING! Electrical shock hazard Before installing the dishwasher, remove the house fuse or open the circuit breaker.

DISHWASHER DW60 models INSTALLATION GUIDE NZ AU 591217C 12.17 1 SAFETY AND WARNINGS! WARNING! Electrical shock hazard Before installing the dishwasher, remove the house fuse or open the circuit breaker.

MAXI PUMP INSTRUCTION MANUAL NE6151B /NE6171B READ THIS MANUAL CAREFULLY BEFORE USING YOUR MAXI PUMP

MAXI PUMP INSTRUCTION MANUAL NE6151B /NE6171B READ THIS MANUAL CAREFULLY BEFORE USING YOUR MAXI PUMP 8104 MAXI-PUMP PARTS BREAKDOWN Re f # 1 2 3 4 5 6 7a 7b 8 9 10 11 12 13 14 15 16 2 Part # NEP2134 NEP2135

MAXI PUMP INSTRUCTION MANUAL NE6151B /NE6171B READ THIS MANUAL CAREFULLY BEFORE USING YOUR MAXI PUMP 8104 MAXI-PUMP PARTS BREAKDOWN Re f # 1 2 3 4 5 6 7a 7b 8 9 10 11 12 13 14 15 16 2 Part # NEP2134 NEP2135

Swimming Pool Heat Pump

Swimming Pool Heat Pump Operation and Installation Manual MODEL FH-020 CONTENTS INTRODUCTION Index............ 2 The unit...... 2 SAFETY INSTRUCTIONS... 4 Electrical Installation Warning.. 4 Location Warning

Swimming Pool Heat Pump Operation and Installation Manual MODEL FH-020 CONTENTS INTRODUCTION Index............ 2 The unit...... 2 SAFETY INSTRUCTIONS... 4 Electrical Installation Warning.. 4 Location Warning

Moisture inside the drum is due to final testing.

Safety instructions Scope of delivery depending on model Moisture inside the drum is due to final testing. Removing the transport safety devices Water connection depending on model The washing machine

Safety instructions Scope of delivery depending on model Moisture inside the drum is due to final testing. Removing the transport safety devices Water connection depending on model The washing machine

NON-SUBMERSIBLE WATER PUMP

NON-SUBMERSIBLE WATER PUMP MODEL NO: CEB103 PART NO: 7230327 OPERATION & MAINTENANCE INSTRUCTIONS LS0114 INTRODUCTION Thank you for purchasing this CLARKE Water Pump, which is a general purpose pump, suitable

NON-SUBMERSIBLE WATER PUMP MODEL NO: CEB103 PART NO: 7230327 OPERATION & MAINTENANCE INSTRUCTIONS LS0114 INTRODUCTION Thank you for purchasing this CLARKE Water Pump, which is a general purpose pump, suitable

JS. Bosch Remote Control

6720606990-00.1JS Bosch Remote Control For: GWH 635 ES/635 ESO/250SX/250SXO/2400E /2400EO/2400ES/2700ES/715ES/C800ES/C920ES /C920ESC/EVOLUTION 500/INTEGRA 500/C1210ES /C1210ESC/C1050ES/C950ES/940ES/940ESO/830ES

6720606990-00.1JS Bosch Remote Control For: GWH 635 ES/635 ESO/250SX/250SXO/2400E /2400EO/2400ES/2700ES/715ES/C800ES/C920ES /C920ESC/EVOLUTION 500/INTEGRA 500/C1210ES /C1210ESC/C1050ES/C950ES/940ES/940ESO/830ES

Koolbreeze. Portable Air-conditioner User s Manual. For Model : CLIMATEASY 14 P14HCP. Downloaded from manuals search engine

Koolbreeze Portable Air-conditioner User s Manual For Model : CLIMATEASY 14 P14HCP Table of Contents 1. Installation.. 2 2. General Safety Reqirements.. 4 3. Product safety.... 5 4. Safety Awareness....

Koolbreeze Portable Air-conditioner User s Manual For Model : CLIMATEASY 14 P14HCP Table of Contents 1. Installation.. 2 2. General Safety Reqirements.. 4 3. Product safety.... 5 4. Safety Awareness....

SPA BLOWER OWNER'S MANUAL XXXX, XXXX, XXXX, XXXX, XXXX, XXXX fax

SPA BLOWER OWNER'S MANUAL 80015-XXXX, 80016-XXXX, 80017-XXXX, 80018-XXXX, 80019-XXXX, 80020-XXXX fax 888.610.3839 2015 323300-015 6/15 THIS PAGE INTENTIONALLY LEFT BLANK. 2 Operating Instructions and Parts

SPA BLOWER OWNER'S MANUAL 80015-XXXX, 80016-XXXX, 80017-XXXX, 80018-XXXX, 80019-XXXX, 80020-XXXX fax 888.610.3839 2015 323300-015 6/15 THIS PAGE INTENTIONALLY LEFT BLANK. 2 Operating Instructions and Parts

TH100 Three in One Instant Hot Water Tap

TH100 Three in One Instant Hot Water Tap Installation, Use and Maintenance Customer Care Department The Group Ltd. Harby Road Langar Nottinghamshire NG13 9HY T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu

TH100 Three in One Instant Hot Water Tap Installation, Use and Maintenance Customer Care Department The Group Ltd. Harby Road Langar Nottinghamshire NG13 9HY T : 01949 862 012 F : 01949 862 003 E : customer.care@cda.eu

Installation and operation manual

Installation and operation manual - + BRC1HHDAW BRC1HHDAS BRC1HHDAK English Table of contents Table of contents 1 General safety precautions 2 1.1 For the user... 2 1.2 For the installer... 2 2 About this

Installation and operation manual - + BRC1HHDAW BRC1HHDAS BRC1HHDAK English Table of contents Table of contents 1 General safety precautions 2 1.1 For the user... 2 1.2 For the installer... 2 2 About this

QUIETFLO OWNER S MANUAL

QUIETFLO OWNER S MANUAL INSTALLATION, OPERATION & PARTS To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completley. CAUTION - We highly recommend a qualified

QUIETFLO OWNER S MANUAL INSTALLATION, OPERATION & PARTS To prevent potential injury and to avoid unnecessary service calls, read this manual carefully and completley. CAUTION - We highly recommend a qualified

IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS. Table of Contents WARNING.

Eagle Pump Owners Manual IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Table of Contents SECTION I. INSTALLATION... 2 SECTION II. OPERATION & MAINTENANCE... 2 SECTION

Eagle Pump Owners Manual IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Table of Contents SECTION I. INSTALLATION... 2 SECTION II. OPERATION & MAINTENANCE... 2 SECTION

User Manual GV25 GV35 GV702. Company information: Original instructions GV12066 (1)

User Manual Original instructions GV25 GV35 GV702 Company information: www.vipercleaning.eu info-eu@vipercleaning.com GV12066 (1) 2012-04-10 USER MANUAL ENGLISH TABLE OF CONTENTS Introduction... 4 Manual

User Manual Original instructions GV25 GV35 GV702 Company information: www.vipercleaning.eu info-eu@vipercleaning.com GV12066 (1) 2012-04-10 USER MANUAL ENGLISH TABLE OF CONTENTS Introduction... 4 Manual

Owner s Manual for Swimming Pool Heat Pump

Owner s Manual for Swimming Pool Heat Pump FC Series nirvanahp.com CONTENTS How it works 1 Installation 2 3 Settings 4 5 6 7 Start-up 8 Winterizing 9 Maintenance 10 Troubleshooting 11 12 13 Warranty 14

Owner s Manual for Swimming Pool Heat Pump FC Series nirvanahp.com CONTENTS How it works 1 Installation 2 3 Settings 4 5 6 7 Start-up 8 Winterizing 9 Maintenance 10 Troubleshooting 11 12 13 Warranty 14

SWIMMING POOL & SPA HEAT PUMPS OWNERS OPERATIONAL MANUAL

SWIMMING POOL & SPA HEAT PUMPS OWNERS OPERATIONAL MANUAL MODEL AT105 AT115 AT130 with Titanium Heat Exchanger 2213 Andrea Lane Ft. Myers FL 33912 888-297-3826 941-482-0606 www.aquathermheatpumps.com DIGITAL

SWIMMING POOL & SPA HEAT PUMPS OWNERS OPERATIONAL MANUAL MODEL AT105 AT115 AT130 with Titanium Heat Exchanger 2213 Andrea Lane Ft. Myers FL 33912 888-297-3826 941-482-0606 www.aquathermheatpumps.com DIGITAL

Specifications. Vacuum motor power consumption(w/hp) 1200 / 1.6. Exhaust water pump power consumption(w/hp 800 / 1.1

Specifications Rated voltage (V) AC 110-120V or 220-240V / 50-60Hz Vacuum motor power consumption(w/hp) 1200 / 1.6 Exhaust water pump power consumption(w/hp 800 / 1.1 Exhaust water pump flow (GPH/LPH)

Specifications Rated voltage (V) AC 110-120V or 220-240V / 50-60Hz Vacuum motor power consumption(w/hp) 1200 / 1.6 Exhaust water pump power consumption(w/hp 800 / 1.1 Exhaust water pump flow (GPH/LPH)

Owner s Manual H _REVB

Owner s Manual H0566000_REVB 1 Important Information Notice for Vinyl Liner Pools: Before installing your pool cleaner, examine the interior of your pool carefully. If the vinyl liner is brittle or has

Owner s Manual H0566000_REVB 1 Important Information Notice for Vinyl Liner Pools: Before installing your pool cleaner, examine the interior of your pool carefully. If the vinyl liner is brittle or has

GDDEM10 DEHUMIDIFIER

GDDEM10 DEHUMIDIFIER SOCIABLE REMARK When using this dehumidifier in the European countries, the following information must be followed: DISPOSAL: Do not dispose this product as unsorted municipal waste.

GDDEM10 DEHUMIDIFIER SOCIABLE REMARK When using this dehumidifier in the European countries, the following information must be followed: DISPOSAL: Do not dispose this product as unsorted municipal waste.

30-pint Dehumidifier User Guide

30-pint Dehumidifier User Guide IVADH30PW Thank you for purchasing the Ivation 30 Pint Dehumidifier. This User Guide is intended to provide you with guidelines to ensure that operation of this product

30-pint Dehumidifier User Guide IVADH30PW Thank you for purchasing the Ivation 30 Pint Dehumidifier. This User Guide is intended to provide you with guidelines to ensure that operation of this product

Installation instructions SIROCCO Air dehumidifier for indoor swimming pools

Installation instructions SIROCCO 55-80-110 Air dehumidifier for indoor swimming pools Réf. : N.D.005.A.EN - Ver. 02-2010 1. Installation... 2 1.1 General... 2 1.1.1 Precautions... 2 1.1.2 General terms

Installation instructions SIROCCO 55-80-110 Air dehumidifier for indoor swimming pools Réf. : N.D.005.A.EN - Ver. 02-2010 1. Installation... 2 1.1 General... 2 1.1.1 Precautions... 2 1.1.2 General terms

IMPORTANT- RETAIN FOR FUTURE REFERENCE CALL:

CORSICA VESSEL FIREPLACE 65573 Assembly instructions Actual product size H00 x W20 x D30cm Need Help? With: Assembly instructions Missing or damaged parts IMPORTANT- RETAIN FOR FUTURE REFERENCE CALL: 0333

CORSICA VESSEL FIREPLACE 65573 Assembly instructions Actual product size H00 x W20 x D30cm Need Help? With: Assembly instructions Missing or damaged parts IMPORTANT- RETAIN FOR FUTURE REFERENCE CALL: 0333

SUBMERSIBLE DIRTY WATER PUMP

SUBMERSIBLE DIRTY WATER PUMP MODEL NO: DWP100A, DWP150A, DWP200A PART NO: 7230098, 7230099, 7230100 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS LS1117 - ISS 2 INTRODUCTION Thank you for

SUBMERSIBLE DIRTY WATER PUMP MODEL NO: DWP100A, DWP150A, DWP200A PART NO: 7230098, 7230099, 7230100 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS LS1117 - ISS 2 INTRODUCTION Thank you for

INSTRUCTION MANUAL. operates with ISO9001 certified quality system. TECSYSTEM S.r.l Corsico (MI) Tel.: Fax:

INSTRUCTION MANUAL TTG SERIES FANS 1MN0069 Rev 0 operates with ISO9001 certified quality system TECSYSTEM S.r.l. 20094 Corsico (MI) Tel.: +9-024581861 Fax: +9-024860078 http://www.tecsystem.it R. 1. 20/02/17

INSTRUCTION MANUAL TTG SERIES FANS 1MN0069 Rev 0 operates with ISO9001 certified quality system TECSYSTEM S.r.l. 20094 Corsico (MI) Tel.: +9-024581861 Fax: +9-024860078 http://www.tecsystem.it R. 1. 20/02/17

Read this manual through carefully before installing/using the cleaner, paying special attention to the SAFETY INSTRUCTIONS

PW1370TD 2 EN Read this manual through carefully before installing/using the cleaner, paying special attention to the SAFETY INSTRUCTIONS 3 E3 E1 C3 A1-A2-A3-A4 B4 B1 B5 B2 C1 B3 D 1 4 1 2 3 4 5 6 7 Ø13

PW1370TD 2 EN Read this manual through carefully before installing/using the cleaner, paying special attention to the SAFETY INSTRUCTIONS 3 E3 E1 C3 A1-A2-A3-A4 B4 B1 B5 B2 C1 B3 D 1 4 1 2 3 4 5 6 7 Ø13

SUBMERSIBLE WATER PUMP. Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS

1117 SUBMERSIBLE WATER PUMP Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS GUARANTEE This product is guaranteed against faults in

1117 SUBMERSIBLE WATER PUMP Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS GUARANTEE This product is guaranteed against faults in

INSTALLATION, COMMISSIONING AND OPERATING MANUAL

INSTALLATION, COMMISSIONING AND OPERATING MANUAL 1 YTBV-D-CE42_0109 CONTENT Available models and capacities Supplier information Warranty Safety Emergency stops/ shutdowns About this manual Models Physical

INSTALLATION, COMMISSIONING AND OPERATING MANUAL 1 YTBV-D-CE42_0109 CONTENT Available models and capacities Supplier information Warranty Safety Emergency stops/ shutdowns About this manual Models Physical

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS Please leave this instruction booklet with the pump as it contains maintenance and safety information (Original Instructions) MODELS This operating manual covers

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS Please leave this instruction booklet with the pump as it contains maintenance and safety information (Original Instructions) MODELS This operating manual covers

MV 4 MV 4 Premium. Operating Instructions. Before first use of the unit read these operating instructions and act in accordance with them.

MV 4 MV 4 Premium Operating Instructions Before first use of the unit read these operating instructions and act in accordance with them. www.kaercher.com/register-and-win 59651790 10/13 3 4 2 5 6 7 1 8

MV 4 MV 4 Premium Operating Instructions Before first use of the unit read these operating instructions and act in accordance with them. www.kaercher.com/register-and-win 59651790 10/13 3 4 2 5 6 7 1 8

Contents. Specifications. Description SV HP 55 SV HP 90. Specifications Warnings Introduction Overview... 4

Contents Specifications Specifications... 1 Warnings... 2 Introduction... 3 Overview... 4 Installation Instructions... 5 Cable Connections... 6 Plumbing Diagram... 7 Electrical Wiring Diagram... 8 SV System

Contents Specifications Specifications... 1 Warnings... 2 Introduction... 3 Overview... 4 Installation Instructions... 5 Cable Connections... 6 Plumbing Diagram... 7 Electrical Wiring Diagram... 8 SV System

INSTALLATION, INSTRUCTION AND SERVICE MANUAL

PLATINUM SMART-HEAT ELECTRIC HEATER SERIES II BY BROMIC INSTALLATION, INSTRUCTION AND SERVICE MANUAL AVAILABLE IN 2300W & 3400W VERSION Original Instructions Version 3.2 AU IMPORTANT READ THIS MANUAL CAREFULLY.

PLATINUM SMART-HEAT ELECTRIC HEATER SERIES II BY BROMIC INSTALLATION, INSTRUCTION AND SERVICE MANUAL AVAILABLE IN 2300W & 3400W VERSION Original Instructions Version 3.2 AU IMPORTANT READ THIS MANUAL CAREFULLY.

CARBON INFRARED HEATER CH1800 RE

CARBON INFRARED HEATER CH1800 RE User s Manual PRECAUTIONS DESCRIPTION OF USE Thank you for purchasing Veito Carbon Infrared Heater. Please read the instructions thoroughly before using your heater. After

CARBON INFRARED HEATER CH1800 RE User s Manual PRECAUTIONS DESCRIPTION OF USE Thank you for purchasing Veito Carbon Infrared Heater. Please read the instructions thoroughly before using your heater. After

PTC Tower Heater. Instruction Manual THE SCIENCE BEHIND HEAT.

PTC Tower Heater Instruction Manual THE SCIENCE BEHIND HEAT www.beldray.com Please read all of the instructions carefully and retain for future reference. Safety Instructions When using electrical appliances,

PTC Tower Heater Instruction Manual THE SCIENCE BEHIND HEAT www.beldray.com Please read all of the instructions carefully and retain for future reference. Safety Instructions When using electrical appliances,

INSTRUCTION MANUAL T30 1MN0107 REV. 0. operates with ISO9001 certified quality system

INSTRUCTION MANUAL 1MN0107 REV. 0 operates with ISO9001 certified quality system TECSYSTEM S.r.l. 20094 Corsico (MI) Tel.: +39-024581861 Fax: +39-0248600783 http://www.tecsystem.it R. 1.1 25/08/16 ENGLISH

INSTRUCTION MANUAL 1MN0107 REV. 0 operates with ISO9001 certified quality system TECSYSTEM S.r.l. 20094 Corsico (MI) Tel.: +39-024581861 Fax: +39-0248600783 http://www.tecsystem.it R. 1.1 25/08/16 ENGLISH

INSTALLATION, INSTRUCTION AND SERVICE MANUAL

PLATINUM SMART-HEAT ELECTRIC HEATER SERIES II BY BROMIC INSTALLATION, INSTRUCTION AND SERVICE MANUAL AVAILABLE IN 2300W VERSION Original Instructions IMPORTANT READ THIS MANUAL CAREFULLY. SEE INSIDE COVER

PLATINUM SMART-HEAT ELECTRIC HEATER SERIES II BY BROMIC INSTALLATION, INSTRUCTION AND SERVICE MANUAL AVAILABLE IN 2300W VERSION Original Instructions IMPORTANT READ THIS MANUAL CAREFULLY. SEE INSIDE COVER

OWNERS GUIDE TO INSTALLATION AND OPERATION

OWNERS GUIDE TO INSTALLATION AND OPERATION SPM SERIES HIGH POWER CENTRIFUGALS READ THESE INSTRUCTIONS CAREFULLY Read these installation instructions in detail before installing your pump. Be sure to check

OWNERS GUIDE TO INSTALLATION AND OPERATION SPM SERIES HIGH POWER CENTRIFUGALS READ THESE INSTRUCTIONS CAREFULLY Read these installation instructions in detail before installing your pump. Be sure to check

USER S MANUAL NKP. Duct heater for supply air pre-heating with external control

USER S MANUAL Duct heater for supply air pre-heating with external control CONTENTS Contents... 2 Safety requirements... 2 Purpose... 4 Delivery set... 4 Designation key... 4 Technical data... 5 Design

USER S MANUAL Duct heater for supply air pre-heating with external control CONTENTS Contents... 2 Safety requirements... 2 Purpose... 4 Delivery set... 4 Designation key... 4 Technical data... 5 Design

FRIDGE / FREEZER OPERATION MANUAL

FRIDGE / FREEZER OPERATION MANUAL Please read all instructions and the safety section carefully before using your new KickAss refrigerator. TABLE OF CONTENTS FEATURES IMPORTANT SAFETY SYMBOLS IMPORTANT

FRIDGE / FREEZER OPERATION MANUAL Please read all instructions and the safety section carefully before using your new KickAss refrigerator. TABLE OF CONTENTS FEATURES IMPORTANT SAFETY SYMBOLS IMPORTANT

User Manual. Electric Heating Element MEG DRY MOA REG 2 REG 3

User Manual Electric Heating Element MEG DRY MOA REG 2 REG 3 User Manual Our products have been designed and manufactured in such a way to ensure that all quality, functionality and aesthetic requirements

User Manual Electric Heating Element MEG DRY MOA REG 2 REG 3 User Manual Our products have been designed and manufactured in such a way to ensure that all quality, functionality and aesthetic requirements

INSTALLATION, INSTRUCTION AND SERVICE MANUAL

PLATINUM SMART-HEAT ELECTRIC HEATER SERIES II BY BROMIC INSTALLATION, INSTRUCTION AND SERVICE MANUAL AVAILABLE IN 2300W & 3400W VERSION Original Instructions Version 2.2 US IMPORTANT READ THIS MANUAL CAREFULLY.

PLATINUM SMART-HEAT ELECTRIC HEATER SERIES II BY BROMIC INSTALLATION, INSTRUCTION AND SERVICE MANUAL AVAILABLE IN 2300W & 3400W VERSION Original Instructions Version 2.2 US IMPORTANT READ THIS MANUAL CAREFULLY.

CRU-S Series Stainless Steel Condensate Recovery Unit

IM-UK-CRU-S UK Issue 1 CRU-S Series Stainless Steel Condensate Recovery Unit 1. Safety information 2. General product information 3. Installation 4. Commissioning 5. Storage, shutdown and equipment protection

IM-UK-CRU-S UK Issue 1 CRU-S Series Stainless Steel Condensate Recovery Unit 1. Safety information 2. General product information 3. Installation 4. Commissioning 5. Storage, shutdown and equipment protection

LC Series - Light Commercial Pump Station Installation and Operation Manual

LC Series - Light Commercial Pump Station Installation and Operation Manual Please keep this manual with the pump station Content Rain Bird LC Series Overview... Safety Instruction... Operation... 3 Pump

LC Series - Light Commercial Pump Station Installation and Operation Manual Please keep this manual with the pump station Content Rain Bird LC Series Overview... Safety Instruction... Operation... 3 Pump

DIRTY WATER SUBMERSIBLE PUMP

WHAT S IN THE BOX DIRTY WATER SUBMERSIBLE PUMP 780W INSTRUCTION MANUAL SPECIFICATIONS Motor: 780W Max. Flow Rate: 15,700l/h Max. Head 8m Max. Immersion: 7m Min. Suction Depth 50mm Max Particle Size: Ø35mm

WHAT S IN THE BOX DIRTY WATER SUBMERSIBLE PUMP 780W INSTRUCTION MANUAL SPECIFICATIONS Motor: 780W Max. Flow Rate: 15,700l/h Max. Head 8m Max. Immersion: 7m Min. Suction Depth 50mm Max Particle Size: Ø35mm

Conception Wall Fire. Instruction Manual THE SCIENCE BEHIND CLEAN.

Conception Wall Fire Instruction Manual BEHIND CLEAN www.beldray.com Please read all of the instructions carefully and retain for future reference. Safety Instructions When using electrical appliances,

Conception Wall Fire Instruction Manual BEHIND CLEAN www.beldray.com Please read all of the instructions carefully and retain for future reference. Safety Instructions When using electrical appliances,

JT-SB116JH-G-NA JT-SB116JH-W-NA

1311875HF4503 Hand dryer MODEL JT-SB116JH-G-NA JT-SB116JH-W-NA Unit color -G (Grey), -W (White) Model Name Display Position. Power voltage display position. INSTRUCTION MANUAL For User Read this manual

1311875HF4503 Hand dryer MODEL JT-SB116JH-G-NA JT-SB116JH-W-NA Unit color -G (Grey), -W (White) Model Name Display Position. Power voltage display position. INSTRUCTION MANUAL For User Read this manual

SuperFlo High Performance Pump

SuperFlo High Performance Pump Installation and User's Guide IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Customer Service If you have questions about ordering

SuperFlo High Performance Pump Installation and User's Guide IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Customer Service If you have questions about ordering

DIRTY WATER SUBMERSIBLE PUMP KIT

WHAT S IN THE BOX DIRTY WATER SUBMERSIBLE PUMP KIT 1000W INSTRUCTION MANUAL SPECIFICATIONS Motor: 1000W Max. Flow Rate: 18,000l/h Max. Head 9m Max. Immersion: 7m Min. Suction Depth 50mm Max Particle Size:

WHAT S IN THE BOX DIRTY WATER SUBMERSIBLE PUMP KIT 1000W INSTRUCTION MANUAL SPECIFICATIONS Motor: 1000W Max. Flow Rate: 18,000l/h Max. Head 9m Max. Immersion: 7m Min. Suction Depth 50mm Max Particle Size:

Inverted Bucket Steam Traps

INSTALLATION AND MAINTENANCE INSTRUCTIONS IM-2-00-US December 201 Inverted Bucket Steam Traps Safety Information Safe operation of these products can only be guaranteed if they are properly installed,

INSTALLATION AND MAINTENANCE INSTRUCTIONS IM-2-00-US December 201 Inverted Bucket Steam Traps Safety Information Safe operation of these products can only be guaranteed if they are properly installed,

12L DEHUMIDIFIER OPERATING INSTRUCTIONS

12L DEHUMIDIFIER OPERATING INSTRUCTIONS Attention: This Dehumidifier is rated to extract 12L per day in an environment of 80% humidity and temperature of 30 C. This is the world-wide standard for rating

12L DEHUMIDIFIER OPERATING INSTRUCTIONS Attention: This Dehumidifier is rated to extract 12L per day in an environment of 80% humidity and temperature of 30 C. This is the world-wide standard for rating

INSTRUCTION MANUAL. operates with ISO9001 certified quality system. TECSYSTEM S.r.l Corsico (MI) Tel.: Fax:

INSTRUCTION MANUAL BAR 1200-1800-3600 1MN0080 Rev 0 operates with ISO9001 certified quality system TECSYSTEM S.r.l. 20094 Corsico (MI) Tel.: +39-024581861 Fax: +39-0248600783 http://www.tecsystem.it R.

INSTRUCTION MANUAL BAR 1200-1800-3600 1MN0080 Rev 0 operates with ISO9001 certified quality system TECSYSTEM S.r.l. 20094 Corsico (MI) Tel.: +39-024581861 Fax: +39-0248600783 http://www.tecsystem.it R.

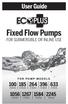

User Guide. Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE FOR PUMP MODELS # # # # # # # # #728333

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

Acquaer Ltd. H-4900, Fehérgyarmat, Szatmári út 11. CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2

CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2 Congratulations on your purchase of a LEO Centrifugal Pump It is important that you read, fully understand and observe the following

CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2 Congratulations on your purchase of a LEO Centrifugal Pump It is important that you read, fully understand and observe the following

INSTALLATION, INSTRUCTION AND SERVICE MANUAL

PLATINUM SMART-HEAT ELECTRIC HEATER SERIES II BY BROMIC INSTALLATION, INSTRUCTION AND SERVICE MANUAL AVAILABLE IN 2300W VERSION Original Instructions IMPORTANT READ THIS MANUAL CAREFULLY. SEE INSIDE COVER

PLATINUM SMART-HEAT ELECTRIC HEATER SERIES II BY BROMIC INSTALLATION, INSTRUCTION AND SERVICE MANUAL AVAILABLE IN 2300W VERSION Original Instructions IMPORTANT READ THIS MANUAL CAREFULLY. SEE INSIDE COVER

HR 601 C A AUS. ENGLISH Instructions for use Page 2

HR 61 C A AUS ENGLISH Instructions for use Page 2 1 INSTRUCTION FOR USE IMPORTANT SAFETY INSTRUCTIONS BEFORE USING THE GLASS CERAMIC HOB INSTALLATION ELECTRICAL CONNECTIONS ENERGY SAVING TIPS SAFEGUARDING

HR 61 C A AUS ENGLISH Instructions for use Page 2 1 INSTRUCTION FOR USE IMPORTANT SAFETY INSTRUCTIONS BEFORE USING THE GLASS CERAMIC HOB INSTALLATION ELECTRICAL CONNECTIONS ENERGY SAVING TIPS SAFEGUARDING

USE AND INSTALLATION HANDBOOK

Date : 10/02/14 Rev. 01 PR.T : FG006176 USE AND INSTALLATION HANDBOOK SIMPLEX-UP CONTROL PANEL FOR 1 ELECTRIC PUMP WITH CURRENT CONTROL. SIMPLEX-UP Via Enrico Fermi, 8-35020 Polverara PD Tel.049/9772407

Date : 10/02/14 Rev. 01 PR.T : FG006176 USE AND INSTALLATION HANDBOOK SIMPLEX-UP CONTROL PANEL FOR 1 ELECTRIC PUMP WITH CURRENT CONTROL. SIMPLEX-UP Via Enrico Fermi, 8-35020 Polverara PD Tel.049/9772407

SPARUS 160 ENERGY EFFICIENT AQUACULTURE DUTY PUMP

AQUATIC ECO-SYSTEMS SPARUS 160 ENERGY EFFICIENT AQUACULTURE DUTY PUMP INSTALLATION AND USER S GUIDE IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS i CUSTOMER SERVICE

AQUATIC ECO-SYSTEMS SPARUS 160 ENERGY EFFICIENT AQUACULTURE DUTY PUMP INSTALLATION AND USER S GUIDE IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS i CUSTOMER SERVICE

E-COMBI EVO E-SYSTEM EVO

E-COMBI EVO E-SYSTEM EVO User s manual CONDENSING WALL-HUNG GAS BOILER G.C.N.:47-116-68 (24 kw) G.C.N.:47-116-69 (30 kw) G.C.N.:47-116-70 (38 kw) G.C.N.:41-116-39 (24 kw) G.C.N.:41-116-40 (30 kw) Country

E-COMBI EVO E-SYSTEM EVO User s manual CONDENSING WALL-HUNG GAS BOILER G.C.N.:47-116-68 (24 kw) G.C.N.:47-116-69 (30 kw) G.C.N.:47-116-70 (38 kw) G.C.N.:41-116-39 (24 kw) G.C.N.:41-116-40 (30 kw) Country