12/50 CENTRIFUGAL PUMPS FOR DC SUPPLY OPERATING INSTRUCTIONS

|

|

|

- Helen Randall

- 5 years ago

- Views:

Transcription

1 12/50 CENTRIFUGAL PUMPS FOR DC SUPPLY OPERATING INSTRUCTIONS Please leave this instruction booklet with the pump as it contains maintenance and safety information (Original Instructions)

2 MODELS 12/50 INDEX Page No Application Product Description Limits of Application Technical Specifi cation Siting of the Pump/Pipework Electrical Installation INDEX Page No Commissioning Maintenance Trouble Shooting Guide Performance Information Environment Protection IMPORTANT NOTES Please read these instructions fully before starting the installation: The installation must comply with the relevant water supply, electrical and building regulations and be installed by a competent person. If in doubt, consult Stuart Turner Ltd. APPLICATION The range of centrifugal pumps is designed to pump clean fresh water. Other clean, non aggressive, non explosive liquids with similar characteristics to water may be pumped. Consult Stuart Turner for advice on such applications. The pumps can be used for pressure boosting, fluid transfer and distribution. They are suitable for flooded suction applications. Alternatively a maximum suction lift of 4.6 metres is permitted when using a Stuart footvalve/strainer. WARNING AGAINST MISUSE This pump set must not be used for any other application without the written consent of Stuart Turner Limited. In particular, it must not be connected directly to the mains water supply, or used outside the conditions specified in the limits of application. This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety. Children should be supervised to ensure that they do not play with the appliance. PRODUCT DESCRIPTION Motor: Permanent magnet D.C. motor, totally enclosed self vent cooling, continuously rated, class F insulation. Motors comply with IEC Enclosure ratings are given in the technical specification section. The standard range of motors are suitable for a supply of either 12 V d.c. or 24 V d.c. dependant upon which model selected. Optional motors are available to suit different voltages, consult Stuart Turner Ltd for further details

3 Pump: Close coupled, end suction configuration and of single stage, centrifugal design. Standard pump materials of construction of major wetted parts are as follows: Model Body Impeller Shaft Mechanical Seal 2/50 Brass Acetal or Brass Stainless Steel Nitrile/Carbon Ceramic/Stainless Steel Other seal options are available. Consult Stuart Turner for further details. LIMITS OF APPLICATION Model Impeller Voltage Max. Liquid Temp. o C Min. Liquid Temp. o C Max. Ambient Air Temp o C Max. Suction Lift (m) Max. Head (Pump Closed Valve) (m) (Redwood No. 1 Scale) Max. Viscosity Centistokes **Max. Working Pressure kpa (bar) Max. Inlet Head (m) Max. No. Starts/h 12/50 Plastic * (5) /50 Brass * (5) /50 Plastic * (5) /50 Brass * (5) *With footvalve fitted. **Note: Max working pressure is the maximum pressure that can be applied to the pump internal casing under any installation conditions. TECHNICAL SPECIFICATION Model Impeller Voltage Rating Nominal Motor Speed (r.p.m.) Nominal Watts Output (Motor) Max. Watts consumed at full flow Full Load (AMPS) Starting Current (AMPS) Enc. Rating Dims (mm) Gross Weight (packed) Connections L W H kg Suction Delivery 12/50 Plastic 12 Cont. (S1) IPX G ¾ G ¾ 12/50 Brass 12 Cont. (S1) IPX G ¾ G ¾ 12/50 Plastic 24 Cont. (S1) IPX G ¾ G ¾ 12/50 Brass 24 Cont. (S1) IPX G ¾ G ¾ Stuart Turner reserve the right to amend the specification in line with its policy of continuous development of its products. Note: For information on other voltages which are not shown, consult any supplementary instruction sheet supplied, or the rating label attached to the pump Cont...

4 SITING OF THE PUMP/PIPEWORK WARNINGS: Pump Location If possible site the pump in a location where in the unlikely event of a liquid leak, any spillage is contained or routed to avoid electrics or areas sensitive to liquid damage. Care should be taken to protect the pump from frost and freezing. Ensure pipework to and from pump is independently supported to prevent stress on the pump inlet and outlet branches. Do not fit a non-return valve, or devices which contain non-return valves, in the suction (inlet) pipework to the pump. Exceptions can be made in the case of suction lift installations when a footvalve is required. Always install isolating valves to both suction and delivery pipework. When a footvalve is required on installations that incorporate automatic pump control, it is recommended that a suitable pressure relief valve be fitted in the discharge (outlet) pipework from the pump. Do not run against a closed valve for periods longer than 5 minutes. Do not allow plastic pump parts to come into contact with oil or cellulose based paints, paint thinners or strippers, acid based descalents or aggressive cleaning agents. Do not introduce solder flux to pumps or pump parts manufactured from plastic. All solder joints should be completed and flux residues removed prior to pump connection. The motor casing can become very hot under normal operating conditions. Care should be taken to ensure it cannot be touched during operation. Site the pump in a dry, frost-free position where it cannot be sprayed with water and as close to the liquid source as possible. The pump enclosure must be ventilated and there should be a minimum clearance of 80 mm between the pump and housing on all sides. To prevent loss of pressure through pipework, use pipe size to match pump whenever possible, minimising 90 bends. It must be ensured that storage capacity of the liquid supply is adequate for the flow rates required by the pump. The pipework feeds to the storage tank should be of adequate size to ensure replenishment rate of tank is sufficient to meet the needs of the pump. Isolating valves should be fitted in suction and delivery pipework to enable easy isolation and access to the pump. When the pump is to be installed in areas where there is a risk of debris or scale build up within the system, it is recommended that the inlet pipework is fitted with an inline strainer. Pump Mounted Above Liquid Source (Suction Lift) The pumps can be used in a suction lift installation providing the height of lift is within the limits specified in the limits of application section. A footvalve and strainer must always be used and the suction pipework size must match the pump

5 Lay the suction piping over the shortest possible distance and ensure there is a constant rise from the liquid source to the pump. Any high spots will cause air pockets to form, reducing system efficiency. Ensure all joints in suction pipework are completely airtight. Failure to comply will result in loss of prime. The intake of the footvalve/strainer should be positioned such that it cannot be blocked with debris or silt that are frequently found in the bottom of sumps and wells. When a footvalve is installed on installations that incorporate automatic pump control, it is recommended that a suitable pressure relief valve be fitted in the discharge (outlet) pipework from the pump. Outlet Inlet Fig. 1 ELECTRICAL INSTALLATION WARNINGS: The electrical installation must be carried out in accordance with the current national electrical regulations and installed by a competent person. Before starting work on the electrical installation ensure the power supply is isolated. This appliance must be earthed. The motor and wiring must not be exposed to water. Do not allow the supply cord to contact hot surfaces, including the motor shell, pump body or pipework. The cord should be safely routed and secured by cable clips. The standard pumps are suitable for a supply of 12 volt d.c. or 24 volt d.c. dependent upon which model selected. Other voltages are available on certain models and it is therefore very important to ensure the voltage on the pump rating plate matches the supply. The motor should be provided with control equipment incorporating means for isolation of supply and protection against overload, eg: connection via a starter with suitable sized thermal overload. The control equipment or starter to which the pump is connected should be mounted in an easily accessible position and labelled if confusion is possible to allow easy isolation of the unit

6 When an alternator or generator is the supply source, ensure correct voltage is available at the motor when pump is operational. Earthing The d.c. supply source to the motor could be from a battery, transformer, altenator or generator, hence there is no requirement or facility for earthing via the supply cable. However certain installations may require additional earthing arrangements to be considered. Static protection & EMC compliance The motor can be connected to earth via it s front mounting foot. This will maximise ability to discharge electro static energy and lightning interference. It will also assist EMC compliance. Supplementary earth bonding Metallic inlet and outlet pipework should be cross bonded where the system continuity has been broken by flexible hoses or plastic components. Wiring The motor is provided with a factory fitted power supply cord. This must be permanently connected to the supply source. The wiring in the power supply cord is coloured in accordance with the following code: Blue: Negative Brown: Positive The pump must run in an anticlockwise direction when looking at the pump inlet port. To ensure this happens the pump supply cord must be connected as follows: The wire coloured blue must be connected to the negative terminal of the supply source, marked with the symbol -. The wire coloured brown must be connected to the positive terminal of the supply source, market with the symbol +. Supply Cord Extension The pumps are fitted with a supply cord to the following specification:- HO5VV-F2 X 1.5 mm² - 16 Amp rated cable If the supply cord is to be extended, a cord of the same specification should be used. Any connections or junction boxes used should be specifically suited for the application and installed in accordance with the manufacturers instructions. Fuses The following table gives the recommended fuse size. Model Fuse Size (AMPS) 12/50 (12 V) 15 12/50 (24 V) 15 Fuse type should be of the delayed action type (type T or motor rated) with good time delay characteristics. The fuse performance variation in relation to ambient temperature should also be considered

7 NOISE The equivalent continuous A-weighted sound pressure level from the pumpset does not exceed 70 db(a) at a distance of one metre. COMMISSIONING WARNINGS: The motor casing can become very hot under normal operating conditions, care should be taken to ensure it cannot be touched during operation. Do not run pump without terminal/brush guard correctly fitted. The pump chamber must be full of liquid at all times. Seal damage will result if the pump runs dry. 1. System Flushing Some pumps incorporate plastic components that must not come into contact with solder flux, acid-based descalents or aggressive cleaning agents. The pipework system should be flushed out prior to the pump being connected, to ensure any contaminants/chemical residues and foreign bodies are removed from elsewhere in the system. 2. Liquid Supply Always ensure that liquid storage capacity is adequate to meet the demand. Ensure the pump chamber is full of liquid before starting the pump. Failure to do this could result in seal damage. To ensure dry running does not occur the pumps must be primed as described in the priming section. Do not run pump dry. 3. Ensure electrical supply is compatible with the details that are stated on the pump rating plate. (The wrong voltage can be dangerous and may damage the pump.) 4. Priming a) Flooded suction installation (without priming plug). This pump range are self venting and hence no priming plugs are fitted. Turn on liquid supply and open outlet valve to allow pump to fill and vent. b) Flooded suction installation (with priming plug). The pump must be primed (filled with liquid) before starting. Turn on liquid supply, prime and vent the pump by unscrewing the priming plug (Fig. 6) slowly until all air escapes and liquid emerges. Re-tighten plug. c) Suction lift installation. Prime the suction pipework and pump by filling with liquid via the pump discharge connection or by filling the suction pipework before attaching to the pump Cont...

8 Priming Plug Without Priming Plug Fig. 2 Fig. 3 With Priming Plug 5. Starting a) Switch on power to the pump which will now be operational. b) Confirm the direction of rotation is correct by stopping and observing over run. The correct direction of rotation is anticlockwise when looking directly at the front of the pump casing. To reverse rotation see wiring diagram section. c) The pump should now be fully operational. d) Carefully check pump and pipework for leaks whilst pump running and stationary before leaving the installation unattended. For Further Technical Support Phone the Stuart Turner Pump Assist team on Our staff are trained to help and advise you over the phone or arrange for a service engineer to call. Note: When pumps are installed in another manufacturers original equipment, please contact the manufacturer for advice. MAINTENANCE WARNINGS: Care should be taken to protect the pump from frost and freezing. Pump Location If possible site the pump in a location where in the unlikely event of a liquid leak, any spillage is contained or routed to avoid electrics or areas sensitive to water damage. 1. Routine maintenance to replace motor brushes will be required, provision should be made for easy access to the pump to allow repairs due to normal wear and tear and brush replacement. 2. Disconnect electrical supply before working on pump. 3. Turn off liquid supplies to the pump and release pressure by opening outlets before attempting maintenance

9 4. If the installation is fitted with a footvalve and strainer or inline suction strainer, the strainer must be cleaned as necessary to ensure the pump has unrestricted flow. 5. After maintenance is completed, refer to commissioning section for instructions on restarting pump. 6. Brush replacement procedure. The pumps are fitted with brush motors. The brushes will require replacement when worn out. The brushes have a life expectancy of approximately 1000 hours running time, which will vary dependant upon motor loading. The bushes are replaced in the following way:- 1. Locate suitable size screwdriver or flat blade into the Brush Retaining Cap slot. Fig Carefully un-screw the Brush Retaining Cap until loose. Note: The Cap will pop out under the force of the Brush Assembly Spring. Fig Carefully remove worn Brush Assembly from motor. Note: Carefully clean carbon dust from aperture with a soft brush. Fig

10 Retaining Slot 4. Replace new Brush Assembly by fitting the carbon head into the retaining slot as shown. Note: the Brass Cap of the assembly also fits into this retaining slot - see section 5. Carbon Head Brass Cap Fig Push the Brush Retaining Cap against the spring tension and screw firmly into place until tight, noting that the Brass Cap of the assembly is correctly located in the retaining slot as shown in section 4. Note: DO NOT OVERTIGHTEN Fig Repeat the process for the opposite site. Cleaners, Disinfectants and Descalents On installations where chemical disinfectants or descalents are periodically used, the compatibility of the chemical solution regarding the pump must be considered. Acid based descalents and aggressive cleaning agents must not come into contact with the pump. The pump must be removed from the system prior to the use of these products. The system should be flushed to remove all chemicals before the pump is re-connected. If in any doubt as to the suitability of the chemical solutions, please contact our Pump Assist helpline. STORAGE If this product is not installed immediately on receipt, store in a dry, frost and vibration free location in its original packaging Cont...

11 TROUBLE SHOOTING GUIDE Symptoms Probable Cause Recommended Action Pump will not start. Electrical supply. Check power to motor. Check circuit breaker is set. Check the correct fuse is being used.. Brush gear in need of replacement. Pump runs, but no liquid is pumped. Air locked. No liquid supply. Motor running backwards. Pump connections reversed. Bleed pipework and pump to clear air. Check the supply valves are turned on. Check outlet not restricted or blocked. Check motor is rotating in the correct direction, if not, reverse connections of the two incoming supply wires. Check liquid connections are on the right way round. No flooded suction. Check the pump has a flooded suction and is primed. Pump running slow/low performance No footvalve. Low voltage. If a suction list exists fit a Stuart footvalve/strainer and ensure suction pipework is airtight. Check correct voltage is available at the pumps. Brush gear in need of replacement. Under size supply cable. PERFORMANCE INFORMATION Performance curves are based on liquids having the same specific gravity and viscosity as clean water at 20 C. 20 FLOW (m³/h) HEAD (metres) /50 24V 12/50 12V FLOW (l/min) Voltage available must be at the rated nominal supply at the motor terminals. ENVIRONMENT PROTECTION Your appliance contains valuable materials which can be recovered or recycled. At the end of the products useful life, please leave it at an appropriate local civic waste collection point

12 DECLARATION OF CONFORMITY 2006/42/EC BS EN ISO , BS EN ISO , BS EN /108/EC BS EN , BS EN , BS EN 55022, BS EN , BS EN , BS EN , BS EN , BS EN , BS EN , BS EN , BS EN IT IS HEREBY CERTIFIED THAT THE STUART ELECTRIC MOTOR DRIVEN PUMP AS SERIAL NUMBER BELOW, COMPLIES WITH THE ESSENTIAL REQUIREMENTS OF THE ABOVE E.E.C. RELEVANT DIRECTIVES. RESPONSIBLE PERSON AND MANUFACTURER STUART TURNER LIMITED HENLEY-ON-THAMES, OXFORDSHIRE RG9 2AD ENGLAND. Signed Customer Relationship Manager Stuart Turner are an approved company to BS EN ISO 9001:2000 YOUR 1 YEAR GUARANTEE Stuart Pumps are guaranteed by Stuart Turner Limited to be free from defects in materials or workmanship for the applicable guarantee period from the date of purchase. The applicable guarantee period is stated in the installation booklet supplied with the pump. Within the guarantee period we will repair, free of charge, any defects in the pump resulting from faults in material or workmanship, repairing, exchanging parts or exchanging the whole unit as we may reasonably decide. Not covered by this guarantee: Damage arising from incorrect installation, improper use, unauthorised repair, normal wear and tear and defects which have a negligible effect on the value or operation of the pump. Reasonable evidence must be supplied that the pump has been purchased within the applicable guarantee period prior to the date of claim (such as proof of purchase or the pump serial number). This guarantee is in addition to your statutory rights as a consumer. If you are in any doubt as to these rights, please contact your local Trading Standards Department or Citizen s Advice Bureau. In the event of a claim please telephone Stuart Turner Limited on or return your pump and flexible hoses with accessories removed, plugs, pipes etc. If you have any doubt about removing a pump, please consult a professional. Proof of purchase should accompany the returned pump to avoid delay in investigation and dealing with your claim. Stuart Turner Ltd, Henley-on-Thames, Oxfordshire RG9 2AD ENGLAND Tel: +44 (0) , Fax: +44 (0) pumps@stuart-turner.co.uk web: V.A.T. REG. No Registered in England No Registered Offi ce: Market Place, Henley-on-Thames Issue No. 4410/1-05 Pt. No

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS Please leave this instruction booklet with the pump as it contains maintenance and safety information (Original Instructions) MODELS This operating manual covers

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS Please leave this instruction booklet with the pump as it contains maintenance and safety information (Original Instructions) MODELS This operating manual covers

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS Please leave this instruction booklet with the pump as it contains maintenance and safety information (Original Instructions) MODELS Kennet K7-2 Kennet K9-2 Kennet

CENTRIFUGAL PUMPS OPERATING INSTRUCTIONS Please leave this instruction booklet with the pump as it contains maintenance and safety information (Original Instructions) MODELS Kennet K7-2 Kennet K9-2 Kennet

Flo~mate Mains Boost Pump Installation & Maintenance Instructions

~ Flo~mate Mains Boost Pump Installation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information FOR POSITIVE

~ Flo~mate Mains Boost Pump Installation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information FOR POSITIVE

Flomate Mains Boost Pump Installation & Maintenance Instructions

Flomate Mains Boost Pump Installation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information PATENT APPROVED

Flomate Mains Boost Pump Installation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information PATENT APPROVED

Installation Instructions For Showermate Eco Shower Booster Pumps S1.5 bar Twin, S2.0 bar Twin, S2.0 bar Single

Installation Instructions For Showermate Eco Shower Booster Pumps S.5 bar Twin, S2.0 bar Twin, S2.0 bar Single INDEX...................... Page No Product Description................ Application.......................

Installation Instructions For Showermate Eco Shower Booster Pumps S.5 bar Twin, S2.0 bar Twin, S2.0 bar Single INDEX...................... Page No Product Description................ Application.......................

Installation Instructions For Monsoon Extra Pressure Sets:

Installation Instructions For Monsoon Extra Pressure Sets: 3.2 bar PS 4.7 bar PS INDEX................. Page No Application.......................... 1 Storage............................ 1 Typical Installation....................

Installation Instructions For Monsoon Extra Pressure Sets: 3.2 bar PS 4.7 bar PS INDEX................. Page No Application.......................... 1 Storage............................ 1 Typical Installation....................

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation Instructions For Monsoon Universal Twin Pump

Installation Instructions For Monsoon Universal Twin Pump Medium Pressure U1.5 bar Medium Pressure U2.0 bar INDEX................. Page No Product Description................... 1 Application..........................

Installation Instructions For Monsoon Universal Twin Pump Medium Pressure U1.5 bar Medium Pressure U2.0 bar INDEX................. Page No Product Description................... 1 Application..........................

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the owner as it contains important guarantee, maintenance and safety information Read this manual carefully

WC2 & WC3 Installation & Maintenance Instructions

WC2 & WC3 Installation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information WC3 shown WC2 WC3 IMPORTANT

WC2 & WC3 Installation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information WC3 shown WC2 WC3 IMPORTANT

Installation Instructions For Monsoon Universal Twin Pump

Installation Instructions For Monsoon Universal Twin Pump Medium Pressure N1.5 bar High Pressure N2.5 bar High Pressure N3.5 bar High Pressure N4.1 bar INDEX........................Page No Product Description....................1

Installation Instructions For Monsoon Universal Twin Pump Medium Pressure N1.5 bar High Pressure N2.5 bar High Pressure N3.5 bar High Pressure N4.1 bar INDEX........................Page No Product Description....................1

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation Instructions For Monsoon Extra Universal Single Duty Pump

Installation Instructions For Monsoon Extra Universal Single Duty Pump Medium Pressure U1.4 bar High Pressure U3.5 bar INDEX................ Page No Application........................ 1 Storage..........................

Installation Instructions For Monsoon Extra Universal Single Duty Pump Medium Pressure U1.4 bar High Pressure U3.5 bar INDEX................ Page No Application........................ 1 Storage..........................

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Installation, Operation & Maintenance Instructions Please leave this instruction booklet with the home owner as it contains important guarantee, maintenance and safety information Read this manual carefully

Mira 1.5 bar Twin Ended Pump Mira 2.0 bar Twin Ended Pump

Mira 1.5 bar Twin Ended Pump Mira 2.0 bar Twin Ended Pump These instructions must be left with the user Installation and User Guide 1 IMPORTANT SAFETY INFORMATION WARNING! 1. Products manufactured by us

Mira 1.5 bar Twin Ended Pump Mira 2.0 bar Twin Ended Pump These instructions must be left with the user Installation and User Guide 1 IMPORTANT SAFETY INFORMATION WARNING! 1. Products manufactured by us

BOILING UNIT REDITAP. Installation and User Guide. IMPORTANT: This booklet should be left with the user after installation and demonstration

in tap Boiling water to in tap sink Drain Valve (as high as possible) REDITAP CONNECTION SUMMARY Amp mains supply cold mains water into in tap optional filter cold water in hot water BOILING UNIT Installation

in tap Boiling water to in tap sink Drain Valve (as high as possible) REDITAP CONNECTION SUMMARY Amp mains supply cold mains water into in tap optional filter cold water in hot water BOILING UNIT Installation

V80-H Multistage Pump Instruction Manual

V80-H Multistage Pump Instruction Manual PRODUCT OVERVIEW The VADA horizontal multistage centrifugal pumps combine the functional benefits of centrifugal pumps and the practical benefits of self priming

V80-H Multistage Pump Instruction Manual PRODUCT OVERVIEW The VADA horizontal multistage centrifugal pumps combine the functional benefits of centrifugal pumps and the practical benefits of self priming

HEAVY DUTY BRASS SHOWER PUMPS

HEAVY DUTY BRASS SHOWER PUMPS YOUR GUARANTEE IS AT RISK IF PUMP NOT INSTALLED CORRECTLY. SEE SECTION 2 IMPORTANT INSTRUCTIONS Performance Shower Products SERVICE HELPLINE TEL: 01883 730339 1. GENERAL Your

HEAVY DUTY BRASS SHOWER PUMPS YOUR GUARANTEE IS AT RISK IF PUMP NOT INSTALLED CORRECTLY. SEE SECTION 2 IMPORTANT INSTRUCTIONS Performance Shower Products SERVICE HELPLINE TEL: 01883 730339 1. GENERAL Your

CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE

User instructions Model X46 Escalator and Travelator cleaner CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE 03-7845-0000 Iss.1 07/04 Fig 1 Fig 2 2 Contents Page 1 Product information... 4 1.1

User instructions Model X46 Escalator and Travelator cleaner CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE 03-7845-0000 Iss.1 07/04 Fig 1 Fig 2 2 Contents Page 1 Product information... 4 1.1

NON-SUBMERSIBLE WATER PUMP

NON-SUBMERSIBLE WATER PUMP MODEL NO: CEB103 PART NO: 7230327 OPERATION & MAINTENANCE INSTRUCTIONS LS0114 INTRODUCTION Thank you for purchasing this CLARKE Water Pump, which is a general purpose pump, suitable

NON-SUBMERSIBLE WATER PUMP MODEL NO: CEB103 PART NO: 7230327 OPERATION & MAINTENANCE INSTRUCTIONS LS0114 INTRODUCTION Thank you for purchasing this CLARKE Water Pump, which is a general purpose pump, suitable

PERFORMANCE SHOWER PRODUCTS

INSTALLER PLEASE LEAVE INSTRUCTIONS WITH CUSTOMER PERFORMANCE SHOWER PRODUCTS INSTALLATION INSTRUCTIONS FOR REGENERATIVE MAINS SHOWER PUMP Model: PR35D Medium pressure twin PR50D Medium pressure twin PR50S

INSTALLER PLEASE LEAVE INSTRUCTIONS WITH CUSTOMER PERFORMANCE SHOWER PRODUCTS INSTALLATION INSTRUCTIONS FOR REGENERATIVE MAINS SHOWER PUMP Model: PR35D Medium pressure twin PR50D Medium pressure twin PR50S

VADA - V80-H PRODUCT OVERVIEW CONSTRUCTION USAGE LIMITATIONS MOTOR WARRANTY

PRODUCT OVERVIEW The VADA horizontal multistage centrifugal pumps combine the functional benefits of centrifugal pumps and the practical benefits of self priming pumps. They warrant high hydraulic and

PRODUCT OVERVIEW The VADA horizontal multistage centrifugal pumps combine the functional benefits of centrifugal pumps and the practical benefits of self priming pumps. They warrant high hydraulic and

CPE RANGE PUMPS CPE RANGE PUMPS. MODEL Nos: CPE15A1 15A3 20A1 20A3 30A1 30A3 PART Nos:

CPE RANGE PUMPS CPE RANGE PUMPS MODEL Nos: CPE15A1 15A3 20A1 20A3 30A1 30A3 PART Nos: 7120305 7120310 7120315 7120320 7120325 7120330 OPERATION & MAINTENANCE INSTRUCTIONS GC0514 Contents Specifications...

CPE RANGE PUMPS CPE RANGE PUMPS MODEL Nos: CPE15A1 15A3 20A1 20A3 30A1 30A3 PART Nos: 7120305 7120310 7120315 7120320 7120325 7120330 OPERATION & MAINTENANCE INSTRUCTIONS GC0514 Contents Specifications...

SHOWER PUMP. Installation and User Guide. These instructions are to be left with the user

SHOWER PUMP Installation and User Guide These instructions are to be left with the user Contents IMPORTANT SAFETY INFORMATION...3 WARNING!...3 CAUTION!...4 Introduction...5 DESCRIPTION...5 Pump Location...5

SHOWER PUMP Installation and User Guide These instructions are to be left with the user Contents IMPORTANT SAFETY INFORMATION...3 WARNING!...3 CAUTION!...4 Introduction...5 DESCRIPTION...5 Pump Location...5

INLINE СENTRIFUGAL FAN BOX BOX-R OPERATION MANUAL

INLINE СENTRIFUGAL FAN BOX BOX-R OPERATION MANUAL CONTENT 3 Introduction 3 General 3 Safety rules 3 Storage and transportation rules 3 Manufacturer s warranty 4 Fan design 4 Delivery set 5 Technical data

INLINE СENTRIFUGAL FAN BOX BOX-R OPERATION MANUAL CONTENT 3 Introduction 3 General 3 Safety rules 3 Storage and transportation rules 3 Manufacturer s warranty 4 Fan design 4 Delivery set 5 Technical data

Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0)

7825 flood PUMP Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 33713-001? 1 AUTO ON AUTO OFF 400mm 190mm 2 3 25mm 32mm 4 5 50cm 50cm

7825 flood PUMP Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 33713-001? 1 AUTO ON AUTO OFF 400mm 190mm 2 3 25mm 32mm 4 5 50cm 50cm

Installation & User Instructions: Model: e600s e600gf e700s e1000s e1000gf e1030gf/2/3 e1500gf/2/3

Installation & User Instructions: Model: e600s e600gf e700s e1000s e1000gf e1030gf/2/3 e1500gf/2/3 Once installed, the installer should take the appropriate steps To ensure that the user understands how

Installation & User Instructions: Model: e600s e600gf e700s e1000s e1000gf e1030gf/2/3 e1500gf/2/3 Once installed, the installer should take the appropriate steps To ensure that the user understands how

User Guide. Please read carefully before use. Your Hoover Guarantee. Your Hoover Guarantee. Contents. IMPORTANT Safety Reminders

Your Hoover Guarantee Contents Your Hoover Guarantee During year 1 HOOVER engineers will replace or repair all defective parts free of charge, except for parts subject to fair wear and tear such as belts,

Your Hoover Guarantee Contents Your Hoover Guarantee During year 1 HOOVER engineers will replace or repair all defective parts free of charge, except for parts subject to fair wear and tear such as belts,

WARNING: Warns of health hazards and identifies possible risks of injury. CAUTION: Indicates possible dangers to the machine or other objects.

VBT3ASV USER GUIDE SAFETY INFORMATION About this user guide Read this user guide completely before using the machine. Keep this user guide for reference. If you pass your machine on to third parties, it

VBT3ASV USER GUIDE SAFETY INFORMATION About this user guide Read this user guide completely before using the machine. Keep this user guide for reference. If you pass your machine on to third parties, it

Multipoint. Installation and User Instructions Instantaneous Hand Wash Models: EV 2008

Installation and User Instructions Instantaneous Hand Wash Models: EV 2008 Multipoint Please read and understand these instructions before starting work. Please leave this leaflet with the user following

Installation and User Instructions Instantaneous Hand Wash Models: EV 2008 Multipoint Please read and understand these instructions before starting work. Please leave this leaflet with the user following

Installation & Operating Instructions. Models: Desire, Ignite & Hereford Electric Stoves

Installation & Operating Instructions Models: Desire, Ignite & Hereford Electric Stoves PLEASE NOTE THAT THIS APPLIANCE USES A MOTOR TO OPERATE THE FLAME EFFECT AND THAT IT MAY BE POSSIBLE TO HEAR IT WHERE

Installation & Operating Instructions Models: Desire, Ignite & Hereford Electric Stoves PLEASE NOTE THAT THIS APPLIANCE USES A MOTOR TO OPERATE THE FLAME EFFECT AND THAT IT MAY BE POSSIBLE TO HEAR IT WHERE

SUBMERSIBLE WATER PUMPS

OPERATING & MAINTENANCE INSTRUCTIONS SUBMERSIBLE WATER PUMPS Model Nos. HIPPO-3 and 3A 6/97 Thank you for purchasing this CLARKE, HIPPO Submersible Pump. These highly efficient pumps are designed for pumping

OPERATING & MAINTENANCE INSTRUCTIONS SUBMERSIBLE WATER PUMPS Model Nos. HIPPO-3 and 3A 6/97 Thank you for purchasing this CLARKE, HIPPO Submersible Pump. These highly efficient pumps are designed for pumping

Installation & Operating Instructions. Models: York Midi & Serrano Electric Stoves

Installation & Operating Instructions Models: York Midi & Serrano Electric Stoves PLEASE NOTE THAT THIS APPLIANCE USES A MOTOR TO OPERATE THE FLAME EFFECT AND THAT IT MAY BE POSSIBLE TO HEAR IT WHERE THE

Installation & Operating Instructions Models: York Midi & Serrano Electric Stoves PLEASE NOTE THAT THIS APPLIANCE USES A MOTOR TO OPERATE THE FLAME EFFECT AND THAT IT MAY BE POSSIBLE TO HEAR IT WHERE THE

airooncentre.co.uk irconcentre.co.uk Xpelair Low Energy Wall/Window Fan Range GX6 EC2 GXC6 EC2 Quick Order Hotline or

Xpelair Low Energy Wall/Window Fan Range GX6 EC2 GXC6 EC2 Installation and Maintenance Instructions Retain for future reference 3. To remove the impeller, unscrew the central screw with a 7mm nut runner

Xpelair Low Energy Wall/Window Fan Range GX6 EC2 GXC6 EC2 Installation and Maintenance Instructions Retain for future reference 3. To remove the impeller, unscrew the central screw with a 7mm nut runner

Whole Room Dryer WRD, WRD/110

Whole Room Dryer WRD, WRD/110 User Instructions Whole Room Dryers CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE 03-8117-0000 Iss.1 12/06 Fig 1 Fig 2 Fig 3 Fig 4 CONTENTS Page 1 Product information...................4

Whole Room Dryer WRD, WRD/110 User Instructions Whole Room Dryers CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE 03-8117-0000 Iss.1 12/06 Fig 1 Fig 2 Fig 3 Fig 4 CONTENTS Page 1 Product information...................4

This label warns for risk of electrical shock when failing to observe.

MANUAL horizontal centrifugal pumps MB series ic drive SB series mechanical seal 1. Introduction 2. Safety precautions 3. Receipt 4. Installation / Operation and Maintenance 4.1 Installation 4.2 Operation

MANUAL horizontal centrifugal pumps MB series ic drive SB series mechanical seal 1. Introduction 2. Safety precautions 3. Receipt 4. Installation / Operation and Maintenance 4.1 Installation 4.2 Operation

SHOWER PUMPS. Installation Manual. 1.5 bar and 2.0 bar

SHOWER PUMPS 1.5 bar and 2.0 bar Twin and single ended pumps designed specifically for gravity feed or stored water systems where the hot water is fed from a hot water cylinder and the cold from a cold

SHOWER PUMPS 1.5 bar and 2.0 bar Twin and single ended pumps designed specifically for gravity feed or stored water systems where the hot water is fed from a hot water cylinder and the cold from a cold

TQ Series. Electronic Control Pump Instruction Manual. 50Hz. ISO 9001 Certified Walrus Pump Co., Ltd.

TQ Series Electronic Control Pump Instruction Manual 50Hz ISO 9001 Certified Walrus Pump Co., Ltd. EC Declaration of Conformity Manufacturer: Walrus Pump Co., Ltd. Address: No. 83-14, Dapiantou, Sanjhih

TQ Series Electronic Control Pump Instruction Manual 50Hz ISO 9001 Certified Walrus Pump Co., Ltd. EC Declaration of Conformity Manufacturer: Walrus Pump Co., Ltd. Address: No. 83-14, Dapiantou, Sanjhih

User instructions. VA20HD, VA55HD, VA55IND and VA75IND. Commercial wet/dry vacuum cleaners CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE

User instructions VA20HD, VA55HD, VA55IND and VA75IND Commercial wet/dry vacuum cleaners CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE 03-8112-0000 Iss.3 07/08 http://www.truvox.com/products/vacuums/valet_aqua

User instructions VA20HD, VA55HD, VA55IND and VA75IND Commercial wet/dry vacuum cleaners CAUTION - READ THESE INSTRUCTIONS BEFORE USING THE MACHINE 03-8112-0000 Iss.3 07/08 http://www.truvox.com/products/vacuums/valet_aqua

VADA - Rain2Main Automatic Rainwater Controller

PRODUCT OVERVIEW / APPLICATION The Vada Rain2Main is designed to select between stored rainwater (when available) and mains supply water, and send this water to your toilet cistern, washing machine, garden

PRODUCT OVERVIEW / APPLICATION The Vada Rain2Main is designed to select between stored rainwater (when available) and mains supply water, and send this water to your toilet cistern, washing machine, garden

CRU-S Series Stainless Steel Condensate Recovery Unit

IM-UK-CRU-S UK Issue 1 CRU-S Series Stainless Steel Condensate Recovery Unit 1. Safety information 2. General product information 3. Installation 4. Commissioning 5. Storage, shutdown and equipment protection

IM-UK-CRU-S UK Issue 1 CRU-S Series Stainless Steel Condensate Recovery Unit 1. Safety information 2. General product information 3. Installation 4. Commissioning 5. Storage, shutdown and equipment protection

SHOWER PUMP. Installation and User Guide. These instructions are to be left with the user 1

SHOWER PUMP Installation and User Guide These instructions are to be left with the user 1 Contents IMPORTANT SAFETY INFORMATION...3 WARNING!...3 CAUTION!...4 Introduction...5 DESCRIPTION...5 Pump Location...5

SHOWER PUMP Installation and User Guide These instructions are to be left with the user 1 Contents IMPORTANT SAFETY INFORMATION...3 WARNING!...3 CAUTION!...4 Introduction...5 DESCRIPTION...5 Pump Location...5

Autofill wall mounted water. boiler. Getting the best from your water. boiler. Please read and keep these instructions

Autofill wall mounted water boiler Please read and keep these instructions For Burco wall mounted boilers 76700 (SKU 444448534), 76702 (SKU 444448546), & 76704 (SKU444448548) Getting the best from your

Autofill wall mounted water boiler Please read and keep these instructions For Burco wall mounted boilers 76700 (SKU 444448534), 76702 (SKU 444448546), & 76704 (SKU444448548) Getting the best from your

Model 1174 Electric Heater User instructions for LED effect 2kw Inset Heater

200688_6 Page 1 Model 1174 Electric Heater User instructions for LED effect 2kw Inset Heater These instructions should be read carefully and retained for future reference Important Notes This heater must

200688_6 Page 1 Model 1174 Electric Heater User instructions for LED effect 2kw Inset Heater These instructions should be read carefully and retained for future reference Important Notes This heater must

High Pressure Washer 130

High Pressure Washer 130 7901 WARNING: Do not use the appliance without reading this instruction sheet ORIGINAL INSTRUCTIONS Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121 313

High Pressure Washer 130 7901 WARNING: Do not use the appliance without reading this instruction sheet ORIGINAL INSTRUCTIONS Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121 313

User Instructions for Remote Controlled 2kW Rotisserie Effect Fan Heater Model 1276

200662_2 Page 1 User Instructions for Remote Controlled 2kW Rotisserie Effect Fan Heater Model 1276 These instructions should be read carefully and retained for future reference. Important Notes These

200662_2 Page 1 User Instructions for Remote Controlled 2kW Rotisserie Effect Fan Heater Model 1276 These instructions should be read carefully and retained for future reference. Important Notes These

Heavy Duty Pressure Washer 150

Heavy Duty Pressure Washer 150 7902 WARNING: Do not use the appliance without reading this instruction sheet Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com

Heavy Duty Pressure Washer 150 7902 WARNING: Do not use the appliance without reading this instruction sheet Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com

Compact Pressure Washer 100

Compact Pressure Washer 100 7900 WARNING: Do not use the appliance without reading this instruction sheet ORIGINAL INSTRUCTIONS Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121

Compact Pressure Washer 100 7900 WARNING: Do not use the appliance without reading this instruction sheet ORIGINAL INSTRUCTIONS Hozelock Ltd. Midpoint Park Birmingham, B76 1AB. England Tel: +44 (0) 121

WALLACE MAXIPUMP 3000, 5000, 6000 and HYDROJET 30P, 30C, 140 AND HJ400 INSTALLATION AND MAINTENANCE INSTRUCTIONS

6 th June 2006 Page 1 WALLACE MAXIPUMP 3000, 5000, 6000 and HYDROJET 30P, 30C, 140 AND HJ400 INSTALLATION AND MAINTENANCE INSTRUCTIONS Please read and follow all these instructions carefully before proceeding

6 th June 2006 Page 1 WALLACE MAXIPUMP 3000, 5000, 6000 and HYDROJET 30P, 30C, 140 AND HJ400 INSTALLATION AND MAINTENANCE INSTRUCTIONS Please read and follow all these instructions carefully before proceeding

Turboboost SHOWER PUMPS. Installation Manual. 1.5 bar and 2.0 bar

Turboboost SHOWER PUMPS 1.5 bar and 2.0 bar Twin and single ended pumps designed specifically for gravity feed or stored water systems where the hot water is fed from a hot water cylinder and the cold

Turboboost SHOWER PUMPS 1.5 bar and 2.0 bar Twin and single ended pumps designed specifically for gravity feed or stored water systems where the hot water is fed from a hot water cylinder and the cold

Ceiling Sweep Fan Assembly Instructions

Ceiling Sweep Fan Assembly Instructions CSF Series Installation Note: This fan must be installed by a licenced electrical contractor Improperly installed ceiling sweep fans can be dangerous and expensive

Ceiling Sweep Fan Assembly Instructions CSF Series Installation Note: This fan must be installed by a licenced electrical contractor Improperly installed ceiling sweep fans can be dangerous and expensive

CLEAN WATER PUMP. MODEL No: Hippo4A OPERATION & MAINTENANCE INSTRUCTIONS. Part No:

CLEAN WATER PUMP MODEL No: Hippo4A Part No: 7230535 OPERATION & MAINTENANCE INSTRUCTIONS 0807 INTRODUCTION Thank you for purchasing this CLARKE clean water pump. This highly efficient pump is designed

CLEAN WATER PUMP MODEL No: Hippo4A Part No: 7230535 OPERATION & MAINTENANCE INSTRUCTIONS 0807 INTRODUCTION Thank you for purchasing this CLARKE clean water pump. This highly efficient pump is designed

FAITH (dmev) 230V / 24V DC SELV Flush Mounted Domestic Continuous Extract Fans

FAITH (dmev) 230V / 24V DC SELV Flush Mounted Domestic Continuous Extract Fans Installation and Maintenance IPX4* The EMC Directive 2014/30/EU The Low Voltage Directive 2014/35/EU 1.0 SAFETY INFORMATION

FAITH (dmev) 230V / 24V DC SELV Flush Mounted Domestic Continuous Extract Fans Installation and Maintenance IPX4* The EMC Directive 2014/30/EU The Low Voltage Directive 2014/35/EU 1.0 SAFETY INFORMATION

T550i power shower pump Installation and operating instructions

power shower pump Installation and operating instructions Installers please note these instructions are to be left with the user 2180149H March 2008 CONTENTS Page Plumbing and electrical notes...1 Introduction...2

power shower pump Installation and operating instructions Installers please note these instructions are to be left with the user 2180149H March 2008 CONTENTS Page Plumbing and electrical notes...1 Introduction...2

Acquaer Ltd. H-4900, Fehérgyarmat, Szatmári út 11. CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2

CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2 Congratulations on your purchase of a LEO Centrifugal Pump It is important that you read, fully understand and observe the following

CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2 Congratulations on your purchase of a LEO Centrifugal Pump It is important that you read, fully understand and observe the following

10 & 12 Ventilator. Please read and fully understand the instructions in this manual before operation. Keep this manual safe for future reference

Please dispose of packaging for the product in a responsible manner. It is suitable for recycling. Help to protect the environment, take the packaging to the local amenity tip and place into the appropriate

Please dispose of packaging for the product in a responsible manner. It is suitable for recycling. Help to protect the environment, take the packaging to the local amenity tip and place into the appropriate

Autofill counter top water boiler

Autofill counter top water boiler Please read and keep these instructions For Burco counter top water boilers 76500 (SKU 444448531) and 76502 (SKU 444448533) Getting the best from your water boiler Remove

Autofill counter top water boiler Please read and keep these instructions For Burco counter top water boilers 76500 (SKU 444448531) and 76502 (SKU 444448533) Getting the best from your water boiler Remove

ELTA FANS IN-LINE MIXED FLOW FAN IMF100 / 125 / 150 / 200 INCLUDING MODELS WITH BUILT-IN-RUN-ON TIMERS T

ELTA FANS IN-LINE MIXED FLOW FAN IMF100 / 125 / 150 / 200 INCLUDING MODELS WITH BUILT-IN-RUN-ON TIMERS T Installation and Maintenance Instructions. THESE INSTRUCTIONS MUST BE READ FULLY BEFORE COMMENCING

ELTA FANS IN-LINE MIXED FLOW FAN IMF100 / 125 / 150 / 200 INCLUDING MODELS WITH BUILT-IN-RUN-ON TIMERS T Installation and Maintenance Instructions. THESE INSTRUCTIONS MUST BE READ FULLY BEFORE COMMENCING

Model No: Little Devil II (inc ss)

GAS HEATER Model No: Little Devil II (inc ss) PART NO: 6926020, 6926025 (SS) OPERATION & MAINTENANCE INSTRUCTIONS LS1213 INTRODUCTION Thank you for purchasing this CLARKE Gas Heater. Before attempting

GAS HEATER Model No: Little Devil II (inc ss) PART NO: 6926020, 6926025 (SS) OPERATION & MAINTENANCE INSTRUCTIONS LS1213 INTRODUCTION Thank you for purchasing this CLARKE Gas Heater. Before attempting

INFRARED IP55 HEATER INSTRUCTIONS FOR: MODEL:- QZWP45N 1. SAFETY INSTRUCTIONS

INSTRUCTIONS FOR: INFRARED IP55 HEATER MODEL:- QZWP45N Thank you for purchasing a Consort Claudgen product. Manufactured to a high standard this product will, if used according to these instructions and

INSTRUCTIONS FOR: INFRARED IP55 HEATER MODEL:- QZWP45N Thank you for purchasing a Consort Claudgen product. Manufactured to a high standard this product will, if used according to these instructions and

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER S USE. Condensate Return Systems General Installation, Operation, & Service Instructions !

Condensate Return Systems General Installation, Operation, & Service Instructions INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER S USE. SAFETY INSTRUCTIONS This safety alert symbol will be used in this

Condensate Return Systems General Installation, Operation, & Service Instructions INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER S USE. SAFETY INSTRUCTIONS This safety alert symbol will be used in this

Tempest TP420/180 Electric Pressure Washer

Please dispose of packaging for the product in a responsible manner. It is suitable for recycling. Help to protect the environment, take the packaging to the local amenity tip and place into the appropriate

Please dispose of packaging for the product in a responsible manner. It is suitable for recycling. Help to protect the environment, take the packaging to the local amenity tip and place into the appropriate

PRESSURE WASHER MODEL NO: JETSTAR 1750 OPERATION & MAINTENANCE INSTRUCTIONS. WARNING Read the instructions before using the machine PART NO:

WARNING Read the instructions before using the machine PRESSURE WASHER MODEL NO: JETSTAR 1750 PART NO: 7333230 OPERATION & MAINTENANCE INSTRUCTIONS LS0711 INTRODUCTION Thank you for purchasing this CLARKE

WARNING Read the instructions before using the machine PRESSURE WASHER MODEL NO: JETSTAR 1750 PART NO: 7333230 OPERATION & MAINTENANCE INSTRUCTIONS LS0711 INTRODUCTION Thank you for purchasing this CLARKE

isense & isense-ht 230V Flush Mounted Domestic Continuous Extract Fans

isense & isense-ht 230V Flush Mounted Domestic Continuous Extract Fans Installation and Maintenance IPX4* The EMC Directive 2014/30/EU The Low Voltage Directive 2014/35/EU 1.0 SAFETY INFORMATI The installation

isense & isense-ht 230V Flush Mounted Domestic Continuous Extract Fans Installation and Maintenance IPX4* The EMC Directive 2014/30/EU The Low Voltage Directive 2014/35/EU 1.0 SAFETY INFORMATI The installation

Internal/External Wall/Window Fan Range GX6. Installation and maintenance instructions Retain for future use

Internal/External Wall/Window Fan Range GX6 Installation and maintenance instructions Retain for future use A GLASS WINDOW B C D ( 6 see F ) 13 E1 E2 E3 G1 G2 G3 G4 H I GB Xpelair GX6, GXC6, GXC6T, GX6HT

Internal/External Wall/Window Fan Range GX6 Installation and maintenance instructions Retain for future use A GLASS WINDOW B C D ( 6 see F ) 13 E1 E2 E3 G1 G2 G3 G4 H I GB Xpelair GX6, GXC6, GXC6T, GX6HT

Power Wash 2000W Car. User Guide. HPW2C-ZA hoover.za.com. Version 1.0

Power Wash 2000W Car User Guide HPW2C-ZA hoover.za.com Version 1.0 2 CONTENTS MACHINE OVERVIEW 3 Contents Machine Overview General Safety Information Operation Maintenance FAQs Warranty Other Information

Power Wash 2000W Car User Guide HPW2C-ZA hoover.za.com Version 1.0 2 CONTENTS MACHINE OVERVIEW 3 Contents Machine Overview General Safety Information Operation Maintenance FAQs Warranty Other Information

USER INSTRUCTION MANUAL. Autofill Water Boiler

USER INSTRUCTION MANUAL Autofill Water Boiler GH187 GC719 (FILTERED PRODUCT) Buffalo Warranty 1 Year Parts 1 Year Labour 083347300-03/06/14 Introduction Thank you for purchasing this Buffalo appliance.

USER INSTRUCTION MANUAL Autofill Water Boiler GH187 GC719 (FILTERED PRODUCT) Buffalo Warranty 1 Year Parts 1 Year Labour 083347300-03/06/14 Introduction Thank you for purchasing this Buffalo appliance.

The Classeq under counter range

Installation & Operators Manual The under counter range Part number 902.0011 Revision C Effective date January 2010 Language English Glasswashers Eco 1 Eco 2 Eco 3 Duo 2 Duo 3 Dishwasher Hydro 500 Hydro

Installation & Operators Manual The under counter range Part number 902.0011 Revision C Effective date January 2010 Language English Glasswashers Eco 1 Eco 2 Eco 3 Duo 2 Duo 3 Dishwasher Hydro 500 Hydro

Models Series Series

Models 31800-Series 31801-Series INDUSTRIAL DIAPHRAGM PUMPS 4 GPM/15 LPM FEATURES Self-Priming Easy Installation Can run dry without damage Low Amp Draw Flow to 4 GPM/15 LPM Compact Size Thermal Overload

Models 31800-Series 31801-Series INDUSTRIAL DIAPHRAGM PUMPS 4 GPM/15 LPM FEATURES Self-Priming Easy Installation Can run dry without damage Low Amp Draw Flow to 4 GPM/15 LPM Compact Size Thermal Overload

Installation & Operators Manual. The Classeq Pass Through Range

Installation & Operators Manual The Classeq Pass Through Range HYDRO 857 HYDRO 957 Service 0844 2245 245 service@classeq.co.uk Part number 902.0005 Revision E Jan 2012 Language English Spares 0844 2245

Installation & Operators Manual The Classeq Pass Through Range HYDRO 857 HYDRO 957 Service 0844 2245 245 service@classeq.co.uk Part number 902.0005 Revision E Jan 2012 Language English Spares 0844 2245

DR6000 UK_110 x /12/13 11:40 Page1

1800129621 DR6000 UK_110 x 154 02/12/13 11:40 Page1 1800129621-48/13 1800129621 DR6000 UK_110 x 154 02/12/13 11:40 Page2 I n s t r u c t i o n f o r u s e EN www.rowenta.com 1800129621 DR6000 UK_110 x

1800129621 DR6000 UK_110 x 154 02/12/13 11:40 Page1 1800129621-48/13 1800129621 DR6000 UK_110 x 154 02/12/13 11:40 Page2 I n s t r u c t i o n f o r u s e EN www.rowenta.com 1800129621 DR6000 UK_110 x

24 & 30 Drum Fan. Please read and fully understand the instructions in this manual before operation. Keep this manual safe for future reference

Please dispose of packaging for the product in a responsible manner. It is suitable for recycling. Help to protect the environment, take the packaging to the local amenity tip and place into the appropriate

Please dispose of packaging for the product in a responsible manner. It is suitable for recycling. Help to protect the environment, take the packaging to the local amenity tip and place into the appropriate

On/off button with booster (max) function* Fine filter Prefilter. Dust container Release button Charging indicator light. Vacuum cleaning cover

Thank you for choosing an Electrolux Rapido vacuum cleaner. Rapido is a rechargeable handheld vacuum cleaner intended for use of light dry household debris. These Operating Instructions cover most Rapido

Thank you for choosing an Electrolux Rapido vacuum cleaner. Rapido is a rechargeable handheld vacuum cleaner intended for use of light dry household debris. These Operating Instructions cover most Rapido

Diamond Cut 2 Slice Toaster Cool Touch Plastic

Diamond Cut 2 Slice Toaster Cool Touch Plastic I/B Version 150217 230V~ 50Hz 1000W Front cover page (first page) Assembly page 1/8 Know Your Appliance 1. Bread Carriage Lever 2. Rotary Browning Control

Diamond Cut 2 Slice Toaster Cool Touch Plastic I/B Version 150217 230V~ 50Hz 1000W Front cover page (first page) Assembly page 1/8 Know Your Appliance 1. Bread Carriage Lever 2. Rotary Browning Control

MW001 Integrated Dishwasher. Manual for Installation, Use and Maintenance

MW001 Integrated Dishwasher Manual for Installation, Use and Maintenance Important The CDA Group Ltd cannot be held responsible for injuries or losses caused by incorrect use or installation of this product.

MW001 Integrated Dishwasher Manual for Installation, Use and Maintenance Important The CDA Group Ltd cannot be held responsible for injuries or losses caused by incorrect use or installation of this product.

SUBMERSIBLE DIRTY WATER PUMP

SUBMERSIBLE DIRTY WATER PUMP MODEL NO: DWP100A, DWP150A, DWP200A PART NO: 7230098, 7230099, 7230100 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS LS1117 - ISS 2 INTRODUCTION Thank you for

SUBMERSIBLE DIRTY WATER PUMP MODEL NO: DWP100A, DWP150A, DWP200A PART NO: 7230098, 7230099, 7230100 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS LS1117 - ISS 2 INTRODUCTION Thank you for

The Professional s Choice

SureFlow compact range: 1000-C & 1000-M Auto-Fill Catering Water Boiler Installation And User Instructions The Professional s Choice CONTENTS CONTENTS & INTRODUCTION 2 SAFETY & ENVIRONMENTAL INFORMATION

SureFlow compact range: 1000-C & 1000-M Auto-Fill Catering Water Boiler Installation And User Instructions The Professional s Choice CONTENTS CONTENTS & INTRODUCTION 2 SAFETY & ENVIRONMENTAL INFORMATION

USER S MANUAL. Centrifugal inline fan. VKMz 100 Q VKMz 100 VKMz 125 Q VKMz 125. VKMz 250 Q VKMz 250 VKMz 315 Q VKMz 315

USER S MANUAL VKMz 100 Q VKMz 100 VKMz 125 Q VKMz 125 VKMz 150 VKMz 160 VKMz 200 Q VKMz 200 VKMz 250 Q VKMz 250 VKMz 315 Q VKMz 315 Centrifugal inline fan VKMz CONTENTS Contents... 2 Safety requirements...

USER S MANUAL VKMz 100 Q VKMz 100 VKMz 125 Q VKMz 125 VKMz 150 VKMz 160 VKMz 200 Q VKMz 200 VKMz 250 Q VKMz 250 VKMz 315 Q VKMz 315 Centrifugal inline fan VKMz CONTENTS Contents... 2 Safety requirements...

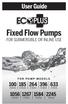

User Guide. Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE FOR PUMP MODELS # # # # # # # # #728333

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

OWNERS INSTRUCTION MANUAL FOR FIXED INSTALLATION COMMERCIAL AND RESIDENTIAL EVAPORATIVE AIR CONDITIONERS

R O O F T O P N A T U R A L A I R C O N D I T I O N E R S OWNERS INSTRUCTION MANUAL FOR FIXED INSTALLATION COMMERCIAL AND RESIDENTIAL EVAPORATIVE AIR CONDITIONERS How to Operate Using Your Air Conditioner

R O O F T O P N A T U R A L A I R C O N D I T I O N E R S OWNERS INSTRUCTION MANUAL FOR FIXED INSTALLATION COMMERCIAL AND RESIDENTIAL EVAPORATIVE AIR CONDITIONERS How to Operate Using Your Air Conditioner

air pump 2700/4500 ? 2YEAR GUARANTEE UK AIRPUMP _33435 CASC /10/ :16 Page 1

33719-000 UK AIRPUMP 2700-4500_33435 CASC.450 13/10/2011 09:16 Page 1 2823 1820 1380 air pump 2700/4500 Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com

33719-000 UK AIRPUMP 2700-4500_33435 CASC.450 13/10/2011 09:16 Page 1 2823 1820 1380 air pump 2700/4500 Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com

SAFETY AND OPERATING MANUAL. Original instructions 2000W WALLPAPER STRIPPER

24 SAFETY AND OPERATING MANUAL Original instructions This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience

24 SAFETY AND OPERATING MANUAL Original instructions This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience

For use with approved Bathstore head kits. Installation guide. Viso Digital installation instructions Page 1

Viso Digital TM For use with approved Bathstore head kits Installation guide Viso Digital installation instructions Page 1 Viso Digital Viso Digital Viso Digital installation instructions Page 2 Components

Viso Digital TM For use with approved Bathstore head kits Installation guide Viso Digital installation instructions Page 1 Viso Digital Viso Digital Viso Digital installation instructions Page 2 Components

HW3 Handwash Installation and Operating Instructions

HW3[16]instructions 10/12/15 14:05 Page 1 HW3 Handwash Installation and Operating Instructions IMPORTANT SAFEGUARDS SPECIFICATION: HW3 RATING: 230-240V, 3000W, ~50Hz; DIMENSIONS: 170w x 190h x 80d mm;

HW3[16]instructions 10/12/15 14:05 Page 1 HW3 Handwash Installation and Operating Instructions IMPORTANT SAFEGUARDS SPECIFICATION: HW3 RATING: 230-240V, 3000W, ~50Hz; DIMENSIONS: 170w x 190h x 80d mm;

6000, 8000, & 15000

aquaforce 2823 1583 1584 1585 1586 6000, 8000, 12000 & 15000 Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 43386-000? 1 A A. Wildlife

aquaforce 2823 1583 1584 1585 1586 6000, 8000, 12000 & 15000 Hozelock Ltd. Midpoint Park, Birmingham B76 1AB. England Tel: +44 (0) 121 313 1122 info@hozelock.com www.hozelock.com 43386-000? 1 A A. Wildlife

Installation and Operating Instructions MODEL: MSE46W

Installation and Operating Instructions MODEL: MSE46W MSE50W MODEL: Free Standing Electric ElectricOven Oven Free Standing Please read these instructions carefully before attempting to install or use this

Installation and Operating Instructions MODEL: MSE46W MSE50W MODEL: Free Standing Electric ElectricOven Oven Free Standing Please read these instructions carefully before attempting to install or use this

SELF-PRIMING CENTRIFUGAL PUMPS BMLS-M & BMLS-H

SELF-PRIMING CENTRIFUGAL PUMPS BMLS-M & BMLS-H INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS HP Phase Medium Head High Head 3 1 BMLS 300 M BMLS 300 H 3 3 BMLS 300 M3 BMLS 300 H3 5 1 BMLS 500 M BMLS

SELF-PRIMING CENTRIFUGAL PUMPS BMLS-M & BMLS-H INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS HP Phase Medium Head High Head 3 1 BMLS 300 M BMLS 300 H 3 3 BMLS 300 M3 BMLS 300 H3 5 1 BMLS 500 M BMLS

Commercial backpack vacuum cleaner

ORIGINAL INSTRUCTIONS CAUTION READ THESE INSTRUCTIONS BEFORE USING THE MACHINE User instructions Valet BackPack Commercial backpack vacuum cleaner 03-8113-0000 Issue 6 10/10 1 2 Contents 1. General information...

ORIGINAL INSTRUCTIONS CAUTION READ THESE INSTRUCTIONS BEFORE USING THE MACHINE User instructions Valet BackPack Commercial backpack vacuum cleaner 03-8113-0000 Issue 6 10/10 1 2 Contents 1. General information...

SHORT WAVE INFRARED PANEL DRYER

INSTRUCTIONS FOR: SHORT WAVE INFRARED PANEL DRYER MODEL: IR3000 Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

INSTRUCTIONS FOR: SHORT WAVE INFRARED PANEL DRYER MODEL: IR3000 Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

Installation Instructions & Operating Manual IMPORTANT

Installation Instructions & Operating Manual IMPORTANT These instructions should be read carefully and retained for future reference TABLE OF CONTENTS SECTION 1: WARNINGS & ELECTRIC SPECIFICATIONS 1.1

Installation Instructions & Operating Manual IMPORTANT These instructions should be read carefully and retained for future reference TABLE OF CONTENTS SECTION 1: WARNINGS & ELECTRIC SPECIFICATIONS 1.1

rev3 INSTALLATION & OPERATION MANUAL OIL CIRCULATING HEATING SYSTEM MODEL OSM

216279-000 rev3 INSTALLATION & OPERATION MANUAL OIL CIRCULATING HEATING SYSTEM MODEL OSM IDENTIFYING YOUR SYSTEM IOM216279-000 The HOTSTART heating system is designed to heat fluids for use in marine

216279-000 rev3 INSTALLATION & OPERATION MANUAL OIL CIRCULATING HEATING SYSTEM MODEL OSM IDENTIFYING YOUR SYSTEM IOM216279-000 The HOTSTART heating system is designed to heat fluids for use in marine