Protein Skimmer 400 HO

|

|

|

- Shanon Lambert

- 5 years ago

- Views:

Transcription

1 Protein Skimmer 400 HO US The sera marin Protein Skimmer 400 HO is a high performance, energy saving and flexibly usable dispergator skimmer for aquariums up to 400 l (06 US gal.). It can be used as a hang-on version (fig. ) as well as in a filter underneath the aquarium (fig. ) (sump). It is therefore optimally suitable for all aquarists that wish to switch over from freshwater aquariums to saltwater aquariums. Included items (fig. 3) 3. Skimmer with holder and built-in tubing 3. Dispergator pump NP 600 with pinwheel 3.3 Stick-on tubing on the pressure side (connection between pump and skimmer) 3.4 Flexible outlet hose 3.5 Air intake with intake nozzle and air regulator for the dispergator pump 3.6 Flexible flotate outlet hose with adjustor Skimmer tasks Information for use sera marin Protein Skimmer 400 HO Please read these instructions carefully and keep for future use. A skimmer is the heart of saltwater aquarium filtration. It removes protein that is permanently released into the water by micro organisms, invertebrates and fish. The skimmer removes particles such as floating matter and aerates the aquarium. Protein not removed from the water will lead to an increasing amount of harmful substances such as ammonia, nitrite and nitrate (bacterial breakdown chain beginning with protein). Keeping saltwater organisms in closed systems would be considerably more difficult or, depending on the requirements of the species in question, even impossible. Function principle (fig. 4) The dispergator pump of the sera marin Protein Skimmer draws in the water from the aquarium or from the filter chamber (4.), mixes it with air drawn in (4.3) by the resulting low pressure inside the gyro case (4.), where it is scattered into tiny air bubbles by the sera pinwheel. The fine air bubbles provide a large surface where the protein can settle. This water/air mixture is pumped into the inner reaction chamber of the protein skimmer (4.4). The outlet directed sideways make the mixture rotate, keeping the air bubbles floating for a longer time and therefore increasing the flotate yield (4.5). The protein attaches to the bubbles within this chamber. The bubbles accumulate at the water surface and form a solid foam while floating there. The narrowing standpipe of the foam cup directs this foam into the flotate cup where it is collected (4.6). The purified water flows into the standpipe at the bottom end of the skimmer and back into the aquarium or filter tank through the outlet hose (4.7) connected to it. Assembly instruction (fig. 5) 5. Cover 5. Flotate cup 5.. Inner tube of flotate cup 5.. Flotate outlet opening with hose and adjustor 5.3 O-ring seal 5.4 Flow adjustor 5.5 Skimmer case 5.6 Water outlet opening 5.7 O-ring seal 5.8 Outlet hose for clean water 5.9 Holder bracket 5.0 Locking screw 5. Water intake pipe 0 mm (0.8 in.) diameter 5. Water intake nozzle 5.3 O-ring seal 5.4. Hose fixture for flotate outlet 5.4. Hose fixture for air intake Flotate outlet hose with adjustor 5.5 Dispergator pump 5.5. Rotor 5.5. Shaft Rubber bearing 5.6 Holder plate 5.7 Pump head with bayonet lock 5.8 Intake opening 5.9 Air hose 5.0 Intake nozzle 5. Air regulator Hang-on installation on the outside of the aquarium glass (fig. ) An easily accessible but well protected place on the side or on the back should be selected for this installation mode. The skimmer is hung on the aquarium edge from the outside using the holder bracket (5.9) (fig. ). The locking screw (5.0) within the holder bracket serves only for securing the skimmer and should be fastened only carefully. The water intake pipe (5.) is pushed onto the water intake nozzle (5.). The pump (5.5) is pushed onto the water intake pipe (5.) on the inside of the aquarium, underneath the water surface. The pump can then hang there without further securing. However, you may additionally attach the pump to the aquarium glass. Insert the holder plate (5.6) into one of the rails on the pump to do so. Due to the suction cups, the pump will then be firmly attached to the aquarium glass. Do not twist the pump when pressing the suction cups, as the bayonet lock of the pump head cover (5.7) might loosen. Installing the pump in deeper water will reduce air intake performance while increasing the water flow rate. The pump (5.5) is connected to the air intake hose (5.9). Stick the air hose (5.9) onto the nozzle on the inner side of the split cone (5.0) to do so. The cone is then pushed into the intake opening (5.8) of the pump. The hose (5.9) is directed through the hose fixture (5.4.) on the skimmer case (5.5) and fixed above the water surface, allowing the pump to draw in air. The air regulator (5.) is attached to the hose end. It will also prevent the hose from slipping out. Push the outlet hose for clean water (5.8) onto the water outlet opening (5.6) and direct the outlet hose over the aquarium edge, allowing the water to flow back into the aquarium. The skimmer is now ready for operation and can be started. Installation in a filter tank (fig. ) The sera marin Protein Skimmer 400 HO can also be installed in a cabinet filter. The installation outside the filter tank (on the aquarium edge) is carried out as described above. It is then hung onto the edge of the filter tank. You can simply place it aside the tank in case the filter tank is not high enough. The dispergator pump is attached inside the filter tank hanging just underneath the water surface. It is advisable to maintain a constant water level by means of automatic evaporation compensation as to prevent the pump running dry. Operation Air is automatically drawn in after switching on the pump. The air is scattered into very fine air bubbles by the rotating pinwheel (5.5.). The special construction of the pump prevents loud noise. The skimmer (5.5) will run full of saltwater. Accordingly, the water level of the aquarium will sink slightly. Top up the tank accordingly with saltwater. The pump will now blend water and air. Starting a skimmer for the first time will often lead to relatively strong foam formation: Extremely moist foam will end up in the flotate cup (5.) which quickly runs full of water this way. In that case a temporarily reduced air intake at the air regulator (5.) or a very low water level inside the skimmer will help. Each aquarium has its own biology and its own protein level. One day after starting up you should adjust the skimmer more accurately for the first time: First open the air regulator (5.) of air intake to the dispergator pump as wide as possible. As a reaction, you will notice that the water/foam level within the skimmer (5.5) rises within the next minutes. This level can be further raised by turning the flow adjustor (5.4) on the outlet of the unit. The level within the skimmer should be approximately cm (0.4 in.) below the gray edge of the flotate cup. Depending on whether you wish to skim moist or rather dry foam you can adjust the air regulator (5.) and the flow adjustor (5.4) in combination. However, the air intake should always be as wide open as possible, i.e. you should primarily adjust the foam amount with the flow adjustor (5.4). Fully open the flow adjustor (5.4) before removing the flotate cup (5.) and switch off the pump if necessary as to prevent water flowing over. Cleaning Although the flotate cup (5.) is equipped with a flotate outlet (5..) through a hole in the bottom it needs to be cleaned every few days. In particular, the inner tube (5..) of the flotate cup must be cleaned regularly as to prevent the air bubbles of the rising foam from bursting at the deposits that often contain fat. The flotate outlet (5..) in the flotate cup can be used for directing the flotate into a larger collection container, e.g. in case of prolonged absence. Deposits may form on the bottom of the skimmer over time, which reduce outflow at the bottom and thus affect the skimmer performance. Therefore, the entire skimmer should be cleaned regularly. The pump (5.5) and the air intake (5.9, 5.0, 5.) should be checked monthly. Lime deposits may especially reduce the air intake (5.). Clean the parts mechanically in case of lime deposits. Persistent deposits can be removed by soaking the parts to be cleaned in sera ph-minus. Do not use any household detergents. Rinse the parts under running water before putting them back in place. Depending on the situation, the rotor (5.5.) of the pump can be covered with mucous and then needs to be cleaned. Simply twist the pump head (5.7) carefully against the pump body, until both parts separate at the bayonet. The rotor (5.5.) can be taken out of the pump along with the magnet after you have taken off the pump head. The shaft (5.5.) can be pulled out of the rotor after removing the stickon rubber bearing (5.5.3).

2 SAFETY PRECAUTIONS: Pull all mains plugs before every maintenance measure in the aquarium! The pump performance will considerably increase in case the air supply is suddenly switched off, the skimmer can overflow, and large amounts of water may be pumped from the tank! Troubleshooting: The sera marin Protein Skimmer 400 HO is an open flow unit. If the water flow back into the aquarium is obstructed or otherwise not possible, large amounts of water can be pumped from the aquarium and cause water damage. Problem Possible cause Troubleshooting Insufficient air intake rate Intake valve (5.) insufficiently o- Open intake valve (5.) further pened Air hose (5.9) is encrusted with Clean lime or dirty Intake nozzle (5.8) on the pump is Pull off and clean dirty Pump performance is too low Clean rotor and shaft Foam too moist/ Water level within the unit is too Open flow adjustor (5.4) further too much foam high Too much air Close intake valve (5.) further, first try to adjust with the flow adjustor (5.4) Foam too dry/ very viscous foam Water level within the unit is too low Slightly reduce flow rate at the flow adjustor (5.4) Insufficient pump performance Clean rotor, shaft and intake nozzle Insufficient foam formation Insufficient amount of air Open intake valve (5.) further Foam formation too strong, very Water strongly polluted Partial water change, feed less brownish flotate, very sticky foam see: Insufficient foam formation Increase flotate moisture Foam formation breaks down Feeding fatty food (fish, mussels) Foam formation will begin again after a few hours Air intake congested Clean air intake or open further Spare parts: Rotor with pinwheel Ceramic shaft with rubber bearings Pump NP 600 (complete) Flotate cup with cover O-ring seal for outlet Disposal of the unit: Waste electrical and electronic equipment (WEEE) must not get into domestic waste! If ever the unit cannot be used anymore, the consumer is legally obliged to hand in waste electrical and electronic equipment (WEEE) separately from domestic waste, e.g. at a collection point of his community/his district. This ensures that waste electrical and electronic equipment (WEEE) is expertly processed and that negative effects to the environment are avoided. Therefore electrical and electronic equipment bears the following symbol: Warranty: When following the directions for use, the sera marin Protein Skimmer 400 HO will perform reliably. We are liable for the freedom from faults of our products only within legal regulations beginning with the purchase date. We are liable for complete flawlessness at delivery. Should usual wear and tear occur by use as intended by us, this is not considered a defect. Warranty claims are also excluded in this case. This particularly refers to the running unit (rotor, shaft, rubber bearings) and the hoses. In every case of a defect we recommend that you consult the specialized retailer where you purchased the unit. He will be able to judge whether it is actually a warranty case. In case of sending the unit to us we will unnecessarily have to charge you for occurring costs. Any liability because of contract breach is limited to intent or gross negligence. sera will be liable in case of slight negligence only in case of injuries to life, body and health, in case of essential contractual obligations and with binding liability according to the product liability code. In that case, the extent of liability is limited to the replacement of contractually typically foreseeable damages. Technical Data: Width: Height: Depth: Volume: 0.7 cm (8. in.) 40 cm (5.8 in.) 8.6 cm (7.3 in.) approx. 3 l (0.8 US gal.) Pump: NP V ~ 50 Hz, 0 W max. 40 C (04 F) Hmax:. m (3.9 ft.) Qmax:,400 l/h (369 US gal./h) IPX8: up to m (3.3 ft.) water depth m (3.3 ft.) 3 4

3 3 3. Protein Skimmer 400 HO

4 Subject to technical alterations and errors 7 Update: 06.08US

5 Protein Skimmer 600 S US The sera marin Protein Skimmer 600 S is a high performance, energy saving dispergator skimmer for filters underneath the aquarium (so-called filter sump). It is easy to operate and suitable for aquariums up to 600 liters (59 US gal.). Included items (fig. ). Skimmer with hose connectors. Dispergator pump NP 600 with pinwheel.3 Connecting hose.4 Flexible outlet hose.5 Air intake with intake nozzle and air regulator for the dispergator pump.6 Flexible flotate outlet hose with adjustor Skimmer tasks Information for use sera marin Protein Skimmer 600 S Please read these instructions carefully and keep for future use. A skimmer is the heart of saltwater aquarium filtration. It removes protein that is permanently released into the water by micro organisms, invertebrates and fish. The skimmer removes particles such as floating matter and aerates the aquarium. Protein not removed from the water will lead to an increasing amount of harmful substances such as ammonia, nitrite and nitrate (bacterial breakdown chain beginning with protein). Keeping saltwater organisms in closed systems would be considerably more difficult or, depending on the requirements of the species in question, even impossible. Function principle (fig. 3) The dispergator pump of the sera marin Protein Skimmer draws in the water from the aquarium or from the filter chamber (3.), mixes it with air drawn in (3.3) by the resulting low pressure inside the gyro case (3.), where it is scattered into tiny air bubbles by the sera pinwheel. The fine air bubbles provide a large surface where the protein can settle. This water/air mixture is pumped into the inner reaction chamber of the protein skimmer (3.4). The outlet directed sideways make the mixture rotate, keeping the air bubbles floating for a longer time and therefore increasing the flotate yield (3.5). The protein attaches to the bubbles within this chamber. The bubbles accumulate at the water surface and form a solid foam while floating there. The narrowing standpipe of the foam cup directs this foam into the flotate cup where it is collected (3.6). The purified water flows into the standpipe at the bottom end of the skimmer and back into the aquarium or filter tank through the outlet hose (3.7) connected to it. Assembly instruction (fig. 4) 4. Cover 4. Flotate cup 4.. Inner tube of flotate cup 4.. Flotate outlet opening with hose and adjustor 4.3 O-ring seal 4.4 Flow adjustor 4.5 Skimmer case 4.6 Water outlet opening 4.7 O-ring seal 4.8 Outlet hose for clean water 4.9 Hose connection 4.0 Water intake nozzle 4. O-ring seal 4.. Hose fixture for flotate outlet 4.. Hose fixture for air intake 4..3 Flotate outlet hose with adjustor 4.3 Dispergator pump 4.3. Rotor 4.3. Shaft Rubber bearing 4.4 Holder plate 4.5 Pump head with bayonet lock 4.6 Intake opening 4.7 Air hose 4.8 Intake nozzle 4.9 Air regulator Installation in a filter tank (fig. ) The sera marin Protein Skimmer 600 S is installed in a cabinet filter. To do so, the pump (on the holder plate 4.4) is connected to the skimmer by means of the included piece of hose before it is placed in the filter sump (fig. ). The recommended water level in the filter sump is between at least 0 cm (4 in.) and max. 0 cm (8 in.). It is advisable to maintain a constant water level by means of automatic evaporation compensation as to prevent the pump running dry. Operation Air is automatically drawn in after switching on the pump. The air is scattered into very fine air bubbles by the rotating pinwheel (4.3.). The special construction of the pump prevents loud noise. The skimmer (4.5) will run full of saltwater. Accordingly, the water level of the aquarium will sink slightly. Top up the tank accordingly with saltwater. The pump will now blend water and air. Starting a skimmer for the first time will often lead to relatively strong foam formation: Extremely moist foam will end up in the flotate cup (4.) which quickly runs full of water this way. In that case a temporarily reduced air intake at the air regulator (4.9) or a very low water level inside the skimmer will help. Each aquarium has its own biology and its own protein level. One day after starting up you should adjust the skimmer more accurately for the first time: First open the air regulator (4.9) of air intake to the dispergator pump as wide as possible. As a reaction, you will notice that the water/foam level within the skimmer (4.5) rises within the next minutes. This level can be further raised by turning the flow adjustor (4.4) on the outlet of the unit. The level within the skimmer should be approximately cm (0.4 in.) below the gray edge of the flotate cup. Depending on whether you wish to skim moist or rather dry foam you can adjust the air regulator (4.9) and the flow adjustor (4.4) in combination. However, the air intake should always be as wide open as possible, i.e. you should primarily adjust the foam amount with the flow adjustor (4.4). Fully open the flow adjustor (4.4) before removing the flotate cup (4.) and switch off the pump if necessary as to prevent water flowing over. Cleaning Although the flotate cup (4.) is equipped with a flotate outlet (4..) through a hole in the bottom it needs to be cleaned every few days. In particular, the inner tube (4..) of the flotate cup must be cleaned regularly as to prevent the air bubbles of the rising foam from bursting at the deposits that often contain fat. The flotate outlet (4..) in the flotate cup can be used for directing the flotate into a larger collection container, e.g. in case of prolonged absence. Deposits may form on the bottom of the skimmer over time, which reduce outflow at the bottom and thus affect the skimmer performance. Therefore, the entire skimmer should be cleaned regularly. The pump (4.3) and the air intake (4.7, 4.8, 4.9) should be checked monthly. Lime deposits may especially reduce the air intake (4.9). Clean the parts mechanically in case of lime deposits. Persistent deposits can be removed by soaking the parts to be cleaned in sera ph-minus. Do not use any household detergents. Rinse the parts under running water before putting them back in place. Depending on the situation, the rotor (4.3.) of the pump can be covered with mucous and then needs to be cleaned. Simply twist the pump head (4.5) carefully against the pump body, until both parts separate at the bayonet. The rotor (4.3.) can be taken out of the pump along with the magnet after you have taken off the pump head. The shaft (4.3.) can be pulled out of the rotor after removing the stickon rubber bearing (4.3.3). SAFETY PRECAUTIONS: Pull all mains plugs before every maintenance measure in the aquarium! The pump performance will considerably increase in case the air supply is suddenly switched off, the skimmer can overflow, and large amounts of water may be pumped from the tank! The sera marin Protein Skimmer 600 S is an open flow unit. If the water flow back into the aquarium is obstructed or otherwise not possible, large amounts of water can be pumped from the aquarium and cause water damage.

6 Troubleshooting: Problem Possible cause Troubleshooting Insufficient air intake rate Intake valve (4.9) insufficiently o- Open intake valve (4.9) further pened Air hose (4.7) is encrusted with Clean lime or dirty Intake nozzle (4.6) on the pump is Pull off and clean dirty Pump performance is too low Clean rotor and shaft Foam too moist/ Water level within the unit is too Open flow adjustor (4.4) further too much foam high Too much air Close intake valve (4.9) further, first try to adjust with the flow adjustor (4.4) Foam too dry/ very viscous foam Water level within the unit is too low Slightly reduce flow rate at the flow adjustor (4.4) Insufficient pump performance Clean rotor, shaft and intake nozzle Insufficient foam formation Insufficient amount of air Open intake valve (4.9) further Foam formation too strong, very Water strongly polluted Partial water change, feed less brownish flotate, very sticky foam see: Insufficient foam formation Increase flotate moisture Foam formation breaks down Feeding fatty food (fish, mussels) Foam formation will begin again after a few hours Air intake congested Clean air intake or open further Spare parts: Rotor with pinwheel Ceramic shaft with rubber bearings Pump NP 600 (complete) Flotate cup with cover O-ring seal for outlet Disposal of the unit: Waste electrical and electronic equipment (WEEE) must not get into domestic waste! If ever the unit cannot be used anymore, the consumer is legally obliged to hand in waste electrical and electronic equipment (WEEE) separately from domestic waste, e.g. at a collection point of his community/his district. This ensures that waste electrical and electronic equipment (WEEE) is expertly processed and that negative effects to the environment are avoided. Therefore electrical and electronic equipment bears the following symbol: Warranty: When following the directions for use, the sera marin Protein Skimmer 600 S will perform reliably. We are liable for the freedom from faults of our products only within legal regulations beginning with the purchase date. We are liable for complete flawlessness at delivery. Should usual wear and tear occur by use as intended by us, this is not considered a defect. Warranty claims are also excluded in this case. This particularly refers to the running unit (rotor, shaft, rubber bearings) and the hoses. In every case of a defect we recommend that you consult the specialized retailer where you purchased the unit. He will be able to judge whether it is actually a warranty case. In case of sending the unit to us we will unnecessarily have to charge you for occurring costs. Any liability because of contract breach is limited to intent or gross negligence. sera will be liable in case of slight negligence only in case of injuries to life, body and health, in case of essential contractual obligations and with binding liability according to the product liability code. In that case, the extent of liability is limited to the replacement of contractually typically foreseeable damages. Technical Data: Height: Width: Depth: Volume: 50.8 cm (0 in.) 6.6 cm (6.5 in.) 8.6 cm (7.3 in.) approx. 3.3 l (0.8 US gal.) Pump: NP V ~ 50 Hz, 0 W max. 40 C (04 F) Hmax:. m (3.9 ft.) Qmax:,400 l/h (369 US gal./h) IPX8: up to m (3.3 ft.) water depth m (3.3 ft.) 3 4

7 Protein Skimmer 600 S Subject to technical alterations and errors 5 6 Update: 06.08US

KOI Professional Pond Filter

US KOI Professional 12000 Pond Filter Step 2: Mechanical water purification sludge removal The split sieve (1.2) removes all particles larger than 0.2 mm. The sieved particles get into the waste water

US KOI Professional 12000 Pond Filter Step 2: Mechanical water purification sludge removal The split sieve (1.2) removes all particles larger than 0.2 mm. The sieved particles get into the waste water

BioMaster 250/350/600 BioMaster Thermo 250/350/600

Downloaded from www.watergardeningdirect.com BioMaster 250/350/600 BioMaster Thermo 250/350/600 A BMR0003 B BMR0004 2 BioMaster 250/350/600, BioMaster Thermo 250/350/600 C D BMR0021 BMR0022 3 Downloaded

Downloaded from www.watergardeningdirect.com BioMaster 250/350/600 BioMaster Thermo 250/350/600 A BMR0003 B BMR0004 2 BioMaster 250/350/600, BioMaster Thermo 250/350/600 C D BMR0021 BMR0022 3 Downloaded

MiniSkim. Inspiring Excellence in Fish Keeping! Instruction version: 17/08/2012.

MiniSkim 80 Inspiring Excellence in Fish Keeping! www.aquaone.com.au Instruction version: 17/08/2012 Important Safeguards To guard against injury, basic safety precautions should be observed, including

MiniSkim 80 Inspiring Excellence in Fish Keeping! www.aquaone.com.au Instruction version: 17/08/2012 Important Safeguards To guard against injury, basic safety precautions should be observed, including

RONDA 2-58 Duo Heavy Duty Industrial Vacuum Cleaner For Liquid Filtration and Transport

V. BRØNDUM A/S Item No. A0800063 RONDA 2-58 Duo Heavy Duty Industrial Vacuum Cleaner For Liquid Filtration and Transport IMPORTANT! Read this manual before you operate the machine Index Description of

V. BRØNDUM A/S Item No. A0800063 RONDA 2-58 Duo Heavy Duty Industrial Vacuum Cleaner For Liquid Filtration and Transport IMPORTANT! Read this manual before you operate the machine Index Description of

AquaReef Cube. Inspiring Excellence in Fish Keeping!

AquaReef 275 Cube Inspiring Excellence in Fish Keeping! www.aquaone.com.au Instruction version: 25/03/2011 Important Safeguards To guard against injury, basic safety precautions should be observed, including

AquaReef 275 Cube Inspiring Excellence in Fish Keeping! www.aquaone.com.au Instruction version: 25/03/2011 Important Safeguards To guard against injury, basic safety precautions should be observed, including

INSTALLATION & OPERATION Rev 1.00A DISTRIBUTED EXCLUSIVELY BY CMA DISHMACHINES KNOTT AVENUE GARDEN GROVE, CALIFORNIA 92841

MODEL UC 60e INSTALLATION & OPERATION Rev 1.00A DISTRIBUTED EXCLUSIVELY BY CMA DISHMACHINES 12700 KNOTT AVENUE GARDEN GROVE, CALIFORNIA 92841 800-854- 6417 FAX 714-895-2141 www.cmadishmachines.com TABLE

MODEL UC 60e INSTALLATION & OPERATION Rev 1.00A DISTRIBUTED EXCLUSIVELY BY CMA DISHMACHINES 12700 KNOTT AVENUE GARDEN GROVE, CALIFORNIA 92841 800-854- 6417 FAX 714-895-2141 www.cmadishmachines.com TABLE

Installation manual Mini Comfort 50 S/L 07/ V EN

Installation manual Mini Comfort 50 S/L 07/2015 - V 1.1 - EN www.veneco-ventilation.be Veneco ventilation by Elek Trends Productions nv Blauwfazantjesstraat 4 B - 7700 Moeskroen Tel. +32 (0)56 48 15 90

Installation manual Mini Comfort 50 S/L 07/2015 - V 1.1 - EN www.veneco-ventilation.be Veneco ventilation by Elek Trends Productions nv Blauwfazantjesstraat 4 B - 7700 Moeskroen Tel. +32 (0)56 48 15 90

MCE 400. Operating instruction and Spare parts list

MCE 400 Operating instruction and Spare parts list EN IMPORTANT SAFETY INSTRUCTIONS EN WARNING To guard against injury, basic safety precautions should be observed, including the following. 1) READ AND

MCE 400 Operating instruction and Spare parts list EN IMPORTANT SAFETY INSTRUCTIONS EN WARNING To guard against injury, basic safety precautions should be observed, including the following. 1) READ AND

2 IN 1 JUICER AND BLENDER

YOUR SAFETY & INSTRUCTION MANUAL PLEASE READ CAREFULLY 2 IN 1 JUICER AND BLENDER MODEL N19001 TECHNICAL DATA Description: Model: Rated Voltage: Frequency: Power consumption: 2 in 1 Juicer and Blender N19001

YOUR SAFETY & INSTRUCTION MANUAL PLEASE READ CAREFULLY 2 IN 1 JUICER AND BLENDER MODEL N19001 TECHNICAL DATA Description: Model: Rated Voltage: Frequency: Power consumption: 2 in 1 Juicer and Blender N19001

Installation & Maintenance Guide

Installation & Maintenance Guide Internal Mini Skimmer 115 For Model 510114 Skimmer 30 Gallon www.aquaticlife.com Thank you for purchasing an AquaticLife Internal Mini Skimmer for use with your marine

Installation & Maintenance Guide Internal Mini Skimmer 115 For Model 510114 Skimmer 30 Gallon www.aquaticlife.com Thank you for purchasing an AquaticLife Internal Mini Skimmer for use with your marine

Operation Manual ARTICEL

Operation Manual ARTICEL 50948 SunSun HW-702A 50949 SunSun HW-702B 50950 SunSun HW-703A 50951 SunSun HW-703B 50952 SunSun HW-704A 50953 SunSun HW-704B Read and follow the operating instructions and safety

Operation Manual ARTICEL 50948 SunSun HW-702A 50949 SunSun HW-702B 50950 SunSun HW-703A 50951 SunSun HW-703B 50952 SunSun HW-704A 50953 SunSun HW-704B Read and follow the operating instructions and safety

Installation and Operating Instructions. Models: T4-12LOW-9IS

Installation and Operating Instructions Models: T4-12LOW-9IS Dear Valued Customer, Thank you and congratulations on purchasing your new Parmco appliance. All Parmco products are made to the highest quality

Installation and Operating Instructions Models: T4-12LOW-9IS Dear Valued Customer, Thank you and congratulations on purchasing your new Parmco appliance. All Parmco products are made to the highest quality

LS Condensate Removal Pump INSTRUCTION MANUAL REVISION A

LS Condensate Removal Pump INSTRUCTION MANUAL 6-71-075-115 REVISION A CAUTION: Combustible liquids may not be pumped! The condensate pump may not be run dry, as this can destroy the bearings in a very

LS Condensate Removal Pump INSTRUCTION MANUAL 6-71-075-115 REVISION A CAUTION: Combustible liquids may not be pumped! The condensate pump may not be run dry, as this can destroy the bearings in a very

Acquaer Ltd. H-4900, Fehérgyarmat, Szatmári út 11. CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2

CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2 Congratulations on your purchase of a LEO Centrifugal Pump It is important that you read, fully understand and observe the following

CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2 Congratulations on your purchase of a LEO Centrifugal Pump It is important that you read, fully understand and observe the following

Operating principle. Bolero XL (2008)

Operating principle Bolero XL (2008) All rights reserved. No part of this document may be copied and/or published by means of printing, photocopying, microfilming or by any other means whatsoever without

Operating principle Bolero XL (2008) All rights reserved. No part of this document may be copied and/or published by means of printing, photocopying, microfilming or by any other means whatsoever without

IMPORTANT SAFETY INSTRUCTIONS WARNING: When using electric appliances, basic

INSTRUCTIONS PERTAINING TO; RISK OF FIRE, ELECTRIC SHOCK OR HARM TO PERSONS IMPORTANT SAFETY INSTRUCTIONS WARNING: When using electric appliances, basic precautions should always be followed, including

INSTRUCTIONS PERTAINING TO; RISK OF FIRE, ELECTRIC SHOCK OR HARM TO PERSONS IMPORTANT SAFETY INSTRUCTIONS WARNING: When using electric appliances, basic precautions should always be followed, including

Auto Top-Off & Ultra-Precise Liquid Level Controller II

Auto Top-Off & Ultra-Precise Liquid Level Controller II (UPLC-II-G6) INSTALLATION MANUAL REV A - 08-26-2010 TABLE OF CONTENTS SYSTEM FEATURES System Specification... 3 DESCRIPTION FOR SETUP Operations...

Auto Top-Off & Ultra-Precise Liquid Level Controller II (UPLC-II-G6) INSTALLATION MANUAL REV A - 08-26-2010 TABLE OF CONTENTS SYSTEM FEATURES System Specification... 3 DESCRIPTION FOR SETUP Operations...

Systemfilter Operation manual GB

Systemfilter 10000 Operation manual GB The systemfilter 10000 has been developed for professional aquarium and aquaculture systems. The maximum recommended water volume depends on the bioload. For display

Systemfilter 10000 Operation manual GB The systemfilter 10000 has been developed for professional aquarium and aquaculture systems. The maximum recommended water volume depends on the bioload. For display

BarAid 400. Installation and. Starting from Serial No.:

Glasswasher BarAid 400 Installation and operation Instructions Starting from Serial No.: 8649 1065 REV. 19.01.2009 DE 1618-A-01-09 Content Page 1 Important Notes... 4 2 Installation... 5 2.1 Location...

Glasswasher BarAid 400 Installation and operation Instructions Starting from Serial No.: 8649 1065 REV. 19.01.2009 DE 1618-A-01-09 Content Page 1 Important Notes... 4 2 Installation... 5 2.1 Location...

HD 525 S 06/03 A ! 5.960

HD 525 S 5 960 845 A2005225 06/03! Please read these operating instructions before starting and strictly observe the Safety Instructions for High Pressure Cleaners (5.951-949). WARNING DO NOT SPRAY ELECTRICAL

HD 525 S 5 960 845 A2005225 06/03! Please read these operating instructions before starting and strictly observe the Safety Instructions for High Pressure Cleaners (5.951-949). WARNING DO NOT SPRAY ELECTRICAL

CP-200 Push Button. CP Warewash Pump Instruction & Operation Manual Push Button , Rev1.0,

CP-200 - Warewash Pump Instruction & Operation Manual Push Button 20-08881-01, Rev1.0, 25.06.2012, Page 1 of 8 Contents A) Description B) Site Survey and Installation Requirements C) Package Contents D)

CP-200 - Warewash Pump Instruction & Operation Manual Push Button 20-08881-01, Rev1.0, 25.06.2012, Page 1 of 8 Contents A) Description B) Site Survey and Installation Requirements C) Package Contents D)

HUMIDIFIERS OWNERS MANUAL A GUIDE TO OPERATING AND MAINTAINING YOUR HUMIDIFIER 49FH, 49FP, 49BF, 49WS, & 49BG

49FH, 49FP, 49BF, 49WS, & 49BG HUMIDIFIERS READ AND SAVE THESE INSTRUCTIONS Model 49FH Fan-Powered A95248 Model 49FP Fan-Powered A95249 Model 49BF Bypass A95250 Model 49WS Water-Saver Bypass A95251 Model

49FH, 49FP, 49BF, 49WS, & 49BG HUMIDIFIERS READ AND SAVE THESE INSTRUCTIONS Model 49FH Fan-Powered A95248 Model 49FP Fan-Powered A95249 Model 49BF Bypass A95250 Model 49WS Water-Saver Bypass A95251 Model

KESSEL Grease separator EasyClean free Standard, Direct - oval in NS 2, 4, 7, 10, 15, 20, 25, 30 for set-up in frost-free rooms

INSTRUCTIONS FOR INSTALLATION, OPERATION AND MAINTENANCE KESSEL Grease separator EasyClean free Standard, Direct - oval in NS 2, 4, 7, 10, 15, 20, 25, 30 for set-up in frost-free rooms GB Page 1-18 Product

INSTRUCTIONS FOR INSTALLATION, OPERATION AND MAINTENANCE KESSEL Grease separator EasyClean free Standard, Direct - oval in NS 2, 4, 7, 10, 15, 20, 25, 30 for set-up in frost-free rooms GB Page 1-18 Product

Fresh Water Protein Skimmer Fresh-Skim 300. Skimming System in connection with air pump and water pump

Fresh Water Protein Skimmer Fresh-Skim 300 Skimming System in connection with air pump and water pump Range of application/ Mode of operation: The Fresh Skim 300 is suitable for garden ponds or breeding

Fresh Water Protein Skimmer Fresh-Skim 300 Skimming System in connection with air pump and water pump Range of application/ Mode of operation: The Fresh Skim 300 is suitable for garden ponds or breeding

WELCOME BLUE - NEUTRAL BROWN LIVE GREEN AND YELLOW - EARTH

Zephyr 16 DC FAN WELCOME Thank you and congratulation for choosing an EcoAir DC Fan to help you improve the air quality within your home. Inside you will find many helpful tips on how to use and maintain

Zephyr 16 DC FAN WELCOME Thank you and congratulation for choosing an EcoAir DC Fan to help you improve the air quality within your home. Inside you will find many helpful tips on how to use and maintain

ALL IN ONE SERIES HOTLINE 1300 AQUATEC INSTRUCTION MANUAL MODEL 03AS310 03AS311. DATE JULY 2017 v2.0. AQP All in One 1000 Instructions.

INSTRUCTION MANUAL DATE JULY 2017 v2.0 HOTLINE 1300 AQUATEC MODEL 03AS310 03AS311 AQP All in One 1000 Instructions.indd 1 CONGRATULATIONS ON YOUR PURCHASE OF THIS PRODUCT BY AQUAPRO, THE ANSWERS FOR YOUR

INSTRUCTION MANUAL DATE JULY 2017 v2.0 HOTLINE 1300 AQUATEC MODEL 03AS310 03AS311 AQP All in One 1000 Instructions.indd 1 CONGRATULATIONS ON YOUR PURCHASE OF THIS PRODUCT BY AQUAPRO, THE ANSWERS FOR YOUR

Operating principle. Quinto

Operating principle Quinto All rights reserved. No part of this document may be copied and/or published by means of printing, photocopying, microfilming or by any other means whatsoever without the prior

Operating principle Quinto All rights reserved. No part of this document may be copied and/or published by means of printing, photocopying, microfilming or by any other means whatsoever without the prior

GB User and maintenance manual

GB User and maintenance manual IMPORTANT SAFETY INSTRUCTIONS These instructions shall also be available on website: docs.whirlpool.eu. YOUR SAFETY AND THAT OF OTHERS IS VERY IMPORTANT This manual and

GB User and maintenance manual IMPORTANT SAFETY INSTRUCTIONS These instructions shall also be available on website: docs.whirlpool.eu. YOUR SAFETY AND THAT OF OTHERS IS VERY IMPORTANT This manual and

User and maintenance manual

GB User and maintenance manual IMPORTANT SAFETY INSTRUCTIONS These instructions shall also be available on website: docs.whirlpool.eu. YOUR SAFETY AND THAT OF OTHERS IS HIGHLY IMPORTANT. This manual and

GB User and maintenance manual IMPORTANT SAFETY INSTRUCTIONS These instructions shall also be available on website: docs.whirlpool.eu. YOUR SAFETY AND THAT OF OTHERS IS HIGHLY IMPORTANT. This manual and

User Manual. Deep Cleaning Bagless Vacuum with Powerhead. Deep Clean W3000

User Manual Deep Cleaning Bagless Vacuum with Powerhead Deep Clean W3000 Features 1 2 3 4 5 6 7 8 9 10 11 On/off button Flexible hose Telescopic wand Wand length adjustment Cord rewind button Combination

User Manual Deep Cleaning Bagless Vacuum with Powerhead Deep Clean W3000 Features 1 2 3 4 5 6 7 8 9 10 11 On/off button Flexible hose Telescopic wand Wand length adjustment Cord rewind button Combination

GARDENA. F 3000 Art F 6000 Art F 9000 Art F Art. 7929

GARDENA D F F 3000 Art. 7926 F 6000 Art. 7927 D Gebrauchsanweisung UVC-Teichfilter Operating Instructions UVC-pond filter F Mode d emploi Filtre UVC pour bassin NL Gebruiksaanwijzing UVC-vijverfilter S

GARDENA D F F 3000 Art. 7926 F 6000 Art. 7927 D Gebrauchsanweisung UVC-Teichfilter Operating Instructions UVC-pond filter F Mode d emploi Filtre UVC pour bassin NL Gebruiksaanwijzing UVC-vijverfilter S

Slow Cooker XJ-13220B User Manual

Slow Cooker XJ-13220B User Manual PLEASE READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE IMPORTANT SAFEGUARDS When using electrical appliances, basic safety precautions should always be followed,

Slow Cooker XJ-13220B User Manual PLEASE READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE IMPORTANT SAFEGUARDS When using electrical appliances, basic safety precautions should always be followed,

APW PSI PRESSURE WASHER

APW5001 1300 PSI PRESSURE WASHER 1300 PSI PRESSURE WASHER Please carefully read this manual which has been specifically designed to provide all the necessary information for the correct use of the machine,

APW5001 1300 PSI PRESSURE WASHER 1300 PSI PRESSURE WASHER Please carefully read this manual which has been specifically designed to provide all the necessary information for the correct use of the machine,

DIRTY WATER SUBMERSIBLE PUMP

WHAT S IN THE BOX DIRTY WATER SUBMERSIBLE PUMP 780W INSTRUCTION MANUAL SPECIFICATIONS Motor: 780W Max. Flow Rate: 15,700l/h Max. Head 8m Max. Immersion: 7m Min. Suction Depth 50mm Max Particle Size: Ø35mm

WHAT S IN THE BOX DIRTY WATER SUBMERSIBLE PUMP 780W INSTRUCTION MANUAL SPECIFICATIONS Motor: 780W Max. Flow Rate: 15,700l/h Max. Head 8m Max. Immersion: 7m Min. Suction Depth 50mm Max Particle Size: Ø35mm

Product waste disposal - Protection of the environment:

Product waste disposal - Protection of the environment: In accordance with the provisions of the Waste Electrical and Electronic Equipment (WEEE - 2002/ 96/ EC) Directive, used electric and electronic

Product waste disposal - Protection of the environment: In accordance with the provisions of the Waste Electrical and Electronic Equipment (WEEE - 2002/ 96/ EC) Directive, used electric and electronic

HOT TANK INSTALLATION AND OPERATING INSTRUCTIONS. Model #: 5000

HOT TANK INSTALLATION AND OPERATING INSTRUCTIONS Model #: 5000 INSTALLATION GUIDE BEFORE YOU BEGIN YOUR INSTALLATION: 1 2 3 4 Turn off water supply. Observe all local plumbing codes. Inspect waste and

HOT TANK INSTALLATION AND OPERATING INSTRUCTIONS Model #: 5000 INSTALLATION GUIDE BEFORE YOU BEGIN YOUR INSTALLATION: 1 2 3 4 Turn off water supply. Observe all local plumbing codes. Inspect waste and

Bedienungsanleitung. Ideas for dental technology. Made in Germany C

Bedienungsanleitung 216604 C 01022013 Made in Germany Ideas for dental technology GLISH Instruction manual 1. Introduction...1 1.1 Employed Symbols...1 2. Safety...2 2.1 Intended use...2 2.2 Improper use...2

Bedienungsanleitung 216604 C 01022013 Made in Germany Ideas for dental technology GLISH Instruction manual 1. Introduction...1 1.1 Employed Symbols...1 2. Safety...2 2.1 Intended use...2 2.2 Improper use...2

NON-CYCLING REFRIGERATED AIR/GAS DRYERS QPNC 75 to QPNC 250 OPERATOR S MANUAL

NON-CYCLING REFRIGERATED AIR/GAS DRYERS QPNC 75 to QPNC 250 OPERATOR S MANUAL DATE OF PURCHASE: MODEL: SERIAL NO.: Record above information from nameplate. Retain this information for future reference.

NON-CYCLING REFRIGERATED AIR/GAS DRYERS QPNC 75 to QPNC 250 OPERATOR S MANUAL DATE OF PURCHASE: MODEL: SERIAL NO.: Record above information from nameplate. Retain this information for future reference.

SK-200. Up to 80 gallons Aquarium. Optional with UV-5W Sterilizer. Refrigerate medium

p.13 Skimmer & Chiller SK-388 SK-200 VA-MSD-1 Up to 80 gallons Aquarium Optional with UV-5W Sterilizer Protein Skimmer Multi-Skimmer SK-200 SK-388 VA-MSD-1 220~230V 220~230V 220~230V Frequency 50 50 50

p.13 Skimmer & Chiller SK-388 SK-200 VA-MSD-1 Up to 80 gallons Aquarium Optional with UV-5W Sterilizer Protein Skimmer Multi-Skimmer SK-200 SK-388 VA-MSD-1 220~230V 220~230V 220~230V Frequency 50 50 50

Owner s Guide. Powerhead Canister Vacuum Cleaner

Owner s Guide Powerhead Canister Vacuum Cleaner INDEX 1. Important Safety Instructions 2. Components & Accessories 3. Assembly 4. How to Operate a. On/Off Switch b. Check bag indicator c. Variable suction

Owner s Guide Powerhead Canister Vacuum Cleaner INDEX 1. Important Safety Instructions 2. Components & Accessories 3. Assembly 4. How to Operate a. On/Off Switch b. Check bag indicator c. Variable suction

EFX 600. aquamanta. Instruction Manual. 4year guarantee. the experts in aquatic technology. >600 Litres

EFX 600 aquamanta TM the experts in aquatic technology >600 Litres Coldwater Tropical Marine 4year guarantee Instruction Manual Important Safeguards This appliance is not intended for use by persons (including

EFX 600 aquamanta TM the experts in aquatic technology >600 Litres Coldwater Tropical Marine 4year guarantee Instruction Manual Important Safeguards This appliance is not intended for use by persons (including

WET & DRY GARAGE VAC 20L CAPACITY WATT 1.5M MOTOR TANK STEEL HOSE KP702 ON BOARD ACCESSORY STORAGE SUCTION STAINLESS

WET & DRY GARAGE VAC 20L CAPACITY 1.5M SUCTION HOSE STAINLESS STEEL TANK ON BOARD ACCESSORY STORAGE 1250 WATT MOTOR KP702 Table of Contents 20L WET & DRY GARAGE VAC Know Your Product...1 Vacuum Safety

WET & DRY GARAGE VAC 20L CAPACITY 1.5M SUCTION HOSE STAINLESS STEEL TANK ON BOARD ACCESSORY STORAGE 1250 WATT MOTOR KP702 Table of Contents 20L WET & DRY GARAGE VAC Know Your Product...1 Vacuum Safety

MODEL HUM HUMIDIFIERS

HOMEOWNER S MANUAL MODEL HUM HUMIDIFIERS Model HUMBBLFP1025-A-- Fan-Powered Humidifier Model HUMBBSFP1016-A-- Fan-Powered Humidifier Model HUMBBLBP2018-A-- Bypass Humidifier Model HUMBBSBP2017-A-- Bypass

HOMEOWNER S MANUAL MODEL HUM HUMIDIFIERS Model HUMBBLFP1025-A-- Fan-Powered Humidifier Model HUMBBSFP1016-A-- Fan-Powered Humidifier Model HUMBBLBP2018-A-- Bypass Humidifier Model HUMBBSBP2017-A-- Bypass

NOTICE TO INSTALLER: Instructions must remain with installation. FW Supersedes HomeGuard OPTIMA

NOTICE TO INSTALLER: Instructions must remain with installation. FW1379 1018 Supersedes 0615 Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies

NOTICE TO INSTALLER: Instructions must remain with installation. FW1379 1018 Supersedes 0615 Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies

Laing Thermotech. Autocirc The Instant Hot Water Pump Models E1-BCANCT1W-06 and E1-BCANRT1W. Installation & Operating Manual

Installation & Operating Manual Please read this manual carefully before attempting to install, operate or maintain the product described. Failure to comply with the information provided in this manual

Installation & Operating Manual Please read this manual carefully before attempting to install, operate or maintain the product described. Failure to comply with the information provided in this manual

O P E R A T I N G M A N U A L

GB/UK O P E R A T I N G M A N U A L Water softening device GAHOtech soft MC-N 16 109850 As of: January 2010 Location of installation Please read the operating manual before startup! The manufacturer is

GB/UK O P E R A T I N G M A N U A L Water softening device GAHOtech soft MC-N 16 109850 As of: January 2010 Location of installation Please read the operating manual before startup! The manufacturer is

AquaReef 300 / 400 Series II

AquaReef 300 / 400 Series II Inspiring Excellence in Fish Care! Instruction version: 5/4/2016 www.aquaone.com.au 1+1 Important Safeguards To guard against injury, basic safety precautions should be observed,

AquaReef 300 / 400 Series II Inspiring Excellence in Fish Care! Instruction version: 5/4/2016 www.aquaone.com.au 1+1 Important Safeguards To guard against injury, basic safety precautions should be observed,

GB Operating instructions

Scope of delivery/device components 1 Carrier for suction nozzles 2 Dust bin 3 Release button (dust bin) 4 On/Off Switch 5 Motor casing 6 Rechargeable battery 7 Release buttons rechargeable battery 8 Swing

Scope of delivery/device components 1 Carrier for suction nozzles 2 Dust bin 3 Release button (dust bin) 4 On/Off Switch 5 Motor casing 6 Rechargeable battery 7 Release buttons rechargeable battery 8 Swing

100 Series Maxi Internal Filters

100 Series Maxi Internal Filters Important Safeguards To guard against injury, basic safety precautions should be observed, including the following: 1. Read and follow all safety instructions and important

100 Series Maxi Internal Filters Important Safeguards To guard against injury, basic safety precautions should be observed, including the following: 1. Read and follow all safety instructions and important

Bagged Vacuum Cleaner with Powerhead. Compact Powerhead for a Powerful Clean Washable HEPA Filtration High Efficiency Soft Start Motor

Bagged Vacuum Cleaner with Powerhead Compact Powerhead for a Powerful Clean Washable HEPA Filtration High Efficiency Soft Start Motor 3 1 2 5006PH Mode Congratulations on the purchase of your new HOOVER

Bagged Vacuum Cleaner with Powerhead Compact Powerhead for a Powerful Clean Washable HEPA Filtration High Efficiency Soft Start Motor 3 1 2 5006PH Mode Congratulations on the purchase of your new HOOVER

Glass and Dishwashers. BarAid 500/800. Installation and. Starting from Serial No.:

Glass and Dishwashers BarAid 500/800 Installation and operation Instructions Starting from Serial No.: 8652 0001 REV. 19.01.2009 1617-A-01-09 Content Page 1 Important Notes... 4 2 Installation... 5 2.1

Glass and Dishwashers BarAid 500/800 Installation and operation Instructions Starting from Serial No.: 8652 0001 REV. 19.01.2009 1617-A-01-09 Content Page 1 Important Notes... 4 2 Installation... 5 2.1

Steam Mop User Manual

Steam Mop User Manual Model No.: CZ-901 Item No. 900127 Rev 2 READ AND SAVE THESE INSTRUCTIONS Note: The specifications and/or components of this appliance are subject to change without prior notice 1

Steam Mop User Manual Model No.: CZ-901 Item No. 900127 Rev 2 READ AND SAVE THESE INSTRUCTIONS Note: The specifications and/or components of this appliance are subject to change without prior notice 1

STEAM WALLPAPER STRIPPER MODEL HTW5

STEAM WALLPAPER STRIPPER MODEL HTW5 From Serial Number 75154 (110 Volt North America only) OWNERS MANUAL & OPERATING INSTRUCTIONS 2016/11 Hiretech Part # 007717 WARNING For safe operation of this machine,

STEAM WALLPAPER STRIPPER MODEL HTW5 From Serial Number 75154 (110 Volt North America only) OWNERS MANUAL & OPERATING INSTRUCTIONS 2016/11 Hiretech Part # 007717 WARNING For safe operation of this machine,

AACH50 1/2 HP GALLONS (200 TO 1200L) INSTRUCTION MANUAL

Ideal for ponic System Reservoirs 1/2 HP 53-317 GALLONS (200 TO 1200L) AACH50 INSTRUCTION MANUAL Before operating this appliance, please read the instruction manual thoroughly and keep on file for future

Ideal for ponic System Reservoirs 1/2 HP 53-317 GALLONS (200 TO 1200L) AACH50 INSTRUCTION MANUAL Before operating this appliance, please read the instruction manual thoroughly and keep on file for future

HOT & COLD WATER PURIFIER CLIMA MESA / PISO

HOT & COLD WATER PURIFIER CLIMA MESA / PISO MESA PISO CONTENTS: Instructions related with power ------------------------------------------------------- 2 Installation Instruction -------------------------------------------------------------------

HOT & COLD WATER PURIFIER CLIMA MESA / PISO MESA PISO CONTENTS: Instructions related with power ------------------------------------------------------- 2 Installation Instruction -------------------------------------------------------------------

OptiClean. U S E R S G U I D E 6 0 A 4 S E R I E S v. Product View. Assembly. Operations. Maintenance and Care.

OptiClean U S E R S G U I D E 6 0 A 4 S E R I E S 2 2 0-2 4 0 v 3 Safety Instructions 4 Product View 5 Assembly 6-8 Operations 9-12 Maintenance and Care 13 Troubleshooting 14 Consumer Services 15 Replacement

OptiClean U S E R S G U I D E 6 0 A 4 S E R I E S 2 2 0-2 4 0 v 3 Safety Instructions 4 Product View 5 Assembly 6-8 Operations 9-12 Maintenance and Care 13 Troubleshooting 14 Consumer Services 15 Replacement

COR-20 STANDALONE MAIN TITLE GOES MODE USER GUIDE HERE

COR-20 STANDALONE MAIN TITLE GOES MODE USER GUIDE HERE CONTENTS INTRODUCTION... 2 COR-20 FEATURES AND SPECIFICATIONS... 2 WHAT S IN THE BOX... 3 GET TO KNOW YOUR COR DRIVER... 4 GET TO KNOW YOUR COR PUMP...

COR-20 STANDALONE MAIN TITLE GOES MODE USER GUIDE HERE CONTENTS INTRODUCTION... 2 COR-20 FEATURES AND SPECIFICATIONS... 2 WHAT S IN THE BOX... 3 GET TO KNOW YOUR COR DRIVER... 4 GET TO KNOW YOUR COR PUMP...

DIRTY WATER SUBMERSIBLE PUMP KIT

WHAT S IN THE BOX DIRTY WATER SUBMERSIBLE PUMP KIT 1000W INSTRUCTION MANUAL SPECIFICATIONS Motor: 1000W Max. Flow Rate: 18,000l/h Max. Head 9m Max. Immersion: 7m Min. Suction Depth 50mm Max Particle Size:

WHAT S IN THE BOX DIRTY WATER SUBMERSIBLE PUMP KIT 1000W INSTRUCTION MANUAL SPECIFICATIONS Motor: 1000W Max. Flow Rate: 18,000l/h Max. Head 9m Max. Immersion: 7m Min. Suction Depth 50mm Max Particle Size:

CP-200 S&T. CP Warewash Pump Instruction & Operation Manual Speed & Time , Rev1.0, , Page 1 of 8

CP-200 - Warewash Pump Instruction & Operation Manual Speed & Time 20-08606-01, Rev1.0, 20.07.2012, Page 1 of 8 Contents A) Description B) Site Survey and Installation Requirements C) Package Contents

CP-200 - Warewash Pump Instruction & Operation Manual Speed & Time 20-08606-01, Rev1.0, 20.07.2012, Page 1 of 8 Contents A) Description B) Site Survey and Installation Requirements C) Package Contents

SELF-CONTAINED POWER MISTER

00 North Main St. Fostoria, OH 0 Phone: 00-95-55 Fax: 9-5-0 www.tpicorp.com If you have questions about the product you have purchased or would like to leave us feedback please contact us via our website

00 North Main St. Fostoria, OH 0 Phone: 00-95-55 Fax: 9-5-0 www.tpicorp.com If you have questions about the product you have purchased or would like to leave us feedback please contact us via our website

PORTABLE DEHUMIDIFIER

PORTABLE DEHUMIDIFIER User s Manual For information or assistance, please contact: Soleus International 9451 Telstar Ave. El Monte, CA 91731 Tel: 1-888-876-5387 www.soleusair.com POWERED BY: KEEP THESE

PORTABLE DEHUMIDIFIER User s Manual For information or assistance, please contact: Soleus International 9451 Telstar Ave. El Monte, CA 91731 Tel: 1-888-876-5387 www.soleusair.com POWERED BY: KEEP THESE

USERS MANUAL FOR GAS BOILERS

USERS MANUAL FOR GAS BOILERS PLEASE READ THE MANUAL CAREFULLY: IT CONTAINS IMPORTANT INFORMATION REGARDING SAFETY, INSTALLATION, USE AND MAINTENANCE OF THE APPLIANCE MODELS: NOVADENS 24 NOVADENS 24C NOVADENS

USERS MANUAL FOR GAS BOILERS PLEASE READ THE MANUAL CAREFULLY: IT CONTAINS IMPORTANT INFORMATION REGARDING SAFETY, INSTALLATION, USE AND MAINTENANCE OF THE APPLIANCE MODELS: NOVADENS 24 NOVADENS 24C NOVADENS

Pond Oxygenator. Single / Twin / Four.

Pond Oxygenator Single / Twin / Four www.blagdonwatergardening.co.uk www.interpetcentral.com Congratulations on buying a Blagdon Pond Oxygenator air pump. These air pumps have been specifically designed

Pond Oxygenator Single / Twin / Four www.blagdonwatergardening.co.uk www.interpetcentral.com Congratulations on buying a Blagdon Pond Oxygenator air pump. These air pumps have been specifically designed

DEHUMIDIFIER USER MANUAL 11 PINT FOR MODEL: 3PAD11 COMFORT...BUILT TO LAST

COMFORT...BUILT TO LAST 11 PINT DEHUMIDIFIER USER MANUAL FOR MODEL: 3PAD11 Before using your dehumidifier, please read this manual carefully and keep it for future reference, along with your receipt. CONTENTS

COMFORT...BUILT TO LAST 11 PINT DEHUMIDIFIER USER MANUAL FOR MODEL: 3PAD11 Before using your dehumidifier, please read this manual carefully and keep it for future reference, along with your receipt. CONTENTS

Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0)

7825 flood PUMP Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 33713-001? 1 AUTO ON AUTO OFF 400mm 190mm 2 3 25mm 32mm 4 5 50cm 50cm

7825 flood PUMP Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 33713-001? 1 AUTO ON AUTO OFF 400mm 190mm 2 3 25mm 32mm 4 5 50cm 50cm

aquamanta the experts in aquatic technology

HFX 70/100/150/200 TM aquamanta the experts in aquatic technology Coldwater Tropical Marine 2+1 year guarantee Instruction Manual Instruction version: 05/06/2012 Technical Information MODEL: HFX 70 HFX

HFX 70/100/150/200 TM aquamanta the experts in aquatic technology Coldwater Tropical Marine 2+1 year guarantee Instruction Manual Instruction version: 05/06/2012 Technical Information MODEL: HFX 70 HFX

ASPIRE Laboratory Aspirator

ASPIRE Laboratory Aspirator USER MANUAL Rev 2/14/18 Accuris Instruments / Benchmark Scientific Ph: (908) 769-5555 E-mail: info@accuris-usa.com (C) Benchmark Scientific, 2018 THE ACCURIS ASPIRE LABORATORY

ASPIRE Laboratory Aspirator USER MANUAL Rev 2/14/18 Accuris Instruments / Benchmark Scientific Ph: (908) 769-5555 E-mail: info@accuris-usa.com (C) Benchmark Scientific, 2018 THE ACCURIS ASPIRE LABORATORY

AQUAMAC MODELS

AQUAMAC MODELS 300-500-800-1000 OUR SYSTEMS CONFORM TO EC STANDARD 73/23 CEE - 89/336 INSTRUCTION MANUAL Cod. 71503095/0-5/97 WARNING! THE FOLLOWING OPERATIONS AND THOSE EVIDENCED WITH THE SYMBOL ON THE

AQUAMAC MODELS 300-500-800-1000 OUR SYSTEMS CONFORM TO EC STANDARD 73/23 CEE - 89/336 INSTRUCTION MANUAL Cod. 71503095/0-5/97 WARNING! THE FOLLOWING OPERATIONS AND THOSE EVIDENCED WITH THE SYMBOL ON THE

INSTRUCTION MANUAL Model: SU3022

INSTRUCTION MANUAL Model: SU3022 GUARANTEE This product is guaranteed for 2 years from the date of original purchase. If any defect arises due to faulty materials or workmanship, the unit will, either

INSTRUCTION MANUAL Model: SU3022 GUARANTEE This product is guaranteed for 2 years from the date of original purchase. If any defect arises due to faulty materials or workmanship, the unit will, either

Operating instructions

Operating instructions (Translation of the original operating instructions) Type TEKA FILTERCUBE-MV TEKA Absaug- und Entsorgungstechnologie GmbH Industriestraße 13 D-46342 Velen Postfach 1137 D-46334 Velen

Operating instructions (Translation of the original operating instructions) Type TEKA FILTERCUBE-MV TEKA Absaug- und Entsorgungstechnologie GmbH Industriestraße 13 D-46342 Velen Postfach 1137 D-46334 Velen

Installation and Operating Instructions DÜRR Regeneration Unit for X-ray developers XR 24, XR24 II, XR 24 Nova, XR 24 Pro

Installation and Operating Instructions DÜRR Regeneration Unit for X-ray developers XR 24, XR24 II, XR 24 Nova, XR 24 Pro 2006/01 Content Important Information 1. Notes... 3 1.1 CE - Labeling... 3 1.2

Installation and Operating Instructions DÜRR Regeneration Unit for X-ray developers XR 24, XR24 II, XR 24 Nova, XR 24 Pro 2006/01 Content Important Information 1. Notes... 3 1.1 CE - Labeling... 3 1.2

SELF-PRIMING JET PUMPS

SS Anti-Rust SS Shaft Copper & Cold-rolled SELF-PRIMING JET PUMPS CONTENTS 1. Applications.... Model Description.... Technical Data... 4. Implementation Standards... 5. Safety Precautions... 6. Product

SS Anti-Rust SS Shaft Copper & Cold-rolled SELF-PRIMING JET PUMPS CONTENTS 1. Applications.... Model Description.... Technical Data... 4. Implementation Standards... 5. Safety Precautions... 6. Product

FC 5 FC 5 Premium. OPERATOR MANUAL Floor Cleaner...2 MANUAL DE USUARIO Limpiador de piso...22 MANUEL D UTILISATION Nettoyant pour sols...

FC 5 FC 5 Premium OPERATOR MANUAL Floor Cleaner.................2 MANUAL DE USUARIO Limpiador de piso............22 MANUEL D UTILISATION Nettoyant pour sols...........44 59682960 2018.03 FLOOR CLEANER

FC 5 FC 5 Premium OPERATOR MANUAL Floor Cleaner.................2 MANUAL DE USUARIO Limpiador de piso............22 MANUEL D UTILISATION Nettoyant pour sols...........44 59682960 2018.03 FLOOR CLEANER

Glass and Dishwashers 402/452/502. (original instructions) (incl. Australian /502) Starting from Serial No.:

Glass and Dishwashers ECOMAX 402/452/502 (incl. Australian 452-90/502) INSTALLATION AND OPERATION INSTRUCTIONS (original instructions) Starting from Serial No.: 8663 4000 REV. 05.10.2015 EN IMPORTANT NOTES

Glass and Dishwashers ECOMAX 402/452/502 (incl. Australian 452-90/502) INSTALLATION AND OPERATION INSTRUCTIONS (original instructions) Starting from Serial No.: 8663 4000 REV. 05.10.2015 EN IMPORTANT NOTES

6000, 8000, & 15000

aquaforce 2823 1583 1584 1585 1586 6000, 8000, 12000 & 15000 Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 43386-000? 1 A A. Wildlife

aquaforce 2823 1583 1584 1585 1586 6000, 8000, 12000 & 15000 Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 43386-000? 1 A A. Wildlife

TQ Series. Electronic Control Pump Instruction Manual. 50Hz. ISO 9001 Certified Walrus Pump Co., Ltd.

TQ Series Electronic Control Pump Instruction Manual 50Hz ISO 9001 Certified Walrus Pump Co., Ltd. EC Declaration of Conformity Manufacturer: Walrus Pump Co., Ltd. Address: No. 83-14, Dapiantou, Sanjhih

TQ Series Electronic Control Pump Instruction Manual 50Hz ISO 9001 Certified Walrus Pump Co., Ltd. EC Declaration of Conformity Manufacturer: Walrus Pump Co., Ltd. Address: No. 83-14, Dapiantou, Sanjhih

Stick Mixer Set brushed stainless steel housing

Stick Mixer Set brushed stainless steel housing BTSMS10 Important Safeguards When using electrical appliances, in order to reduce the risk of fire, electric shock and/or injury to persons, basic safety

Stick Mixer Set brushed stainless steel housing BTSMS10 Important Safeguards When using electrical appliances, in order to reduce the risk of fire, electric shock and/or injury to persons, basic safety

2-IN-1 UPRIGHT HANDHELD VACUUM CLEANER INSTRUCTION MANUAL

2-IN-1 UPRIGHT HANDHELD VACUUM CLEANER INSTRUCTION MANUAL MODEL NUMBER VSC02A861 Thank you for choosing BLACK+DECKER PLEASE READ BEFORE RETURNING THIS PRODUCT FOR ANY REASON. If you have a question or

2-IN-1 UPRIGHT HANDHELD VACUUM CLEANER INSTRUCTION MANUAL MODEL NUMBER VSC02A861 Thank you for choosing BLACK+DECKER PLEASE READ BEFORE RETURNING THIS PRODUCT FOR ANY REASON. If you have a question or

OWNER'S MANUAL Model VPW46H 120V., 60 Hz., 13 Amps. PRESSURE WASHER. FANTOM 94 Main Mill Street, Door 16 Plattsburgh, NY Tel.

OWNER'S MANUAL Model VPW46H 120V., 60 Hz., 13 Amps. WASHER FANTOM 94 Main Mill Street, Door 16 Plattsburgh, NY 12901 Tel.: 1 (800) 275-9251 SAFETY & INSTRUCTIONS For safety reasons, it is recommended that

OWNER'S MANUAL Model VPW46H 120V., 60 Hz., 13 Amps. WASHER FANTOM 94 Main Mill Street, Door 16 Plattsburgh, NY 12901 Tel.: 1 (800) 275-9251 SAFETY & INSTRUCTIONS For safety reasons, it is recommended that

Cordless Water Kettle LD-K3030A User Manual

Cordless Water Kettle LD-K3030A User Manual PLEASE READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE PARTS DESCRIPTION TECHNICAL DATA Specifications: Voltage:220-240V~ Frequency:50-60 Hz Wattage:1850-2200W

Cordless Water Kettle LD-K3030A User Manual PLEASE READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE PARTS DESCRIPTION TECHNICAL DATA Specifications: Voltage:220-240V~ Frequency:50-60 Hz Wattage:1850-2200W

REVOLUTION BAGLESS CANISTER VACUUM

REVOLUTION BAGLESS CANISTER VACUUM 12901 IMPORTANT SAFETY INSTRUCTIONS READ ALL INSTRUCTIONS BEFORE USING YOUR VACUUM. When using an electrical appliance, basic precautions should be observed, including

REVOLUTION BAGLESS CANISTER VACUUM 12901 IMPORTANT SAFETY INSTRUCTIONS READ ALL INSTRUCTIONS BEFORE USING YOUR VACUUM. When using an electrical appliance, basic precautions should be observed, including

THROUGH-WALL AIR-TO-AIR HEAT PUMP AND AIR CONDITIONER. Instruction Manual. Model AMB-12H

THROUGH-WALL AIR-TO-AIR HEAT PUMP AND AIR CONDITIONER Instruction Manual Model AMB-12H PLEASE READ THIS INSTRUCTION MANUAL CAREFULLY BEFORE USING THIS UNIT. Table of Contents 1. SAFETY WARNINGS 2 2. CONSTRUCTION...

THROUGH-WALL AIR-TO-AIR HEAT PUMP AND AIR CONDITIONER Instruction Manual Model AMB-12H PLEASE READ THIS INSTRUCTION MANUAL CAREFULLY BEFORE USING THIS UNIT. Table of Contents 1. SAFETY WARNINGS 2 2. CONSTRUCTION...

6L PRESSURE COOKER. Instruction Manual. Model: PLA1424

6L PRESSURE COOKER Instruction Manual Model: PLA1424 Due to ongoing product improvements, specifications and accessories may change without notice. Actual product may differ slightly to that depicted.

6L PRESSURE COOKER Instruction Manual Model: PLA1424 Due to ongoing product improvements, specifications and accessories may change without notice. Actual product may differ slightly to that depicted.

AUTOMATIC GRANULAR ICE FLAKER

AUTOMATIC GRANULAR ICE FLAKER INSTRUCTIONS AND WARNINGS 24480 rev. 01 It is strictly forbidden to reproduce this instruction manual or any part thereof. Dear Customer, Congratulations on choosing a

AUTOMATIC GRANULAR ICE FLAKER INSTRUCTIONS AND WARNINGS 24480 rev. 01 It is strictly forbidden to reproduce this instruction manual or any part thereof. Dear Customer, Congratulations on choosing a

AVAC9000W Portable Air Conditioner with 24 hour timer Installation Instructions and User Guide

AVAC9000W[15]instructions 9/4/15 09:43 Page 1 AVAC9000W Portable Air Conditioner with 24 hour timer Installation Instructions and User Guide IMPORTANT SAFEGUARDS WHEN USING ANY ELECTRICAL APPLIANCE, BASIC

AVAC9000W[15]instructions 9/4/15 09:43 Page 1 AVAC9000W Portable Air Conditioner with 24 hour timer Installation Instructions and User Guide IMPORTANT SAFEGUARDS WHEN USING ANY ELECTRICAL APPLIANCE, BASIC

SUBMERSIBLE WATER PUMP. Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS

1117 SUBMERSIBLE WATER PUMP Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS GUARANTEE This product is guaranteed against faults in

1117 SUBMERSIBLE WATER PUMP Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS GUARANTEE This product is guaranteed against faults in

Cooker Hood User Manual

Cooker Hood User Manual HCB93042X EN 01M-8850803200-0116-02 Please read this manual first! Dear Customers! Thank you for preferring a Beko product. We hope that you get the best results from your product

Cooker Hood User Manual HCB93042X EN 01M-8850803200-0116-02 Please read this manual first! Dear Customers! Thank you for preferring a Beko product. We hope that you get the best results from your product

Prolux Tritan INSTRUCTION MANUAL

Prolux Tritan INSTRUCTION MANUAL For your safety please read the Owners Manual in its entirety Congratulations on your purchase of your new Prolux Tritan Vacuum! With the Prolux Tritan s adjustable operation

Prolux Tritan INSTRUCTION MANUAL For your safety please read the Owners Manual in its entirety Congratulations on your purchase of your new Prolux Tritan Vacuum! With the Prolux Tritan s adjustable operation

POWER WASHER MODEL NO: JET 9000 OPERATION & MAINTENANCE INSTRUCTIONS. WARNING: Do not use the machine without reading this manual PART NO:

WARNING: Do not use the machine without reading this manual POWER WASHER MODEL NO: JET 9000 PART NO: 7333502 OPERATION & MAINTENANCE INSTRUCTIONS GC0913 INTRODUCTION Thank you for purchasing this CLARKE

WARNING: Do not use the machine without reading this manual POWER WASHER MODEL NO: JET 9000 PART NO: 7333502 OPERATION & MAINTENANCE INSTRUCTIONS GC0913 INTRODUCTION Thank you for purchasing this CLARKE

Washing Machine OWNER S MANUAL TRWTL-70. Before using your washing machine, please read this manual carefully and keep it for future reference.

Before using your washing machine, please read this manual carefully and keep it for future reference. Washing Machine OWNER S MANUAL TRWTL-70 Read This Manual Inside you will find many helpful hints on

Before using your washing machine, please read this manual carefully and keep it for future reference. Washing Machine OWNER S MANUAL TRWTL-70 Read This Manual Inside you will find many helpful hints on

Tornado Operations & Maintenance Manual

Tornado Industries, LLC 333 Charles Court West Chicago, IL 60185 www.tornadovac.com Tornado Operations & Maintenance Manual MODEL NO. 99414 Form No. L9740AB Tornado Industries, LLC. All rights reserved

Tornado Industries, LLC 333 Charles Court West Chicago, IL 60185 www.tornadovac.com Tornado Operations & Maintenance Manual MODEL NO. 99414 Form No. L9740AB Tornado Industries, LLC. All rights reserved

SILENT compact /

SILT compact 2934 0000 / 2934 1000 TRANSLATION OF THE ORIGINAL INSTRUCTIONS FOR USE Made in Germany Ideas for dental technology 21-2245 21052015 / A Contents 1. Introduction...3 1.1 Symbols...3 2. Safety...3

SILT compact 2934 0000 / 2934 1000 TRANSLATION OF THE ORIGINAL INSTRUCTIONS FOR USE Made in Germany Ideas for dental technology 21-2245 21052015 / A Contents 1. Introduction...3 1.1 Symbols...3 2. Safety...3

Owner s. 18 Misting MF18W. To view

Owner s Manual MF18W 18 Misting Fan IMPORTANT SAFETY INFORMATION: Please carefully read this manual before attempting to install or use this misting fan. For your safety, comply with all safety instructionss

Owner s Manual MF18W 18 Misting Fan IMPORTANT SAFETY INFORMATION: Please carefully read this manual before attempting to install or use this misting fan. For your safety, comply with all safety instructionss

Installation and Operating Instructions

Installation and Operating Instructions CHEOPS for Pre-Filter Module Order No. CHEOPS 0015 CHEOPS and Main Filter Module Order No. CHEOPS 0010 Before putting the filter system into operation please carefully

Installation and Operating Instructions CHEOPS for Pre-Filter Module Order No. CHEOPS 0015 CHEOPS and Main Filter Module Order No. CHEOPS 0010 Before putting the filter system into operation please carefully

Glass and Dishwashers AMX / AUX Series

Glass and Dishwashers AMX / AUX Series INSTALLATION OPERATION VERSION 24.02.04 Important Notes Use in Accordance with Regulations This machine is exclusively to be used to wash ware such as plates, cups,

Glass and Dishwashers AMX / AUX Series INSTALLATION OPERATION VERSION 24.02.04 Important Notes Use in Accordance with Regulations This machine is exclusively to be used to wash ware such as plates, cups,

Twister / Twister venturi

Twister / Twister venturi Nr. 1826 / 1827 2010-09/A 21-6603 Ideas for dental technology 1 2 3 4 10 mm 0,4 Inch 5 6 7 8 9 10 11 12 13 14 15 16 C B A 17 H I K G D F E 18 E B C A D 19 20 21 22 23 24 25 26

Twister / Twister venturi Nr. 1826 / 1827 2010-09/A 21-6603 Ideas for dental technology 1 2 3 4 10 mm 0,4 Inch 5 6 7 8 9 10 11 12 13 14 15 16 C B A 17 H I K G D F E 18 E B C A D 19 20 21 22 23 24 25 26

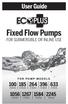

User Guide. Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE FOR PUMP MODELS # # # # # # # # #728333

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

Warranty. Thanks. Thank you for purchasing the Oliso Smart Iron, a safer, smarter way to iron.

User Manual Warranty Oliso, Inc. warrants that for a period of one year from the date of the original purchase, this product will be free from defects in material and workmanship, when utilized for normal

User Manual Warranty Oliso, Inc. warrants that for a period of one year from the date of the original purchase, this product will be free from defects in material and workmanship, when utilized for normal

Model No.: VUM33AS20G

Model No.: VUM33AS0G USER MANUAL IMPORTANT SAFETY INSTRUCTIONS Before operating the appliance for the first time, read these instructions carefully. Please store this user manual for future reference..

Model No.: VUM33AS0G USER MANUAL IMPORTANT SAFETY INSTRUCTIONS Before operating the appliance for the first time, read these instructions carefully. Please store this user manual for future reference..

Cool Mist Ultrasonic Humidifier

Cool Mist Ultrasonic Humidifier Instruction Manual and Warranty Information HUM-CM50 IMPORTANT SAFETY INSTRUCTIONS: WHEN USING ELECTRICAL PRODUCTS, ESPECIALLY WHEN CHILDREN ARE PRESENT, BASIC SAFETY PRECAUTIONS

Cool Mist Ultrasonic Humidifier Instruction Manual and Warranty Information HUM-CM50 IMPORTANT SAFETY INSTRUCTIONS: WHEN USING ELECTRICAL PRODUCTS, ESPECIALLY WHEN CHILDREN ARE PRESENT, BASIC SAFETY PRECAUTIONS