IMER USA (301) Koine 35 Quick User Guide IMER USA

|

|

|

- Joshua Miller

- 5 years ago

- Views:

Transcription

1 IMER USA (301) Koine 35 Quick User Guide IMER USA 1

2 Koine 35 Quick User Guide Thank you for choosing IMER USA for your mixing and pumping needs. This is a quick user guide intended to be used as a reference and not intended to replace the operating manual. A full understanding of the systems and operation is required for anyone using this pump. The following pages will list the basic steps assuming that the power requirements and water connections are satisfactory for the performance of the pump. Bagged materials present many different characteristics when mixing, spraying or pumping. Please consult with the material producers or IMER to learn if the Koine 35 is the right pumping system for the material to be used. The Koine 35 is a continuous pump / mixer that can only be used with pre-blended materials. It is not suitable for use with bulk sand and cement. It should not be used after the product has been mixed with an external mixer. The product to be used should be preblended with sand and cement which is uniform in consistency and quality. Materials that require longer mixing times are not suitable for the Koine 35. Mortars with more than 2.5 parts sand to 1 part cement / lime should not be used unless additives are mixed into the dry powder at the time of blending. Grouts less than 3500 PSI are not recommended. Aggregate sizes and concentrations should be minimal. Concrete sand is about as course of an aggregate to use. Content Setup 3 Priming and Calibrating 5 Pumping and Spraying 9 Momentary Stoppage 9 Clean-Up 9 Error Codes 12 2

3 Setup IMER USA (301) Step 1: Plug the 220V, single phase connection into the plug and switch ON the main on/off switch (3) as shown on the control panel (Fig. 1). A blue light (2) indicates that the power is on. Note: A flashing blue light indicates that the power exceeds 240V and the panel is shutting down as power is outside of the normal operating range. Fig. 1 Control panel 1 Smart display panel 3 2 Current indicator light 3 ON/OFF switch Emergency stop button 5 5 Manual water control Water booster pump switch 6 7 Water pressure indicator 2 8 Mixing chamber safety sensor 7 9 Forward / Reverse Rotor / stator speed control Step 2: Attach the water supply line to the bottom port of the booster pump (Fig. 2). Water can be supplied by either a water supply source or from a water tank with clean water. Water booster pump switch must be turned on (Fig. 3) Pull out the switch to enable. To use without the air compressor, remove compressor plug (Fig. 3). The air compressor is used for spraying applications only. Note: To use water from a water tank, the hose must be primed first by filling the hose completely with water. Fig. 2 Fig. 3 Water booster and air compressor switch. Water inlet 3 Air compressor plug.

4 Koine 35 Quick User Guide Setup (Continued) Step 4 (For Spraying): Attach the air hose to the air port (Fig. 4) and to the spray wand. Open the air valve on the spray wand. (Fig. 5) There are different spray nozzle tips, the sizes depend upon the application, spray pattern and volume desired. Try the different nozzles and pick the one that is best for your application Note: Air compressor and spray wand are used only for spraying applications such as fireproofing, plastering or stucco.the air compressor (if supplied) can be removed from it s cradle simply by pulling out the unit. You should use only IMER supplied air hose and couplers. Using smaller diameter hose or couplers will affect the operation of the compressor or pump. Fig. 4 Air hose connection Fig. 5 Air valve on the spray wand 4

5 Priming and Calibrating IMER USA (301) Step 5: Fill the mixing chamber with water (Fig. 6) by removing the water feed hose and directing water into the port allowing the mixing chamber to overflow. Press the manual water control switch (5) shown in (Fig. 7) to allow water to flow. If the green light (7) is not lit then then you do not have enough water pressure. If that is the case you must switch on the booster pump (6) shown in (Fig 7). Note: Water pressure must be more than 40 PSI for the green light (7) to be on. Using the water booster is recommended to keep the pressure at the correct level. Fig. 6 Fig. 7 Control panel Smart display panel 2 Current indicator light 3 ON/OFF switch 4 Emergency stop button 5 Manual water control 6 Water booster pump switch 7 Water pressure indicator 8 Mixing chamber safety sensor 9 Forward / Reverse 10 Rotor / stator speed control 5

6 Koine 35 Quick User Guide Priming and Calibrating (Continued) Step 6: Load the feeding hopper (Fig. 8) with the bags of material to be pumped or sprayed and switch on the hopper feeding wheel (Fig. 9). The feeding wheel will not start spinning until (9) forward (Fig. 7) is turned on. Note: Water pressure must be more than 40 PSI for the green light (7) to be on. Switching on the water booster (6) in (Fig. 7) is recommended to keep the pressure elevated. Fig. 8 Fig. 9 Hopper feeding wheel switch. 6

7 IMER USA (301) Step 7: Once the switch (9) in (Fig. 7) is engaged to forward, the system will start to feed material into the mixing chamber and material will start to flow from the material hose outlet (Fig. 10). While the material is flowing out, use the valve on the water column to fine tune the water ratio (Fig. 11). Make small adjustments. When the material coming out is the consistency that you like, that is your water setting. Note: A good starting point for the water column is at 600 LPH (159 gallons per hour) for most materials such as fireproofing and grout. Better to start too wet than too dry. Pumping speed and rotor/stator type will also affect the ratio. Make incremental adjustments until you have the appropriate material consistency. Fig. 10 Priming and Calibrating (Continued) 35 to 25mm adapter Fig. 11 Waste material bag Water column / volume adjustment valve 7 Top of float indicates water volume

8 Koine 35 Quick User Guide Priming and Calibrating (Continued) Step 8: Prime the material hose with portland cement slurry by mixing a small bucket of straight portland cement and water, mixing to a flowable pancake batter consistency free of lumps. A good rule of thumb is about 1 gallon per every 100 of hose. Pour the slurry into the hose to prime it (Fig. 12). If this step is skipped there is a high probability that the material will not make it through the hose as the hose will absorb the cement from the material and leave behind sand which plug up the hose. The longer the hose, the more cement that will be needed to prime the hose. The cement slurry coats the inside of the hose to fill in the pores and slick the line. This priming method is used for every type of cement pump. Note: This process can be skipped if using a product with high cement content such as a grout with 28 day break strength of 6500 PSI or more, self-leveling underlayments and also fireproofing. If unsure if the process is needed then better to err on the side of caution and prime the hose. After priming the hose, allow the slurry to run out into a bucket. You should visibly be able to see when the slurry runs out and the good material begins. This priming step must be performed each time the hose is flushed out, before commencement of pumping or spraying. Fig. 12 Pour the portland cement slurry into the hose Cam lock fitting female side of material hose 8

9 Pumping and Spraying IMER USA (301) Step 9: Once the material hose is connected after you have calibrated and primed the pump you may commence operation of the pump. Ensure that the feeding wheel is set to on, the water booster switch is on. Engage the forward / reverse switch to forward. If the word STOP flashes then open the air valve at the end of the spray wand. The pump should be feeding material from the hopper to the mixing chamber and material will begin to flow from the end of the hose or spray wand. Note: If you encounter any error codes displayed on the display panel, consult the troubleshooting guide in the manual. Momentary Stoppage Step 10: If you need to stop for a short period of time then close the air valve on spray wand if spraying or switch off the forward / reverse switch (9) in (Fig. 7) if you are just pumping. You can resume again by opening air valve in spray wand or switching the switch (9) in (Fig. 7) back to forward. Note: If you are going to stop for more than a couple of minutes then you should consider cleaning out the pump and hose, depending on the material used, temperatures and fast setting characteristics of the bagged material being used. Clean-Up Step 11: Material can be left in the hopper as you can switch off the feeding wheel as this material is dry and can be used later. When you switch off the feeding wheel (Fig. 9), material will stop being fed into the mixing chamber. The pump will still pump out what is left in the hose and mixing chamber. Note: You can continue to use that material till you notice that the material becomes wetter. This is because no more dry mateiral is being directed into the mixing chamber. 9

10 Koine 35 Quick User Guide Clean-Up (Continued) Step 12: Now you need to run water through the material hose to clear it out. Place a sponge ball into the material hose from the cam lock end and attach it to the supplied 25mm to geka coupler adapter. Then connect this hose onto the the water supply geka fitting (Fig 13). Collect the sponge ball from the other end (Fig. 14). Note: You only need to run the ball through the hose one time, it cleans the hose real well. Fig. 13 Material hose connected to water supply geka Fig. 14 Clean-out sponge ball 10

11 Clean-Up (Continued) IMER USA (301) Step 13: Open the main motor hatch and remove the mixing paddle and insert the clean-out tool (Fig. 15). Insert the tool into the stator end making sure that it is seated properly. Close the motor hatch gently and make sure to align the motor coupler with the shaft. Switch on the pump in which the clean-out tool will scrape the sides as it lowers down the mixing chamber. You should notice the water coming out clear after a few moments (Fig. 16). Note: Completely disassemble the spray wand making sure to clean out the cap and air stem. Fig. 15 Scraper cleaning tool Scraper cleaning shaft Fig. 16 Clean water after scraper tool 11

12 Koine 35 Quick User Guide Koine 35 Error Code Table These error messages are shown on the inverter display panel when specific situations arise: - ERR 00: The drive motor is open or the mixing chamber is not 90º The main power cord from the motor to the feeding wheel switch disconnected. The emergency stop button is in. The control panel has a malfunction. - ERR 01: The electronic control system (inverter) has over heated, wait for it to cool down and try again. - ERR 02: The mixing paddle and stator/rotor drive motor has over heated, it is running too hard. Wait for it to cool down and try again. - ERR 03: The drive motor is jamming up, it cannot turn the stator/rotor. Check that the material you are pumping is not too stiff a mix. If using a long length of hose, shorten it. Finally, make sure that the mixing chamber does not have dry material built up inside it, the mixing paddle could be binding up - ERR 04: The drive motor is being overloaded. Make sure your material is not too stiff, make sure you have 220 volts of current and 30 amps, slow down your pumping speed. - ERR 05: The water pump and the compressor have been turned on for more than 15 minutes and during this period they have not been used. Or the compressor air hose system is leaking somewhere. - ERR 06: The compressor is seized up or the switch on the compressor has not been turned on. - ERR 07: The unit is shorting out, this is a very dangerous situation. Check for water in the control panel or loose wires. Contact IMER , or to: mace@imerusa.com. - ERR 08: Voltage is too low. Inverter is not receiving enough single phase current to power on. - ERR 09: The loading hopper feeding blade is blocked or turning too slowly. Clean out any obstructions. It could also be that water has backed up into the feeding hopper. Clean it and dry it out thoroughly. - BLOC : The stator/rotor is jammed up, or the material hose is jammed up, material cannot move through either one. - H2O : The volume of water being supplied to the pump is too low to operate the pump correctly. Get a better water supply. - VOLT : Blue light switches off rapidly. Voltage too high and the inverter is shutting down to avoid damage. 12

Setup. Important. Texture Spraying (material supplied from unit)

Setup Setup Important If you are going to stop spraying for more than 5 minutes, turn sprayer off to prevent shortened pump hose life. Do not allow material to dry inside pump, hoses, gun or spray system.

Setup Setup Important If you are going to stop spraying for more than 5 minutes, turn sprayer off to prevent shortened pump hose life. Do not allow material to dry inside pump, hoses, gun or spray system.

DEHUMIDIFIER INSTRUCTION MANUAL

MODEL: OBZ-50DHPN CONTENTS SAFETY PRECAUTIONS Warning...2 Caution...2 Electrical information...3 DEHUMIDIFIER CONTROLS Control panel...4 Other features......5 DESCRIPTION OF PARTS Identifying the parts.......6

MODEL: OBZ-50DHPN CONTENTS SAFETY PRECAUTIONS Warning...2 Caution...2 Electrical information...3 DEHUMIDIFIER CONTROLS Control panel...4 Other features......5 DESCRIPTION OF PARTS Identifying the parts.......6

A Steam-e product All Rights Reserved. STEAM CLEANER Operating Instructions - June 2018

A Steam-e product. 2018 All Rights Reserved. STEAM CLEANER Register your machine online Model: Speed-e Date of purchase: Serial Number: ST.. Purchased From: Address: Phone Number: Company name of owner:

A Steam-e product. 2018 All Rights Reserved. STEAM CLEANER Register your machine online Model: Speed-e Date of purchase: Serial Number: ST.. Purchased From: Address: Phone Number: Company name of owner:

Wheelbarrow Mixer Operations Manual

Wheelbarrow Mixer Operations Manual Part# MIX3, MIX3-UK EDI# 27275, 27276 104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 Fax 800-477-6341 / 641-753-6341 www.marshalltown.com 1 of 20

Wheelbarrow Mixer Operations Manual Part# MIX3, MIX3-UK EDI# 27275, 27276 104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 Fax 800-477-6341 / 641-753-6341 www.marshalltown.com 1 of 20

COOLING SYSTEM 1. Section V CONTENTS DATA AND SPECIFICATIONS. Page. Fluid Fan Drive (Silent Flite) 3. Water Pump 4. Radiator 5

Section V COOLING SYSTEM CONTENTS Fluid Fan Drive (Silent Flite) 3 Water Pump 4 Radiator 5 Water Temperature Gauge 6 Thermostat 7 Radiator Pressure Cap 7 Service Diagnosis 7 DATA AND SPECIFICATIONS COOLING

Section V COOLING SYSTEM CONTENTS Fluid Fan Drive (Silent Flite) 3 Water Pump 4 Radiator 5 Water Temperature Gauge 6 Thermostat 7 Radiator Pressure Cap 7 Service Diagnosis 7 DATA AND SPECIFICATIONS COOLING

Encyclon Inc. Cyclonic Filtration Systems

Encyclon Inc. Cyclonic Filtration Systems INSTALLATION OPERATION AND MAINTENANCE INSTRUCTIONS FOR ENCYCLON FILTRATION SYSTEMS MODEL NO. 651SP-MWTT SERIAL NO. 20347 6705 14th Avenue PO Box 1258 Kenosha,

Encyclon Inc. Cyclonic Filtration Systems INSTALLATION OPERATION AND MAINTENANCE INSTRUCTIONS FOR ENCYCLON FILTRATION SYSTEMS MODEL NO. 651SP-MWTT SERIAL NO. 20347 6705 14th Avenue PO Box 1258 Kenosha,

General Characteristics.3. S.M.A.R.T System Set-up...5. Start-up Procedures.6. Shut-down Procedures 8. General Maintenance..8

1-800-661-3842 1 TABLE OF CONTENTS General Characteristics.3 How the S.M.A.R.T System Works..3 S.M.A.R.T Technical Specifications..3 Erecting the S.M.A.R.T System..4 S.M.A.R.T System Set-up...5 Start-up

1-800-661-3842 1 TABLE OF CONTENTS General Characteristics.3 How the S.M.A.R.T System Works..3 S.M.A.R.T Technical Specifications..3 Erecting the S.M.A.R.T System..4 S.M.A.R.T System Set-up...5 Start-up

ICED CAPPUCCINO MACHINE Taylor MODEL: 390

4.8.6.3 ICED CAPPUCCINO MACHINE Taylor MODEL: 390 LOCATION: Front of House WHEN CLEANED: Daily, Weekly, Monthly, Seasonal TOOLS/SUPPLIES REQUIRED: Salmon Cloth 2 or 3-Compartment Sink Sink Detergent Sanitizer

4.8.6.3 ICED CAPPUCCINO MACHINE Taylor MODEL: 390 LOCATION: Front of House WHEN CLEANED: Daily, Weekly, Monthly, Seasonal TOOLS/SUPPLIES REQUIRED: Salmon Cloth 2 or 3-Compartment Sink Sink Detergent Sanitizer

A Steam-e product All Rights Reserved. GUM REMOVER Operating Instructions - June 2018

A Steam-e product. 2018 All Rights Reserved. Register your machine online Model: Gum-e Date of purchase: Serial Number: ST.. Purchased From: Address: Phone Number: Company name of owner: 12 month warranty

A Steam-e product. 2018 All Rights Reserved. Register your machine online Model: Gum-e Date of purchase: Serial Number: ST.. Purchased From: Address: Phone Number: Company name of owner: 12 month warranty

13 GALLON Extractor MODEL NO

13 GALLON Extractor MODEL NO. 98260 FIG. 1B VACUUM SWITCH DUMP VALVE RECOVERY TANK FIG. 1A VACUUM HOSE PUMP SWITCH SOLUTION TUB SOLUTION INLET HOSE SOLUTION DELIVERY HOSE NOTE - FOR COLOR FASTNESS:

13 GALLON Extractor MODEL NO. 98260 FIG. 1B VACUUM SWITCH DUMP VALVE RECOVERY TANK FIG. 1A VACUUM HOSE PUMP SWITCH SOLUTION TUB SOLUTION INLET HOSE SOLUTION DELIVERY HOSE NOTE - FOR COLOR FASTNESS:

SAFETY OPERATION & MAINTENANCE MANUAL X-405 CARPET EXTRACTOR This unit is intended for commercial use.

SAFETY OPERATION & MAINTENANCE MANUAL X-405 CARPET EXTRACTOR This unit is intended for commercial use. READ AND FOLLOW ALL INSTRUCTIONS, WARNINGS AND CAUTIONS BEFORE USING THIS EXTRACTOR Address: 777 South

SAFETY OPERATION & MAINTENANCE MANUAL X-405 CARPET EXTRACTOR This unit is intended for commercial use. READ AND FOLLOW ALL INSTRUCTIONS, WARNINGS AND CAUTIONS BEFORE USING THIS EXTRACTOR Address: 777 South

CMU701/ 705 OPERATIONS & INSTRUCTION MANUAL

CMU701/ 705 OPERATIONS & INSTRUCTION MANUAL MANUFACTURED BY 2519 Fairmont Road Morgantown, West Virginia 26501 PHONE: (304)-983-2642 FAX: (304)-983-2643 www.imswv.com 1 TABLE OF CONTENTS: 1.) Introduction

CMU701/ 705 OPERATIONS & INSTRUCTION MANUAL MANUFACTURED BY 2519 Fairmont Road Morgantown, West Virginia 26501 PHONE: (304)-983-2642 FAX: (304)-983-2643 www.imswv.com 1 TABLE OF CONTENTS: 1.) Introduction

What to expect from your water softener

What to expect from your water softener All water softeners work on the same basic principal. Hard water flows through a bed of resin and the calcium and magnesium, the minerals that are responsible for

What to expect from your water softener All water softeners work on the same basic principal. Hard water flows through a bed of resin and the calcium and magnesium, the minerals that are responsible for

OPERATING MANUAL. Reverse Osmosis Equipment Model: Frame Mount Vertical FMV-1 through FMV-6. Made in U.S.A.

OPERATING MANUAL Reverse Osmosis Equipment Model: Frame Mount Vertical FMV-1 through FMV-6 Made in U.S.A. TABLE OF CONTENTS Model: Frame Mount Vertical COMPONENT IDENTIFICATION Page 1 IMAGE OF R. O. SYSTEM

OPERATING MANUAL Reverse Osmosis Equipment Model: Frame Mount Vertical FMV-1 through FMV-6 Made in U.S.A. TABLE OF CONTENTS Model: Frame Mount Vertical COMPONENT IDENTIFICATION Page 1 IMAGE OF R. O. SYSTEM

DEHUMIDIFIER OWNER S MANUAL. Read this manual carefully before operating the appliance and retain it for future reference.

OWNER S MANUAL DEHUMIDIFIER ESPAÑOL FRANÇAIS Read this manual carefully before operating the appliance and retain it for future reference. Model : UD701KOG1 P/NO : MFL68026017 www.lg.com TABLE OF CONTENTS

OWNER S MANUAL DEHUMIDIFIER ESPAÑOL FRANÇAIS Read this manual carefully before operating the appliance and retain it for future reference. Model : UD701KOG1 P/NO : MFL68026017 www.lg.com TABLE OF CONTENTS

Operating Instructions

Operating Instructions Mixing Pump duo-mix 2000 220V 60Hz 3ph 2 duo-mix 2000 2003 m-tec mathis technik gmbh Copyright in these operating instructions is owned by m-tec mathis technik gmbh. These operating

Operating Instructions Mixing Pump duo-mix 2000 220V 60Hz 3ph 2 duo-mix 2000 2003 m-tec mathis technik gmbh Copyright in these operating instructions is owned by m-tec mathis technik gmbh. These operating

SAFETY OPERATION & MAINTENANCE MANUAL X-612 CARPET EXTRACTOR

SAFETY OPERATION & MAINTENANCE MANUAL X-612 CARPET EXTRACTOR W/PARTS LIST This unit is intended for commercial use. READ AND FOLLOW ALL INSTRUCTIONS, WARNINGS AND CAUTIONS BEFORE USING THIS EXTRACTOR Address:

SAFETY OPERATION & MAINTENANCE MANUAL X-612 CARPET EXTRACTOR W/PARTS LIST This unit is intended for commercial use. READ AND FOLLOW ALL INSTRUCTIONS, WARNINGS AND CAUTIONS BEFORE USING THIS EXTRACTOR Address:

BEFORE OPERATING THE MACHINE: WARNING

BEFORE OPERATING THE MACHINE: Read the manual carefully and completely before attempting to operate the unit. This manual has important information for the use and safe operation of the machine. Keep this

BEFORE OPERATING THE MACHINE: Read the manual carefully and completely before attempting to operate the unit. This manual has important information for the use and safe operation of the machine. Keep this

HMT-D30-A HMT-D45E-A HMT-D70E-A. Model Numbers: HMT-D30-A HMT-D45E-A HMT-D70E-A. Portable Dehumidifier Operating Instructions V.

HMT-D30-A HMT-D45E-A HMT-D70E-A Model Numbers: HMT-D30-A HMT-D45E-A HMT-D70E-A Portable Dehumidifier Operating Instructions 3119233 V.141217 General Dehumidifier Information RECOMMENDED HUMIDITY LEVELS

HMT-D30-A HMT-D45E-A HMT-D70E-A Model Numbers: HMT-D30-A HMT-D45E-A HMT-D70E-A Portable Dehumidifier Operating Instructions 3119233 V.141217 General Dehumidifier Information RECOMMENDED HUMIDITY LEVELS

Portable Dehumidifier

Portable Dehumidifier OPERATING INSTRUCTIONS HMT-D30-A Model Numbers: HMT-D30-A HMT-D45E-A HMT-D70E-A HMT-D45E-A HMT-D70E-A 3058080 V.161115 PURCHASE INFORMATION Thank you for choosing a Soleus Air Portable

Portable Dehumidifier OPERATING INSTRUCTIONS HMT-D30-A Model Numbers: HMT-D30-A HMT-D45E-A HMT-D70E-A HMT-D45E-A HMT-D70E-A 3058080 V.161115 PURCHASE INFORMATION Thank you for choosing a Soleus Air Portable

π H-6369, H-6370 DEHUMIDIFIER GENERAL INFORMATION uline.com WATER IN THE BUCKET RECOMMENDED HUMIDITY LEVELS WARM AIR EXHAUST IS NORMAL

π H-6369, H-6370 DEHUMIDIFIER 1-800-295-5510 uline.com GENERAL INFORMATION RECOMMENDED HUMIDITY LEVELS Spring/Summer: 35% - 50% Fall/Winter: 35% - 40% WARM AIR EXHAUST IS NORMAL During operation your dehumidifier

π H-6369, H-6370 DEHUMIDIFIER 1-800-295-5510 uline.com GENERAL INFORMATION RECOMMENDED HUMIDITY LEVELS Spring/Summer: 35% - 50% Fall/Winter: 35% - 40% WARM AIR EXHAUST IS NORMAL During operation your dehumidifier

TM AUTOMATIC FERTILIZING SYSTEM GARDEN PRODUCTS INSTALLATION AND OPERATING GUIDE Model: EZ 2005-HB Low Pressure Garden & Drip Feeder 3/4 Gallon Liquid / 5 LB Dry Capacity CAUTION: Installing your system

TM AUTOMATIC FERTILIZING SYSTEM GARDEN PRODUCTS INSTALLATION AND OPERATING GUIDE Model: EZ 2005-HB Low Pressure Garden & Drip Feeder 3/4 Gallon Liquid / 5 LB Dry Capacity CAUTION: Installing your system

PUGMILL/MIXER. Instruction Manual NVS-07

92895B PUGMILL/MIXER Instruction Manual NVS-07 Attention After carefully reading this manual, be sure to store it in a safe and convenient place for easy reference. Before using this unit, please read

92895B PUGMILL/MIXER Instruction Manual NVS-07 Attention After carefully reading this manual, be sure to store it in a safe and convenient place for easy reference. Before using this unit, please read

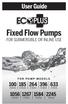

User Guide. Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE FOR PUMP MODELS # # # # # # # # #728333

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

SuperKlean Washdown Products

February 2012 DURAMIX 8000 INSTALLATION AND MAINTENANCE INSTRUCTIONS **DO NOT THROW AWAY AFTER INSTALLATION** **SAVE AND DISPLAY PROMINENTLY WHERE THIS EQUIPMENT IS USED** WARNING HIGH PRESSURE AND HOT

February 2012 DURAMIX 8000 INSTALLATION AND MAINTENANCE INSTRUCTIONS **DO NOT THROW AWAY AFTER INSTALLATION** **SAVE AND DISPLAY PROMINENTLY WHERE THIS EQUIPMENT IS USED** WARNING HIGH PRESSURE AND HOT

Page 1 of 18. Part# /5/2013

Part# 1002655-06 8/5/2013 This manual contains important information concerning the installation and operation of the gun washers listed above. Read manual thoroughly and keep for future reference INSTRUCTIONS

Part# 1002655-06 8/5/2013 This manual contains important information concerning the installation and operation of the gun washers listed above. Read manual thoroughly and keep for future reference INSTRUCTIONS

READ MANUAL BEFORE OPERATING SYSTEM Read the owner s manual thoroughly before operating to ensure the most efficient use of the system.

READ MANUAL BEFORE OPERATING SYSTEM Read the owner s manual thoroughly before operating to ensure the most efficient use of the system. Attention Installer: Please be sure this manual and warranty information

READ MANUAL BEFORE OPERATING SYSTEM Read the owner s manual thoroughly before operating to ensure the most efficient use of the system. Attention Installer: Please be sure this manual and warranty information

TM AUTOMATIC FERTILIZING SYSTEM GARDEN PRODUCTS INSTALLATION AND OPERATING GUIDE Model: EZ 2005-HB Low Pressure Garden & Drip Feeder 3/4 Gallon Liquid / 5 LB Dry Capacity CAUTION: Installing your system

TM AUTOMATIC FERTILIZING SYSTEM GARDEN PRODUCTS INSTALLATION AND OPERATING GUIDE Model: EZ 2005-HB Low Pressure Garden & Drip Feeder 3/4 Gallon Liquid / 5 LB Dry Capacity CAUTION: Installing your system

INSTRUCTION MANUAL FOR DUTCHESS MODEL 260 BAGEL & BUN SLICER

INSTRUCTION MANUAL FOR DUTCHESS MODEL 260 BAGEL & BUN SLICER Table of Contents Safety Information I thru VII Uncrating Instructions 1 Introduction 2 Adjustment Instructions 3 Operating Instructions, Cleaning,

INSTRUCTION MANUAL FOR DUTCHESS MODEL 260 BAGEL & BUN SLICER Table of Contents Safety Information I thru VII Uncrating Instructions 1 Introduction 2 Adjustment Instructions 3 Operating Instructions, Cleaning,

UNDERCOUNTER DISHWASHER

OWNER S MANUAL BLAKESLEE Division of Blako Inc. UNDERCOUNTER DISHWASHER UC-21 I.R.S. INTEGRATED RECIRCULATING SYSTEM DESIGN 1844 South Laramie Avenue Chicago, IL 60804 Phone (708) 656-0660 Fax (708) 656-0017

OWNER S MANUAL BLAKESLEE Division of Blako Inc. UNDERCOUNTER DISHWASHER UC-21 I.R.S. INTEGRATED RECIRCULATING SYSTEM DESIGN 1844 South Laramie Avenue Chicago, IL 60804 Phone (708) 656-0660 Fax (708) 656-0017

INSTALLATION & OPERATION Rev 1.00A DISTRIBUTED EXCLUSIVELY BY CMA DISHMACHINES KNOTT AVENUE GARDEN GROVE, CALIFORNIA 92841

MODEL UC 60e INSTALLATION & OPERATION Rev 1.00A DISTRIBUTED EXCLUSIVELY BY CMA DISHMACHINES 12700 KNOTT AVENUE GARDEN GROVE, CALIFORNIA 92841 800-854- 6417 FAX 714-895-2141 www.cmadishmachines.com TABLE

MODEL UC 60e INSTALLATION & OPERATION Rev 1.00A DISTRIBUTED EXCLUSIVELY BY CMA DISHMACHINES 12700 KNOTT AVENUE GARDEN GROVE, CALIFORNIA 92841 800-854- 6417 FAX 714-895-2141 www.cmadishmachines.com TABLE

SAFETY, OPERATION AND MAINTENANCE MANUAL. MX-1408 SELF-CONTAINED EXTRACTOR This unit is intended for commercial use.

SAFETY, OPERATION AND MAINTENANCE MANUAL MX-1408 SELF-CONTAINED EXTRACTOR This unit is intended for commercial use. READ & FOLLOW ALL INSTRUCTIONS, WARNINGS & CAUTIONS BEFORE USING THIS EXTRACTOR This

SAFETY, OPERATION AND MAINTENANCE MANUAL MX-1408 SELF-CONTAINED EXTRACTOR This unit is intended for commercial use. READ & FOLLOW ALL INSTRUCTIONS, WARNINGS & CAUTIONS BEFORE USING THIS EXTRACTOR This

Model Numbers: HCT-D30-A (TDA30) HCT-D45E-A (TDA45E) HCT-D70E-A (TDA70E) Portable Dehumidifier Operating Instructions V

Model Numbers: HCT-D30-A (TDA30) HCT-D45E-A (TDA45E) HCT-D70E-A (TDA70E) Portable Dehumidifier Operating Instructions 3119233 V.140529 General Dehumidifier Information RECOMMENDED HUMIDITY LEVELS Spring/Summer:

Model Numbers: HCT-D30-A (TDA30) HCT-D45E-A (TDA45E) HCT-D70E-A (TDA70E) Portable Dehumidifier Operating Instructions 3119233 V.140529 General Dehumidifier Information RECOMMENDED HUMIDITY LEVELS Spring/Summer:

Models: GW/R-T GW/R-2-T GW/R-3-T

Part# GW/R-T-OM 1/12/04 TN Models: GW/R-T GW/R-2-T GW/R-3-T This manual contains important information concerning the installation and operation of the gun washers listed above. Read manual thoroughly

Part# GW/R-T-OM 1/12/04 TN Models: GW/R-T GW/R-2-T GW/R-3-T This manual contains important information concerning the installation and operation of the gun washers listed above. Read manual thoroughly

120V CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ ALL SECTIONS OF THIS INSTRUCTION MANUAL IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

KING COBRA 1200 120V INFORMATION & OPERATING INSTRUCTIONS CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ ALL SECTIONS OF THIS INSTRUCTION MANUAL IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

KING COBRA 1200 120V INFORMATION & OPERATING INSTRUCTIONS CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ ALL SECTIONS OF THIS INSTRUCTION MANUAL IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

INSTALLATION AND OPERATION MANUAL STEAM COIL BASE CONVECTION STEAMER MODEL SCX-16

INSTALLATION AND OPERATION MANUAL STEAM COIL BASE CONVECTION STEAMER MODEL SCX-16 CROWN FOOD SERVICE EQUIPMENT LTD. 70 OAKDALE ROAD, DOWNSVIEW, (TORONTO), ONTARIO, CANADA, M3N 1V9 TELEPHONE: (416) 746-2358,

INSTALLATION AND OPERATION MANUAL STEAM COIL BASE CONVECTION STEAMER MODEL SCX-16 CROWN FOOD SERVICE EQUIPMENT LTD. 70 OAKDALE ROAD, DOWNSVIEW, (TORONTO), ONTARIO, CANADA, M3N 1V9 TELEPHONE: (416) 746-2358,

PRO 2000i LOW LEVEL DEPOSITOR

DEPOSITORS AND AUTOMATED CAKE PRODUCTION SYSTEMS PRO 2000i LOW LEVEL DEPOSITOR OPERATION AND SPARE PARTS MANUAL Serial No. PR2L- (Please quote this number when ordering spares, and making service calls)

DEPOSITORS AND AUTOMATED CAKE PRODUCTION SYSTEMS PRO 2000i LOW LEVEL DEPOSITOR OPERATION AND SPARE PARTS MANUAL Serial No. PR2L- (Please quote this number when ordering spares, and making service calls)

REVERSE OSMOSIS SYSTEMS

REVERSE OSMOSIS SYSTEMS TABLE OF CONTENTS R.O. SYSTEM DESCRIPTION... 2 R.O. EQUIPMENT INSTALLATION...3 R.O. SYSTEM CHECK-OUT PROCEDURE... 4 R.O. UNIT TURN ON PROCEDURE...5 R.O. UNIT RATING.. 6 R.O. BAY

REVERSE OSMOSIS SYSTEMS TABLE OF CONTENTS R.O. SYSTEM DESCRIPTION... 2 R.O. EQUIPMENT INSTALLATION...3 R.O. SYSTEM CHECK-OUT PROCEDURE... 4 R.O. UNIT TURN ON PROCEDURE...5 R.O. UNIT RATING.. 6 R.O. BAY

FROZEN CONCOCTION MAKER

The Navigator Bahamas TM FROZEN CONCOCTION MAKER The Best Margaritas Come From Margaritaville Model DM0500 Series User Manual IMPORTANT SAFEGUARDS WHEN USING ELECTRICAL APPLIANCES, BASIC SAFETY PRECAUTIONS

The Navigator Bahamas TM FROZEN CONCOCTION MAKER The Best Margaritas Come From Margaritaville Model DM0500 Series User Manual IMPORTANT SAFEGUARDS WHEN USING ELECTRICAL APPLIANCES, BASIC SAFETY PRECAUTIONS

LITTLE BLASTER LARRY HESS AND ASSOCIATES, INC. BLAST-IT-ALL P.O. BOX 1615 SALISBURY, NC WITH DUST COLLECTOR

LITTLE BLASTER LARRY HESS AND ASSOCIATES, INC. BLAST-IT-ALL P.O. BOX 1615 SALISBURY, NC 28145 WWW.BLAST-IT-ALL.COM LITTLE BLASTER WITH DUST COLLECTOR MANUAL NUMBER: 561 TABLE OF CONTENTS PAGE FIGURE 1

LITTLE BLASTER LARRY HESS AND ASSOCIATES, INC. BLAST-IT-ALL P.O. BOX 1615 SALISBURY, NC 28145 WWW.BLAST-IT-ALL.COM LITTLE BLASTER WITH DUST COLLECTOR MANUAL NUMBER: 561 TABLE OF CONTENTS PAGE FIGURE 1

Automated Plastic Extruder Doser Manual

Automated Plastic Extruder Doser Manual ENGR 480: Manufacturing Fall 2015 Produced by Team Loewen: Nathan Loewen Zachary Arnott Rodrigo Alvares Kendrick Rady Table of Contents Table of Figures... 3 Introduction...

Automated Plastic Extruder Doser Manual ENGR 480: Manufacturing Fall 2015 Produced by Team Loewen: Nathan Loewen Zachary Arnott Rodrigo Alvares Kendrick Rady Table of Contents Table of Figures... 3 Introduction...

OWNER S MANUAL COMMERCIAL COLD PRESS JUICER

COMMERCIAL COLD PRESS JUICER REV.3 Introduction WARNING: To limit risk of personal injury and material damage, all users must read these instructions in their entirety and follow them strictly. MACHINE

COMMERCIAL COLD PRESS JUICER REV.3 Introduction WARNING: To limit risk of personal injury and material damage, all users must read these instructions in their entirety and follow them strictly. MACHINE

OWNER S MANUAL VERSION 4.4 SERIAL # X-1 SINGLE LAYER PRESS. With EG-260 Variable Speed Grinder

OWNER S MANUAL VERSION 4.4 CONFORMS TO UL STD 763, NSF/ANSI STD 8 CERTIFIED TO CSA STD C22.2 #195 CONFORMS TO CE, IEC TESTED X-1 SINGLE LAYER PRESS With EG-260 Variable Speed Grinder SERIAL # 2 20 INTRODUCTION

OWNER S MANUAL VERSION 4.4 CONFORMS TO UL STD 763, NSF/ANSI STD 8 CERTIFIED TO CSA STD C22.2 #195 CONFORMS TO CE, IEC TESTED X-1 SINGLE LAYER PRESS With EG-260 Variable Speed Grinder SERIAL # 2 20 INTRODUCTION

Tornado Operations & Maintenance Manual

TORNADO INDUSTRIES 7401 W. LAWRENCE AVENUE CHICAGO, IL 60706 (708) 867-5100 FAX (708) 867-6968 www.tornadovac.com Tornado Operations & Maintenance Manual MODEL NO. 99690 BD 22/14, 99720 BD 26/14 L9722

TORNADO INDUSTRIES 7401 W. LAWRENCE AVENUE CHICAGO, IL 60706 (708) 867-5100 FAX (708) 867-6968 www.tornadovac.com Tornado Operations & Maintenance Manual MODEL NO. 99690 BD 22/14, 99720 BD 26/14 L9722

Professional Mixing Drills for Fast, Efficient Mixing

EIBENSTOCK POWER TOOLS Professional Mixing Drills for Fast, Efficient Mixing From self-leveling cements to prefab mortar, CS Unitec has a portable mixer to do the job quickly. Every CS Unitec mixer has

EIBENSTOCK POWER TOOLS Professional Mixing Drills for Fast, Efficient Mixing From self-leveling cements to prefab mortar, CS Unitec has a portable mixer to do the job quickly. Every CS Unitec mixer has

17 GALLON PROFESSIONAL RESTROOM CLEANER

CR2 COMPLETE RESTROOM RESTORATION 17 GALLON PROFESSIONAL RESTROOM CLEANER OWNER S/OPERATOR S MANUAL PROUDLY DESIGNED AND MANUFACTURED BY WWW.EDIC-USA.COM UNPACKING YOUR NEW CR2: When your machine is delivered,

CR2 COMPLETE RESTROOM RESTORATION 17 GALLON PROFESSIONAL RESTROOM CLEANER OWNER S/OPERATOR S MANUAL PROUDLY DESIGNED AND MANUFACTURED BY WWW.EDIC-USA.COM UNPACKING YOUR NEW CR2: When your machine is delivered,

Concept 7400 Kitchen Machines for model: MUM 7400 UC

Owner s Manual Concept 7400 Kitchen Machines for model: MUM 7400 UC READ THIS MANUAL thoroughly for important safety and operating instructions before using this appliance. 1 IMPORTANT SAFEGUARDS WARNING:

Owner s Manual Concept 7400 Kitchen Machines for model: MUM 7400 UC READ THIS MANUAL thoroughly for important safety and operating instructions before using this appliance. 1 IMPORTANT SAFEGUARDS WARNING:

TSS 15/55 Hi-Lift Vacuum

TSS 15/55 Hi-Lift Vacuum OPERATOR S MANUAL 2007 ICS, Blount Inc. F/N 71335 Oct 07 TABLE OF TITLE CONTENTS SYMBOLS & LABELS 4 SAFETY 5 TECHNICAL SPECIFICATIONS 6 SET-UP 7 OPERATION 8 MAINTENANCE 9 TROUBLESHOOTING

TSS 15/55 Hi-Lift Vacuum OPERATOR S MANUAL 2007 ICS, Blount Inc. F/N 71335 Oct 07 TABLE OF TITLE CONTENTS SYMBOLS & LABELS 4 SAFETY 5 TECHNICAL SPECIFICATIONS 6 SET-UP 7 OPERATION 8 MAINTENANCE 9 TROUBLESHOOTING

Eco-Safe Digester. Installation Manual For E3 Series Digesters. Version 1.6 Published: Apr. 13, 2017

Eco-Safe Digester Installation Manual For E3 Series Digesters Version 1.6 Published: Apr. 13, 2017 Eco-Safe Digester Installation Manual Table of Contents Preface... iv 1. Document Revision History...

Eco-Safe Digester Installation Manual For E3 Series Digesters Version 1.6 Published: Apr. 13, 2017 Eco-Safe Digester Installation Manual Table of Contents Preface... iv 1. Document Revision History...

Safety. Rinse Kit for Multi-Pro 1200 and 1250 Turf Sprayers Model No Safety and Instructional Decals. Installation Instructions

Rinse Kit for Multi-Pro 1200 and 1250 Turf Sprayers Model No. 106-4842 Form No. 3353-529 Rev B Installation Instructions Note: Determine the left and right sides of the machine from the normal operating

Rinse Kit for Multi-Pro 1200 and 1250 Turf Sprayers Model No. 106-4842 Form No. 3353-529 Rev B Installation Instructions Note: Determine the left and right sides of the machine from the normal operating

Sanitise Syrup Lines & Valves. Taylor PH61 Cleaning every 14 days

Taylor PH61 Cleaning every 14 days Drain the Syrup Lines Remove each syrup feed tube from syrup bottle and let excess syrup drain from the feed tube back into the syrup bottle. When flow of syrup from

Taylor PH61 Cleaning every 14 days Drain the Syrup Lines Remove each syrup feed tube from syrup bottle and let excess syrup drain from the feed tube back into the syrup bottle. When flow of syrup from

MODEL A18 SOLVENT RECOVERY SYSTEMS (EXPLOSION PROOF UNITS)

MODEL A18 SOLVENT RECOVERY SYSTEMS (EXPLOSION PROOF UNITS) FOR PROPER AND SAFE USE OF THIS CHEMCHAMP EQUIPMENT, PLEASE FOLLOW THIS DOCUMENT AND LOCAL AUTHORITY. KEEP THIS DOCUMENT FOR FUTURE REFERENCE.

MODEL A18 SOLVENT RECOVERY SYSTEMS (EXPLOSION PROOF UNITS) FOR PROPER AND SAFE USE OF THIS CHEMCHAMP EQUIPMENT, PLEASE FOLLOW THIS DOCUMENT AND LOCAL AUTHORITY. KEEP THIS DOCUMENT FOR FUTURE REFERENCE.

A Green Solutions Company

A Green Solutions Company INSTALLATION AND OPERATING GUIDE HIGH CAPACITY SYSTEMS MODELS: EZ010-HC, EZ017-HC, EZ025-HC (EZ010-HC PICTURED) For an overview of the EZ-FLO System Installation & operation:

A Green Solutions Company INSTALLATION AND OPERATING GUIDE HIGH CAPACITY SYSTEMS MODELS: EZ010-HC, EZ017-HC, EZ025-HC (EZ010-HC PICTURED) For an overview of the EZ-FLO System Installation & operation:

Full Size Canister Service Manual Riccar Models 1700 / 1800 Power Nozzles RPB-100 / RPB-220 / RPB-224 / RPB-250

Full Size Canister Service Manual Riccar Models 1700 / 1800 Power Nozzles RPB-100 / RPB-220 / RPB-224 / RPB-250 Table of Contents I. General Full Size Canister Issues...2 A. Full Bag Indicator...2 1. General

Full Size Canister Service Manual Riccar Models 1700 / 1800 Power Nozzles RPB-100 / RPB-220 / RPB-224 / RPB-250 Table of Contents I. General Full Size Canister Issues...2 A. Full Bag Indicator...2 1. General

8070 Mytee Lite. Instructions for. Please read before use. Register your product at support/register.

Instructions for 8070 Mytee Lite Please read before use. Register your product at http://www.mytee.com/ support/register Model # Serial # Form # ADP-8070 06-16 1 GENERAL INFORMATION Dear Customer: Congratulations

Instructions for 8070 Mytee Lite Please read before use. Register your product at http://www.mytee.com/ support/register Model # Serial # Form # ADP-8070 06-16 1 GENERAL INFORMATION Dear Customer: Congratulations

TERMINATOR 120V CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ ALL SECTIONS OF THIS INSTRUCTION MANUAL

TERMINATOR 120V INFORMATION & OPERATING INSTRUCTIONS CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ ALL SECTIONS OF THIS INSTRUCTION MANUAL 56041962 IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

TERMINATOR 120V INFORMATION & OPERATING INSTRUCTIONS CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ ALL SECTIONS OF THIS INSTRUCTION MANUAL 56041962 IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE OPERATING THE MACHINE

XAACT Xtract 200 INFORMATION & OPERATING INSTRUCTIONS READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE OPERATING THE MACHINE 78-00018 Rev B 032912 1 CONTENTS: Machine Specifications............ 2 Record Important

XAACT Xtract 200 INFORMATION & OPERATING INSTRUCTIONS READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE OPERATING THE MACHINE 78-00018 Rev B 032912 1 CONTENTS: Machine Specifications............ 2 Record Important

EXTRACTOR Operation & Maintenance Manual

EXTRACTOR Operation & Maintenance Manual 12 Gallon Carpet Extractor Models 2-100 2-100-H 3-100 3-100-H 2-200 2-200-H 3-200 3-200-H 2-500 2-500-H 3-500 3-500-H US & Foreign Patents Pending The design features

EXTRACTOR Operation & Maintenance Manual 12 Gallon Carpet Extractor Models 2-100 2-100-H 3-100 3-100-H 2-200 2-200-H 3-200 3-200-H 2-500 2-500-H 3-500 3-500-H US & Foreign Patents Pending The design features

Clean Water Made Easy. Fleck 7000 Tannin Filter Installation & Startup Guide. Questions?

Clean Water Made Easy www.cleanwaterstore.com Fleck 7000 Tannin Filter Installation & Startup Guide For Tannin Filters with Vortech Distributor Screen Thank you for purchasing a Clean Water System! With

Clean Water Made Easy www.cleanwaterstore.com Fleck 7000 Tannin Filter Installation & Startup Guide For Tannin Filters with Vortech Distributor Screen Thank you for purchasing a Clean Water System! With

HMT-D30-A HMT-D45E-A HMT-D70E-A. Model Numbers: HMT-D30-A HMT-D45E-A HMT-D70E-A. Portable Dehumidifier Operating Instructions V.

HMT-D30-A HMT-D45E-A HMT-D70E-A Model Numbers: HMT-D30-A HMT-D45E-A HMT-D70E-A Portable Dehumidifier Operating Instructions 3058080 V.151201 General Dehumidifier Information RECOMMENDED HUMIDITY LEVELS

HMT-D30-A HMT-D45E-A HMT-D70E-A Model Numbers: HMT-D30-A HMT-D45E-A HMT-D70E-A Portable Dehumidifier Operating Instructions 3058080 V.151201 General Dehumidifier Information RECOMMENDED HUMIDITY LEVELS

APPLICATION INSTRUCTIONS FOR MASCOAT SOUND CONTROL-dB

APPLICATION INSTRUCTIONS FOR MASCOAT SOUND CONTROL-dB OVERVIEW: This coating is designed to provide dramatic sound dampening characteristics when applied correctly. All ingredients are considered safe

APPLICATION INSTRUCTIONS FOR MASCOAT SOUND CONTROL-dB OVERVIEW: This coating is designed to provide dramatic sound dampening characteristics when applied correctly. All ingredients are considered safe

LC Series - Light Commercial Pump Station Installation and Operation Manual

LC Series - Light Commercial Pump Station Installation and Operation Manual Please keep this manual with the pump station Content Rain Bird LC Series Overview... Safety Instruction... Operation... 3 Pump

LC Series - Light Commercial Pump Station Installation and Operation Manual Please keep this manual with the pump station Content Rain Bird LC Series Overview... Safety Instruction... Operation... 3 Pump

Water Softener Installation Guide Effective for all Softeners from our Range

Water Softener Installation Guide Effective for all Softeners from our Range Planning Your Installation Always observe the water byelaws. Ensure there is only one rising main, that you have allowed space

Water Softener Installation Guide Effective for all Softeners from our Range Planning Your Installation Always observe the water byelaws. Ensure there is only one rising main, that you have allowed space

EFX 600. aquamanta. Instruction Manual. 4year guarantee. the experts in aquatic technology. >600 Litres

EFX 600 aquamanta TM the experts in aquatic technology >600 Litres Coldwater Tropical Marine 4year guarantee Instruction Manual Important Safeguards This appliance is not intended for use by persons (including

EFX 600 aquamanta TM the experts in aquatic technology >600 Litres Coldwater Tropical Marine 4year guarantee Instruction Manual Important Safeguards This appliance is not intended for use by persons (including

INSTALLATION & INSTRUCTION MANUAL

INSTALLATION & INSTRUCTION MANUAL CLEARADON SERIES 3311 SHALLOWTRAY AERATION SYSTEM RadonAway 3 Saber Way Ward Hill, MA 01835 radonaway.com TABLE OF CONTENTS SAFETY FIRST!... 1 INSTALLATION PROCEDURE...

INSTALLATION & INSTRUCTION MANUAL CLEARADON SERIES 3311 SHALLOWTRAY AERATION SYSTEM RadonAway 3 Saber Way Ward Hill, MA 01835 radonaway.com TABLE OF CONTENTS SAFETY FIRST!... 1 INSTALLATION PROCEDURE...

FOR SERVICE TECHNICIAN ONLY DO NOT REMOVE OR DESTROY WARNING

WARNING Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in injury or death. IMPORTANT Electric Discharge (ESD) Sensitive

WARNING Electrical Shock Hazard Disconnect power before servicing. Replace all parts and panels before operating. Failure to do so can result in injury or death. IMPORTANT Electric Discharge (ESD) Sensitive

FD Heavy Duty Feeder for FD 280 Tabbing System

FD 280-10 Heavy Duty Feeder for FD 280 Tabbing System Operator Manual 8/2011 First Edition TABLE OF CONTENTS 1. INTRODUCTION... 1 1.1 Feeder Description... 1 1.2 Items Included... 1 1.3 Operating Manual

FD 280-10 Heavy Duty Feeder for FD 280 Tabbing System Operator Manual 8/2011 First Edition TABLE OF CONTENTS 1. INTRODUCTION... 1 1.1 Feeder Description... 1 1.2 Items Included... 1 1.3 Operating Manual

Owner s Manual CPU-1QD CPU-1 CPU-1T CPU-2 CPU-2T HEAVY DUTY UPRIGHT VACUUMS. Save These Instructions

Owner s Manual HEAVY DUTY UPRIGHT VACUUMS CPU-1QD CPU-1 CPU-1T CPU-2 CPU-2T Save These Instructions Index Important Safety Instructions.... 2 Polarization Instructions....3 Grounding Instructions.....

Owner s Manual HEAVY DUTY UPRIGHT VACUUMS CPU-1QD CPU-1 CPU-1T CPU-2 CPU-2T Save These Instructions Index Important Safety Instructions.... 2 Polarization Instructions....3 Grounding Instructions.....

Juice Extractor Kitchen Juicer USER MANUAL MODEL: PKJC40

Juice Extractor Kitchen Juicer USER MANUAL MODEL: PKJC40 Main Components Diagram 1. Pushing Jar 2. Transparent Cover 3. Juicing Net 4. Middle Ring 5. Handle 6. Residue Barrel 7. Main Machine 8. Juicer

Juice Extractor Kitchen Juicer USER MANUAL MODEL: PKJC40 Main Components Diagram 1. Pushing Jar 2. Transparent Cover 3. Juicing Net 4. Middle Ring 5. Handle 6. Residue Barrel 7. Main Machine 8. Juicer

R100 Oil-Less Refrigerant Recovery Unit

R100 Oil-Less Refrigerant Recovery Unit Operation Manual 1 INTRODUCTION Welcome to simple, efficient refrigerant recovery with your new YELLOW JACKET Refrigerant Recovery Unit, R100. This unit combines

R100 Oil-Less Refrigerant Recovery Unit Operation Manual 1 INTRODUCTION Welcome to simple, efficient refrigerant recovery with your new YELLOW JACKET Refrigerant Recovery Unit, R100. This unit combines

Read this owner's manual thoroughly before operating the appliance and retain it for future reference. TYPE : PORTABLE AIR CONDITIONER

ENGLISH ESPAÑOL Read this owner's manual thoroughly before operating the appliance and retain it for future reference. TYPE : PORTABLE AIR CONDITIONER MODEL : LP0817WSR LP1017WSR LP1217GSR LP1417SHR LP1417GSR

ENGLISH ESPAÑOL Read this owner's manual thoroughly before operating the appliance and retain it for future reference. TYPE : PORTABLE AIR CONDITIONER MODEL : LP0817WSR LP1017WSR LP1217GSR LP1417SHR LP1417GSR

Peacock Salt. Multisol Pro VA Operation & Training Manual

Multisol Pro VA Operation & Training Manual Peacock Salt CONTENTS PAGE 1. Saturator Tank Diagram 2 2. Saturator Cabinet Diagram 3 3. Saturator Function 4 4. Inlet water 5. Adding Salt 6. Producing Brine

Multisol Pro VA Operation & Training Manual Peacock Salt CONTENTS PAGE 1. Saturator Tank Diagram 2 2. Saturator Cabinet Diagram 3 3. Saturator Function 4 4. Inlet water 5. Adding Salt 6. Producing Brine

BL250. Pulse Blender OWNER S GUIDE

BL250 OWNER S GUIDE Pulse Blender 1-877-646-5288 IMPORTANT SAFETY INSTRUCTIONS For Household Use Only WHEN USING ELECTRICAL APPLIANCES, BASIC SAFETY PRECAUTIONS SHOULD ALWAYS BE FOLLOWED, INCLUDING THE

BL250 OWNER S GUIDE Pulse Blender 1-877-646-5288 IMPORTANT SAFETY INSTRUCTIONS For Household Use Only WHEN USING ELECTRICAL APPLIANCES, BASIC SAFETY PRECAUTIONS SHOULD ALWAYS BE FOLLOWED, INCLUDING THE

VPMmini. Operator's Manual

VPMmini Operator's Manual Whip Mix Corporation 361 Farmington Ave. P.O. Box 17183 Louisville, KY 40217-0183 USA 502-637-1451 800-626-5651 Fax 502-634-4512 www.whipmix.com Features The Whip Mix VPMmini

VPMmini Operator's Manual Whip Mix Corporation 361 Farmington Ave. P.O. Box 17183 Louisville, KY 40217-0183 USA 502-637-1451 800-626-5651 Fax 502-634-4512 www.whipmix.com Features The Whip Mix VPMmini

INSTRUCTIONS AND SPARE PARTS

COM1000i DEPOSITOR INSTRUCTIONS AND SPARE PARTS Manual Part # COMi-Ins-UK 12/08/2010 Translation from the Original Instructions Table of Contents Table of Contents 2 Safety Instructions and Warnings 5

COM1000i DEPOSITOR INSTRUCTIONS AND SPARE PARTS Manual Part # COMi-Ins-UK 12/08/2010 Translation from the Original Instructions Table of Contents Table of Contents 2 Safety Instructions and Warnings 5

Venco 75mm (3 ) Standard and De-airing Pugmill

Owner s manual for Venco 75mm (3 ) Standard and De-airing Pugmill Venco Products 29 Owen Road Kelmscott, Western Australia 6111 ph +61 8 9399-5265 fax +61 8 9 497 1335 email: venwest@iinet.net.au www.venco.com.au

Owner s manual for Venco 75mm (3 ) Standard and De-airing Pugmill Venco Products 29 Owen Road Kelmscott, Western Australia 6111 ph +61 8 9399-5265 fax +61 8 9 497 1335 email: venwest@iinet.net.au www.venco.com.au

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE OPERATING THE MACHINE

XAACT Xtract 500 INFORMATION & OPERATING INSTRUCTIONS READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE OPERATING THE MACHINE 78-00015 Rev B 032912 1 CONTENTS: Machine Specifications............ 2 Record Important

XAACT Xtract 500 INFORMATION & OPERATING INSTRUCTIONS READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE OPERATING THE MACHINE 78-00015 Rev B 032912 1 CONTENTS: Machine Specifications............ 2 Record Important

Vacuum Homogenizing Emulsification Machine. Instruction Manual

Vacuum Homogenizing Emulsification Machine Instruction Manual 1 Please study this manual carefully before operating the machine, you are welcome to call our service department or check in our website for

Vacuum Homogenizing Emulsification Machine Instruction Manual 1 Please study this manual carefully before operating the machine, you are welcome to call our service department or check in our website for

690 and Power Fishing Systems

INSTRUCTION MANUAL 690 and 690-22 Power Fishing Systems Includes Serial Number AAR 3800 and higher (120 volt model) Includes Serial Number AAT 00500 and higher (220 volt model) Read and understand all

INSTRUCTION MANUAL 690 and 690-22 Power Fishing Systems Includes Serial Number AAR 3800 and higher (120 volt model) Includes Serial Number AAT 00500 and higher (220 volt model) Read and understand all

INTELLIGENT, HEALTHFUL LIVING

Lee Household Flour Mill MODEL S-700 INTELLIGENT, HEALTHFUL LIVING 1 M150701302 Rev G T En an w Pa Im 3 B H Sp W R C Tr D C 2 Lee Household Flour Mill MODEL S-700 Thank you for purchasing your Lee Household

Lee Household Flour Mill MODEL S-700 INTELLIGENT, HEALTHFUL LIVING 1 M150701302 Rev G T En an w Pa Im 3 B H Sp W R C Tr D C 2 Lee Household Flour Mill MODEL S-700 Thank you for purchasing your Lee Household

Explorer CleaningPartsDirect.com Carpet Extractor. Operator and Parts Manual. Home Find... Go To.. Model No.: Can.

Explorer 1500 Carpet Extractor Model No.: 608808 609231 Can. Operator and Parts Manual CleaningPartsDirect.com 662-393-3045 NOBLES 12875 RANSOM STREET HOLLAND MI 49424 U.S.A. CUSTOMER SERVICE: 1-800-365-6625

Explorer 1500 Carpet Extractor Model No.: 608808 609231 Can. Operator and Parts Manual CleaningPartsDirect.com 662-393-3045 NOBLES 12875 RANSOM STREET HOLLAND MI 49424 U.S.A. CUSTOMER SERVICE: 1-800-365-6625

Operating Instructions Plastering Machine mono-mix fu

Operating Instructions Plastering Machine mono-mix fu 387604 04/2003 2 mono-mix fu Circuit Diagram 71 2002 m-tec mathis technik gmbh Copyright in these operating instructions is owned by m-tec mathis technik

Operating Instructions Plastering Machine mono-mix fu 387604 04/2003 2 mono-mix fu Circuit Diagram 71 2002 m-tec mathis technik gmbh Copyright in these operating instructions is owned by m-tec mathis technik

Model HC-2. Crathco Whipped Hot Chocolate Dispenser. Table of Contents. Operation and Instruction Manual. for

Crathco Whipped Hot Chocolate Dispenser Operation and Instruction Manual Table of Contents Introduction...1 Specifications...2 Installation and Start-Up Procedures...2 How to Dispense Hot Chocolate...3

Crathco Whipped Hot Chocolate Dispenser Operation and Instruction Manual Table of Contents Introduction...1 Specifications...2 Installation and Start-Up Procedures...2 How to Dispense Hot Chocolate...3

English Manual for Jewelry Casting and Investing The professional choice

English Manual for Jewelry Casting and Investing The professional choice QUICK START GUIDE: For thorough instructions, please review attached instructions. However, below, you will find a simplified start-up

English Manual for Jewelry Casting and Investing The professional choice QUICK START GUIDE: For thorough instructions, please review attached instructions. However, below, you will find a simplified start-up

English. Important Read this user manual carefully before you use the appliance and save it for future reference.

FC849-FC840 3 3 4 5 6 7 8 9 0 34 3 4 5 3 30 6 33 7 9 8 3 8 7 6 5 4 9 3 0 6 English Introduction Congratulations on your purchase and welcome to Philips! To fully benefit from the support that Philips offers,

FC849-FC840 3 3 4 5 6 7 8 9 0 34 3 4 5 3 30 6 33 7 9 8 3 8 7 6 5 4 9 3 0 6 English Introduction Congratulations on your purchase and welcome to Philips! To fully benefit from the support that Philips offers,

GENERAL 2004 HVAC SYSTEMS. Manual HVAC System - Sorento SPECIFICATIONS. Fig. 1: Air Conditioner Specifications Courtesy of KIA MOTORS AMERICA, INC.

Fig. 2: Blower & Evaporator Unit Specifications 2004 HVAC SYSTEMS Manual HVAC System - Sorento GENERAL SPECIFICATIONS AIR CONDITIONER Fig. 1: Air Conditioner Specifications BLOWER AND EVAPORATOR UNIT HEATER

Fig. 2: Blower & Evaporator Unit Specifications 2004 HVAC SYSTEMS Manual HVAC System - Sorento GENERAL SPECIFICATIONS AIR CONDITIONER Fig. 1: Air Conditioner Specifications BLOWER AND EVAPORATOR UNIT HEATER

Clean Water Made Easy. CWS Time Clock Softener Installation & Start Up Guide. Questions?

Clean Water Made Easy www.cleanwaterstore.com CWS Time Clock Softener Installation & Start Up Guide Thank you for purchasing a Clean Water System! With proper installation and a little routine maintenance

Clean Water Made Easy www.cleanwaterstore.com CWS Time Clock Softener Installation & Start Up Guide Thank you for purchasing a Clean Water System! With proper installation and a little routine maintenance

FAULT FINDING. Water Gas Cassette Toilet FAULT FINDING

Water... 208 Gas... 210 Cassette Toilet... 211 207 WATER FAULTS Water Fault Cause Remedy Water not flowing from any tap when operated but pump runs Pump does not run Water flows from cold tap but not from

Water... 208 Gas... 210 Cassette Toilet... 211 207 WATER FAULTS Water Fault Cause Remedy Water not flowing from any tap when operated but pump runs Pump does not run Water flows from cold tap but not from

POLIVAC PREDATOR MKIII OPERATIONS MANUAL & TROUBLE SHOOTING GUIDE

POLIVAC PREDATOR MKIII OPERATIONS MANUAL & TROUBLE SHOOTING GUIDE 1 This is an introduction on the use of the Polivac Predator Carpet Extraction unit. DIRECTIONS FOR USE 1. Connect 240v extension cable

POLIVAC PREDATOR MKIII OPERATIONS MANUAL & TROUBLE SHOOTING GUIDE 1 This is an introduction on the use of the Polivac Predator Carpet Extraction unit. DIRECTIONS FOR USE 1. Connect 240v extension cable

Operating Instructions

Operating Instructions 1. Preparation of Organic Feed. 1. To avoid flooding the columns during start-up, check that the main valves for water (VS1) and organic phase feed (VF2) on the 1 st floor are closed

Operating Instructions 1. Preparation of Organic Feed. 1. To avoid flooding the columns during start-up, check that the main valves for water (VS1) and organic phase feed (VF2) on the 1 st floor are closed

Portable Dehumidifier with Internal Pump

Portable Dehumidifier with Internal Pump OPERATING INSTRUCTIONS 115 Pint Portable Dehumidifier With Internal Pump Model Number: DMC-115IP-210 3092402 V161220 PURCHASE INFORMATION Thank you for choosing

Portable Dehumidifier with Internal Pump OPERATING INSTRUCTIONS 115 Pint Portable Dehumidifier With Internal Pump Model Number: DMC-115IP-210 3092402 V161220 PURCHASE INFORMATION Thank you for choosing

ADVANTAGE-100H-SC EXTRACTOR

ADVANTAGE-100H-SC EXTRACTOR 120V INFORMATION & OPERATING INSTRUCTIONS CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ ALL SECTIONS OF THIS INSTRUCTION MANUAL IMPROPER USE OF THE MACHINE WILL VOID THE

ADVANTAGE-100H-SC EXTRACTOR 120V INFORMATION & OPERATING INSTRUCTIONS CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ ALL SECTIONS OF THIS INSTRUCTION MANUAL IMPROPER USE OF THE MACHINE WILL VOID THE

PUREPOWER SERIES CENTRAL VACUUM POWER UNITS PP500, PP600 & PP650

USER GUIDE PUREPOWER SERIES CENTRAL VACUUM POWER UNITS PP500, PP600 & PP650 AB0039 FOR RESIDENTIAL USE ONLY!! MODELS SFDB-DQ, SFDB-DR AND SFDB-DS 30042509E IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS

USER GUIDE PUREPOWER SERIES CENTRAL VACUUM POWER UNITS PP500, PP600 & PP650 AB0039 FOR RESIDENTIAL USE ONLY!! MODELS SFDB-DQ, SFDB-DR AND SFDB-DS 30042509E IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS

Operating and Maintenance Manual

Models: FX-88 FX-88HP Operating and Maintenance Manual Congratulations and thank you for buying a FX-88 portable extractor. The FX-88 is designed to give you truckmount performance in a portable machine

Models: FX-88 FX-88HP Operating and Maintenance Manual Congratulations and thank you for buying a FX-88 portable extractor. The FX-88 is designed to give you truckmount performance in a portable machine

BLAST-IT-ALL BUMPER BLASTER

LARRY HESS AND ASSOCIATES, INC 185 PIPER LANE / SALISBURY, NC 28147 PHONE: 1-800-535-2612 / FAX: 1-704-638-9311 WWW.BLAST-IT-ALL.COM BLAST-IT-ALL BUMPER BLASTER SUCTION BLAST CABINET NOTE: It is the responsibility

LARRY HESS AND ASSOCIATES, INC 185 PIPER LANE / SALISBURY, NC 28147 PHONE: 1-800-535-2612 / FAX: 1-704-638-9311 WWW.BLAST-IT-ALL.COM BLAST-IT-ALL BUMPER BLASTER SUCTION BLAST CABINET NOTE: It is the responsibility

- 1 - Updated on 18 March, 2010

- 1 - Updated on 18 March, 2010 TABLE OF CONTENTS 1. SPECIFICATION & PARTS IDENTIFICATION...3 2. OPERATION & FUNCTION OF PARTS...4, 5 A. Cooling Operation B. Heating Operation C. Function of Parts 3. LOCATION

- 1 - Updated on 18 March, 2010 TABLE OF CONTENTS 1. SPECIFICATION & PARTS IDENTIFICATION...3 2. OPERATION & FUNCTION OF PARTS...4, 5 A. Cooling Operation B. Heating Operation C. Function of Parts 3. LOCATION

Installation Manual CARBONATOR With Plain-Water Booster

CORNELIUS INC One Cornelius Place Anoka, MN 55303-6234 Telephone (800) 238-3600 Facsimile (763) 422-3246 Installation Manual CARBONATOR With Plain-Water Booster IMPORTANT: It is the responsibility of the

CORNELIUS INC One Cornelius Place Anoka, MN 55303-6234 Telephone (800) 238-3600 Facsimile (763) 422-3246 Installation Manual CARBONATOR With Plain-Water Booster IMPORTANT: It is the responsibility of the

AmazonBasics 12-Sheet Cross-Cut Paper/ CD/ Credit Card Shredder. Customer Service B0714PJR6F

AmazonBasics 12-Sheet Cross-Cut Paper/ CD/ Credit Card Shredder Customer Service 1-844-303-4244 B0714PJR6F Instruction Manual English AmazonBasics 12-Sheet Cross-Cut Paper/ CD/ Credit Card Shredder CONTENTS

AmazonBasics 12-Sheet Cross-Cut Paper/ CD/ Credit Card Shredder Customer Service 1-844-303-4244 B0714PJR6F Instruction Manual English AmazonBasics 12-Sheet Cross-Cut Paper/ CD/ Credit Card Shredder CONTENTS

HID312, HID525 and HID540 Meridian Ice Maker-Dispensers Technical Service

HID312, HID525 and HID540 Meridian Ice Maker-Dispensers Technical Service What you will learn Introduction Installation Operation Maintenance Take It Apart Diagnostics HID Ice Maker-Dispensers HID models

HID312, HID525 and HID540 Meridian Ice Maker-Dispensers Technical Service What you will learn Introduction Installation Operation Maintenance Take It Apart Diagnostics HID Ice Maker-Dispensers HID models

Designed in the UK. Rapide Ultimate. User Guide Vax Rapide Ultimate

Designed in the UK Rapide Ultimate User Guide Vax Rapide Ultimate VCWRU Contents Contents 1 Machine Overview 2 General Safety Information 3 Getting Started 5 How To Use 6 Looking After Your Machine 9 FAQs

Designed in the UK Rapide Ultimate User Guide Vax Rapide Ultimate VCWRU Contents Contents 1 Machine Overview 2 General Safety Information 3 Getting Started 5 How To Use 6 Looking After Your Machine 9 FAQs