PBX series OPERATION MANUAL

|

|

|

- Jonas Peters

- 5 years ago

- Views:

Transcription

1 Submersible pump for pumping sandy water PBX series OPERATION MANUAL Thank you for purchasing a KOSHIN submersible pump. This instruction manual contains cautionary points for using the pump safely. Be sure to read the instructions before using the pump, and make sure that you understand how to use it. (Incorrect operation can lead to accidents and injury). The instruction manual should be stored carefully in a place where it can be viewed at any time. SAFETY CAUTIONS Before using the pump, read these safety cautions carefully and use the pump correctly. The cautionary points presented here are designed to ensure that you use the product correctly and to prevent danger or damage to yourself and others. The levels of danger and damage that will be incurred by ignoring the cautions and using the pump incorrectly are explained under the classifications of "DANGER," "WARNING," and "CAUTION." All three represent important safety information, and you should observe them without fail. DANGER WARNING CAUTION This is used for cases where there is a high risk of death or serious injury occurring. This is used for cases where it is possible that death or serious injury could occur. CAUTION This is used for cases where it is possible that injury could occur. ENG

2 DANGER WARNING CAUTION WARNING CAUTION Do not use this pump with combustible, flammable, or volatile liquids. Make sure to ground the pump properly. There is a risk of electric shock. Repairs and disassembly should be undertaken only by someone who understands the structure of the pump. * Contact your dealer for information about the structure. Do not touch the power plug with wet hands. Do not use the pump in an area accessible to people or animals. Set up a separation barrier to ensure that children, or people not of sound mind or body cannot come in contact with the pump. Have any power supply equipment and piping installation carried out by a professional service provider. Disconnect the power plug when cleaning or inspecting the pump. Do not put your hand or finger inside the unit. This product is for use with sandy water. If the pump is used with any liquid other than sandy water or fresh water, it will not be covered by the warranty. * Fresh water refers to water-supply water, well-water with no heavy filth (such as silt, clay, heavy mud). * Sandy water refers to dirty water that does not contain heavy filth. Do not drop the pump or put it anywhere close to fire. Check regularly to make sure that the power cord and plug are not damaged, the power socket is not distorted, and there is no dust on or around the power plug. Do not use the pump if there are any abnormalities. Do not move the pump while it is operating. After use, always make sure to disconnect the power plug before lifting the pump out of the water. If the product does not operate, or if there is any abnormality, immediately disconnect the power plug and request an inspection and repair from your dealer. RESTRICTIONS ) Make sure that the liquid in which the pump is used meets the following conditions. Temperature: 5 40 C (4 04F ) Viscosity: <5cP ph: (Do not use the pump in liquid that is combustible, flammable, or volatile, or with liquid containing oil, pharmaceuticals, salt, strong alkali, or strong acid.) 2) Make sure that power supply meets the following conditions. Voltage: ±0% Frequency: ±% If both the voltage and frequency fluctuate, the power supply must be within half of these tolerances. 2

3 SPECIFICATIONS MODEL PBX PBX-550 PBX-650 TYPE BAA BAB/BAE BAC/BAD BAB BAC BAB Connection mm 50 Dia inch 2 Max.Head m ft 3 33 Max.Delivery L/min 30 GPH 4,870 Voltage [V] AC 220 AC 0 Frequency [Hz] Rated Current [A] Output [W] 400 Consumption [W] Revolution [rpm] 2,800 3,200 VCT H07RN-F H07RN-F H07RN-F STOW Power Cord 3C.25mm 2 3G.0mm 2 3G.5mm 2 3G.5mm 2 3/6AWG 6m 0m 0m 20m 0m Maximum usage depth Net Weight [kg] *without cable 3.4 Standard Accessories Hoseband, Rope HoseCoupling, Hoseband Hoseband PUMP MOTER MODEL PBX PBX7-550 PBX7-650 TYPE BAA BAB/BAC/BAD/BAE BAB BAC BAB Connection mm 50 Dia inch 2 Max.Head m 5 6 ft Max.Delivery L/min 330 GPH 5,240 Voltage [V] AC 220 AC 0 Frequency [Hz] Rated Current [A] Output [W] 750 Consumption [W],250 Revolution [rpm] 2,800 3,200 VCT H07RN-F H07RN-F VCT Power Cord 3C 2.0mm 2 3G.5mm 2 3G.5mm 2 3C 2.0mm 2 0m 0m 20m 5m Maximum usage depth Net Weight [kg] *without cable Standard Accessories Hoseband,Rope HoseCoupling,Hoseband Hoseband PUMP MOTER DIMENSION *This is the view of PBX BAA MAX96 Direction of dischargeport is switchable. (80) MAX Top view φ Side view PERFORMANCE CURVE TOTAL HEAD (m) PBX7-650 PBX-550 PBX PBX7-550 PBX (GPH) PBX DELIVERY VOLUME (L/min) * Starting current is three times higher than rated current. (ft) φ94 MAX246 3

4 BEFORE USE. Check that the model type, frequency, and voltage of the pump are correct. (Refer to the model number plate) 2. Connect the ground wire to ground before connecting the power plug. To prevent ground leakage incidents, install a ground leakage circuit breaker. 3. Hold the handle when carrying the pump. Also, when installing the pump, tie a rope or similar line to the handle. 4. The pump should be installed in the position where water accumulates most easily. When installing on soft ground, such as gravel or sand, position wooden boards or blocks, etc. below the strainer to prevent the pump from sinking. The figure on the left shows an example of an installation method for reducing the chance of intaking sediment. 5. To change the hose angle, remove the delivery flange nuts and, taking care not to drop the packing, rotate the hose through 90 degrees and reattach it. WARNING CAUTION Be aware of the water-hammer effect. If the delivery hose is stepped on or the delivery side valve closed suddenly while the pump is in operation, a great pressure will build up instantaneously inside the pump case. Be careful, as this can cause damage to the pump. -3-4

5 6. Thermal protector A thermal protector is installed inside the pump to protect the motor. If the pump is operated at excessive load for some reason, the thermal protector automatically stops the pump to protect the motor. (Once the motor temperature has cooled, it restarts automatically.) If this situation continues, carry out the following inspections. * Always remove the power plug from the power supply whenever you conduct an inspection. Has any foreign matter (such as lint, solids or filth) gotten stuck and locked the impeller? Has the power supply voltage become lower? (If using an extension cord or generator) Is the pump being used for liquid with a high specific gravity or high viscosity? 7. Operation of the air valve This pump is fitted with an air valve. The air valve prevents air lock from occurring on operation start up, and a continuous airflow through the air valve will cool the motor, preventing overheating with the pump is running dry (without water). WARNING CAUTION If debris, etc., becomes stuck in the air valve, it may not operate correctly. Check that there is no foreign matter in the air valve before installing and operating the Fig. pump. 4 a. At operation start up b. During normal operation c. During dry operation OPEN CLOSED OPEN 8. When using a generator, it must have a capacity 3 5 times of the electric power consumption of the pump.(read the operating manual of the generator carefully and use it correctly). 5

6 HOW TO USE THE PUMP. S ubmerse the pump in the water. If you lower the pump by holding the power cord or hose, the cord will be broken and the hose will come out. Tie a rope to the pump handle, and lower the pump slowly into the water. 2. D o not allow the end of the delivery hose to become submerged. If the end of the hose is higher than the surface of the water when the pump is stopped, the water will flow back due to the siphon effect. 3. Connect the power plug _M_PBX(ENG)_ok_A4P6_804_.indd 6 208/04/26 :06:55

7 CAUTIONS AFTER USE. After use, always make sure to disconnect the power plug and lift the pump out of the water. The insulation will degrade and it will cause an electric shock or an electric leakage. 2. If the pump is used in water containing a large quantity of sand or heavy filth, and it is left standing after being stopped, the sand, etc. will remain inside the pump. Before storing the pump, wash the inside thoroughly and dry it completely. REPAIR AND INSPECTION. Check insulation resistance Check the resistance of the insulation regularly. Use a tester to measure the resistance between the ground wire and the power cord. 20 MΩ or more: Normal -20 MΩ: Sufficient to operate the pump but the power cord and motor should be inspected as soon as possible. MΩ or less: Abnormal. Conduct inspection and repair. 2. Replacing the paraffin The shaft seal whitch is the pump's most important water tight component is sealed with liquid paraffin. Inspect the liquid paraffin every,000 hours (or every 3 months). If the liquid paraffin gets impure when removed, or if water is mixed into it, the seal assembly (mechanical seals, etc.) needs to be replaced. (The amount of liquid paraffin in the seal is 280 cc.) 7

8 3. Replacing the mechanical seals This submersible pump uses a double mechanical seal. During assembly, install a carbon mechanical seal on the motor side, and a silicon carbide mechanical seal on the pump side. Black Carbon Dark Gray Silicon carbide φ20.5 φ6.0 φ5.5 φ20.0 Motor side Pump side 4. Impeller inspection If foreign matter is stuck in the strainer or the impeller, the delivery volume will decrease and it will also have a negative impact on the life time of the pump. Conduct an inspection by carrying out the following procedure. * Always remove the power plug whenever you conduct an inspection. A B C Suction cover Impeller Tightening torque(n m / lb ft) A 5 N m.06 lb ft B 5 N m.06 lb ft C 5 N m 3.68 lb ft Tightening torque (N m) A 5 N m B 5 N m C 5 N m Wash the strainer and impeller with clean water. Wash away any dirt around the motor shaft with water. Reassemble the components by performing the disassembly procedure in reverse order. Always replace any damaged or worn components. 5. Power cord replacement If the power cord requires replacement due to wear or damage, contact your dealer to request replacement. 6. (for PBX ) After stopping the operation, high electric voltage should remain in the capacitor under head cover. Maintenance or repairing works must be restricted by skilled staff. Improper works may cause serious injury by strong electric shock. Please be careful for handling. 8

9 OPTIONAL COMPONENTS HIGH PRESSURE IMPELLER (PBX7 series only) Switching to a high pressure impeller will increase the total head and reduce the maximum delivery volume. * The performance specifications are shown in the following table and graph. SPECIFICATIONS PERFORMANCE CURVE CURVE MODEL MODEL PBX H PBX7-550-H PBX7-650-H mm mm Connection Connection Dia Dia inch inch 2 2 m m Max.Head Max.Head ft ft L/min L/min Max.Delivery Max.Delivery GPH GPH 3,70 3,70 Output Output [W] [W] Revolution Revolution [rpm] [rpm] 2,800 2,800 3,200 3,200 Rated Rated Current Current [A] [A] Consumption Consumption [W] [W] ,00,00 Voltage Voltage [V] [V] AC 220 AC 220 AC 0 AC 0 Frequency Frequency [Hz] [Hz] FLOAT SWITCH Enables automatic control of pump start and stop. The pump starts automatically when the water level rises and the float comes up to the ON water level and stops automatically when the water level falls and the float comes down to the OFF water level. TOTAL HEAD (m) (GPH) (GPH) (ft) PBX7-650-H PBX7-650-H PBX7-550-H 0 PBX7-550-H 35 PBX H PBX H DELIVERY DELIVERY VOLUME VOLUME (L/min) (L/min) TOTAL HEAD (m) (ft) The ON water level mm The OFF water level mm mm Float switch Leave space 9

10 FAULTS AND HANDLING Symptom Cause Remedy No power supply Connect to power supply Pump will not turn Pump stops during operation Decrease in pump performance Air valve will not close Power supply is switched on Power cord cut or not contacting properly Voltage drop Impeller locked due to entry by foreign matter Water penetration into motor Safety device is operating (thermal protector) Impeller locked due to entry by foreign matter Rise in water temperature Incorrect frequency/voltage Loss due to clogging or bending of hose Hose bore too small, hose too long The pump is sucking in air Worn impeller Clogging inside pump Pump head too high Foreign matter clogging air valve The pump is sucking in air Inspection and repair at dealer Check extension cord Clean strainer and casing Inspection and repair at dealer Inspect piping and pump to reduce the load Clean strainer and casing Lower water temperature Check that the value on the model number plate and the power supply are the same. Wash the inside of the hose and remove bends Use a hose with a wider bore, shorten hose Increase water level Replace impeller Wash inside pump Lower the pump head Clean air valve Increase water level 0

11 PARTS LIST PBX BAA, -BAB, -BAC, -BAD, -BAE PBX-550-BAB, -BAC / PBX-650-BAB No. PARTS CODE PARTS NAME QTY No. PARTS CODE PARTS NAME QTY PBX-50 Motor Set Screw (M3x6) 2 400W/0V (No.2-20,55,56) Band PBX-5022 Motor Set Connector 400W/220V (No.2-20,55,56) Atype plug Head Cover VCT 3Cx.25mm 2 x6m Motor Frame (PBX BAA) Bolt (M6x35) Motor Bracket Condenser (25VAC 50μF) Screw (M4x6) Screw (M4x8) Head Packing Oil Seal Wave Washer Thermal Protector (Spec. 400W/0V) Thermal Protector (Spec. 400W/220V) Bolt (M4x6) Centrifugal Force Switch-cover Centrifugal Force Switch Toothed Washer Stop Ring CEE7/4 Schuko plug H07RN-F 3Gx.0mm 2 x0m (PBX BAB/BAE) BFtype plug H07RN-F 3Gx.5mm 2 x0m (PBX BAC) CEE7/4 Schuko plug H07RN-F 3Gx.5mm 2 x0m (PBX BAD) B3type plug H07RN-F 3Gx.5mm 2 x0m (PBX-550-BAB) B3type plug H07RN-F 3Gx.5mm 2 x20m (PBX-550-BAC)

12 No. PARTS CODE PARTS NAME QTY No. PARTS CODE PARTS NAME QTY A PBX-550-BAB-0 (with ground pin)type plug STOW 3/6AWGx0m (PBX-650-BAB) PBX-550-BAC Float Cap PBX-650-BAB Float Cap Holder Screw (M5x4) Mechanical Seal Bolt (M5x8) Oil Seal Chain Assy Seal Ring Cord Supporter Screw (M6x8) Cord Band Socket Bolt (M0x2) Screw (M5x0) Seal Washer Nut (M5) Delivery Flange (G) 3 Out Cover "PONSTAR" (PBX BAB/BAC/BAD (PBX-55022/550) /BAE/PBX-550-BAB/BAC) Out Cover "KOSHIN" 59 Delivery Flange (Nipple) (PBX-650) (PBX BAA) Air Valve Out Packing Outer Casing Bolt (M6x35) Inner Casing Strainer Nut (M8) O-Ring (G0) O-Ring (S70) Suction Cover Spacer Stud Bolt Hz Impeller Hz Impeller Impeller Bush Sleeve Impeller Adjusting Washer Washer Toothed Washer Handle Bolt (M8x8) PBX BAA PBX BAB PBX BAC PBX BAD PBX BAE Delivery Flange (NPT) (PBX-650-BAB) Delivery Packing Cap Nut (M8) Coupling Nipple Coupling Packing Hose Band (φ60) Rope (PBX BAA) Bearing Washer UK Socket (PBX BAB) Grease Ground Wire Assy Lead Wire Assy A Lead Wire Assy B Paraffin 2.8 Optional Components A Float Switch (PA-396) *62-64 is Attachment for PBX BAB/BAC/BAD/BAE/ PBX-550-BAB/BAC *Contact your dealer for information about the component list and optional components. 2

13 PARTS LIST PBX BAA, -BAB, -BAC, -BAD, -BAE PBX7-550-BAB, -BAC / PBX7-650-BAB No. PARTS CODE PARTS NAME QTY No. PARTS CODE PARTS NAME QTY PBX7-50 Motor Set Toothed Washer 750W/0V (No.2-20,55,56) Stop Ring PBX Motor Set Screw (M3x6) 2 750W/220V (No.2-20,55,56) Band Head Cover Connector Motor Frame Atype plug Bolt (M6x35) VCT 3Cx2.0mm 2 x Motor Bracket (PBX BAA) Condenser (25VAC 50μF) CEE7/4 Schuko plug Screw (M4x6) 2 H07RN-F 3Gx.5mm 2 x0m Screw (M4x8) (PBX BAB/BAD/BAE) Head Packing Oil Seal BFtype plug H07RN-F 3Gx.5mm Wave Washer x0m (PBX BAC) Thermal Protector (Spec. 750W/0V) 2 B3type plug Thermal Protector H07RN-F 3Gx.5mm 2 x0m (Spec. 750W/220V) (PBX7-550-BAB) Bolt (M4x6) 3 Centrifugal Force Switch-cover B3type plug (PBX7-550, PBX7-650) H07RN-F 3Gx.5mm 4 x20m Centrifugal Force Switch-cover (PBX7-550-BAC) (PBX ) Centrifugal Force Switch 3

14 No. PARTS CODE PARTS NAME QTY No. PARTS CODE PARTS NAME QTY A PBX7-650-BAB-0 (with ground pin)type plug VCT 3x2.0mm 2 x5m Mechanical Seal (PBX7-650-BAB) Oil Seal Float Cap Seal Ring Float Cap Holder Screw (M6x8) Screw (M5x4) Socket Bolt (M0x2) Bolt (M5x8) Seal Washer Chain Assy Delivery Flange (G) Cord Supporter (PBX BAB/BAC/BAD Cord Band /BAE/PBX7-550-BAB/BAC) Screw (M5x0) 59 Delivery Flange (Nipple) Nut (M5) (PBX BAA) 3 Out Cover "PONSTAR" Delivery Flange (NPT) (PBX /550) (PBX7-650-BAB) Out Cover "KOSHIN" (PBX7-650) Air Valve Out Packing Outer Casing Bolt (M6x35) Inner Casing Strainer Nut (M8) O-Ring (G0) O-Ring (S70) Suction Cover Spacer Stud Bolt Hz Impeller Hz Impeller Impeller Bush Sleeve Impeller Adjusting Washer Washer Toothed Washer Handle Bolt (M8x8) PBX BAA PBX BAB PBX BAC PBX BAD PBX BAE PBX7-550-BAB PBX7-550-BAC Delivery Packing Cap Nut (M8) Coupling Nipple Coupling Packing Hose Band (φ60) Rope (PBX BAA) Power Relay (PBX ) Caution Label (PBX ) Bearing Washer Scotch lok Connector (PBX ) Lead Wire Assy A (PBX ) Lead Wire Assy B (PBX ) Lead Wire Assy C (PBX ) Lead Wire Assy D (PBX ) Lead Wire Assy E (PBX ) Bolt (M3x0) (PBX ) Washer (M3) (PBX ) Nut (M3) (PBX ) UK Socket (PBX BAB) USA Plug (PBX7-650-BAB) Grease Ground Wire Assy Lead Wire Assy A (PBX7-550, PBX7-650) Lead Wire Assy B (PBX7-550, PBX7-650) Paraffin 2.8 Optional Components A Float Switch (PA-396) High Pressure Impeller PBX7 50Hz 220V (PA-394) B High Pressure Impeller PBX7 50Hz 0V/220V (PA-393) High Pressure Impeller PBX7 60Hz 0V (PA-395) *62-64 is Attachment for PBX BAB/BAC/BAD/BAE PBX7-550-BAB/BAC *Contact your dealer for information about the component list and optional components. 4

15 MEMO 5

16 SPARE PARTS Click For spare parts information, visit 2 Kami-Hachinotsubo Kotari, Nagaokakyo City, Kyoto JAPAN TEL FAX

SUBMERSIBLE DIRTY WATER PUMP

SUBMERSIBLE DIRTY WATER PUMP MODEL NO: DWP100A, DWP150A, DWP200A PART NO: 7230098, 7230099, 7230100 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS LS1117 - ISS 2 INTRODUCTION Thank you for

SUBMERSIBLE DIRTY WATER PUMP MODEL NO: DWP100A, DWP150A, DWP200A PART NO: 7230098, 7230099, 7230100 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS LS1117 - ISS 2 INTRODUCTION Thank you for

KQ Series. Multistage Booster Pump System. Installation Manual. ISO 9001 Certified KQ200/400 KQ800

KQ Series Multistage Booster Pump System Installation Manual KQ200/400 KQ800 ISO 9001 Certified Description The KQ series booster pump is an all-in-one compact and reliable automatic multistage centrifugal

KQ Series Multistage Booster Pump System Installation Manual KQ200/400 KQ800 ISO 9001 Certified Description The KQ series booster pump is an all-in-one compact and reliable automatic multistage centrifugal

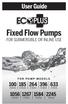

User Guide. Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE FOR PUMP MODELS # # # # # # # # #728333

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

User Guide Fixed Flow Pumps FOR SUBMERSIBLE OR INLINE USE 100 #728492 1056 #728320 FOR PUMP MODELS 185 264 396 633 #728300 #728305 #728310 #728315 1267 #728325 1584 #728330 2245 #728333 Fixed Flow Pumps

ECOPLUS MAG DRIVE UTILITY PUMP INSTRUCTIONS

ECOPLUS MAG DRIVE UTILITY PUMP INSTRUCTIONS 250 GPH 350 GPH 500 GPH 700 GPH 900 GPH Before operating this appliance please read this instruction manual carefully and keep it stored in safe place for future

ECOPLUS MAG DRIVE UTILITY PUMP INSTRUCTIONS 250 GPH 350 GPH 500 GPH 700 GPH 900 GPH Before operating this appliance please read this instruction manual carefully and keep it stored in safe place for future

DESCRIPTION IMPELLER INSPECTION MAINTENANCE POWER CORD REPLACEMENT IMPELLER REPLACEMENT MECHANICAL SEAL REPLACEMENT IMPELLER INSPECTION /REPLACEMENT

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

OPERATION & MAINTENANCE INSTRUCTIONS

SUBMERSIBLE PUMPS MODEL NO: PSV3A, PSV4A, PSSV2A & PVP11A PART NO: 7236042, 7236044, 7236050 & 7236060 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS GC07/17 iss 4 INTRODUCTION Thank you for

SUBMERSIBLE PUMPS MODEL NO: PSV3A, PSV4A, PSSV2A & PVP11A PART NO: 7236042, 7236044, 7236050 & 7236060 OPERATION & MAINTENANCE INSTRUCTIONS ORIGINAL INSTRUCTIONS GC07/17 iss 4 INTRODUCTION Thank you for

LC Series - Light Commercial Pump Station Installation and Operation Manual

LC Series - Light Commercial Pump Station Installation and Operation Manual Please keep this manual with the pump station Content Rain Bird LC Series Overview... Safety Instruction... Operation... 3 Pump

LC Series - Light Commercial Pump Station Installation and Operation Manual Please keep this manual with the pump station Content Rain Bird LC Series Overview... Safety Instruction... Operation... 3 Pump

SUBMERSIBLE WATER PUMPS

OPERATING & MAINTENANCE INSTRUCTIONS SUBMERSIBLE WATER PUMPS Model Nos. HIPPO-3 and 3A 6/97 Thank you for purchasing this CLARKE, HIPPO Submersible Pump. These highly efficient pumps are designed for pumping

OPERATING & MAINTENANCE INSTRUCTIONS SUBMERSIBLE WATER PUMPS Model Nos. HIPPO-3 and 3A 6/97 Thank you for purchasing this CLARKE, HIPPO Submersible Pump. These highly efficient pumps are designed for pumping

KC22/32 SERIES Sealless Non-Metallic Centrifugal Pumps Installation and Maintenance Instructions

KC22/32 SERIES Sealless Non-Metallic Centrifugal Pumps Installation and Maintenance Instructions ASSEMBLY Unpack pump from carton and check for shipping damage. WARNING: Magnetic field hazard. This pump

KC22/32 SERIES Sealless Non-Metallic Centrifugal Pumps Installation and Maintenance Instructions ASSEMBLY Unpack pump from carton and check for shipping damage. WARNING: Magnetic field hazard. This pump

SUBMERSIBLE WATER PUMP. Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS

1117 SUBMERSIBLE WATER PUMP Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS GUARANTEE This product is guaranteed against faults in

1117 SUBMERSIBLE WATER PUMP Model Nos. CSE1 - CSE1A - CSE2 - CSE2A CSD3- -CSD3A CSV1A - CSV2 - CSV2A - CSW1A OPERATING & MAINTENANCE INSTRUCTIONS GUARANTEE This product is guaranteed against faults in

IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS. Table of Contents WARNING.

Eagle Pump Owners Manual IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Table of Contents SECTION I. INSTALLATION... 2 SECTION II. OPERATION & MAINTENANCE... 2 SECTION

Eagle Pump Owners Manual IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS Table of Contents SECTION I. INSTALLATION... 2 SECTION II. OPERATION & MAINTENANCE... 2 SECTION

TCUT10UL 2.5 HP 10 Tile Saw Assembly & Operating Instructions

TCUT10UL 2.5 HP 10 Tile Saw Assembly & Operating Instructions READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT. This manual provides important information on proper operation and maintenance.

TCUT10UL 2.5 HP 10 Tile Saw Assembly & Operating Instructions READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT. This manual provides important information on proper operation and maintenance.

PJ130S High Pressure Cleaner

PJ130S High Pressure Cleaner Operator Manual Original instructions WARNING: Do not use the machine without reading the instruction sheet. Item Description OVERVIEW 1. High pressure washer 2. On/off switch

PJ130S High Pressure Cleaner Operator Manual Original instructions WARNING: Do not use the machine without reading the instruction sheet. Item Description OVERVIEW 1. High pressure washer 2. On/off switch

"S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S12 S16

Webster Pumps "S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S12 S16 PLEASE READ THE FOLLOWING INFORMATION PRIOR TO INSTALLING AND USING Webster PUMPS or HAYWARD VALVES,

Webster Pumps "S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S12 S16 PLEASE READ THE FOLLOWING INFORMATION PRIOR TO INSTALLING AND USING Webster PUMPS or HAYWARD VALVES,

Warranty Details page 2. Pump Description & Technical page 3 Specifications. Transportation, Storage & Installation page 4. Pump Maintenance page 5

5 . Manual Contents Warranty Details page 2 Pump Description & Technical page 3 Specifications Transportation, Storage & Installation page 4 Pump Maintenance page 5 Wet end Dismantling page 6 Wet end Assembly

5 . Manual Contents Warranty Details page 2 Pump Description & Technical page 3 Specifications Transportation, Storage & Installation page 4 Pump Maintenance page 5 Wet end Dismantling page 6 Wet end Assembly

This label warns for risk of electrical shock when failing to observe.

MANUAL horizontal centrifugal pumps MB series ic drive SB series mechanical seal 1. Introduction 2. Safety precautions 3. Receipt 4. Installation / Operation and Maintenance 4.1 Installation 4.2 Operation

MANUAL horizontal centrifugal pumps MB series ic drive SB series mechanical seal 1. Introduction 2. Safety precautions 3. Receipt 4. Installation / Operation and Maintenance 4.1 Installation 4.2 Operation

KRS data sheet parts list exploded view dimensional drawing sectional drawing performance curve. parts list as Excel-spreadsheet

KRS822-50 data sheet parts list exploded view dimensional drawing sectional drawing performance curve parts list as Excel-spreadsheet Heltorfer Str.6 40472 Düsseldorf Germany Tel.: +49-2-479373 Fax: +49-2-479429

KRS822-50 data sheet parts list exploded view dimensional drawing sectional drawing performance curve parts list as Excel-spreadsheet Heltorfer Str.6 40472 Düsseldorf Germany Tel.: +49-2-479373 Fax: +49-2-479429

Specifications Information and Repair Parts Manual 316A-95, 316B-95, 393A-95, 393B A-95 thru 394D-95, 399A-95

Specifications Information and Repair Parts Manual 316A-95, 316B-95, 393A-95, 393B-95 394A-95 thru 394D-95, 399A-95 Please read and save this Repair Parts Manual. Read this manual and the General Operating

Specifications Information and Repair Parts Manual 316A-95, 316B-95, 393A-95, 393B-95 394A-95 thru 394D-95, 399A-95 Please read and save this Repair Parts Manual. Read this manual and the General Operating

HORIZONTAL MULTISTAGE CENTRIFUGAL PUMP

HORIZONTAL MULTISTAGE CENTRIFUGAL PUMP WWPPCHLFT260 Instructions WWPPCHLFT260_Horizontal Multistage Centrifugal Pump_IB.indd 1 READ THIS MANUAL CAREFULL BEFORE INSTALL, START THE PUMP 1. Suction 2. Plug

HORIZONTAL MULTISTAGE CENTRIFUGAL PUMP WWPPCHLFT260 Instructions WWPPCHLFT260_Horizontal Multistage Centrifugal Pump_IB.indd 1 READ THIS MANUAL CAREFULL BEFORE INSTALL, START THE PUMP 1. Suction 2. Plug

IMAGE V. Parts and Service Manual

IMAGE 0V Section II Parts and Service Manual (88B) CLARKE TECHNOLOGY Image Operator's Manual Page AUTHORIZED PERSONNEL MAINTENANCE To Access Pump Motor. Remove brush housing from machine. See "Brush Motor

IMAGE 0V Section II Parts and Service Manual (88B) CLARKE TECHNOLOGY Image Operator's Manual Page AUTHORIZED PERSONNEL MAINTENANCE To Access Pump Motor. Remove brush housing from machine. See "Brush Motor

OPERATOR'S MANUAL. IMPORTANT: READ OPERATOR'S MANUAL CAREFULLY Please fill out & return your warranty card! DP80405

CARBON SPOT 30 EXTRACTOR OPERATOR'S MANUAL IMPORTANT: READ OPERATOR'S MANUAL CAREFULLY Please fill out & return your warranty card! DP80405 Diamond Products www.diamondproductsus.com Printed in the U.S.A.

CARBON SPOT 30 EXTRACTOR OPERATOR'S MANUAL IMPORTANT: READ OPERATOR'S MANUAL CAREFULLY Please fill out & return your warranty card! DP80405 Diamond Products www.diamondproductsus.com Printed in the U.S.A.

RING BLOW VFC 8 TH Series

Instruction Manual RING BLOW VFC 8 TH Series CAUTION Read the instruction manual carefully before you install, put into operation and maintain the Ring Blow and handle it properly. For the sake of safety,

Instruction Manual RING BLOW VFC 8 TH Series CAUTION Read the instruction manual carefully before you install, put into operation and maintain the Ring Blow and handle it properly. For the sake of safety,

Original instructions. Operation Manual & Cautions

Original instructions Operation Manual & Cautions Thank you for purchasing the Mistresa from Showa Denki. This manual explains the specifications for the [Mistresa units from CRN Series]. Please read the

Original instructions Operation Manual & Cautions Thank you for purchasing the Mistresa from Showa Denki. This manual explains the specifications for the [Mistresa units from CRN Series]. Please read the

SERIES 'HE' PLASTIC HORIZONTAL PUMP MODEL: H2 x1½

SERIES 'HE' PLASTIC HORIZONTAL PUMP MODEL: H2 x1½ OPERATION AND SERVICE GUIDE O-820_R FEBRUARY 2013 Refer to Bulletin P-201 and Parts Lists: P-7200, P-7250. SAFETY PRECAUTIONS BEFORE STARTING PUMP 1. Read

SERIES 'HE' PLASTIC HORIZONTAL PUMP MODEL: H2 x1½ OPERATION AND SERVICE GUIDE O-820_R FEBRUARY 2013 Refer to Bulletin P-201 and Parts Lists: P-7200, P-7250. SAFETY PRECAUTIONS BEFORE STARTING PUMP 1. Read

MD SERIES Instruction Manual

IWAKI Magnetic Drive Pump MD SERIES Instruction Manual Read this manual before use of product Thank you for having selected the Iwaki Magnetic Drive Pump MD series. This manual deals with the correct handling

IWAKI Magnetic Drive Pump MD SERIES Instruction Manual Read this manual before use of product Thank you for having selected the Iwaki Magnetic Drive Pump MD series. This manual deals with the correct handling

MECHANICAL SEAL REPLACEMENT UNPACKING MAINTENANCE. Figure 1 & 2 - Mechanical Seal Replacement

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Patterson/AMT Inline Circulator Pump Refer to pump manual for General Operating and Safety Instructions.

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

MECHANICAL SEAL REPLACEMENT UNPACKING MAINTENANCE. Figure 1 & 2 - Mechanical Seal Replacement

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

12 VELOCITY OWNER S MANUAL OPERATING INSTRUCTIONS - MAINTENANCE - SAFETY - TROUBLESHOOTING

12 VELOCITY OWNER S MANUAL OPERATING INSTRUCTIONS - MAINTENANCE - SAFETY - TROUBLESHOOTING This manual contains very important safety warnings and information. Read and save these instructions for future

12 VELOCITY OWNER S MANUAL OPERATING INSTRUCTIONS - MAINTENANCE - SAFETY - TROUBLESHOOTING This manual contains very important safety warnings and information. Read and save these instructions for future

STAINLESS STEEL UNITS

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

SMF PUMP OWNER S MANUAL

SMF PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

SMF PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

Service Manual This Service Manual is written for the after sail service department, especially for the fix and maintenance workers.

Service Manual This Service Manual is written for the after sail service department, especially for the fix and maintenance workers. Energy Recovery Ventilator (sold in Europe market) Model No. Panasonic

Service Manual This Service Manual is written for the after sail service department, especially for the fix and maintenance workers. Energy Recovery Ventilator (sold in Europe market) Model No. Panasonic

EYS SEPARATOR EYS 01 G. USER MANUAL for EYS SCREW-PRESS SEPARATOR MODEL EYS 01 G. User Manual for EYS 01G Screw-Press Separator

USER MANUAL for EYS SCREW-PRESS SEPARATOR MODEL EYS 01 G User Manual for EYS 01G Screw-Press Separator Table of Contents Page 1. Introduction 2 2. General Safety Instructions 3 3. Installation 5 4. Start-up

USER MANUAL for EYS SCREW-PRESS SEPARATOR MODEL EYS 01 G User Manual for EYS 01G Screw-Press Separator Table of Contents Page 1. Introduction 2 2. General Safety Instructions 3 3. Installation 5 4. Start-up

Cleaning unit for coolant. :_decftez`_>r_fr] Book No.: V2

![Cleaning unit for coolant. :_decftez`_>r_fr] Book No.: V2 Cleaning unit for coolant. :_decftez`_>r_fr] Book No.: V2](/thumbs/90/104143238.jpg) Cleaning unit for coolant :_decftez`_>r_fr] Book No.: 1271526-02 V2 Alfa Laval Separation AB Separator Manuals, dept. SKEL S-147 80 Tumba, Sweden Telephone: +46 8 53 06 50 00 Telefax: +46 8 53 03 10 40

Cleaning unit for coolant :_decftez`_>r_fr] Book No.: 1271526-02 V2 Alfa Laval Separation AB Separator Manuals, dept. SKEL S-147 80 Tumba, Sweden Telephone: +46 8 53 06 50 00 Telefax: +46 8 53 03 10 40

Parts and Service Manual

Section II Parts and Service Manual (70241A) CLARKE TECHNOLOGY Operator's Manual - MINI MAX Page -29- Frame and Front Cover Assembly Drawing 2/01 Page -30- CLARKE TECHNOLOGY Operator's Manual -MINI MAX

Section II Parts and Service Manual (70241A) CLARKE TECHNOLOGY Operator's Manual - MINI MAX Page -29- Frame and Front Cover Assembly Drawing 2/01 Page -30- CLARKE TECHNOLOGY Operator's Manual -MINI MAX

PS PS PSA 2 500

0154621en 003 1008 Pump PS 2 500 PS 2 750 PSA 2 500 OPERATOR S MANUAL 0 1 5 4 6 2 1 E N Foreword Foreword This manual provides information and procedures to safely operate and maintain this Wacker Neuson

0154621en 003 1008 Pump PS 2 500 PS 2 750 PSA 2 500 OPERATOR S MANUAL 0 1 5 4 6 2 1 E N Foreword Foreword This manual provides information and procedures to safely operate and maintain this Wacker Neuson

KC22/32 SERIES Sealless Non-Metallic Centrifugal Pumps Installation and Maintenance Instructions

KC22/32 SERIES Sealless Non-Metallic Centrifugal Pumps Installation and Maintenance Instructions ASSEMBLY Unpack pump from carton and check for shipping damage. WARNING: Magnetic field hazard. This pump

KC22/32 SERIES Sealless Non-Metallic Centrifugal Pumps Installation and Maintenance Instructions ASSEMBLY Unpack pump from carton and check for shipping damage. WARNING: Magnetic field hazard. This pump

568X, 587X, 588X Series

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

APW PSI PRESSURE WASHER

APW5001 1300 PSI PRESSURE WASHER 1300 PSI PRESSURE WASHER Please carefully read this manual which has been specifically designed to provide all the necessary information for the correct use of the machine,

APW5001 1300 PSI PRESSURE WASHER 1300 PSI PRESSURE WASHER Please carefully read this manual which has been specifically designed to provide all the necessary information for the correct use of the machine,

KTZ data sheet parts list exploded view dimensional drawing sectional drawing performance curve. parts list as Excel-spreadsheet

KTZ22.2-5 data sheet parts list exploded view dimensional drawing sectional drawing performance curve parts list as Excel-spreadsheet Heltorfer Str.6 40472 Düsseldorf Germany Tel.: +49-2-479373 Fax: +49-2-479429

KTZ22.2-5 data sheet parts list exploded view dimensional drawing sectional drawing performance curve parts list as Excel-spreadsheet Heltorfer Str.6 40472 Düsseldorf Germany Tel.: +49-2-479373 Fax: +49-2-479429

569, 570, 571, 572 Series

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

FRL 10 Centrifugal blowers

FRL 10 Centrifugal blowers User instructions 2 Kongskilde Blower model FRL10. Motor mounting instructions Motor Specifications: Model FRL 10 Blower/Aspirator fans are designed to be driven by Single or

FRL 10 Centrifugal blowers User instructions 2 Kongskilde Blower model FRL10. Motor mounting instructions Motor Specifications: Model FRL 10 Blower/Aspirator fans are designed to be driven by Single or

submersible water pumps

instructions for submersible water pumps model no s: WPC100.V2 WPC100A.V2 WPC150.V2 WPC150A.V2 WPC235.V2 WPC235A.V2 WPC250 WPC250A Thank you for purchasing a Sealey product. Manufactured to a high standard,

instructions for submersible water pumps model no s: WPC100.V2 WPC100A.V2 WPC150.V2 WPC150A.V2 WPC235.V2 WPC235A.V2 WPC250 WPC250A Thank you for purchasing a Sealey product. Manufactured to a high standard,

SWP. (Models SWP08 through SWP20) IMPORTANT! Read before proceeding! OPERATION & MAINTENANCE MANUAL

SWP (Models SWP08 through SWP20) OPERATION & MAINTENANCE MANUAL IMPORTANT! Read before proceeding! Read carefully before attempting to assemble, install, operate or maintain the product described. Protect

SWP (Models SWP08 through SWP20) OPERATION & MAINTENANCE MANUAL IMPORTANT! Read before proceeding! Read carefully before attempting to assemble, install, operate or maintain the product described. Protect

APW-VAP-150P High Pressure Cleaner Operator Manual

APW-VAP-150P High Pressure Cleaner Operator Manual BEFORE OPERATING THIS APPLIANCE PLEASE READ THESE INSTRUCTIONS CAREFULLY Item Description OVERVIEW 1. High pressure washer 2. On/off switch 3. Water outlet

APW-VAP-150P High Pressure Cleaner Operator Manual BEFORE OPERATING THIS APPLIANCE PLEASE READ THESE INSTRUCTIONS CAREFULLY Item Description OVERVIEW 1. High pressure washer 2. On/off switch 3. Water outlet

SuperKlean Washdown Products

DURAREEL DR8 & DR8S INSTALLATION AND MAINTENANCE INSTRUCTIONS **DO NOT THROW AWAY AFTER INSTALLATION** **SAVE AND DISPLAY PROMINENTLY WHERE THIS EQUIPMENT IS USED** GENERAL WARNINGS High pressure and hot

DURAREEL DR8 & DR8S INSTALLATION AND MAINTENANCE INSTRUCTIONS **DO NOT THROW AWAY AFTER INSTALLATION** **SAVE AND DISPLAY PROMINENTLY WHERE THIS EQUIPMENT IS USED** GENERAL WARNINGS High pressure and hot

Nilfisk Inc Winnetka Avenue North Minneapolis, MN REV.03( ) VF80189

Nilfisk Inc. 9435 Winnetka Avenue North Minneapolis, MN 55445 www.usviper.com REV.03(05-) VF8089 SAFETY PRECAUTIONS This machine is intended for commercial use. It is constructed for use in an indoor

Nilfisk Inc. 9435 Winnetka Avenue North Minneapolis, MN 55445 www.usviper.com REV.03(05-) VF8089 SAFETY PRECAUTIONS This machine is intended for commercial use. It is constructed for use in an indoor

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning

ECONO FLO 2.7HP VARIABLE SPEED PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning

AC6 & AC8 HORIZONTAL SERIES Sealed Metallic Centrifugal Pumps Installation and Maintenance Instructions

AC6 & AC8 HORIZONTAL SERIES Sealed Metallic Centrifugal Pumps Installation and Maintenance Instructions ASSEMBLY PUMPS WITH MOTORS 1. No assembly required. Unpack the pump and motor and examine for any

AC6 & AC8 HORIZONTAL SERIES Sealed Metallic Centrifugal Pumps Installation and Maintenance Instructions ASSEMBLY PUMPS WITH MOTORS 1. No assembly required. Unpack the pump and motor and examine for any

INSTRUCTION AND REPAIR MANUAL

SECTION 6 ITEM 390 DATED JANUARY 2003 SUPERSEDES SECTION 6 ITEM 390 DATED OCTOBER 2000 INSTRUCTION AND REPAIR MANUAL SERIES 390 6 The 390 Series is a superior commercial Multi-Stage Vertical In-Line Centrifugal

SECTION 6 ITEM 390 DATED JANUARY 2003 SUPERSEDES SECTION 6 ITEM 390 DATED OCTOBER 2000 INSTRUCTION AND REPAIR MANUAL SERIES 390 6 The 390 Series is a superior commercial Multi-Stage Vertical In-Line Centrifugal

RING BLOW VFZ-e Standard Model Series

Instruction Manual RING BLOW VFZ-e Standard Model Series CAUTION Read the instruction manual carefully before you install, put into operation and maintain the Ring Blow and handle it properly. For the

Instruction Manual RING BLOW VFZ-e Standard Model Series CAUTION Read the instruction manual carefully before you install, put into operation and maintain the Ring Blow and handle it properly. For the

INSTALLATION OPERATION MAINTENANCE LANCASTER MODELS X99M33 & X99M50

BULLETIN X99M EFFECTIVE NOV. 2005 INSTALLATION OPERATION MAINTENANCE LANCASTER MODELS X99M33 & X99M50 MANUAL LAUNDRY TRAY WASTE WATER PUMPS INTRODUCTION LANCASTER models X99M33 & X99M50 pumps are designed

BULLETIN X99M EFFECTIVE NOV. 2005 INSTALLATION OPERATION MAINTENANCE LANCASTER MODELS X99M33 & X99M50 MANUAL LAUNDRY TRAY WASTE WATER PUMPS INTRODUCTION LANCASTER models X99M33 & X99M50 pumps are designed

Patterson/AMT Inline Circulator Pump Refer to pump manual for General Operating and Safety Instructions.

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Elite Primer Baldor Series External Pond Pump

Elite Primer Baldor Series External Pond Pump ( 5250PPB21, 6440PPB23, 7550PPB26, 9600PPB28) Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS, READ AND FOLLOW ALL INSTRUCTIONS. SAVE THESE INSTRUCTIONS

Elite Primer Baldor Series External Pond Pump ( 5250PPB21, 6440PPB23, 7550PPB26, 9600PPB28) Installation and User s Guide IMPORTANT SAFETY INSTRUCTIONS, READ AND FOLLOW ALL INSTRUCTIONS. SAVE THESE INSTRUCTIONS

MODEL MC-UL592 MC-UL594 POWER SOURCE. 230V - 240V ~ 50 Hz MAX INPUT 1400 W 1500 W NOMINAL INPUT DIMENSIONS (W x L x H)

Order Number: PMMA091040CE Vacuum Cleaner MC-UL592/MC-UL594 SPECIFICATION MODEL MC-UL592 MC-UL594 POWER SOURCE 230V - 240V ~ 50 Hz MAX INPUT 1400 W 1500 W NOMINAL INPUT DIMENSIONS (W x L x H) 1200-1300

Order Number: PMMA091040CE Vacuum Cleaner MC-UL592/MC-UL594 SPECIFICATION MODEL MC-UL592 MC-UL594 POWER SOURCE 230V - 240V ~ 50 Hz MAX INPUT 1400 W 1500 W NOMINAL INPUT DIMENSIONS (W x L x H) 1200-1300

569, 570, 571, 572 Series

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

OWNER S MANUAL FOR AIR ADMIRAL VACUUM/PRESSURE STATION MODELS:

OWNER S MANUAL FOR AIR ADMIRAL VACUUM/PRESSURE STATION MODELS: 79202-00 79202-05 79202-30 79202-35 Approval Agency s Model 79202-00 & 79202-05 Model 79202-30 & 79202-35 Not recommended for pumping acid,

OWNER S MANUAL FOR AIR ADMIRAL VACUUM/PRESSURE STATION MODELS: 79202-00 79202-05 79202-30 79202-35 Approval Agency s Model 79202-00 & 79202-05 Model 79202-30 & 79202-35 Not recommended for pumping acid,

CPE RANGE PUMPS CPE RANGE PUMPS. MODEL Nos: CPE15A1 15A3 20A1 20A3 30A1 30A3 PART Nos:

CPE RANGE PUMPS CPE RANGE PUMPS MODEL Nos: CPE15A1 15A3 20A1 20A3 30A1 30A3 PART Nos: 7120305 7120310 7120315 7120320 7120325 7120330 OPERATION & MAINTENANCE INSTRUCTIONS GC0514 Contents Specifications...

CPE RANGE PUMPS CPE RANGE PUMPS MODEL Nos: CPE15A1 15A3 20A1 20A3 30A1 30A3 PART Nos: 7120305 7120310 7120315 7120320 7120325 7120330 OPERATION & MAINTENANCE INSTRUCTIONS GC0514 Contents Specifications...

POWER WASHER MODEL NO: JET 9000 OPERATION & MAINTENANCE INSTRUCTIONS. WARNING: Do not use the machine without reading this manual PART NO:

WARNING: Do not use the machine without reading this manual POWER WASHER MODEL NO: JET 9000 PART NO: 7333502 OPERATION & MAINTENANCE INSTRUCTIONS GC0913 INTRODUCTION Thank you for purchasing this CLARKE

WARNING: Do not use the machine without reading this manual POWER WASHER MODEL NO: JET 9000 PART NO: 7333502 OPERATION & MAINTENANCE INSTRUCTIONS GC0913 INTRODUCTION Thank you for purchasing this CLARKE

PUDDLE PUMP PUDDLE PUMP. MODEL No: PSP125 OPERATION & MAINTENANCE INSTRUCTIONS. Part No:

PUDDLE PUMP PUDDLE PUMP MODEL No: PSP125 Part No: 7230692 OPERATION & MAINTENANCE INSTRUCTIONS 1007 SPECIFICATIONS Model number... PSP125 Rated voltage... 230VAC 50Hz Input power... 293 Watts Maximum delivery

PUDDLE PUMP PUDDLE PUMP MODEL No: PSP125 Part No: 7230692 OPERATION & MAINTENANCE INSTRUCTIONS 1007 SPECIFICATIONS Model number... PSP125 Rated voltage... 230VAC 50Hz Input power... 293 Watts Maximum delivery

Specifications. Vacuum motor power consumption(w/hp) 1200 / 1.6. Exhaust water pump power consumption(w/hp 800 / 1.1

Specifications Rated voltage (V) AC 110-120V or 220-240V / 50-60Hz Vacuum motor power consumption(w/hp) 1200 / 1.6 Exhaust water pump power consumption(w/hp 800 / 1.1 Exhaust water pump flow (GPH/LPH)

Specifications Rated voltage (V) AC 110-120V or 220-240V / 50-60Hz Vacuum motor power consumption(w/hp) 1200 / 1.6 Exhaust water pump power consumption(w/hp 800 / 1.1 Exhaust water pump flow (GPH/LPH)

Desoldering Tool. Instruction Manual

Desoldering Tool Instruction Manual Thank you for purchasing the Hakko 472D desoldering tool with digital temperature display. Please read this manual before operating the Hakko 472D. Keep this manual

Desoldering Tool Instruction Manual Thank you for purchasing the Hakko 472D desoldering tool with digital temperature display. Please read this manual before operating the Hakko 472D. Keep this manual

Instruction manual RING COMPRESSOR VFZ-7W(5W) Standard Model Series VFC805A-7(5)WS WARNING Read the instruction manual carefully before you install, put into operation and maintain the Ring Compressor

Instruction manual RING COMPRESSOR VFZ-7W(5W) Standard Model Series VFC805A-7(5)WS WARNING Read the instruction manual carefully before you install, put into operation and maintain the Ring Compressor

Patterson/AMT Inline Circulator Pump Refer to pump manual for General Operating and Safety Instructions.

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

"S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S2 S4 S5 SS6 SS7 S8

Webster Pumps "S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S2 S4 S5 SS6 SS7 S8 PLEASE READ THE FOLLOWING INFORMATION PRIOR TO INSTALLING AND USING Webster PUMPS or HAYWARD

Webster Pumps "S" SERIES IMMERSIBLE PUMP OWNER'S MANUAL INSTALLATION OPERATION PARTS Models S2 S4 S5 SS6 SS7 S8 PLEASE READ THE FOLLOWING INFORMATION PRIOR TO INSTALLING AND USING Webster PUMPS or HAYWARD

CHAMPION PUMP OWNER S MANUAL

CHAMPION PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

CHAMPION PUMP OWNER S MANUAL IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS WARNING: Before installing this product, read and follow all warning notices and instructions

X1 series Submersible Drainage Pump

X1 series Submersible Drainage Pump 50HZ STAIRS INDUSTRIAL CO., LTD. X1 SERIES - Submersible Pump Model code X1-03 M A - 32 Discharge size A =Float switch S =Vertical level switch M = Single Phase T =

X1 series Submersible Drainage Pump 50HZ STAIRS INDUSTRIAL CO., LTD. X1 SERIES - Submersible Pump Model code X1-03 M A - 32 Discharge size A =Float switch S =Vertical level switch M = Single Phase T =

RC-54CA RO-50CA RC-54HA RO-50HA. SPLIT TYPE AIR CONDITIONER CASSETTE TYPE (50Hz) Indoor unit Outdoor unit

SPLIT TYPE AIR CONDITIONER CASSETTE TYPE (50Hz) Indoor unit Outdoor unit RCW-54CB RO-50CA RC-54CA RO-50CA RC-54HA RO-50HA CONTENTS SPECIFICATIONS OUTLINE AND DIMENTIONS CIRCUIT DIAGRAM REFRIGERANT SYSTEM

SPLIT TYPE AIR CONDITIONER CASSETTE TYPE (50Hz) Indoor unit Outdoor unit RCW-54CB RO-50CA RC-54CA RO-50CA RC-54HA RO-50HA CONTENTS SPECIFICATIONS OUTLINE AND DIMENTIONS CIRCUIT DIAGRAM REFRIGERANT SYSTEM

INSTRUCTION MANUAL DN0136 REVISION D

INSTRUCTION MANUAL DN0136 REVISION D PIPING (Returns) Gravity return lines from system must be properly pitched down to unit inlet. Returns must also be trapped to prevent steam entry into the unit. An

INSTRUCTION MANUAL DN0136 REVISION D PIPING (Returns) Gravity return lines from system must be properly pitched down to unit inlet. Returns must also be trapped to prevent steam entry into the unit. An

489 & 490 Series CAST IRON UNITS BRONZE UNITS STAINLESS STEEL UNITS MAINTENANCE. Figure 1 - Mechanical Seal Replacement

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Grinding mill MISTRAL 50L (art. 650P)

Grinding mill MISTRAL 50L (art. 650P) USE AND MAINTENANCE MANUAL RIVER SYSTEMS SRL Via Marco Polo, 33-35011 Campodarsego (Padova) Italy Tel. +39-049-9202464 - Fax: +39-049-9216057 - e-mail: info@riversystems.it

Grinding mill MISTRAL 50L (art. 650P) USE AND MAINTENANCE MANUAL RIVER SYSTEMS SRL Via Marco Polo, 33-35011 Campodarsego (Padova) Italy Tel. +39-049-9202464 - Fax: +39-049-9216057 - e-mail: info@riversystems.it

BlueHeat AirTop 2000 Heater

BlueHeat AirTop 000 Heater Air Heater Installation Manual Ford E-Series 6.0L Diesel Beginning Model Year: 006 Special instructions for these models Part locations may differ slightly dependent on the vehicle

BlueHeat AirTop 000 Heater Air Heater Installation Manual Ford E-Series 6.0L Diesel Beginning Model Year: 006 Special instructions for these models Part locations may differ slightly dependent on the vehicle

D14 & D18 Upright Vacuum

Operator's Manual D14 & D18 Upright Vacuum READ THIS BOOK This book has important information for the use and safe operation of this machine. Failure to read this book prior to operating or attempting

Operator's Manual D14 & D18 Upright Vacuum READ THIS BOOK This book has important information for the use and safe operation of this machine. Failure to read this book prior to operating or attempting

Installation/Instruction Manual

1510876HC8902 Pressurized ventilators (for device cooling) Model Blade diameter (cm) Indoor or outdoor EF-20UYS-UL EF-25UAS-UL EF-30UBS-UL 20 25 30 Indoor Installation/Instruction Manual For customers

1510876HC8902 Pressurized ventilators (for device cooling) Model Blade diameter (cm) Indoor or outdoor EF-20UYS-UL EF-25UAS-UL EF-30UBS-UL 20 25 30 Indoor Installation/Instruction Manual For customers

BESF Box Ventilator. Installation & Operating Manual USA CAN READ AND SAVE THESE INSTRUCTIONS

Installation & Operating Manual 3001806 03.02 USA CAN BESF Box Ventilator READ AND SAVE THESE INSTRUCTIONS 1200 Northmeadow Parkway, STE 180 Roswell, GA 30076 (770) 587-3238 (800) 255-2923 Fax (770) 587-4731

Installation & Operating Manual 3001806 03.02 USA CAN BESF Box Ventilator READ AND SAVE THESE INSTRUCTIONS 1200 Northmeadow Parkway, STE 180 Roswell, GA 30076 (770) 587-3238 (800) 255-2923 Fax (770) 587-4731

Scrubber User Manual

Scrubber User Manual AS430C VIPER NORTH AMERICA [866] 418-4737 [866] 41-VIPER VF90031-US Rev.01 TABLE OF CONTENTS USER MANUAL INTRODUCTION... 2 CONTENTS............................. 2 PURPOSE.............................

Scrubber User Manual AS430C VIPER NORTH AMERICA [866] 418-4737 [866] 41-VIPER VF90031-US Rev.01 TABLE OF CONTENTS USER MANUAL INTRODUCTION... 2 CONTENTS............................. 2 PURPOSE.............................

Lubi Submersible Condensate Removal Pumps

Please read and retain these instructions for future reference. Kindly read this manual carefully before making any effort to assemble, install, operate or maintain our pumps. Please protect yourself and

Please read and retain these instructions for future reference. Kindly read this manual carefully before making any effort to assemble, install, operate or maintain our pumps. Please protect yourself and

1 L Rotary Vacuum Evaporator Instruction Manual

1 L Rotary Vacuum Evaporator Instruction Manual Important This manual is designed for safe and optimal performance of this unit Please read manual carefully before operating this unit Keep this manual

1 L Rotary Vacuum Evaporator Instruction Manual Important This manual is designed for safe and optimal performance of this unit Please read manual carefully before operating this unit Keep this manual

BESB Box Ventilator USA CAN. Product Information. Mechanical Installation. ... Chapter 3. Electrical Installation. ... Chapter 4

Installation & Operating Manual BESB Box Ventilator USA CAN Product Information... Chapter 1 + 2 Mechanical Installation... Chapter 3 Electrical Installation... Chapter 4 Start Up and Configuration...

Installation & Operating Manual BESB Box Ventilator USA CAN Product Information... Chapter 1 + 2 Mechanical Installation... Chapter 3 Electrical Installation... Chapter 4 Start Up and Configuration...

489G DESCRIPTION CAST IRON UNITS BRONZE UNITS 316 STAINLESS STEEL UNITS. Maintenance. General Safety Information for 12 Volt DC Power

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Chemical Motor Pump Unit BN

Operating & Maintenance Instructions BW 5 02 01 / 1 The operating instructions of the centrifugal pump and the accessories should be located close to the pump. These instructions should be read carefully

Operating & Maintenance Instructions BW 5 02 01 / 1 The operating instructions of the centrifugal pump and the accessories should be located close to the pump. These instructions should be read carefully

CLEAN WATER PUMP. MODEL No: Hippo4A OPERATION & MAINTENANCE INSTRUCTIONS. Part No:

CLEAN WATER PUMP MODEL No: Hippo4A Part No: 7230535 OPERATION & MAINTENANCE INSTRUCTIONS 0807 INTRODUCTION Thank you for purchasing this CLARKE clean water pump. This highly efficient pump is designed

CLEAN WATER PUMP MODEL No: Hippo4A Part No: 7230535 OPERATION & MAINTENANCE INSTRUCTIONS 0807 INTRODUCTION Thank you for purchasing this CLARKE clean water pump. This highly efficient pump is designed

INSTRUCTIONS MANUAL ELECTRIC COMMERCIAL GRADE PATIO COOLER

INSTRUCTIONS MANUAL ELECTRIC COMMERCIAL GRADE PATIO COOLER @2012.11-V1.1 Aviator X2 Page 2 of 15 Contents Instruction......3 Outline Drawing...3 Wiring Diagram......4 Installation Instructions...5-8 Checking

INSTRUCTIONS MANUAL ELECTRIC COMMERCIAL GRADE PATIO COOLER @2012.11-V1.1 Aviator X2 Page 2 of 15 Contents Instruction......3 Outline Drawing...3 Wiring Diagram......4 Installation Instructions...5-8 Checking

BG6UL. 6 Inch Bench Grinder Assembly & Operating Instructions

BG6UL 6 Inch Bench Grinder Assembly & Operating Instructions READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. This manual provides important information

BG6UL 6 Inch Bench Grinder Assembly & Operating Instructions READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. This manual provides important information

Acquaer Ltd. H-4900, Fehérgyarmat, Szatmári út 11. CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2

CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2 Congratulations on your purchase of a LEO Centrifugal Pump It is important that you read, fully understand and observe the following

CENTRIFUGAL PUMP Instruction Manual ACm60 / ACm75 / ACm150 / ACm150B2 Congratulations on your purchase of a LEO Centrifugal Pump It is important that you read, fully understand and observe the following

GRUNDFOS INSTRUCTIONS. Sololift2 C-3. Installation and operating instructions

GRUNDFOS INSTRUCTIONS Sololift2 C-3 Installation and operating instructions English (US) English (US) Installation and operating instructions Original installation and operating instructions. CONTENTS

GRUNDFOS INSTRUCTIONS Sololift2 C-3 Installation and operating instructions English (US) English (US) Installation and operating instructions Original installation and operating instructions. CONTENTS

Service Manual Washing Machine

Http://global.midea.com.cn Service Manual Washing Machine Note: Before serving the unit,please read this at first, Always contact wih your service center if meet problem. TABLE OF CONTENTS 1. SAFETY PRECAUTION...

Http://global.midea.com.cn Service Manual Washing Machine Note: Before serving the unit,please read this at first, Always contact wih your service center if meet problem. TABLE OF CONTENTS 1. SAFETY PRECAUTION...

TECHNICAL INFORMATION Touchtronic Clothes Dryers

TECHNICAL INFORMATION Touchtronic Clothes Dryers Includes: T1302, T1303, T1322, T1329ci T1403 & T1405 2004 Miele This page intentionally left blank. Table of Contents GENERAL INFORMATION A. Warning and

TECHNICAL INFORMATION Touchtronic Clothes Dryers Includes: T1302, T1303, T1322, T1329ci T1403 & T1405 2004 Miele This page intentionally left blank. Table of Contents GENERAL INFORMATION A. Warning and

Operator & Parts Manual Self_Contained Extractor ie U REV.05( ) INTERNATIONAL CLEANING EQUIPMENT

www.icecompanies.com Operator & Parts Manual Self_Contained Extractor ie410 6210149U REV.05(11-2016) INTERNATIONAL CLEANING EQUIPMENT TABLE OF CONTENTS SAFETY PRECAUTION..................... 2 MACHINE

www.icecompanies.com Operator & Parts Manual Self_Contained Extractor ie410 6210149U REV.05(11-2016) INTERNATIONAL CLEANING EQUIPMENT TABLE OF CONTENTS SAFETY PRECAUTION..................... 2 MACHINE

CombiGrinder. Instruction manual. Grinder for cattle, horse and pet clipper blades. swiss made. Version/Index: CombiGrinder/A 09-16

swiss made CombiGrinder Grinder for cattle, horse and pet clipper blades Instruction manual Version/Index: CombiGrinder/A 09-16 1 Instruction manual / CombiGrinder Contents 1 Safety regulations 1.1 Symbols

swiss made CombiGrinder Grinder for cattle, horse and pet clipper blades Instruction manual Version/Index: CombiGrinder/A 09-16 1 Instruction manual / CombiGrinder Contents 1 Safety regulations 1.1 Symbols

Model 6050-Series. PumpAgents.com - buy pumps and parts online SELF-PRIMING PUMPS. Model 6050-Series

PumpAgents.com - Click here for Pricing/Ordering Model 6050-Series SELF-PRIMING PUMPS FEATURES Body: Impeller: Shaft: Wearplate: Shaft Seal: Ports: Motor: Weight: Bronze Construction JABSCO Nitrile 316

PumpAgents.com - Click here for Pricing/Ordering Model 6050-Series SELF-PRIMING PUMPS FEATURES Body: Impeller: Shaft: Wearplate: Shaft Seal: Ports: Motor: Weight: Bronze Construction JABSCO Nitrile 316

15-BER3. parts list as Excel-spreadsheet. Tsurumi Europe GmbH

5-BER3 data sheet parts list exploded view dimensional drawing free standing type dimensional drawing TOS-type sectional drawing free standing type sectional drawing TOS-type performance curve parts list

5-BER3 data sheet parts list exploded view dimensional drawing free standing type dimensional drawing TOS-type sectional drawing free standing type sectional drawing TOS-type performance curve parts list

TECHNICAL & SERVICE MANUAL WINDOW TYPE AIR CONDITIONER SA 183A FILE NO. SA 183A REFERENCE NO. SM Destination Australia SA-183A

TECHNICAL & SERVICE MANUAL SA 183A FILE NO. WINDOW TYPE AIR CONDITIONER Model No. Product Code No. SA-183A 1 851 006 96 Destination Australia SA 183A REFERENCE NO. SM700514 IMPORTANT! Please Read Before

TECHNICAL & SERVICE MANUAL SA 183A FILE NO. WINDOW TYPE AIR CONDITIONER Model No. Product Code No. SA-183A 1 851 006 96 Destination Australia SA 183A REFERENCE NO. SM700514 IMPORTANT! Please Read Before

TTB582PMP Barcode: Ref. No.: 55753

Original Instructions_DFT_TTB582PMP(XKS-751PW)_V1_131114 TTB582PMP Barcode: 01045598 Ref. No.: 55753 Submersible Pump TTB582PMP This product can be used by children aged from 8 years and above and persons

Original Instructions_DFT_TTB582PMP(XKS-751PW)_V1_131114 TTB582PMP Barcode: 01045598 Ref. No.: 55753 Submersible Pump TTB582PMP This product can be used by children aged from 8 years and above and persons

DESCRIPTION MAINTENANCE INSTALLATION OF NEW SEAL REMOVAL OF OLD SHAFT SEAL

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate or maintain the product described. Protect

USER S MANUAL BUCKET FAN SERIES BUCKET FAN WHISPER SERIES

USER S MANUAL BUCKET FAN SERIES BUCKET FAN WHISPER SERIES Bucket Fan 420 Bucket Fan 1055 Bucket Fan 1460 420 1055 1460 2 Bucket Fan CONTENT INTRODUCTION 3 USE 3 WHAT S INCLUDED IN THE BOX 3 DESIGNATION

USER S MANUAL BUCKET FAN SERIES BUCKET FAN WHISPER SERIES Bucket Fan 420 Bucket Fan 1055 Bucket Fan 1460 420 1055 1460 2 Bucket Fan CONTENT INTRODUCTION 3 USE 3 WHAT S INCLUDED IN THE BOX 3 DESIGNATION

MODEL 7000 SUCTION UNIT

MODEL 7000 SUCTION UNIT OPERATOR S MANUAL Caution Federal law restricts this device to sale by or on order of a physician, or any other practitioner licensed by the law of the State in which he practices

MODEL 7000 SUCTION UNIT OPERATOR S MANUAL Caution Federal law restricts this device to sale by or on order of a physician, or any other practitioner licensed by the law of the State in which he practices

W Model 1RKU2 w/optional Wall mount. Unit Model Weight (Lbs) Kilowatts Volts- Phase Amps Fan Output Heat Output

Operating Instructions & Parts Manual 1RKT2, 1RKT3, 1RKT4, 1RKT5, 1RKT9 and 1RKU2 Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

Operating Instructions & Parts Manual 1RKT2, 1RKT3, 1RKT4, 1RKT5, 1RKT9 and 1RKU2 Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

SELF-PRIMING JET PUMPS

SS Anti-Rust SS Shaft Copper & Cold-rolled SELF-PRIMING JET PUMPS CONTENTS 1. Applications.... Model Description.... Technical Data... 4. Implementation Standards... 5. Safety Precautions... 6. Product

SS Anti-Rust SS Shaft Copper & Cold-rolled SELF-PRIMING JET PUMPS CONTENTS 1. Applications.... Model Description.... Technical Data... 4. Implementation Standards... 5. Safety Precautions... 6. Product

DF400/DF600. Construction Heaters. Installation and Maintenance Manual

342 N. Co. Rd. 400 East Valparaiso, IN 46383 219-464-8818 Fax 219-462-7985 www.heatwagon.com Installation and Maintenance Manual Please retain this manual for future reference. DF400/DF600 Construction

342 N. Co. Rd. 400 East Valparaiso, IN 46383 219-464-8818 Fax 219-462-7985 www.heatwagon.com Installation and Maintenance Manual Please retain this manual for future reference. DF400/DF600 Construction