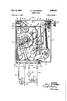

May 17, A, G. THOMAS 2,470,532 ELECTRIC IRON WITH THERMGKINETIc SWITCH

|

|

|

- Calvin Cunningham

- 5 years ago

- Views:

Transcription

1 May 17, A, G. THOMAS 2,470,32 Filed Aug. 14, 1943 ELECTRIC IRON WITH THERMGKINETIc SWITCH 2 Sheets-Sheet NVENTOR

2 May 17, A, G, THOMAS 2,470,32 ELECTRIC IRON WITH THERMOKINETIC SWITCH Filed Aug. 14, l943 2 Sheets-Sheet 2 7AA. A. af Asia, /46 St. (i. Yg 23S2, /72 A. NVENTOR

3 Patented May 17, ,470,32 UNITED STATES PATENT OFFICE 2,470,32 ELECTRIC RON WITH THERMOK NETC SWITCB Albert G. Thomas, Lynchburg, Wa. Application August 14, 1943, serial No. 499,621 This invention relates to electric irons and other devices and is a continuation-in-part of my co-pending application, Serial No. 446,68, filed June 12, 1942 issued August 14, 19 as Patent No. 2,382,87. An object is to provide an electric iron that will maintain the current connection to its heat ing element as long as the iron is kept in move ment, from use, but which will break the Cur rent connection if the iron is left stationary for a period longer than a predetermined interval. In this way fires can be prevented and scorched or burned ironing boards will be obviated. Another object is to provide an iron with an automatic current cut-off, depending upon move ment of the iron and also with a thermostatic current cut-off. A further object is to provide an iron with an automatic cut-off, depending upon movement of the iron, and also with a thermostatic cut-off, the latter dominating the former so that move ment of the iron will not close the circuit of the heating element if the iron is hotter than a pre determined temperature as determined by the setting of thermostat. An additional object is the provision of the above features in combination with an adjust able thermostat. Another object is to provide an iron with the above described characteristics, of simple and practical construction, so that it will stand up under long usage and yet will be cheap to manu facture. A further object is the provision of an elec tric iron that will lift its sole plate above an ironing board or other Supporting Surface, after an interval, if it is left stationary and in iron ing position. Another object is to provide an electric iron that will lift itself above its supporting surface after being left stationary for an interval, and which will also cut off the current to the heat ing unit. A still further object is the provision of an electric iron that will lift its heating unit above its ironing Surface, if left stationary for an in terval. An additional object is to provide an attach ment for electric irons, which will automatically cut off the current to the heating element if the iron is left stationary for an excessive interval. Other objects will appear in the specification. In the drawings: Figure l is a top plan view of the inner base or weight of an electric iron, showing automatic 8 Claims. (CI ) ) 2 cut-off mechanism for the heating element switch. Figure 2 is a view similar to that of Figure 1, but showing an alternative construction. Figure 3 is a side elevation, in part section, of an electric iron which lifts its bottom surface above an ironing board or other support, after being left stationary for a predetermined time. interval. Figure 4 is a side elevation, in part section, of an electric iron which lifts its heating unit above its ironing botton plate, if left stationary for a predetermined time interval. Figure is a side elevation, in part section, of a connection plug for an electric iron, the plug having a switch which automatically cuts off the current to the iron, if left stationary for an excessive interval as determined by a thermostat or other timing device. Figure 6 is an end view of an inertia operated roller weight attached to the arm of a switch for an electric iron. Figure 7 is a longitudinal part sectional view of an automatic switch cut-off for an electric iron, adapted to be connected into the cord cir cuit. This Switch is escapement-controlled so that its operation is independent of the tempera ture of the iron, In Figure 1, integral arms and 2 are pivoted to Swing horizontally above weight or plate 3 of the iron which contains the heating element 4, shown in fragmentary manner. Pivot pin is passed through a Suitable bore at the junction of arms and 2 and is threaded into a hole in weight 3, or otherwise fastened. One end of ten sion spring 6 is fastened to arm by means of a hole or pin 7 and the other end is similarly fastened to weight 3 or to another support at point 8. Flexible metal strip 9 with attached electrical contact 0 is riveted or otherwise fastened to arm, with mica or other suitable insulation intervening. One end of wire 2 is flexibly connected to strip 9 and the other end leads to terminal post 3 suitably insulated from weight 3 by mica or otherwise. Electrical con tact 4, mounted on bracket f which is fastened to weight 3 by means of screw 6 or in any suit able manner, is insulated from the weight and is connected with insulated conductor 7 leading to insulated connection post 8 to which is con nected one end of heating wire or element 4 which also is insulated from the metal of the iron. Conductor or wire. 7 is shown as being placed in or beneath weight 3 but it may be fastened

4 above it. The other end of heating wire 4 is connected to insulated terminal post 9 Sup ported on weight 3. Current may be supplied to the heating element 4 by a connection plug having current connections making contact with elements f3 and 9. Recess or trough 20 is provided in weight 3 SO that ball 2, preferably rather heavy, can roll lengthwise therein. This ball is of Such size that it will strike arm 2 as it rolls in rearward direction. While recess 20 is shown it is obvious that it is not essential as ball 2 may be guided to roll on the surface of weight 3 by means of a raised U shaped or rectangular boundary strip fastened to the weight. Flexible spring strips 22 are fastened to the weight at either end of the trough 20 to act as flexible buffers for the ball, to reduce noise. Bimetal strip 23 is fastened at one end to block 24, integral with or fastened to weight 3, by means of screw 2. Cam 26, fastened to rod 27 having rotary bearing in a suitable bore or hole in weight 3, serves as a stop for bimetal strip 23 which is urged in rearward direction by its own resiliency. Rod 27 is extended vertically and passes through a hole in the cover, not shown, of the iron so that the cam may be rotated to place strip 23 nearer to or further from arm 2 as desired. A suitable indexed knob may be fas tened to the upper end of rod 27 and this knob may be rotated relative to a temperature or other scale placed on the outside of the cover. Friction means may be provided to hold rod 27 in any set position. The proximity of strip 23 to arm 2 for any given strip, determines the temperature at which the Switch will be opened. Threaded holes 28 may be provided in weight 2,470,82 3 so that the cover and handle may be attached by means of bolts or screws. Stop 29 against which switch arm is pulled by spring 6, when the switch is in open position, is fastened to weight 3 or is integral therewith. Fastening point 8 is so positioned that spring 6 will lie to one side of pivot when arm rests against stop 29 and lies on the other side of pivot when arm f is moved toward contact 4 sufficiently. When this happens contact G touches contact 4 so that current is supplied to heating element 4. In operation, if the switch is in open circuit po sition as shown and if the iron is cold so that bimetal strip 23 is in the position indicated the switch may be closed by standing the iron on its rear-end so that the weight of ball 2 will force arm 2 down to bring arm toward contact f. so that spring 6 will pass over pivot and contact 0 will be pressed against contact 4. Or, the iron may be moved forward and backward rapidly for a few strokes so that ball 2 will roll against arm 2 and will move it rearward to cause the snap action of the SWitch to close the circuit. When this happens arm 2 will be carried nearer to strip 23. When the iron reaches a predetermined tem perature, dependent upon the setting of cam 26, bimetal strip 23 will have bent to the left sufficiently to strike arm 2. When this happens the heating circuit will not be immediately broken, on account of the flexibility of strip 9, but cur rent will continue to energize heating element until arm has been moved toward stop 29 a. Sufficient distance for spring to cross over pivot and so to Snap arm against stop 29. Contact fo is then separated from contact 8 and the heating circuit is broken. This arrangement is 0 s provided so that the iron will not cool down sufficiently to withdraw the bimetal from arm 2 before the switch is snapped open. If thermo static element 23 is a snapping disc or similar type giving quick appreciable movement in one direction or the other, then flexible strip 9 would not be needed and contact can be fastened to an insulated support on arm 6. When the Switch is opened by the thermostat it will remain open as long as the iron remains stationary. The iron will then cool and strip 23 will return to the starting position shown. If, however, the iron is given normal movement of use, ball 2 will be caused to roll back and forth in trough 20 so that the ball will strike arm 2 and will knock it rearward, with the result that arm will be carried toward contact 6 and Spring will Snap over pivot to bring contact 0 against contact 4 to close the heating circuit. Bimetal strip 23 is preferably of such strength orrigidity that it will prevent closing of the switch, due to action of the ball, unless the tem perature of the iron is below the value as de termined by the position of cam 26. This can be true even if the iron is turned up on end. While tension spring 6 is shown, it is obvious that a form of compression spring or a flat spring pressing against plane surfaces on the junction of arms and 2, can be used. The cover or any other suitable guard can prevent ball 2 from falling Out of trough 20 if the iron is turned on end. 6 If the user leaves this iron in ironing position for a period longer than a safe interval, then the Switch will be automatically opened, to prevent 70 fires or burned boards or the like. If, however, the iron is kept in forward and backward move ment, as in normal use, then the action of ball 2 on arm 2 will keep the switch closed, as long as the temperature of the iron is below that set by the thermostat. In Figure 2, iron weight 30 contains heating element 3 one end of which is connected to insulated contact 32 and the other end of which is connected to insulated terminal 33. Wire 34 connects the other terminal 3 with metal arm 36 through a flexible connection. This arm car ries contact 37 and is pivoted to block 38 by pin 7 or screw 39. Block 33 and stop 4 are fastened to and are insulated from weight 30. Tension spring 4 is fastened to sector 42 at point 43 and the other end of the spring is fastened to Weight 30 at point 48. Spring 4 may be insulated from weight 30 or sector 42 may be of insulating material such as a heat resistant ceramic. Lugs and 46 depend from sector 42 and are adapted to strike arm 36 at the end of travel of sector G2 in either direction. Weight 47, which may be fixed to the end of arm 36 or pivoted to it with a lost motion connec tion as shown, serves to force arm 36 forward during use of the iron, due to momentum of the Weight, so that spring 4 will snap over to the left of pivot 39 and lug will press arm 36 to the left to force contact 3 against contact 32 to close the heating circuit. If the temperature be comes excessive, bimetal strip 48 fastened to support 49, will bend and will force sector 42 to the right until spring 4f passes to the right of pivot 39 so that sector 42 will be snapped to the right until lug 46 strikes arm 36 and forces it against stop 36 thereby breaking the heating circuit. The lost notion tonnection of sector 2 with arm 36 allows the heating circuit to remain closed

5 until the spring is moved over the pivot point of arm B and sector 42. Support 49 may be ro tatable so that position of strip 48 relative to sector 42 may be adjusted. The contact 32 may be placed at a greater arcuate distance from a perpendicular cross line through pivot 39 than stop, so that once the switch is closed, the momentum of weight 47 will not be sufficient to open it, although the momentum in the opposite direction will be enough to close it. Holes for attaching the cover and handle may be pro vided as in Figure 1. In Figure 3 the iron has handle attached to cover 2 which has slot 3 for lever arm 4 and slots S and 6 for legs 7 and 8 respectively. leg 7 is pivoted to the cover or to the sole plate 60 by pivot 9 and leg 8 is similarly pivoted by pivot 6. Link arm 62 is pivoted to a branch of leg T at 63 and to lever arm 4 by pivot 64. Arm 4 is pivoted to support 6 by pivot 66. Support 6 is fastened to plate 67 containing a suitable electrical heating element and has off set extension 68 to which catch 69 is pivoted at 70. Spring 7 normally urges catch 69 in down ward direction against a suitable stop. Bent arm 72 is integral with catch 69 and is positioned to be struck by weight 73 fastened to arm 74 which is attached to shaft 7 having bearing in escape ment controlled or other time switch 76 fastened to plate 67 or to any suitable part of the iron. This time switch may be similar to that shown and described in my above mentioned co-pending application. Spring 77, attached to support 68 and to arm 74 tends to pull this arm to the left, the rate of movement being controlled by an escapement or other delaying means. ink arm 78 is pivoted to arm 4 at 79 and to arm 80, integral with leg 8, at 8. Notched arm or hook 82 is integral with arm 4 and is normally held in the position shown by catch 69. Connection plug 83 is fastened to the iron, and wire 84, properly insulated, makes connection with a switch contact in switch 76, through thermostat 8. The other switch contact is connected to wire 86 leading to the heating ele ment. Likewise, wire 87 leads from plug 83 to the other terminal of the heating element. Ten sion spring 88 is connected between arm 4 and plate 67 or other part which may be of any de sired thickness or weight. This plate is screwed to or otherwise fastened to sole plate 60, or it can be held by pressure. Spring 88 could of course be attached to cover 2 or some other part. In operation, as long as the iron is used, the movement keeps weight 73 thrown back out of contact with arm 72, a ratchet being provided to allow free movement of weight 73 in the rear ward direction, against the tension of spring TT, but causing the Weight to be delayed in forward direction by means of an escapement or other time delay means. Therefore as long as the iron is used the legs 7 and 8 remain folded within the iron casing as shown. If, however, the iron is left stationary for a period longer than a predetermined interval, de termined by the tension of spring 77 and the escapement, weight 73 will be pulled forward in a circular path by spring TT and will strike arm 2 which lifts catch 69 and releases lever arm 4 which is quickly pulled to the left by spring 88. When this happens, legs 7 and 8, through link ages 62 and 78, are rotated outward about pivots 9 and 6 f and are brought down to positions be low sole plate 60. This immediately lifts sole plate 60 above the cloth or other supporting sur 2,470, face so that burning or scorching will be pre vented or reduced. Leg 8 can be wide or pivot can extend across to another similar leg so that there will be a three point support for the iron. The ends of the legs can be rounded so they will not damage the cloth. When it is desired to re-set the iron it is lifted and lever 4 is pulled back. When this happens arm 89, pivoted to lever 4 at 90, strikes weight 73 and throws it back to the rear. Then catch 69 will engage hook 82 and legs and 8 will have been pulled back into the iron, around pivots 9 and 6, by linkages 62 and 8. Legs and 8 may be of any desired shape and may be placed in any desired locations. They may be arranged to slide out of the iron along linear paths if desired. Thermostat 8 can be used to prevent the iron from overheating in use, This iron therefore both cuts of the current and lifts the hot sole plate above the supporting surface, if it is left stationary too long in ironing position. The time switch, however, keeps the heating circuit closed for brief periods of rest so that the contacts will not be constantly arcing. In Figure 4 handle 9 is attached to iron cover 92 to which are fastened bottom lugs or plates 93, by means of screws preferably. Relatively heavy metal plate 94, containing a suitable heat ing element which may be detachable, is provided with shoulders 9 which strike plates 93 when compression springs 96, fastened to or guided by cover 92 in any suitable Way, push against flanges 97 to lift cover 92 and plate 94. These flanges are integral with rods 98 which are slidable in guide openings in plate 94. Springs 96 surround the upper ends of rods 98 as shown. Sole plate 99 is fastened to the lower ends of rods 98. This plate is preferably made rather thin so that it will cool quickly when separated from plate 94. Plate 94 may be rather solid with an imbedded heating unit or it can be made of two or more plates bolted or screwed together, with a heating unit between. Likewise, the heating wires could be placed in grooves in the bottom of plate 94 which could be of fire resistant ceramic material. It would be preferable to have mica between the heating wire and the sole plate. Time delay switch foo, shown diagrammatically, may be of the Same general type as disclosed in my co-pending application, Serial No. 446,68, filed June 12, This switch has weight to fastened to the lower end of arm 02 which is fastened to shaft 03 having bearing in the switch or casing. As shown in the prior application, although in reverse direction, weight Of will be moved against the tension of spring 04 which is fastened to arm O2 and to the switch casing, when the iron is accelerated forward and when the iron is stationary or is accelerated in reverse direction weight O will act against a retarding escapement so that spring 04 will pull arm f O2 slowly in clockwise direction to close a pair of contacts to which wires O7 and G8 lead. Wire f08 leads also to a terminal of the heating ele ment in plate 94, through thermostat 09 and wire O is connected with terminal plug if G fastened to the iron. Wire it connects the other terminal of the heating element with the remain-- ing terminal of plug O. Latch 2, pivoted to the casing of switch foo at 3 is normally held down against stop 4 on the casing of the switch by means of com pression spring connected between lower arm

6 2,470, is of the latch and a support point on switch tact 27 when weight 9 is thrown to the left to carry spring 22 past piyot In the open circuit position shown, arm 20 The inset surfaces of the ends of plate 9 are rests against stop 29 projecting from the casing. vertically slidable relative to plates 93 so that when handle 9 is pressed down to compress This stop is preferably of such length that arm 20 is positioned just slightly past the vertical, springs 96 and to slide plate 94 downward rela so that excessive momentum will not be required tive to rods 98, a left flange 97 lifts latch 2 which to throw weight 9 forward to close the heating is then pressed up against the flange by Springs 96 circuit. Contact 27, however, is positioned so acting against cover 92. The sliding movement of plate 94 insures that sole plate 99 will be pulled 10 that spring 22 will be well to the left of pivot 2 so that the rearward movement and stopping up tightly against heating plate 94 since Springs of weight 9, during ironing, will not open the it press plate 94 downward but allow latch 2 switch. If, however, the iron overheats, beyond to pass under flange 97 and thus to hold Sole plate a predetermined temperature rise, the heat Will 99 yieldingly in contact with heating plate 94. When the handle is released the springs force be transmitted to thermostatic bimetal strip 30 fastened to casing A8 by a screw or otherwise, heating plate 94 tightly against Sole plate 99. so that it will bend to the right and will force The heat conduction will then be good and the arm 20 to the position shown, resting against iron can be used. stop 29, with the heating circuit open. The Latch 2 has an inclined surface so that it circuit will remain open unless the iron is given will be moved to the right when flange 97 strikes 20 normal movement as in use, in which case weight it from underneath. a 9 will be thrown to the left by the momenturn, In operation, if the iron gets too hot, thermo stat 09 will break the circuit and if the iron is left stationary and in ironing position longer than a certain time interval, weight O will be 2 pulled in clockwise direction, against the con trolling escapement or other device, and will strike arm 6. When this happens latch 2 is moved to the right, away. from flange 9, and springs 96 quickly lift cover 92, plate 94 and at 30 tached parts upward until the top surface of plate 94 strikes the under surfaces of flanges 9, as ill lustrated. In this position sole plate 99 is sepa rated from heating plate 94 and the thin Sole plate will quickly cool. Rods 98 can be of poor heat conductivity metal such as some grades of steel or they can be of nonmetallic material. Switch 00 cuts of the current in wires 0 and 08 when weight O strikes arm f6, in similar manner to that described in the above mentioned application. As long as the iron is kept in movement weight of is kept thrown away from arm f 6 so that sole plate 99 is held against heating plate 94 but if for any reason the iron is forgotten or neglected for a period longer than an interval which may be settable, the hot iron is lifted above the Sole plate to prevent burning and at the same time the heating circuit is opened. Latch ff2 or a similar latch can also be ar ranged to be pressed against flange 97 at the rear, to prevent binding. Sole plate 99 can be pivoted to linkages which may be pivoted to the sides or in grooves in plate 94 So that a swinging or rotary movement will lift the iron above the sole plate. Many other changes of detail can be readily made. In Figure the Casing 8 of the iron connec tion plug shown is preferably made of heat resist ant electrical insulating material. Weight 9 is fastened to arm 20 which is pivoted to the casing at 2. Tension spring 22 is fastened to arm 20 and to some part of the plug such as metallic connector 23 adapted to make electrical connection with a terminal of an electric iron. A similar connector is placed on the cut-away side of the plug for connection with the other heating unit terminal of the iron. Conductor 24 of the iron connection cord is brought into the plug through opening 2 and is electrically connected to the connector not shown. The other cord conductor 26, is connected to switch contact 27 fastened to the casing. Metal lic arm f2o is provided with switch contact 28 which closes the heating circuit by touching con 3 to close the heating circuit through contacts 2 and 28 and spring 22 if the iron has in the meantime cooled sufficiently to allow strip 20 to bend back to the left a sufficient distance. The section 3 of the casing may be made of metal and may be so designed that it will come into contact with a hot surface of the iron, to facilitate transfer of heat to the bimetal 36. This connection plug can be adapted for use with many different types of electric irons and will provide an automatic cut-off feature for the heating element, if the iron is not used. This ) device can be placed in the cord circuit at any position where it will be given movement but if separated from the iron a timing switch such as switch be of Figure 4 should be used since this switch is not dependent upon the temperature of the iron for operation. In Figure 6, roller 32 is a metal cylinder fas tened to the end of switch arm 33 by means of Screw 34 which passes through a central hole in the roller and is threaded into the end of arm 33. This roller is supported by track 3 which 60 6 may be any suitable surface of the iron. By this construction roller 32 may be quite heavy, in Order to furnish considerable momentum to close the Switch. When the iron is used, but its Weight will be supported and it will not tend to bend the Switch arm or produce excessive friction. In Figure switch casing 36 is preferably of 70 non-conducting plastic material or of porcelain or the like. It may be split and the parts joined by bolts. Switch arm 637 carrying ratchet pawl i38, is pivoted to the casing by pivot 39 and coiled spring, attached to arm 37 and to the casing, urges the artin in clockwise direction. Gear 4 having bearing on stubshaft 42 one end of which is screwed or otherwise fastened to casing 36, is placed adjacent a side wall of the Casing and is provided with suitable indentations 43 which may be engaged by ratchet 38 to rotate gear 6 in clockwise direction. Ratchet 38 allows free movement of arm f37 in COunter clockwise direction against the torsion of spring (. Gear 4 is meshed with pinion 44 rotata ble around a suitable stub shaft along with at tached star wheel 6 which engages pivoted escapement or verge 46 which limits the rate of movement of arm 3 in clockwise direction.. Flexible metal switch contact 4 is fastened to casing 36 and is connected to one of the con ductors in iron cord 48. The other conductor 7 is connected to conductor. 49 which is connected

7 to a conductor in iron cord SO at the opposite end of casing fit. The other conductor of cord is connected to metal arm 3 through con ductor. which may be suitably insulated if desired.. Metal ball 2 is adapted to roll on an inner surface of the switch and if the iron cord is given normal movement this ball will oscillate and will strike arm. 37 with the result that this arm will be pushed into contact with flexible strip 4 with a certain amount of Overlap. When this happens the circuit supplying energy to the heating ele ment of the iron will be closed through conduc tor, spring, arm 37 and strip 47. As long as the iron is kept in use the rolling action of ball 2 will keep arm 3 in contact with strip 4 but if the iron is left stationary for an interval, greater than a predetermined amount, depending upon the Overlap, the tension in spring, and the escapement, then arm 3 will be slowly rotated in clockwise direction until it is out of contact with strip 47 and the circuit will be broken. It is obvious that many detailed changes can be made. For instance, ball 2 could be at tached to arm f3. Or it could be designed to be effective when moved in any direction, by means of universal connections. What I claim is: 1. An electric iron comprising, an ironing ele switch for opening and closing a circuit includ ing said heating element, Snap-acting spring operated means for holding said switch closed or, Open, an iron-motion-responsive weight for now ing the Snap-acting means to close said switch, and time-delay means for moving the snap-acting means to open said Switch. 2. An electric iron comprising, an ironing ele switch for opening and closing a circuit includ ing said heating element, Snap-acting spring operated means for holding said switch closed or open, a rollable element responsive to movement of said iron for moving the Snap-acting means to close said switch, and time-delay means for moving the snap-acting means to open said switch. 3. An electric iron comprising, an ironing ele switch for Opening and closing a circuit includ operated means for holding said switch closed or open, a ball responsive to ironing movement of said iron for moving the snap-acting means to close said Switch, and time-delay means for mov ing the snap-acting means to open said switch. 4. An electric iron comprising, an ironing ele switch for Opening and closing a circuit includ Operated means for holding said switch closed or Open, a ball responsive to ironing movement of 2,470, said iron for moving the snap-acting means to close said switch, means for guiding movement of said ball, and time-delay means for moving the Snap-acting means to open said switch.. An electric iron comprising, an ironing ele Switch for opening and closing a circuit includ Operated means for holding said switch closed or Open, an iron-motion-responsive weight for mov ing the Snap-acting means to close said switch, time-delay means for moving the snap-acting means to Open said Switch, and means for ad justing said time delay means for various delay periods. 6. An electric iron comprising, an ironing ele, Switch including a resilient contact member for opening and closing a circuit including said heat ing element, Snap-acting spring-operated means for holding said switch closed or open, an iron motion-responsive weight for moving the snap acting means to close said switch, and time-delay means for moving the Snap-acting means to open Said Switch. 7. An electric iron comprising, an ironing ele Switch including a pivoted arm for opening and closing a circuit including said heating element, Snap-acting means including a pivoted member and a Spring for holding said arm in closed-switch or Open-switch position, said pivoted member in cluding a pair of separated elements for striking Said arm on Opposite sides thereof, an iron motion-responsive weight for moving said arm to close said Switch and to cause said pivoted mem ber to maintain said switch closed, and time delay means for moving said pivoted member to move said arm to open-switch position and to maintain said switch open. 8. In an electric iron, a heating element, a Switch for opening and closing a circuit includ Operated means for holding said switch closed or Open, an iron-motion-responsive weight for mov ing the Snap-acting means to close said switch, and time-delay means for moving the snap-act ing means to open said switch. ABER. C. TEOMAS, REFERENCES CTED The following references are of record in the fille of this patent: UNITED STATES PATENTs Number Nane Date. 1,366,480 Balda Jan. 2, ,224 Poole July 11, ,607,1 Malley Nov. 16, ,69,636 Null Feb. 21, ,143,701 Kelly Jan. 10, ,219,6 Steinel et al Oct. 29, 19 2,382,87 Thomas Aug. 14, 19

United States Patent 19 Kootte

United States Patent 19 Kootte 54 POWER CRIMPING TOOL HAVING IMPROVED CRIMPING MECHANISM FOR TAPE FEED PRODUCTS 75) Inventor: Eric Kootte, Harrisburg, Pa. 73) Assignee: The Whitaker Corporation, Wilmington,

United States Patent 19 Kootte 54 POWER CRIMPING TOOL HAVING IMPROVED CRIMPING MECHANISM FOR TAPE FEED PRODUCTS 75) Inventor: Eric Kootte, Harrisburg, Pa. 73) Assignee: The Whitaker Corporation, Wilmington,

(12) United States Patent

US007 145105B2 (12) United States Patent Gaullard (10) Patent No.: (45) Date of Patent: Dec. 5, 2006 (54) ELECTRIC KETTLE (75) Inventor: Hervé Gaullard, Courtefontaine (FR) (73) Assignee: SEB SA, Ecully

US007 145105B2 (12) United States Patent Gaullard (10) Patent No.: (45) Date of Patent: Dec. 5, 2006 (54) ELECTRIC KETTLE (75) Inventor: Hervé Gaullard, Courtefontaine (FR) (73) Assignee: SEB SA, Ecully

A-li. AzWZ/pZ.Azas. Patented Mar, 9, A. L., EWERS. SEAM SEALING DEWICE FOR, CIGARETTE MACHINES. APPLICATION FILED APR, 29, 1913.

A. L., EWERS. SEAM SEALING DEWICE FOR, CIGARETTE MACHINES. 1130,720. APPLICATION FILED APR, 29, 1913. Patented Mar, 9, 1915. 2 SHEETS-SHEET l. 3S A-li ITNESSES: Y 7h BY INVENTOR. AzWZ/pZ.Azas e - ATTORNEYS.

A. L., EWERS. SEAM SEALING DEWICE FOR, CIGARETTE MACHINES. 1130,720. APPLICATION FILED APR, 29, 1913. Patented Mar, 9, 1915. 2 SHEETS-SHEET l. 3S A-li ITNESSES: Y 7h BY INVENTOR. AzWZ/pZ.Azas e - ATTORNEYS.

WILLIAM. A. HoUSTON AND DILLMAN CHARLEs HOUSTON, or Los ANGELEs, CATTEOBNIA.???NTAIN PEN. Application filed November 29, Serial No

Patented Aug. 6, 19s. UNITED STATES PATENT OFFICE. WILLIAM. A. HoUSTON AND DILLMAN CHARLEs HOUSTON, or Los ANGELEs, CATTEOBNIA.???NTAIN PEN. Application filed November 29, 1928. Serial No. 151459. 1,123,171

Patented Aug. 6, 19s. UNITED STATES PATENT OFFICE. WILLIAM. A. HoUSTON AND DILLMAN CHARLEs HOUSTON, or Los ANGELEs, CATTEOBNIA.???NTAIN PEN. Application filed November 29, 1928. Serial No. 151459. 1,123,171

(12) Patent Application Publication (10) Pub. No.: US 2010/ A1

(19) United States US 2010O136392A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0136392 A1 PULLIAM et al. (43) Pub. Date: Jun. 3, 2010 (54) CELL TEMPERATURE SENSING (21) Appl. No.: 12/571,926

(19) United States US 2010O136392A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0136392 A1 PULLIAM et al. (43) Pub. Date: Jun. 3, 2010 (54) CELL TEMPERATURE SENSING (21) Appl. No.: 12/571,926

Oct. 29, 1957 R. W. BRACKETT 2,810,983 ANIMAL TRAP ATTACHMENT. 2. Sheets-Sheet l. Filed March 5, 1956 INVENTOR. . BY A:ORNEY

Oct. 29, 1957 R. W. BRACKETT ANIMAL TRAP ATTACHMENT Filed March 5, 1956 2. Sheets-Sheet l. BY INVENTOR. A:ORNEY Oct. 29, 1957 R. W. BRACKETT ANIMAL TRAP ATTACHMENT Filed March 5, 1956 2 Sheets-Sheet 2

Oct. 29, 1957 R. W. BRACKETT ANIMAL TRAP ATTACHMENT Filed March 5, 1956 2. Sheets-Sheet l. BY INVENTOR. A:ORNEY Oct. 29, 1957 R. W. BRACKETT ANIMAL TRAP ATTACHMENT Filed March 5, 1956 2 Sheets-Sheet 2

April 8, 1952 F. W. EDWARDs 2,592,400 HEATER. INVENTOR. Z2-a/aa227A 2.27te2/-23, leadopt ul. "feuwaa Stavvula. a?7215/yat-s.

April 8, 192 F. W. EDWARDs HEATER Filed June 10, 1946 3. Sheets-Sheet l leadopt ul INVENTOR. Z2-a/aa227A 2.27te2/-23, "feuwaa Stavvula a?721/yat-s. April 8, 192 April 8, 192 Filed June 10, 1946 F. W. EDWARDS

April 8, 192 F. W. EDWARDs HEATER Filed June 10, 1946 3. Sheets-Sheet l leadopt ul INVENTOR. Z2-a/aa227A 2.27te2/-23, "feuwaa Stavvula a?721/yat-s. April 8, 192 April 8, 192 Filed June 10, 1946 F. W. EDWARDS

Feb. 23, 1960 F. M., JONES 2,926,005 THERMOSTAT AND TEMPERATURE CONTROL SYSTEM. Filed Dec. 2, E I I\ 2O. C O O4.

Feb. 23, 19 F. M., JONES THERMOSTAT AND TEMPERATURE CONTROL SYSTEM Filed Dec. 2, 194 ; UNIT A UNT B HEAT REFRGERATION HEAT REFRGERATION 6O ) 66 ) 66 64 ) RRF 38 1341 E- - -- I 32 26 I\ 2O C O O4. 22 s

Feb. 23, 19 F. M., JONES THERMOSTAT AND TEMPERATURE CONTROL SYSTEM Filed Dec. 2, 194 ; UNIT A UNT B HEAT REFRGERATION HEAT REFRGERATION 6O ) 66 ) 66 64 ) RRF 38 1341 E- - -- I 32 26 I\ 2O C O O4. 22 s

July 10, 1962 E. C. ARMENTROUT 3,043,569 BUTTER STORAGE IN A REFRIGERATOR INVENTOR. Avereff C. Arnenfo/f BY A7/ 52% /9. 4. ey P

July 10, 1962 E. C. ARMENTROUT 3,043,69 BUTTER STORAGE IN A REFRIGERATOR Fied Feb. 24, 19 2 Sheets-Sheet INVENTOR. Avereff C. Arnenfo/f BY A7/ 2% /9. 4. ey P July 10, 1962 E. C. ARMENTROUT 3,043,69 BUTTER

July 10, 1962 E. C. ARMENTROUT 3,043,69 BUTTER STORAGE IN A REFRIGERATOR Fied Feb. 24, 19 2 Sheets-Sheet INVENTOR. Avereff C. Arnenfo/f BY A7/ 2% /9. 4. ey P July 10, 1962 E. C. ARMENTROUT 3,043,69 BUTTER

F. J. FISHER. AUTOMATIC SMUDGE POT, APPLICATION FILED JULY 15, 1913, 1,095, Patented May 5, ZzZy, Z. 2 Y A-Z2 NWENTOR

F. J. FISHER. AUTOMATIC SMUDGE POT, APPLICATION FILED JULY 15, 1913, 1,095,496. - Patented May 5, 1914. 3. SHEETS-SHEET ZzZy, Z. 2 Y A-Z2 ise-z2 6 9 f? y NWENTOR?/2.4% 7eezeya 4/72g/ept 67e/a44ez, n,74e/27,

F. J. FISHER. AUTOMATIC SMUDGE POT, APPLICATION FILED JULY 15, 1913, 1,095,496. - Patented May 5, 1914. 3. SHEETS-SHEET ZzZy, Z. 2 Y A-Z2 ise-z2 6 9 f? y NWENTOR?/2.4% 7eezeya 4/72g/ept 67e/a44ez, n,74e/27,

Nov. 10; 1970 w. E. WILSON ' 3,539,773 ELECTRICAL APPLIANCES FOR HEATING LIQUIDS. Filed Aug.'7, ,Sheets-Sheet 1. MW (0M1 MW: Q m.

' Nov. 10; 1970 w. E. WILSON ' 3,539,773 ELECTRICAL APPLIANCES FOR HEATING LIQUIDS Filed Aug.'7, 1967. 4,Sheets-Sheet 1 MW (0M1 MW: Q m AWL? %MJMM%/ /@y_ ' Nov. 10, 1970 w. E. WILSON 3,539,773 ELECTRICAL

' Nov. 10; 1970 w. E. WILSON ' 3,539,773 ELECTRICAL APPLIANCES FOR HEATING LIQUIDS Filed Aug.'7, 1967. 4,Sheets-Sheet 1 MW (0M1 MW: Q m AWL? %MJMM%/ /@y_ ' Nov. 10, 1970 w. E. WILSON 3,539,773 ELECTRICAL

May 19, ,513,290. Filed April 20, 1967 AUTOMATICALLY HEATED ICE-CREAM SCOOP WITH STAND. 2. Sheets-Sheet W. L. BURLEY ET AL

May 19, 1970 W. L. BURLEY ET AL AUTOMATICALLY HEATED ICE-CREAM SCOOP WITH STAND Filed April, 1967 2. Sheets-Sheet May 19, 1970 W. L. BURLEY ET AL AUTOMATICALLY HEATED ICE-CREAM SCOOP WITH STAND Filed April,

May 19, 1970 W. L. BURLEY ET AL AUTOMATICALLY HEATED ICE-CREAM SCOOP WITH STAND Filed April, 1967 2. Sheets-Sheet May 19, 1970 W. L. BURLEY ET AL AUTOMATICALLY HEATED ICE-CREAM SCOOP WITH STAND Filed April,

United States Patent (19) (11) Patent Number: 5,033,657

United States Patent (19) (11) Patent Number: 5,033,657 Whittington 45) Date of Patent: Jul. 23, 1991 54 ADJUSTABLESTROKE PUMP DISPENSER 4,978,036 12/1990 Burd... 222/2O7 75) Inventor: Jimmie L. Whittington,

United States Patent (19) (11) Patent Number: 5,033,657 Whittington 45) Date of Patent: Jul. 23, 1991 54 ADJUSTABLESTROKE PUMP DISPENSER 4,978,036 12/1990 Burd... 222/2O7 75) Inventor: Jimmie L. Whittington,

United States Patent 19)

United States Patent 19) Bernath [11] 3,804,129 (45) Apr. 16, 1974 54 FILLING THREAD STOP MOTION DEVICE FOR A SHUTTLELESS WEAVING MACHINE 75 inventor: Oskar Bernath, Umiken, Switzerland 73) Assignee: George

United States Patent 19) Bernath [11] 3,804,129 (45) Apr. 16, 1974 54 FILLING THREAD STOP MOTION DEVICE FOR A SHUTTLELESS WEAVING MACHINE 75 inventor: Oskar Bernath, Umiken, Switzerland 73) Assignee: George

United States Patent (19)

United States Patent (19) Vanags 54 BATHING DEVICE 75) Inventor: 73 Assignee: Paul Vanags, Swansea, Wales Portasauna Limited, Merthyr Tydfil, Wales 21 Appl. No.: 18,837 22 Filed: Aug. 27, 1980 (30) Foreign

United States Patent (19) Vanags 54 BATHING DEVICE 75) Inventor: 73 Assignee: Paul Vanags, Swansea, Wales Portasauna Limited, Merthyr Tydfil, Wales 21 Appl. No.: 18,837 22 Filed: Aug. 27, 1980 (30) Foreign

USOO A United States Patent (19) 11 Patent Number: 5,931,089 Viesselmann et al. (45) Date of Patent: *Aug. 3, 1999

USOO5931089A United States Patent (19) 11 Patent Number: Viesselmann et al. (45) Date of Patent: *Aug. 3, 1999 54) BALE STARTING CHAMBER WITH 4,870,812 10/1989 Jennings et al.... 100/88 TENSIONING DEVICE

USOO5931089A United States Patent (19) 11 Patent Number: Viesselmann et al. (45) Date of Patent: *Aug. 3, 1999 54) BALE STARTING CHAMBER WITH 4,870,812 10/1989 Jennings et al.... 100/88 TENSIONING DEVICE

2. f. Feb. 10, 1970 J. L. SLONNEGER 3,495,101 "6,442-. THERMAL MOTOR. Jeara Al,SAoranger. 1ezorezay. Filed Jan. 8, sheets-sheet 1 N.

Feb. 10, 1970 J. L. SLONNEGER THERMAL MOTOR Filed Jan. 8, 1969 4 sheets-sheet 1 2. f ife ill l N.VENOR, Jeara Al,SAoranger "6,442-. 1ezorezay. Feb. 10, 1970 J. L., SLONNEGER HERMA, MOTOR Filed Jan, 8,

Feb. 10, 1970 J. L. SLONNEGER THERMAL MOTOR Filed Jan. 8, 1969 4 sheets-sheet 1 2. f ife ill l N.VENOR, Jeara Al,SAoranger "6,442-. 1ezorezay. Feb. 10, 1970 J. L., SLONNEGER HERMA, MOTOR Filed Jan, 8,

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O184524A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0184524A1 Stravitz (43) Pub. Date: Aug. 25, 2005 (54) QUICK-CONNECT/QUICK-DISCONNECT Publication Classification

(19) United States US 2005O184524A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0184524A1 Stravitz (43) Pub. Date: Aug. 25, 2005 (54) QUICK-CONNECT/QUICK-DISCONNECT Publication Classification

United States Patent (19) Debs

United States Patent (19) Debs 54) VENETIAN BLIND 75 Inventor: Victor Debs, Staten Island, N.Y. 73 Assignee: Levolor Lorentzen, Inc., Lyndhurst, N.J. (21) Appl. No.: 380,947 22 Filed: May 21, 1982 51)

United States Patent (19) Debs 54) VENETIAN BLIND 75 Inventor: Victor Debs, Staten Island, N.Y. 73 Assignee: Levolor Lorentzen, Inc., Lyndhurst, N.J. (21) Appl. No.: 380,947 22 Filed: May 21, 1982 51)

"(.6% 6. rida. % s SA. Aa/7 (2442/7. Feb. 4, 1964 INVENTOR. W. G. LPPERT 3,120,168 CONTROL MECHANISM FOR POPCORN MACHINE. Filed July 30, 1958

Feb. 4, 1964. G. LPPERT 3,1,168 COTROL MECHAISM FOR POPCOR MACHIE Filed July, 198 2 Sheets-Sheet I S rida % s SA 4. B an Maaawaaaaaaaaaaa...a AAAAAA IVETOR. Aa/7 (2442/7 "(.6% 6. 47 72away2 Feb. 4, 1964.

Feb. 4, 1964. G. LPPERT 3,1,168 COTROL MECHAISM FOR POPCOR MACHIE Filed July, 198 2 Sheets-Sheet I S rida % s SA 4. B an Maaawaaaaaaaaaaa...a AAAAAA IVETOR. Aa/7 (2442/7 "(.6% 6. 47 72away2 Feb. 4, 1964.

Nov. 3, 1959 CLEANER INOPERATIVE IF NO BAG IS IN PLACE. JoAw 7 AFfeeA9EAS PNEUMATIC MECHANISM FOR RENDERIN. Filed Dec. 26, 1956 HIS ATTORNEY

Nov. 3, 1959 J. T. FERRARIS PNEUMATIC MECHANISM FOR RENDERIN CLEANER INOPERATIVE IF NO BAG IS IN PLACE Filed Dec. 26, 1956 N?Y? INVENTOR. JoAw 7 AFfeeA9EAS HIS ATTORNEY Nov. 3, 1959 J. T. FERRARIs PNEUMATIC

Nov. 3, 1959 J. T. FERRARIS PNEUMATIC MECHANISM FOR RENDERIN CLEANER INOPERATIVE IF NO BAG IS IN PLACE Filed Dec. 26, 1956 N?Y? INVENTOR. JoAw 7 AFfeeA9EAS HIS ATTORNEY Nov. 3, 1959 J. T. FERRARIs PNEUMATIC

Feb. 7, 1967 A. ZICHE 3,302,368 AUTOMATIC PACKING MACHINE WII A 2. INVENTOR. A Zulu. Glow's 3-(oat

Feb. 7, 1967 A. ZICHE Filed Dec. 31, 1963 6 Sheets-Sheet l WII T A 2 A Zulu Glow's 3-(oat - a Feb. 7, 1967 Filed Dec. 31, 1963 A. ZCHE 6. Sheets-Sheet 2 A. Zi ulu Feb. 7, 1967 A. ZICHE Filed Dec. 5, 1963

Feb. 7, 1967 A. ZICHE Filed Dec. 31, 1963 6 Sheets-Sheet l WII T A 2 A Zulu Glow's 3-(oat - a Feb. 7, 1967 Filed Dec. 31, 1963 A. ZCHE 6. Sheets-Sheet 2 A. Zi ulu Feb. 7, 1967 A. ZICHE Filed Dec. 5, 1963

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0307237 A1 CHEN US 2013 0307237A1 (43) Pub. Date: Nov. 21, 2013 (54) MEDICAL CART SYSTEM (75) Inventor: (73) Assignee: (21)

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0307237 A1 CHEN US 2013 0307237A1 (43) Pub. Date: Nov. 21, 2013 (54) MEDICAL CART SYSTEM (75) Inventor: (73) Assignee: (21)

Original Filed Dec, 26, 1956

June 13, 1961 PNEUMATIC MECHANISM FOR RENDERING A Original Filed Dec, 26, 196 2 Sheets-Sheet li INVENTOR. c/o//w 7/2feeee/ HIS ATTORNEY June 13, 1961 J. T. FERRARIS PNEUMATIC MECHANISM FOR RENDERING A

June 13, 1961 PNEUMATIC MECHANISM FOR RENDERING A Original Filed Dec, 26, 196 2 Sheets-Sheet li INVENTOR. c/o//w 7/2feeee/ HIS ATTORNEY June 13, 1961 J. T. FERRARIS PNEUMATIC MECHANISM FOR RENDERING A

BY Nov. 3, 1970 R. J. ALVAREZ 3,537,132. As Attornyev. Filed Sept. 3, Sheets-Sheet 1

Nov. 3, 1970 R. J. ALVAREZ HOUSEHOLD REFRIGERATOR WITH THROUGH-THE-DOOR ICE SERVICE Filed Sept. 3, 1968 2 Sheets-Sheet 1 INVENTOR. ROSER. J. AVAREZ. BY 2224 As Attornyev Nov. 3, 1970 R. J. ALWAREZ HOUSEHOLD

Nov. 3, 1970 R. J. ALVAREZ HOUSEHOLD REFRIGERATOR WITH THROUGH-THE-DOOR ICE SERVICE Filed Sept. 3, 1968 2 Sheets-Sheet 1 INVENTOR. ROSER. J. AVAREZ. BY 2224 As Attornyev Nov. 3, 1970 R. J. ALWAREZ HOUSEHOLD

USOO A United States Patent (19) 11 Patent Number: 6,073,624 Laurent (45) Date of Patent: Jun. 13, 2000

USOO6073624A United States Patent (19) 11 Patent Number: Laurent (45) Date of Patent: Jun. 13, 2000 54 SUPPORTING ARRANGEMENT, FOR OVENS OR THE LIKE, SUSPENDED ON PARALLEL 2,382,354 2.944,540 8/1945 Wales...

USOO6073624A United States Patent (19) 11 Patent Number: Laurent (45) Date of Patent: Jun. 13, 2000 54 SUPPORTING ARRANGEMENT, FOR OVENS OR THE LIKE, SUSPENDED ON PARALLEL 2,382,354 2.944,540 8/1945 Wales...

Feb. 16, ENVELOPE MACHINE Original Filed Dec. 5, 1936 G. W. ANDERSON 2,311, Sheets-Sheet lil

Feb. 16, 1943. G. W. ANDERSON 2,311,017 Original Filed Dec. 5, 1936 4 Sheets-Sheet lil Feb. 16, 1943. G, W. ANDERSON Original Filed Dec. 5, 1936 2,311.017 Feb. 16, 1943. G. W. ANDERSON Original Filed Dec.

Feb. 16, 1943. G. W. ANDERSON 2,311,017 Original Filed Dec. 5, 1936 4 Sheets-Sheet lil Feb. 16, 1943. G, W. ANDERSON Original Filed Dec. 5, 1936 2,311.017 Feb. 16, 1943. G. W. ANDERSON Original Filed Dec.

Nov. 1, J. R. ERC 2,134,682 POPCORN MACHINE Filed July 25, Sheets-Sheet.. Zw law 7 oa. Ju//a/. A vaca. (2777 oawa Y

Nov. 1, 1938. J. R. ERC POPCORN MACHINE Filed July, 1936 2. Sheets-Sheet.. s Zw law 7 oa Ju//a/. A vaca. (2777 oawa Y Nov. 1, 1938. J. R. Burch POPCORN MACHINE Filed July, 1936 2 Sheets-Sheet 2 27/ 2.2

Nov. 1, 1938. J. R. ERC POPCORN MACHINE Filed July, 1936 2. Sheets-Sheet.. s Zw law 7 oa Ju//a/. A vaca. (2777 oawa Y Nov. 1, 1938. J. R. Burch POPCORN MACHINE Filed July, 1936 2 Sheets-Sheet 2 27/ 2.2

(12) Patent Application Publication (10) Pub. No.: US 2010/ A1

(19) United States US 2010O288790A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0288790 A1 Keller (43) Pub. Date: Nov. 18, 2010 (54) DISPENSINGAPPLIANCE FOR AMULTIPLE Publication Classification

(19) United States US 2010O288790A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0288790 A1 Keller (43) Pub. Date: Nov. 18, 2010 (54) DISPENSINGAPPLIANCE FOR AMULTIPLE Publication Classification

JPMW 2276M. Hr» 1,084,593. an. Patented Jan. 13, SHEETS-SHEET 1.

1,084,593. \ H; DE ESIO'OBALES &'"P. P. AMPUDIA. WRAPPING. MACHINE. - APPLIOATION rum) FEB. 17, 1913. Patented Jan. 13, 1914. 4 SHEETS-SHEET 1. MN M» *N W Q.. MR w/mmsm: 2276M Hr» JPMW MA m/ m A HUM/EV

1,084,593. \ H; DE ESIO'OBALES &'"P. P. AMPUDIA. WRAPPING. MACHINE. - APPLIOATION rum) FEB. 17, 1913. Patented Jan. 13, 1914. 4 SHEETS-SHEET 1. MN M» *N W Q.. MR w/mmsm: 2276M Hr» JPMW MA m/ m A HUM/EV

III. United States Patent (19) Morad et al. 11 Patent Number: 5,274, Date of Patent: Jan. 4, 1994

United States Patent (19) Morad et al. 54 SEMI-AUTOMATIC MOP WRINGER 75) Inventors: Fred I. Morad, Toluca Lake; Armond Asadurian, Glendale, both of Calif. 73 Assignee: Worldwide Integrated Resources, Inc.,

United States Patent (19) Morad et al. 54 SEMI-AUTOMATIC MOP WRINGER 75) Inventors: Fred I. Morad, Toluca Lake; Armond Asadurian, Glendale, both of Calif. 73 Assignee: Worldwide Integrated Resources, Inc.,

April 14, 1970 H, KOCH ETAL 3,506,140 APPARATUS FOR HANDLING EGGS. 1uon-tota: Heinrich Koch. Kurt Hermsmever. * 76e 47%

April 14, 1970 H, KOCH ETAL APPARATUS FOR HANDLING EGGS Filed June 21, 1968 2 Sheets-Sheet l 1uon-tota: Heinrich Koch Kurt Hermsmever * 76e 47% April 14, 1970 Filed June 21, 1968 H. KOCH ET All APPARATUS

April 14, 1970 H, KOCH ETAL APPARATUS FOR HANDLING EGGS Filed June 21, 1968 2 Sheets-Sheet l 1uon-tota: Heinrich Koch Kurt Hermsmever * 76e 47% April 14, 1970 Filed June 21, 1968 H. KOCH ET All APPARATUS

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2015/0348392 A1 Burtner et al. US 20150348392A1 (43) Pub. Date: Dec. 3, 2015 (54) (71) (72) (73) (21) (22) WATER LEAK DETECTOR Applicant:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2015/0348392 A1 Burtner et al. US 20150348392A1 (43) Pub. Date: Dec. 3, 2015 (54) (71) (72) (73) (21) (22) WATER LEAK DETECTOR Applicant:

e 9 REm- / H2.11-2s el-61 United States Patent (19) Barnard et al. 4,822,175 Apr. 18, Patent Number: 45) Date of Patent:

United States Patent (19) Barnard et al. 11 Patent Number: 45) Date of Patent: 4,822,175 Apr. 18, 1989 (54) SPLASH GUARD FOR A FOOD MIXER 75 Inventors: John K. Barnard, Bay Village; Richard D. Boozer,

United States Patent (19) Barnard et al. 11 Patent Number: 45) Date of Patent: 4,822,175 Apr. 18, 1989 (54) SPLASH GUARD FOR A FOOD MIXER 75 Inventors: John K. Barnard, Bay Village; Richard D. Boozer,

March 31, ,503,138. %2A /6 a. Azese ACA. J&Aaro/ 6 2zzcás. Józze/2/ors, R. c. Fuchs ETAL. 3 Sheets-Sheet l HAIR DRYER.

March 31, 1970 R. c. Fuchs ETAL HAIR DRYER 3 Sheets-Sheet l Józze/2/ors, J&Aaro/ 6 2zzcás %2A /6 a. Azese ACA - arre J/4, March 31, 1970 R. c. Fuchs et Al HAIR DRYER 5 Sheets-Sheet 2 &zvez Áors, %zra 8,

March 31, 1970 R. c. Fuchs ETAL HAIR DRYER 3 Sheets-Sheet l Józze/2/ors, J&Aaro/ 6 2zzcás %2A /6 a. Azese ACA - arre J/4, March 31, 1970 R. c. Fuchs et Al HAIR DRYER 5 Sheets-Sheet 2 &zvez Áors, %zra 8,

Dec. 15, ,318. Filed July 26, Sheets-Sheet l REFRIGERATING SYSTEM N. H. GAY

Dec. 1, 1931. N. H. GAY 1836,318 REFRIGERATING SYSTEM Filed July 26, 1926 2 Sheets-Sheet l Dec. 1, 1931. N. H. GAY REFRIGERATING SYSTEM Filed July 26, l926 l,836,318 2 Sheets-Sheet 2 Patented Dec. 1, 1931

Dec. 1, 1931. N. H. GAY 1836,318 REFRIGERATING SYSTEM Filed July 26, 1926 2 Sheets-Sheet l Dec. 1, 1931. N. H. GAY REFRIGERATING SYSTEM Filed July 26, l926 l,836,318 2 Sheets-Sheet 2 Patented Dec. 1, 1931

Altra Series Dampener

Crestline TM Altra Series Dampener Installation Instructions Heidelberg MO X88-66 10/97 Rev-A GENERAL INFORMATION ATTENTION CRESTLINE ALTRA SERIES TM DAMPENER OWNER! Accel Graphic Systems provides parts

Crestline TM Altra Series Dampener Installation Instructions Heidelberg MO X88-66 10/97 Rev-A GENERAL INFORMATION ATTENTION CRESTLINE ALTRA SERIES TM DAMPENER OWNER! Accel Graphic Systems provides parts

978,739. Patented Dec. 18, 1910.

M, 0, GRISWOLD & T, BRIEGEL, DUST COLLECTOR, APPLIO ATION FILED FEB. 5, 1910, 978,739. Patented Dec. 18, 1910. 2. SHEETS-SHEET 1. 9 s as s -- 928) itv.coco A7 O. Gasnoa,. v?2% Theodore Ariege, UNITED

M, 0, GRISWOLD & T, BRIEGEL, DUST COLLECTOR, APPLIO ATION FILED FEB. 5, 1910, 978,739. Patented Dec. 18, 1910. 2. SHEETS-SHEET 1. 9 s as s -- 928) itv.coco A7 O. Gasnoa,. v?2% Theodore Ariege, UNITED

United States Patent (19) Anwunah et al.

United States Patent (19) Anwunah et al. (54) BATH ROOM SOAP RECYCLING DEVICE 76 Inventors: Vincent Anwunah, John Anwunah, both of 12015 Prest, Detroit, Mich. 48227 (21) Appl. No.: 398,357 (22 Filed: Mar.

United States Patent (19) Anwunah et al. (54) BATH ROOM SOAP RECYCLING DEVICE 76 Inventors: Vincent Anwunah, John Anwunah, both of 12015 Prest, Detroit, Mich. 48227 (21) Appl. No.: 398,357 (22 Filed: Mar.

May 30, ,322,144 H. O. DE BOER, JR., E A HAIR DRYER CURLING ATTACHMENT. Filed June 30, Sheets-Sheet

May 30, 1967 Filed June 30, 1965 H. O. DE BOER, JR., E A HAIR DRYER CURLING ATTACHMENT 3. Sheets-Sheet / May 30, 1967 Filed June 30, 1965 H. O. DE BOER, JR., ETAL HAIR DRYER CURLING ATTACHMENT Sheets-Sheet

May 30, 1967 Filed June 30, 1965 H. O. DE BOER, JR., E A HAIR DRYER CURLING ATTACHMENT 3. Sheets-Sheet / May 30, 1967 Filed June 30, 1965 H. O. DE BOER, JR., ETAL HAIR DRYER CURLING ATTACHMENT Sheets-Sheet

Technical Data. Name: ERIKA Automat fully automatic machine to divide and to round dough pieces of the same size

AUTOMAT MANUAL 1 Technical Data Name: ERIKA Automat fully automatic machine to divide and to round dough pieces of the same size Type Divisions Dough Portions (in ounces) Plate Nos. 3 30 1.0 3.5 #35 4/40A

AUTOMAT MANUAL 1 Technical Data Name: ERIKA Automat fully automatic machine to divide and to round dough pieces of the same size Type Divisions Dough Portions (in ounces) Plate Nos. 3 30 1.0 3.5 #35 4/40A

United States Patent (19) Smith et al.

United States Patent (19) Smith et al. 54 AUTOMATIC CLOTHES WASHING MACHINES 75 Inventors: Dennis E. Smith; Graeme D. Thomas; Keith D. Ferguson, all of Auckland, New Zealand 73) Assignee: Fisher & Paykel

United States Patent (19) Smith et al. 54 AUTOMATIC CLOTHES WASHING MACHINES 75 Inventors: Dennis E. Smith; Graeme D. Thomas; Keith D. Ferguson, all of Auckland, New Zealand 73) Assignee: Fisher & Paykel

Kaminski (45) Date of Patent: Dec. 1, ) Assignee: Owens-Illinois Plastic Products, Inc., 57) ABSTRACT

United States Patent (19) (11 USOO567316A Patent Number: Kaminski (45) Date of Patent: Dec. 1, 1992 (54) POSITIONING AND INDEXING MOLDED HOLLOW PASTIC ARTICLES 75 Inventor: Ronald S. Kaminski, Bowling

United States Patent (19) (11 USOO567316A Patent Number: Kaminski (45) Date of Patent: Dec. 1, 1992 (54) POSITIONING AND INDEXING MOLDED HOLLOW PASTIC ARTICLES 75 Inventor: Ronald S. Kaminski, Bowling

Oct. 11, M. E. PENNINGTON 1,882,030 CONDITIONING SYSTEM FOR COLD STORAGE ROOMS

Oct. 11, 1932. M. E. PENNINGTON 1,882,030 CONDITIONING SYSTEM FOR COLD STORAGE ROOMS 24%23. Filed Oct. 18, 1929 a 2. s 2 % 2 2 s2 2 % 2 as sease teams ass=sessessessessessesserences 2 2 272,222 % % 2.

Oct. 11, 1932. M. E. PENNINGTON 1,882,030 CONDITIONING SYSTEM FOR COLD STORAGE ROOMS 24%23. Filed Oct. 18, 1929 a 2. s 2 % 2 2 s2 2 % 2 as sease teams ass=sessessessessessesserences 2 2 272,222 % % 2.

United States Patent (19)

United States Patent (19) Rutledge, Jr. et al. 54 METHODS FOR PULLING SUCKERROD STRINGS 75) Inventors: Woodrow T. Rutledge, Jr.; Russel P. Rutledge; John E. Freeman, Jr., all of Big Spring, Tex. 73) Assignee:

United States Patent (19) Rutledge, Jr. et al. 54 METHODS FOR PULLING SUCKERROD STRINGS 75) Inventors: Woodrow T. Rutledge, Jr.; Russel P. Rutledge; John E. Freeman, Jr., all of Big Spring, Tex. 73) Assignee:

2,751,086. June 9, 1956 APPARATUS FOR THE SEPARATION OF FARTICLES, PARTICULARLY FIBRES, THAT ARE SUSPENDED IN A LIQUID. Filed July 6, 1952

June 9, 1956 O. B. RdSRJESON APPARATUS FOR THE SEPARATION OF FARTICLES, PARTICULARLY FIBRES, THAT ARE SUSPENDED IN A LIQUID Filed July 6, 1952 4. Sheets-Sheet l 2y June 19, 1956 Filed July 16, 1952 APPARATUS

June 9, 1956 O. B. RdSRJESON APPARATUS FOR THE SEPARATION OF FARTICLES, PARTICULARLY FIBRES, THAT ARE SUSPENDED IN A LIQUID Filed July 6, 1952 4. Sheets-Sheet l 2y June 19, 1956 Filed July 16, 1952 APPARATUS

Oct. 6, 1953 A. D. ALTEMLLER 2,654,823 POPCORN MACHINE --- II a T71 a. Refee. 78/ a7. Aaza/l/a A. AA7 AA7/Zlata %

Oct. 6, 1953 A. D. ALTEMLLER 2,654,823 POPCORN MACHINE Filed Sept. 15, 1948 2. Sheets-Sheet l II a T71 a IA Refee Illé 2. Silic if --- rea fa Acts: 78/ a7 Aaza/l/a A. AA7 AA7/Zlata 273.32% a 77 oa Waf-2.

Oct. 6, 1953 A. D. ALTEMLLER 2,654,823 POPCORN MACHINE Filed Sept. 15, 1948 2. Sheets-Sheet l II a T71 a IA Refee Illé 2. Silic if --- rea fa Acts: 78/ a7 Aaza/l/a A. AA7 AA7/Zlata 273.32% a 77 oa Waf-2.

St. Hists. Fig.1. 9)Nim. N s SHRM. Charles N.F lagg 2-4 FOR 3. Jan. 12, C. N. FLAGG 2,067,629 AUTOMATIC VALWE FOR HEATING SYSTEMS.

Jan. 12, 1937. C. N. FLAGG AUTOMATIC VALWE FOR HEATING SYSTEMS Filed July 28, 1932 2 Sheets-Sheet l Fig.1. Return pipe (2 Rs.2 N s SR2 AA SHRM N Hists St. 9)Nim f an NWeNTOR Charles N.F lagg 2-4 FOR 3.

Jan. 12, 1937. C. N. FLAGG AUTOMATIC VALWE FOR HEATING SYSTEMS Filed July 28, 1932 2 Sheets-Sheet l Fig.1. Return pipe (2 Rs.2 N s SR2 AA SHRM N Hists St. 9)Nim f an NWeNTOR Charles N.F lagg 2-4 FOR 3.

United States Patent (19) Cook

United States Patent (19) Cook (54) SOLAR WATER HEATING SYSTEM (75) Inventor: Robert E. Cook, Kankakee, Ill. 73 Assignee: A. O. Smith Corporation, Milwaukee, Wis. 21 Appl. No.: 708,876 (22 Filed: Jul.

United States Patent (19) Cook (54) SOLAR WATER HEATING SYSTEM (75) Inventor: Robert E. Cook, Kankakee, Ill. 73 Assignee: A. O. Smith Corporation, Milwaukee, Wis. 21 Appl. No.: 708,876 (22 Filed: Jul.

R. A. BUSH ET AL DRINK MIXER. Filed May 4, Sheets-Sheet. l. \ lll . a. ßasá

R. A. BUSH ET AL Filed May 4, 1929 2 Sheets-Sheet. l \ lll. 16 J5 @well a. ßasá YM @S1 Jan, 14, 1930. R. A. BLISH ET AL Y Filed May 4, 1929 2 Sheets-Sheet 2 f 1.11% 2k Mv Y y p Patented Jan. 14, 1930 10

R. A. BUSH ET AL Filed May 4, 1929 2 Sheets-Sheet. l \ lll. 16 J5 @well a. ßasá YM @S1 Jan, 14, 1930. R. A. BLISH ET AL Y Filed May 4, 1929 2 Sheets-Sheet 2 f 1.11% 2k Mv Y y p Patented Jan. 14, 1930 10

No. 731,341, PATENTED JUNE 16, 1903.

No. 731,341, PATENTED JUNE 16, 1903. J. G., COCHRANE, DISH WASHING MACHINE, APPLICATION FILED SEPT, 28, 1899, NO MODE, 2. SHEETS-SHEET 1. Z-2 474-Z- visa tjes ess The NORR35 Peres co, photo-i.tho...washi

No. 731,341, PATENTED JUNE 16, 1903. J. G., COCHRANE, DISH WASHING MACHINE, APPLICATION FILED SEPT, 28, 1899, NO MODE, 2. SHEETS-SHEET 1. Z-2 474-Z- visa tjes ess The NORR35 Peres co, photo-i.tho...washi

May 23, c. H. Hapgood 1,910,830

May 23, 1933. c. H. Hapgood 1,9,8 Filed July 15, 1929 2 Sheets-Sheet l 7&az, Af/6. M M/p/a/V72A Grzs /wa//7%zzeea/ /3eled ase-1 %a--4-4 1777aarava (s. May 23, 1933. C. H. HAPGOOD 19,8 Filed July 15, 1929

May 23, 1933. c. H. Hapgood 1,9,8 Filed July 15, 1929 2 Sheets-Sheet l 7&az, Af/6. M M/p/a/V72A Grzs /wa//7%zzeea/ /3eled ase-1 %a--4-4 1777aarava (s. May 23, 1933. C. H. HAPGOOD 19,8 Filed July 15, 1929

4-26. United States Patent (19) Woollenweber et al. R XI N Patent Number: 6,102,672 (45) Date of Patent: Aug. 15, (75)

United States Patent (19) Woollenweber et al. 54 (75) MOTOR-DRIVEN CENTRIFUGAL AIR COMPRESSOR WITH INTERNAL COOLING ARFLOW Inventors: William E. Woollenweber, Carlsbad; Edward M. Halimi, Montecito, both

United States Patent (19) Woollenweber et al. 54 (75) MOTOR-DRIVEN CENTRIFUGAL AIR COMPRESSOR WITH INTERNAL COOLING ARFLOW Inventors: William E. Woollenweber, Carlsbad; Edward M. Halimi, Montecito, both

into "ill (12) Patent Application Publication (10) Pub. No.: US 2008/ A1 (19) United States 12d Roberts (43) Pub. Date: Feb.

(19) United States US 2008.0034781A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0034781 A1 Roberts (43) Pub. Date: Feb. 14, 2008 (54) BEVERAGE PITCHER COLD PLATE STATION (76) Inventor:

(19) United States US 2008.0034781A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0034781 A1 Roberts (43) Pub. Date: Feb. 14, 2008 (54) BEVERAGE PITCHER COLD PLATE STATION (76) Inventor:

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 2004.0099384A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0099384 A1 W (43) Pub. Date: May 27, 2004 (54) ART WALL PAINTING CURTAIN STRUCTURE (76) Inventor: Chieh-Yuan

(19) United States US 2004.0099384A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0099384 A1 W (43) Pub. Date: May 27, 2004 (54) ART WALL PAINTING CURTAIN STRUCTURE (76) Inventor: Chieh-Yuan

United States Patent Modine et al.

United States Patent Modine et al. 54 MODULAR AR COOLED CONDENSER 72) Inventors: Arthur B. Modine; Homer D. Hug gins; Neal A. Cook, all of Racine, Wis. 73) Assignee: Modine Manufacturing Company 22 Filed:

United States Patent Modine et al. 54 MODULAR AR COOLED CONDENSER 72) Inventors: Arthur B. Modine; Homer D. Hug gins; Neal A. Cook, all of Racine, Wis. 73) Assignee: Modine Manufacturing Company 22 Filed:

219,432,433,436,528,529, 99,483 is ABSTRACT 56) References Cited

USOO6075229A United States Patent (19) 11 Patent Number: 6,075,229 Vanselow (45) Date of Patent: Jun. 13, 2000 54). CUP WARMER HOLDER 4,442,343 4/1984 Genuit et al.... 219/433 4,463,664 8/1984 Peace......

USOO6075229A United States Patent (19) 11 Patent Number: 6,075,229 Vanselow (45) Date of Patent: Jun. 13, 2000 54). CUP WARMER HOLDER 4,442,343 4/1984 Genuit et al.... 219/433 4,463,664 8/1984 Peace......

Hakki Pilke Raven spare parts manual

1 ENGLISH Hakki Pilke Raven spare parts manual Valimotie 1, FI-85800 Haapajärvi, FINLAND Tel. +358 8 772 7300, Fax +358 8 772 732 info@maaselankone.fi, www.maaselankone.fi 2 Table of contents 1 Upper section

1 ENGLISH Hakki Pilke Raven spare parts manual Valimotie 1, FI-85800 Haapajärvi, FINLAND Tel. +358 8 772 7300, Fax +358 8 772 732 info@maaselankone.fi, www.maaselankone.fi 2 Table of contents 1 Upper section

United States Patent (19) Owens

United States Patent (19) Owens (54 ICE CREAM DISPENSER 76 Inventor: James D. Owens, P.O. Box 14943, Orlando, Fla. 32857 21 Appl. No.: 925,236 22 Filed: Jul. 17, 1978 51 Int, C.... B26D 4/42 52 U.S. C....

United States Patent (19) Owens (54 ICE CREAM DISPENSER 76 Inventor: James D. Owens, P.O. Box 14943, Orlando, Fla. 32857 21 Appl. No.: 925,236 22 Filed: Jul. 17, 1978 51 Int, C.... B26D 4/42 52 U.S. C....

HHHHHHHH. United States Patent (19) 11 Patent Number: 5,078, Date of Patent: Jan. 7, Shotey SLIDING COVER AND SHROUD FOR

United States Patent (19) Shotey 54 76 21 22 51 52 58 56 SLIDIG COVER AD SHROUD FOR ELECTRICAL OUTLETS Inventor: Michael J. Shotey, 7733 E. Cypress, Scottsdale, Ariz. 852.57 Appl. o.: 596,777 Filed: Oct.

United States Patent (19) Shotey 54 76 21 22 51 52 58 56 SLIDIG COVER AD SHROUD FOR ELECTRICAL OUTLETS Inventor: Michael J. Shotey, 7733 E. Cypress, Scottsdale, Ariz. 852.57 Appl. o.: 596,777 Filed: Oct.

(12) United States Patent (10) Patent No.: US 6,517,499 B1

US006517499B1 (12) United States Patent (10) Patent No.: Pereira (45) Date of Patent: Feb. 11, 2003 (54) MASSAGE DEVICE WITH ROTATING 6,090,055 A * 7/2000 Frajdenrajch... 601/7 ELEMENTS FOREIGN PATENT

US006517499B1 (12) United States Patent (10) Patent No.: Pereira (45) Date of Patent: Feb. 11, 2003 (54) MASSAGE DEVICE WITH ROTATING 6,090,055 A * 7/2000 Frajdenrajch... 601/7 ELEMENTS FOREIGN PATENT

TECHNICAL INFORMATION B 890 and B 990 Rotary Irons (US Models)

TECHNICAL INFORMATION B 890 and B 990 Rotary Irons (US Models) 2011 Miele USA Table of Contents A B C D 010 Warning and Safety Instructions... 5 1 General... 5 2 Touch Current Measurement... 6 3 Risk of

TECHNICAL INFORMATION B 890 and B 990 Rotary Irons (US Models) 2011 Miele USA Table of Contents A B C D 010 Warning and Safety Instructions... 5 1 General... 5 2 Touch Current Measurement... 6 3 Risk of

A, F, MEYER, FEED GRNDER AND FEEDING MACHENE 2 SHEETS-SHEE 1. APPCA as s ,171,742. Patented Feb, 15, 1916,

A, F, MEYER, FEED GRNDER AND FEEDING MACHENE APPCA as s 1915.. Patented Feb, 15, 1916, 2 SHEETS-SHEE 1. A, F, MEYER FEED GRNDER AND FEED ING MACH NE, APPECATION FED MAR 2, 1924. RENEWED JUNE 23, 1915,,

A, F, MEYER, FEED GRNDER AND FEEDING MACHENE APPCA as s 1915.. Patented Feb, 15, 1916, 2 SHEETS-SHEE 1. A, F, MEYER FEED GRNDER AND FEED ING MACH NE, APPECATION FED MAR 2, 1924. RENEWED JUNE 23, 1915,,

Tikhonov et al. (45) Date of Patent: Mar. 13, (54) REFRIGERATOR WITH SELECTIVE (56) References Cited ARFLOWPASSAGES BETWEEN THE

(12) United States Patent USOO8132423B2 () Patent No.: US 8,132,423 B2 Tikhonov et al. (45) Date of Patent: Mar. 13, 2012 (54) REFRIGERATOR WITH SELECTIVE (56) References Cited ARFLOWPASSAGES BETWEEN THE

(12) United States Patent USOO8132423B2 () Patent No.: US 8,132,423 B2 Tikhonov et al. (45) Date of Patent: Mar. 13, 2012 (54) REFRIGERATOR WITH SELECTIVE (56) References Cited ARFLOWPASSAGES BETWEEN THE

A1(t1) (12) Patent Application Publication (10) Pub. No.: US 2011/ A1. (19) United States. Jiang et al. (43) Pub. Date: Sep.

(19) United States US 2011 O232884A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0232884 A1 Jiang et al. (43) Pub. Date: Sep. 29, 2011 (54) HEAT EXCHANGER (75) Inventors: Jianlong Jiang,

(19) United States US 2011 O232884A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0232884 A1 Jiang et al. (43) Pub. Date: Sep. 29, 2011 (54) HEAT EXCHANGER (75) Inventors: Jianlong Jiang,

(12) Patent Application Publication (10) Pub. No.: US 2017/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0210517 A1 Mackenzie et al. US 20170210517A1 (43) Pub. Date: Jul. 27, 2017 (54) (71) (72) (21) (22) (63) (60) PORTABLE BEVERAGE

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0210517 A1 Mackenzie et al. US 20170210517A1 (43) Pub. Date: Jul. 27, 2017 (54) (71) (72) (21) (22) (63) (60) PORTABLE BEVERAGE

(12) United States Patent (10) Patent No.: US 6,718,974 B1

USOO6718974B1 (12) United States Patent (10) Patent No.: Moberg (45) Date of Patent: Apr. 13, 2004 (54) CPAP HUMIDIFIER HAVING SLIDING 5,231.979 A 8/1993 Rose et al. ACCESS DRAWER 5,343,551 A 8/1994 Glucksman...

USOO6718974B1 (12) United States Patent (10) Patent No.: Moberg (45) Date of Patent: Apr. 13, 2004 (54) CPAP HUMIDIFIER HAVING SLIDING 5,231.979 A 8/1993 Rose et al. ACCESS DRAWER 5,343,551 A 8/1994 Glucksman...

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120217851A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0217851 A1 BAE et al. (43) Pub. Date: Aug. 30, 2012 (54) LAUNDRY TREATMENT APPARATUS Jan. 6, 2012 (KR)...

(19) United States US 20120217851A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0217851 A1 BAE et al. (43) Pub. Date: Aug. 30, 2012 (54) LAUNDRY TREATMENT APPARATUS Jan. 6, 2012 (KR)...

June 21, F. J. HANSON 1863,691 COMBINE HARWESTER. Filed April 19, l930 5 Sheets-Sheet l INVENRR. Ae/ye7A/72/75o/7 " 46%2'- ATTORNEY.

June 21, 1932. F. J. HANSON 1863,691 R COMBINE HARWESTER Filed April 19, l930 5 Sheets-Sheet l r S. N 7 INVENRR. Ae/ye7A/72/75o/7 " 46%2'- ATTORNEY. E s June 21, 1932. FP. J. HANSON COMBINE HARWESTER Filed

June 21, 1932. F. J. HANSON 1863,691 R COMBINE HARWESTER Filed April 19, l930 5 Sheets-Sheet l r S. N 7 INVENRR. Ae/ye7A/72/75o/7 " 46%2'- ATTORNEY. E s June 21, 1932. FP. J. HANSON COMBINE HARWESTER Filed

United States Patent (19) Fischereder

United States Patent (19) Fischereder 54 76 22 21 ) 30 52 51 58 56 ADJUSTABLE PUPPET SHOWSTAGE Inventor: Franz Fischereder, Mainaustrabe 67, Munich, Germany Filed: Jan. 29, 1973 Appl. No.: 327,315 Foreign

United States Patent (19) Fischereder 54 76 22 21 ) 30 52 51 58 56 ADJUSTABLE PUPPET SHOWSTAGE Inventor: Franz Fischereder, Mainaustrabe 67, Munich, Germany Filed: Jan. 29, 1973 Appl. No.: 327,315 Foreign

(12) United States Patent

USOO823 O714B2 (12) United States Patent Intagliata et al. (10) Patent No.: US 8,230,714 B2 (45) Date of Patent: Jul. 31, 2012 (54) (75) (73) (*) (21) (22) (65) (60) (51) (52) (58) DE CARRIER ASSEMBLY

USOO823 O714B2 (12) United States Patent Intagliata et al. (10) Patent No.: US 8,230,714 B2 (45) Date of Patent: Jul. 31, 2012 (54) (75) (73) (*) (21) (22) (65) (60) (51) (52) (58) DE CARRIER ASSEMBLY

Sept. 17, 1963 W. C. MARKLEY, JR 3,104,306 INSTANT HOT WATER DISPENSER. Filed Aug. 12, ZWil/7/AN' Afg. 3

Sept. 17, 1963 W. C. MARKLEY, JR 3,104,306 INSTANT HOT WATER DISPENSER Filed Aug. 12, 199 3. 38 34-3-36 U. 3. 44 8 s N 4 3 ZWil/7/AN' Z Afg. 3 INVENTOR Vern C. Mark/ey Jr. Aig. 4 BY 2ice Z /&/ ATTORNEYS

Sept. 17, 1963 W. C. MARKLEY, JR 3,104,306 INSTANT HOT WATER DISPENSER Filed Aug. 12, 199 3. 38 34-3-36 U. 3. 44 8 s N 4 3 ZWil/7/AN' Z Afg. 3 INVENTOR Vern C. Mark/ey Jr. Aig. 4 BY 2ice Z /&/ ATTORNEYS

United States Patent Brooks

United States Patent Brooks 54 FISHATTRACTING DEVICE 72 Inventor: Ray G. Brooks, Irving, Tex. 73) Assignee: Product Promotions, Inc., Dallas, Tex. 22 Filed: Oct. 1, 1970 (21) Appl. No.: 77,209 (52) U.S.

United States Patent Brooks 54 FISHATTRACTING DEVICE 72 Inventor: Ray G. Brooks, Irving, Tex. 73) Assignee: Product Promotions, Inc., Dallas, Tex. 22 Filed: Oct. 1, 1970 (21) Appl. No.: 77,209 (52) U.S.

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/01851 11 A1 Zagone US 2008O1851 11A1 (43) Pub. Date: Aug. 7, 2008 (54) (75) (73) (21) (22) (60) PARTITION APPARATUS AND SYSTEM

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/01851 11 A1 Zagone US 2008O1851 11A1 (43) Pub. Date: Aug. 7, 2008 (54) (75) (73) (21) (22) (60) PARTITION APPARATUS AND SYSTEM

(12) United States Patent (10) Patent No.: US B2

USOO8432266B2 (12) United States Patent (10) Patent No.: US 8.432.266 B2 Varieur (45) Date of Patent: Apr. 30, 2013 (54) PULL STATION D428,351 S 7, 2000 Hohlfelder 6,380,846 B1 4/2002 Hohlfelder (75) Inventor:

USOO8432266B2 (12) United States Patent (10) Patent No.: US 8.432.266 B2 Varieur (45) Date of Patent: Apr. 30, 2013 (54) PULL STATION D428,351 S 7, 2000 Hohlfelder 6,380,846 B1 4/2002 Hohlfelder (75) Inventor:

Aug. 13, 1974 J. SPIEGEL ET AL 3,829,348

Aug. 13, 1974 J. SPIEGEL ET AL 3,829,348 DECORATIVE THREE-DIMENSIONAL OBJECTS Filed April 7, 1972 2 Sheets-Sheest l O O O CO O O O O?O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O

Aug. 13, 1974 J. SPIEGEL ET AL 3,829,348 DECORATIVE THREE-DIMENSIONAL OBJECTS Filed April 7, 1972 2 Sheets-Sheest l O O O CO O O O O?O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O

(12) United States Patent (10) Patent No.: US 7.437,888 B2. Son et al. (45) Date of Patent: Oct. 21, 2008

US007437888B2 (12) United States Patent (10) Patent No.: US 7.437,888 B2 Son et al. (45) Date of Patent: Oct. 21, 2008 (54) REFRGERATOR 6,352,105 B1* 3/2002 Serratto... 165,221 6,488,009 B2 * 12/2002 Sakurai

US007437888B2 (12) United States Patent (10) Patent No.: US 7.437,888 B2 Son et al. (45) Date of Patent: Oct. 21, 2008 (54) REFRGERATOR 6,352,105 B1* 3/2002 Serratto... 165,221 6,488,009 B2 * 12/2002 Sakurai

Crestline Dampening System

Crestline Dampening System Installation Instructions Hamada 500, 600, 700, E-47, SU47 Series Parent Press X88-25 01/2001 Rev-C 2593 GENERAL INFORMATION ATTENTION CRESTLINE DAMPENER OWNER! Accel Graphic

Crestline Dampening System Installation Instructions Hamada 500, 600, 700, E-47, SU47 Series Parent Press X88-25 01/2001 Rev-C 2593 GENERAL INFORMATION ATTENTION CRESTLINE DAMPENER OWNER! Accel Graphic

United States Patent (19)

United States Patent (19) Montalto 54 ELECTRICALLY HEATED BEVERAGE CONTANER 76) Inventor: Bartolino P. Montalto, Burns St., New Bedford, Mass. O2740 21 Appl. No.: 660,690 (22 Filed: May 6, 1991 51 Int.

United States Patent (19) Montalto 54 ELECTRICALLY HEATED BEVERAGE CONTANER 76) Inventor: Bartolino P. Montalto, Burns St., New Bedford, Mass. O2740 21 Appl. No.: 660,690 (22 Filed: May 6, 1991 51 Int.

(12) Patent Application Publication (10) Pub. No.: US 2009/ A1

(19) United States US 200901586.16A1 (12) Patent Application Publication (10) Pub. No.: US 2009/0158616 A1 Ricklefs et al. (43) Pub. Date: Jun. 25, 2009 (54) LAUNDRY DRYER HAVING THREE ROLLER DRUMSUPPORT

(19) United States US 200901586.16A1 (12) Patent Application Publication (10) Pub. No.: US 2009/0158616 A1 Ricklefs et al. (43) Pub. Date: Jun. 25, 2009 (54) LAUNDRY DRYER HAVING THREE ROLLER DRUMSUPPORT

. E. N. United States Patent (19) Pullen, deceased et al. Stitt N. 5,129,576 Jul. 14, El 2. Patent Number: 54) 75 (58) Date of Patent:

United States Patent (19) Pullen, deceased et al. 54) 75 73 21) 22 62) 51 52) (58) (56) THERMOSTATIC PRESSURE BALANCED VALVE ASSEMBLY Inventors: Assignee: Appl. No.: Fied: Eric V. Pullen, deceased, late

United States Patent (19) Pullen, deceased et al. 54) 75 73 21) 22 62) 51 52) (58) (56) THERMOSTATIC PRESSURE BALANCED VALVE ASSEMBLY Inventors: Assignee: Appl. No.: Fied: Eric V. Pullen, deceased, late

United States Patent (19)

United States Patent (19) Walter et al. 54) SWIVELLING ELECTRICAL CONNECTION 75 Inventors: Henry J. Walter, Wilton; William E. Springer, Shelton, both of Conn. 73 Assignee: Clairol Incorporated, New York,

United States Patent (19) Walter et al. 54) SWIVELLING ELECTRICAL CONNECTION 75 Inventors: Henry J. Walter, Wilton; William E. Springer, Shelton, both of Conn. 73 Assignee: Clairol Incorporated, New York,

United States Patent (19)

United States Patent (19) Studinger (54) MOBILE SELF CONTAINED PRESSURE SPRAYER 76 Inventor: John H. Studinger, 5700 Montview Blvd., Denver, Colo. 80207 (22 Filed: June 26, 1972 21 Appl. No. 266,415 52

United States Patent (19) Studinger (54) MOBILE SELF CONTAINED PRESSURE SPRAYER 76 Inventor: John H. Studinger, 5700 Montview Blvd., Denver, Colo. 80207 (22 Filed: June 26, 1972 21 Appl. No. 266,415 52

Dec. 23, ,520,092. S. SHALER COMBINATION PADLOCK Filed Jan. 20, 1922 III. A.A.A./f A/Z. A. Az-z-'ez-Zor. Cz-za-A-2A-a-Aer; SE, 77* 744.

Dec. 23, 1924. 1,,092 S. SHALER COMBINATION PADLOCK Filed Jan., 1922 III 4724. A/Z. A 7 A.A.A./f. 2.É: Az-z-'ez-Zor. Cz-za-A-2A-a-Aer; SE, 77* 744. 0. 40 4 0 Patenied Dec. 23, 1924. UNETED STATES 1,,092

Dec. 23, 1924. 1,,092 S. SHALER COMBINATION PADLOCK Filed Jan., 1922 III 4724. A/Z. A 7 A.A.A./f. 2.É: Az-z-'ez-Zor. Cz-za-A-2A-a-Aer; SE, 77* 744. 0. 40 4 0 Patenied Dec. 23, 1924. UNETED STATES 1,,092

2.2. Kós S&NNN. 24a 1N. No. 646,944. Patented Apr. 10, u era (?ors. 4-d G. W. BAKER. SEWING MACHINE. (Application filed Mar. 14, 1896.

No. 646,944. Patented Apr. 10, 1900. G. W. BAKER. SEWING MACHINE. (Application filed Mar. 14, 1896.) (No Rode.) 3 Sheets-Sheet. 4-d if AIAW N&z, a -A 3 Kós SNNNSSS SZZ S&NNN St. A E. 24a 1N 2.2 % zz %2

No. 646,944. Patented Apr. 10, 1900. G. W. BAKER. SEWING MACHINE. (Application filed Mar. 14, 1896.) (No Rode.) 3 Sheets-Sheet. 4-d if AIAW N&z, a -A 3 Kós SNNNSSS SZZ S&NNN St. A E. 24a 1N 2.2 % zz %2

United States Patent (19) Olin et al.

United States Patent (19) Olin et al. 54) VACUUM TOILET UNIT 75 Inventors: Henry Olin, Espoo; Gunner Lindroos, Helsinki; Roland Mattsson, Espoo, all of Finland 73 Assignee: Evac International Oy, Helsinki,

United States Patent (19) Olin et al. 54) VACUUM TOILET UNIT 75 Inventors: Henry Olin, Espoo; Gunner Lindroos, Helsinki; Roland Mattsson, Espoo, all of Finland 73 Assignee: Evac International Oy, Helsinki,

United States Patent (19.

United States Patent (19. avarro 54 AUTOMATIC DOG OR CAT FEEDER 76 Inventor: Jesus avarro, 911 E. 39th Pl., Hialeah, Fla. 33013 21 Appl. o.: 94,219 22 Filed: ov. 14, 1979 51) Int. CI.3.... A01K 5/02 52

United States Patent (19. avarro 54 AUTOMATIC DOG OR CAT FEEDER 76 Inventor: Jesus avarro, 911 E. 39th Pl., Hialeah, Fla. 33013 21 Appl. o.: 94,219 22 Filed: ov. 14, 1979 51) Int. CI.3.... A01K 5/02 52

EP A1 (19) (11) EP A1 (12) EUROPEAN PATENT APPLICATION. (43) Date of publication: Bulletin 2010/17

(19) (12) EUROPEAN PATENT APPLICATION (11) EP 2 179 656 A1 (43) Date of publication: 28.04.2010 Bulletin 2010/17 (51) Int Cl.: A22C 7/00 (2006.01) (21) Application number: 09013444.6 (22) Date of filing:

(19) (12) EUROPEAN PATENT APPLICATION (11) EP 2 179 656 A1 (43) Date of publication: 28.04.2010 Bulletin 2010/17 (51) Int Cl.: A22C 7/00 (2006.01) (21) Application number: 09013444.6 (22) Date of filing:

(12) United States Patent

USOO8546,731B2 (12) United States Patent Pellerin et al. (10) Patent No.: (45) Date of Patent: Oct. 1, 2013 (54) ELECTRICAL APPLIANCE FOR COOKING FOOD (75) Inventors: Olivier Pellerin, Caluire et Cuire

USOO8546,731B2 (12) United States Patent Pellerin et al. (10) Patent No.: (45) Date of Patent: Oct. 1, 2013 (54) ELECTRICAL APPLIANCE FOR COOKING FOOD (75) Inventors: Olivier Pellerin, Caluire et Cuire

United States Patent 19) Carnahan

United States Patent 19) Carnahan 54 (76. (21) (22) (51) (52) (58) (56) REMOUNTABLE WALL/CELNG MOLDING Inventor: V. B. Carnahan, 522 Devils Hole Rd., R.D. #1, Cresco, Pa. 18326 Appl. No.: 932,623 Filed:

United States Patent 19) Carnahan 54 (76. (21) (22) (51) (52) (58) (56) REMOUNTABLE WALL/CELNG MOLDING Inventor: V. B. Carnahan, 522 Devils Hole Rd., R.D. #1, Cresco, Pa. 18326 Appl. No.: 932,623 Filed:

(12) United States Patent

(12) United States Patent US006 173454B1 (10) Patent No.: US 6,173,454 B1 Alvarez (45) Date of Patent: Jan. 16, 2001 (54) JONNISAFE 5,191,991 3/1993 Jackson... 220/207 5,347,663 9/1994 Yost... 4/253 (76)

(12) United States Patent US006 173454B1 (10) Patent No.: US 6,173,454 B1 Alvarez (45) Date of Patent: Jan. 16, 2001 (54) JONNISAFE 5,191,991 3/1993 Jackson... 220/207 5,347,663 9/1994 Yost... 4/253 (76)

16.22%- June 25, 1968 s. WILBURN 3,389,716 SAMPSON WILBURN BY. Filed July 19, Sheets-Sheet l ATTORNEYS INVENTOR.

June 5, 1968 s. WILBURN DRAFT BEER CLEANING AND FLUSHING APPARATUS Filed July 19, 1965. Sheets-Sheet l GN N INVENTOR. SAMPSON WILBURN BY 16.%- ATTORNEYS June 5, 1968 S. WBURN DRAFT BEER CLEANING AND FLUSHING

June 5, 1968 s. WILBURN DRAFT BEER CLEANING AND FLUSHING APPARATUS Filed July 19, 1965. Sheets-Sheet l GN N INVENTOR. SAMPSON WILBURN BY 16.%- ATTORNEYS June 5, 1968 S. WBURN DRAFT BEER CLEANING AND FLUSHING

May 13, 1958 G. J. FEDERIGH ETAL 2,834,364 AUTOMATIC LIQUID SOAP OR DETERGENT DISPENSER

May 13, 1958 G. J. FEDERIGH ETAL 2,834,364 Filed Oct. 3, 1955 3. Sheets-Sheet 1 to-n-- INVENTORS G. Ed Rose J. FedER get To Re H. No R. En a T To an e Ys May 13, 1958 Filed Oct. 13. 1955 2,834,364 G. J.

May 13, 1958 G. J. FEDERIGH ETAL 2,834,364 Filed Oct. 3, 1955 3. Sheets-Sheet 1 to-n-- INVENTORS G. Ed Rose J. FedER get To Re H. No R. En a T To an e Ys May 13, 1958 Filed Oct. 13. 1955 2,834,364 G. J.

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0089676 A1 Klemm US 2007.0089676A1 (43) Pub. Date: Apr. 26, 2007 (54) ARRANGEMENT FOR THE VAPOR DEPOSITION ON SUBSTRATES (76)

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0089676 A1 Klemm US 2007.0089676A1 (43) Pub. Date: Apr. 26, 2007 (54) ARRANGEMENT FOR THE VAPOR DEPOSITION ON SUBSTRATES (76)

USOO A United States Patent (19) 11 Patent Number: 5,875,645 Dunnigan (45) Date of Patent: Mar. 2, 1999

USOO5875645A United States Patent (19) 11 Patent Number: Dunnigan (45) Date of Patent: Mar. 2, 1999 54). SELF-SEALING VENDING MACHINE 5,678,421 10/1997 Maynard et al.... 62/407 REFRIGERATION APPARATUS

USOO5875645A United States Patent (19) 11 Patent Number: Dunnigan (45) Date of Patent: Mar. 2, 1999 54). SELF-SEALING VENDING MACHINE 5,678,421 10/1997 Maynard et al.... 62/407 REFRIGERATION APPARATUS

Bliss Box Former Troubleshooting. 6.1 Troubleshooting Chart. Troubleshooting INTRODUCTION SAFETY PROCEDURES

6.0 Bliss Box Former 1.0 INTRODUCTION Table 6-1 provides a logical sequence of tests that are designed to isolate problems with the Bliss Box Former machines. This table includes a list of probable causes

6.0 Bliss Box Former 1.0 INTRODUCTION Table 6-1 provides a logical sequence of tests that are designed to isolate problems with the Bliss Box Former machines. This table includes a list of probable causes

BY : 79 NY2KS. Nov. 29, 1960 R. HORLAND 2,962,190 RCHARD HORLAND. Filed April 2, Sheets-Sheet 1 PILL DISPENSING UNIT 12 4.

Nov. 29, 19 R. HRLAND Filed April 2, 198 2 Sheets-Sheet 1 12 4. 214777, E. 2 6 N NY2KS RS 2.893: 79 2s N RCHARD HRLAND BY 64-624 A722eway Nov. 29, 19 R. HRLAND Filed April 21, 198 2 Sheets-Sheet 2 % s

Nov. 29, 19 R. HRLAND Filed April 2, 198 2 Sheets-Sheet 1 12 4. 214777, E. 2 6 N NY2KS RS 2.893: 79 2s N RCHARD HRLAND BY 64-624 A722eway Nov. 29, 19 R. HRLAND Filed April 21, 198 2 Sheets-Sheet 2 % s

Part 2: Installation Instructions cl

Contents Page: Part 2: Installation Instructions cl. 381-382 1. Delivery scope............................... 3 2. General and Transportation safety precautions........... 3 3. Stand installation 3.1 Installing